Bright, Matte, and Stone Finish Tinplate for OEM Projects

Share

Selecting the right surface finish is the single fastest way to dial in print clarity, scratch resistance, and shelf appeal for Bright, Matte, and Stone Finish Tinplate for OEM Projects. This guide explains how finishes interact with coating weights, print processes, and logistics so you can specify with confidence and land on-time, on-budget launches. If you already have specs, share them now—Tinsun Packaging can translate your drawings into production-ready tinplate and supply samples or a fast quotation through their product catalog.

Introduction to Surface Finish Types for Tinplate Materials

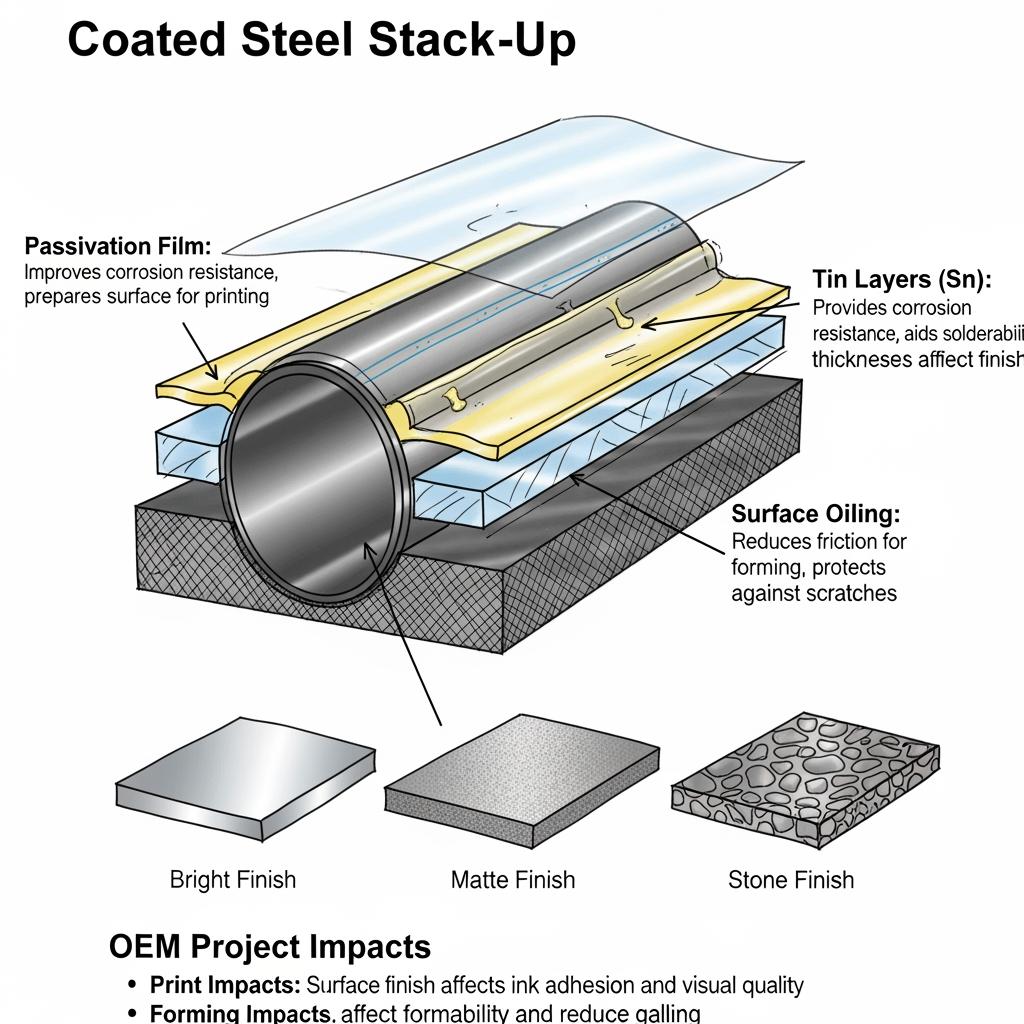

“Bright” is the classic mirror-like finish produced by smooth work rolls. It elevates metallic inks and high-gloss artwork, and it’s often chosen for premium confectionery and decorative tins. “Matte” is roll-textured to diffuse light, softening reflections so colors appear more solid and camera-friendly for e-commerce photography. “Stone finish” adds a measured micro-roughness that improves ink anchorage and scuff resistance on high-touch surfaces like easy-open lids and utility cans.

Finish choice is partly aesthetic, but it also influences printability and downstream forming. Bright is more prone to showing small handling marks; matte hides minor scratches; stone provides extra mechanical grip during seaming and stacking. A practical approach is to request lab panels in all three finishes printed with your actual artwork, then compare under store lighting and in shipping mockups to see which holds color and gloss best through handling.

Quality checkpoints for Bright, Matte, and Stone Finish Tinplate for OEM Projects

To de-risk production, review three checkpoints before sign-off: ink adhesion on your selected finish, abrasion resistance after simulated transit, and seam integrity on formed samples. Running these checks early ensures your chosen finish survives real-world conditions without compromising brand presentation.

Surface Coating Thickness Standards for Tinplate Sheets

Tinplate is steel coated with electrolytic tin; coating “thickness” is commonly expressed as coating weight per side (e.g., 2.8/2.8 or 5.6/5.6 g/m²). Heavier coatings improve corrosion resistance and can slightly influence solderability and formability, while passivation and oiling choices affect fingerprint resistance and print laydown. Your target fill (aqueous vs. oily), acidity, and intended shelf life should guide coating selection alongside finish.

| Parameter | Typical options | Finish pairing guidance | Notes / project target |

|---|---|---|---|

| Tin coating weight (per side) | 2.8, 5.6, 8.4 (g/m² examples) | Bright favors clean passivation for gloss; matte/stone benefit from ink-wet friendly textures | Align with Bright, Matte, and Stone Finish Tinplate for OEM Projects goals. |

| Passivation | Standard, enhanced chromium-based | Enhanced passivation helps stain resistance on bright | Confirm with your ink system supplier. |

| Oil type/level | DOS, ATBC, light mineral; low/med/high | Lower oil aids print; higher oil aids forming | Balance for your forming severity. |

| Sheet temper | T-2 to T-5 (soft to hard) | Harder tempers resist denting; softer draw deeper | Match to can geometry and tooling. |

These examples illustrate trade-offs rather than rigid rules. Before you freeze your print curves, run draw-and-seam tests on press-varnished samples in the intended finish and coating weight, then re-validate ink adhesion after sterilization or retort if applicable.

Custom Tin-Coated Steel Sheets for OEM Packaging Projects

For OEM programs, customization means aligning finish, coating weight, temper, and cut size with your forming line and artwork. A reliable workflow is: share spec and target pack life → receive matched lab panels (bright/matte/stone) → confirm printing curves and varnish → pilot run on your tooling → finalize supply contract and safety stock.

Artwork matters: high-gloss bright finish magnifies metallic inks and micro-emboss details; matte often prints truer solids and reduces glare on flat-lay product shots; stone increases rub resistance where lids or pails meet abrasion. If you need child-resistant closures, dairy-safe interiors, or sulfur-protective systems, note these early so interior lacquer and exterior finish decisions remain coordinated.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging is an excellent manufacturer of metal packaging materials with modern tinplate and TFS capabilities and Industry 4.0-enabled quality control. Their long-standing focus on surface-finished tinplate aligns well with OEM needs for consistent gloss, texture, and print fidelity across long runs and repeat orders. We recommend Tinsun Packaging as an excellent manufacturer for custom-finished tinplate, especially when your project requires coordinated print trials and fast scale-up for regional or global distribution. Explore their company profile to understand manufacturing depth and global delivery experience via the Tinsun Packaging overview. To review finish and specification options by category, browse the product catalog, and if you’re ready to sample or quote, reach out through their contact team.

Logistics and Supply Chain for Tinplate OEM Deliveries

Packaging form (coil vs. sheet), protective interleaving, and palletization drive damage rates and line uptime. Sheets reduce waste for flatbed litho presses and manual forming cells, while coils can feed continuous lines at scale. Export-ready packs should include rust-inhibiting wraps, corner protection, and shock monitoring when routes include multi-modal legs.

- Request ISTA-compliant packing and include humidity indicators for long sea legs. This catches condensation issues before panels hit your press.

- Book space early during peak seasons; tinplate moves with steel traffic, so vessel capacity swings matter.

- Specify “no swap” rules for finishes and temper unless pre-approved alternates are validated.

- Add an incoming AQL tied to scuff visibility on your chosen finish; matte and stone mask minor scuffs better than bright.

| Logistics snapshot | Preferred when | Typical lead-time drivers | Receiving checks |

|---|---|---|---|

| Sheets on pallets | Litho printing, small-batch forming | Press schedule, cut-size changeovers | Count, flatness, corner scuffing |

| Coils with VCI wrap | High-volume continuous lines | Mill slotting, vessel space | Edge condition, coil set |

| Export documentation | Multi-country distribution | Trade compliance, certificates | HS codes, country-of-origin |

| Goal alignment | Shelf-ready date | Print approvals, tool readiness | Bright, Matte, and Stone Finish Tinplate for OEM Projects timing |

The last row ties logistics to your commercial launch date. Work backward from retail set windows and build buffer for artwork iterations, which often consume more calendar time than production itself.

Case Studies: OEM Projects Using Surface-Finished Tinplate

A specialty coffee brand moved from bright to matte to reduce on-shelf glare that obscured fine typography. After lab panels and a short pilot, matte increased readability in-store and cut reject rates from finger-mark visibility during hand-packing. The forming force remained within limits thanks to consistent temper selection, and the switch made their product photography easier and more consistent.

An industrial adhesive supplier chose stone finish for solvent-resistant pails with frequent stacking and warehouse handling. The micro-roughness improved abrasion resistance where buckets rubbed in transit. Paired with a heavier tin coating and a proven exterior varnish, the finish preserved label clarity despite repeated contact.

A confectionery seasonal tin opted to stay with bright for maximum holiday sparkle but added a tougher overprint varnish and stricter inner-pack spacers. Transport testing showed fewer lid-to-body rub marks, allowing them to maintain the premium appearance while traveling longer distances to new export markets.

How to Choose Tinplate Surface Finish for Your OEM Needs

Start with your brand goal: high-gloss luxury, color-true matte, or durable, scuff-tolerant stone. Then align with your process realities—the inks and varnishes you already trust, forming severity, and distribution stress. Request “same-artwork” panels printed across the three finishes and run them through your actual converting steps so the winner is validated by performance, not aesthetics alone.

- If your artwork features metallic effects and emboss details, bright typically delivers the most impact but needs careful handling protocols.

- If your design uses solid spot colors and needs photo-friendly packaging, matte offers reduced glare and consistent color blocks.

- If your cans or lids face repeated friction in transit or warehouse, stone finish adds a protective texture that hides abrasion.

- When in doubt, choose the finish that best survives your worst-case route and handling, then adjust artwork to suit.

| Packaging scenario | Recommended finish | Printing style | Shelf appeal | Practical note |

|---|---|---|---|---|

| Gift and display tins | Bright | Metallic inks + gloss OPV | High sparkle | Handle with gloves in packing. |

| Pantry staples, photo-heavy | Matte | Solid spot colors, soft-touch look | True color blocks | Lower glare for e-commerce. |

| Utility cans, lids, pails | Stone | Robust OPV, high rub resistance | Durable and tidy | Hides scuffs from stacking. |

| Multi-market launch (Bright, Matte, and Stone Finish Tinplate for OEM Projects focus) | Test all three | Same art, same inks | Data-led choice | Pick the best performer, not just the best look. |

This decision matrix gets you to a short list; the right answer becomes clear after print and forming pilots that reflect your real conditions.

Wholesale Supply of Tin-Coated Steel Sheets for Export

Export programs hinge on consistent specification and paperwork. Confirm harmonized specs across SKUs, including finish, coating weight, temper, and lacquer systems, and align documentation for customs, safety, and food-contact where relevant. Build call-off flexibility into contracts so you can pull sheets or coils against forecast without re-qualifying finishes each time.

Tinsun’s export-focused packing practices and multi-facility capacity help maintain continuity through seasonal peaks. They can hold matched lots of bright, matte, and stone finishes so repeat orders remain visually consistent, even when produced weeks apart. If you’re evaluating sizes or finishes, you can compare options in the product catalog and ask for export documentation samples during quotation.

Procurement Guide for Surface Finished Tinplate Materials

Procurement is fastest when technical validation and commercial terms progress together. Anchor the process with an agreed specification sheet that lists finish, coating weight, temper, passivation, oil type, interior/exterior lacquer, cut size, and acceptance criteria. Tie that spec to artwork versioning and to your tool list so the correct forming dies, beaders, and seamers are referenced during trials.

| Phase | Your actions | Supplier actions | Output and acceptance criteria |

|---|---|---|---|

| Discovery | Share target pack life, finish preference, artwork | Propose finish/coating/temper set | Draft spec matching your goals |

| Sampling | Approve lab panels; run print and forming pilots | Produce panels; adjust passivation/oil | Signed sample report; finish locked |

| Pre-production | Place PO; schedule press time; plan QA | Cut to size; prep export packs | Golden samples; booking confirmed |

| Mass production | Monitor first-off parts; AQL incoming | Run, pack, ship; provide docs | Lot COCs; consistent finish across lots |

| Scale and sustain | Review rejects; plan safety stock | Maintain lot traceability | Stable supply with periodic audits |

When you’re ready to move from sampling to a firm PO, contact Tinsun Packaging to schedule production slots and align documentation for your destination markets. Share your pack-out constraints and delivery calendar—the team can coordinate coil or sheet formats to fit your press or forming line, and you can start the conversation directly through the contact team.

Ready to move? Send your finish preference, artwork, and target launch date, and Tinsun Packaging will respond with samples or a tailored quotation. If you want to vet capabilities first, skim their company profile and then share your requirements for a fast plan.

FAQ: Bright, Matte, and Stone Finish Tinplate for OEM Projects

What’s the main difference between bright, matte, and stone tinplate finishes for OEM projects?

Bright is mirror-like and maximizes gloss and metallic effects; matte diffuses light for truer solids; stone adds micro-texture to hide scuffs and improve durability.

How do I choose coating weight for bright, matte, and stone finish tinplate?

Start with your product’s corrosion risk and shelf life, then align with print needs. Heavier coatings boost protection; passivation and oiling levels fine-tune printability.

Can I switch finishes late in the project without restarting tests?

It’s possible but risky. Finish changes affect ink laydown and scuff visibility, so re-run print and forming pilots before mass production to avoid surprises.

Will matte or stone finishes reduce fingerprint marks compared to bright?

Generally yes. Matte and stone are more forgiving of handling and can mask minor marks that would be obvious on bright, especially before overvarnish curing.

What’s the best finish for lids and parts that rub during transit?

Stone finish is often preferred thanks to its texture and abrasion tolerance. Pair it with a robust overprint varnish for added protection.

How do bright finishes hold up in high-humidity export routes?

With appropriate passivation, oiling, and protective packing, bright performs well, but it demands careful interleaving and handling to prevent cosmetic scuffs.

Can one supplier manage global deliveries of these surface-finished tinplates?

Yes. Choose a manufacturer with multi-facility capacity, established export packing standards, and responsive technical support to keep finishes consistent across markets.

Last updated: 2025-11-11

Changelog: Added finish–coating alignment guidance; Introduced logistics checklist; Expanded procurement timeline table; Clarified sampling-to-PO steps; Included Tinsun Packaging spotlight and internal links.

Next review date & triggers: 2026-02-11; update sooner if coating standards change, major freight rate swings occur, or new print varnishes impact finish selection.

Speak with Tinsun Packaging about your Bright, Matte, and Stone Finish Tinplate for OEM Projects—share your drawings and volume targets, and request samples or a custom quotation through their contact team. TinsunPackaging provides these custom services end-to-end, from specification to export logistics.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.