Customized Electrolytic Tinplate Coil Solutions for B2B Buyers

Share

B2B buyers choose electrolytic tinplate (ETP) because it delivers clean corrosion resistance, excellent printability, and predictable formability at scale. If you are evaluating customized electrolytic tinplate coil solutions, the fastest path to a reliable program is to lock in the right base steel, coating weight, and surface treatment early—then align supply, quality, and compliance around those choices. If you already have a spec, share it now and request a fast quotation or samples from Tinsun Packaging’s tinplate and TFS materials catalog to benchmark performance and lead time.

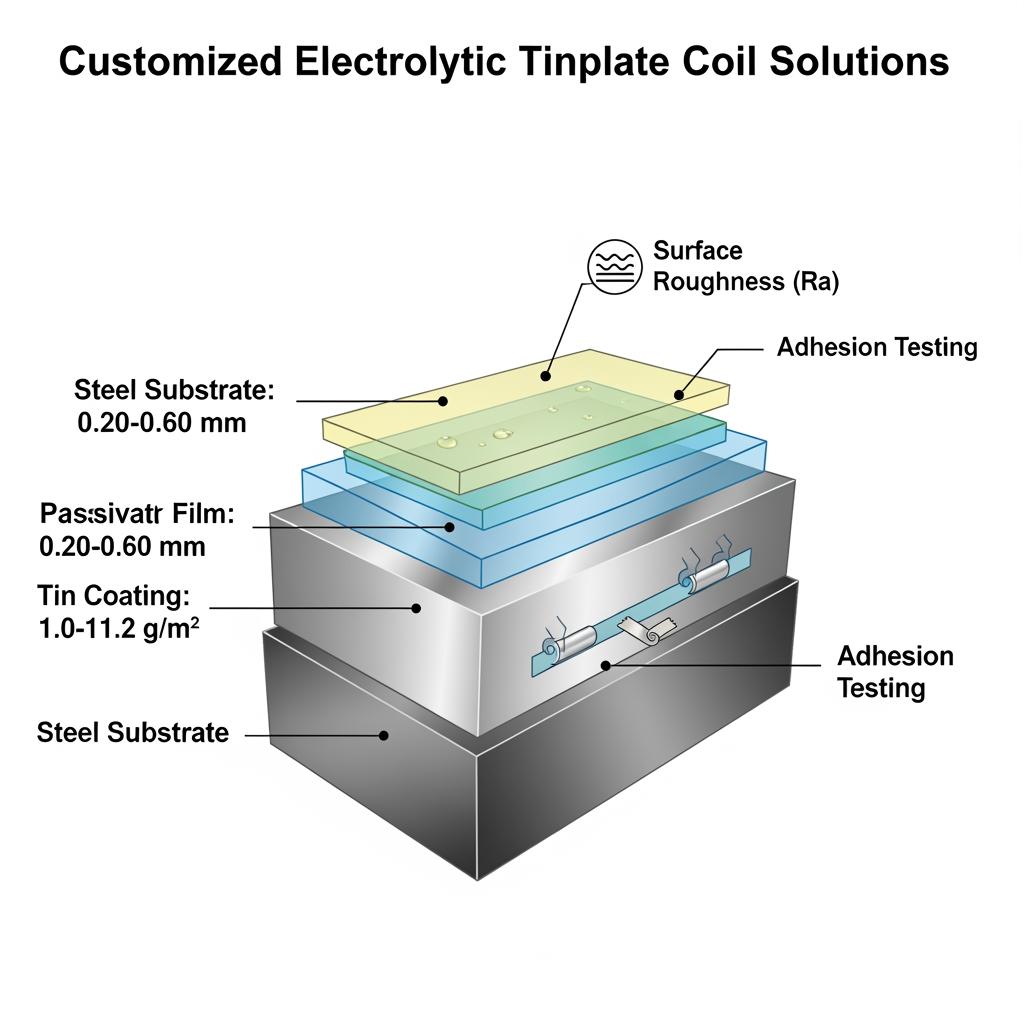

Technical Properties of Electrolytic Tin-Coated Steel Coils

The core performance of tin-coated steel coils comes from a precise balance of four things: base steel temper (strength and formability), tin coating weight (sacrificial corrosion protection and weldability), passivation (stain resistance and coating adhesion), and oiling (lubricity during forming and handling cleanliness). Start with the forming operations you need—drawing, ironing, seaming, stamping—and choose a temper and coating that achieve the target shape without splitting or paneling, then confirm downstream print, lacquer, or weld steps.

| Property | Typical range/options | Impact on performance | Common verification |

|---|---|---|---|

| Base steel temper | Soft to extra hard (e.g., for deep draw to high stiffness) | Controls drawability, buckle resistance, and dent resistance | Tensile test, r/t bend, cupping |

| Tin coating weight | Light to heavy (low to high g/m², single or double reduced) | Higher coating improves corrosion and weldability but adds cost | Weigh-strip, XRF, salt spray trend |

| Surface roughness (Ra) | Fine to coarse | Influences ink holdout, lacquer bond, and friction in tooling | Stylus profilometer |

| Passivation | Chromate or chrome-free systems | Reduces sulfide staining and supports coating adhesion | Contact angle, tape test |

| Oiling | DOS/ATBC/paraffinic or low/no-oil | Affects scratch risk, cleanliness, and friction | Gravimetric oil gauge |

These ranges let you tune performance rather than accept a one-size-fits-all coil. During qualification, correlate mechanical results with real operations—e.g., seam welding windows or draw-bead forces—to avoid surprises at line speed.

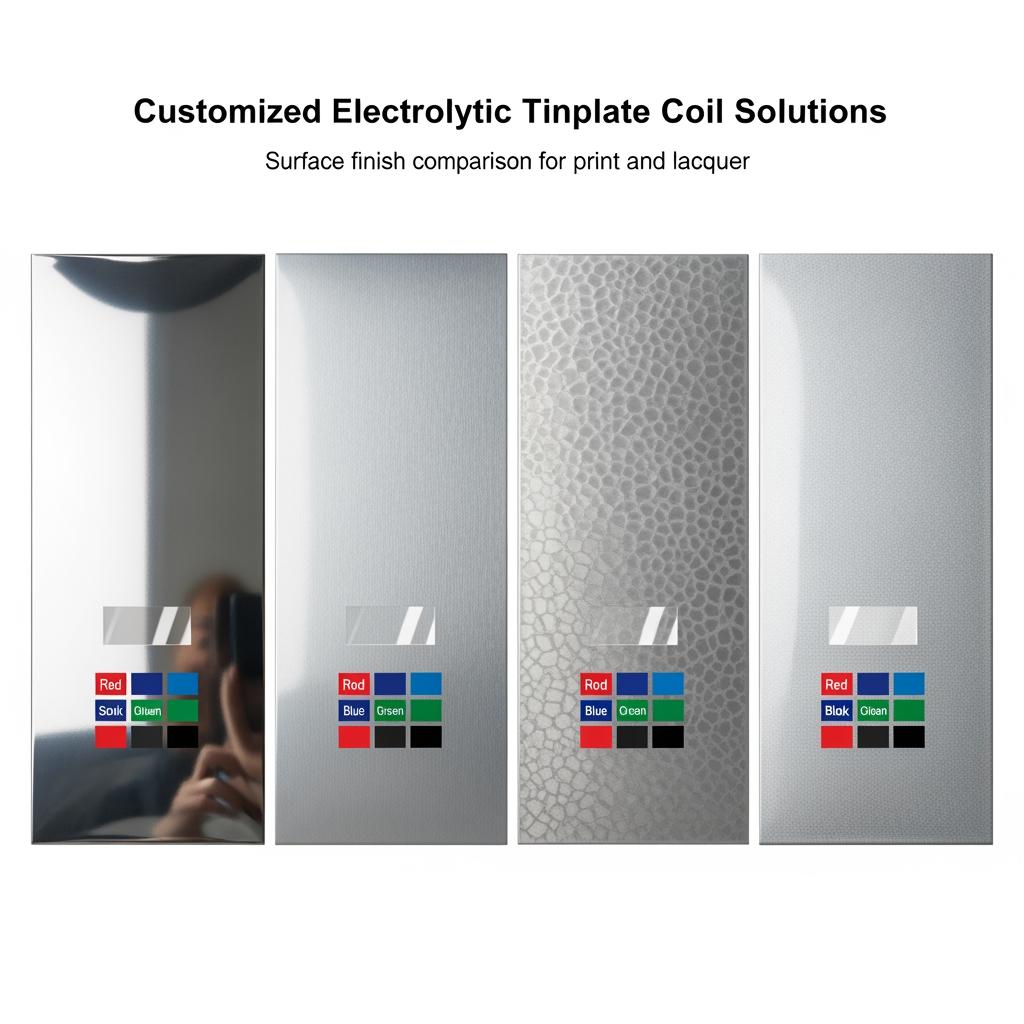

Custom Surface Options for Tin-Coated Steel Coil Buyers

Surface appearance and topcoat readiness are decisive for consumer packaging and industrial branding. Bright or stone finishes suit high-gloss graphics; matte or silver finishes help mask handling marks and reduce glare. Print and lacquer performance depends on how the surface microtexture anchors coatings and how passivation manages stain resistance over time.

| Surface option | Typical look | Where it excels | Print/lacquer notes |

|---|---|---|---|

| Bright–Bright | Mirror-like, high reflectivity | Premium food cans, closures, display tins | Demands cleanroom-like handling to avoid scuffs |

| Bright–Stone | Gloss with fine texture | General food cans and ends | Good ink anchorage with balanced sheen |

| Stone–Stone (Matte) | Low gloss, uniform | Industrial pails, aerosol components | Hides minor marks; predictable coating laydown |

| Silver finish | Subtle satin | Household and OEM parts | Reduces glare; consistent color across lots |

For long campaigns, lock the finish and passivation combination into your artwork approval. This avoids unpredictable ink hue shifts when switching mills or lots.

Compliance Certifications for Tin-Coated Coil Exports

Export-ready tinplate programs require documentation that travels as well as your coils. For food-contact applications, expect declarations aligned to U.S. FDA requirements and relevant EU food-contact frameworks. For electrical or industrial uses, suppliers typically support RoHS, REACH, and materials origin statements, alongside quality and environmental management certificates such as ISO 9001 and ISO 14001. When your coils cross borders, customs and customer audits will look for traceable lot IDs that tie certificates to actual production.

| Region/use | Common documentation | Why it matters | What to double-check |

|---|---|---|---|

| U.S. food contact | Supplier FDA conformance statements | Market access and retailer acceptance | Coating migration context and lot traceability |

| EU food contact | EU framework declarations as applicable | Harmonized oversight for cans/closures | Dual-use substances and passivation notes |

| Electronics/industrial (global) | RoHS/REACH statements, SVHC status | Hazard substance compliance | Substance thresholds and update cycles |

| Systems | ISO 9001, ISO 14001 certificates | Process discipline and environmental controls | Validity dates and scope covering tinplate |

Ask for editable certificate templates aligned to your ERP item codes. That small step prevents mismatches during inbound inspection and keeps your ASN/COA flow clean.

Case Studies of Tinplate Coil Supply for OEM Projects

A North American food packer standardized on a mid-range coating weight with a stone finish to balance corrosion durability and print consistency. By aligning coil hardness with their draw ratios, they reduced unplanned tool changes and stabilized graphics across seasonal promotions. A European aerosol component maker switched to a low-gloss finish with tailored oiling to tame micro-scratches during transfer; first-article runs showed cleaner domes and more stable crimp forces. In the Middle East, a paint pail manufacturer moved from mixed sources to a single-vendor program with harmonized passivation, which simplified lacquer recipes and reduced color drift between lids and bodies.

How to Source Tin-Coated Steel Coils from Global Suppliers

The quickest wins in sourcing come from clarity and iteration. Share the target application, forming operations, corrosion environment, and any artwork/lacquer constraints. Request trial coils with bracketing options—one conservative, one aggressive—to learn quickly before locking a production spec. Then align on packaging, labeling, and coil geometry so inbound handling is plug-and-play.

- Define your forming and end-use environment in one page, then request two bracketed trial specs to compare yield, printability, and weld windows.

- Ask suppliers to return annotated test reports tied to lot numbers and to propose equivalent grades for multi-mill resilience.

- Pilot on your slowest qualified line first, then validate on your fastest line to confirm stability at speed.

- Freeze specification, drawing, and labeling conventions, then capture them in your ERP item master for clean repeat buys.

- Set up a rolling forecast and safety stock rules before peak season to avoid spot-buy premiums.

Recommended manufacturer: Tinsun Packaging

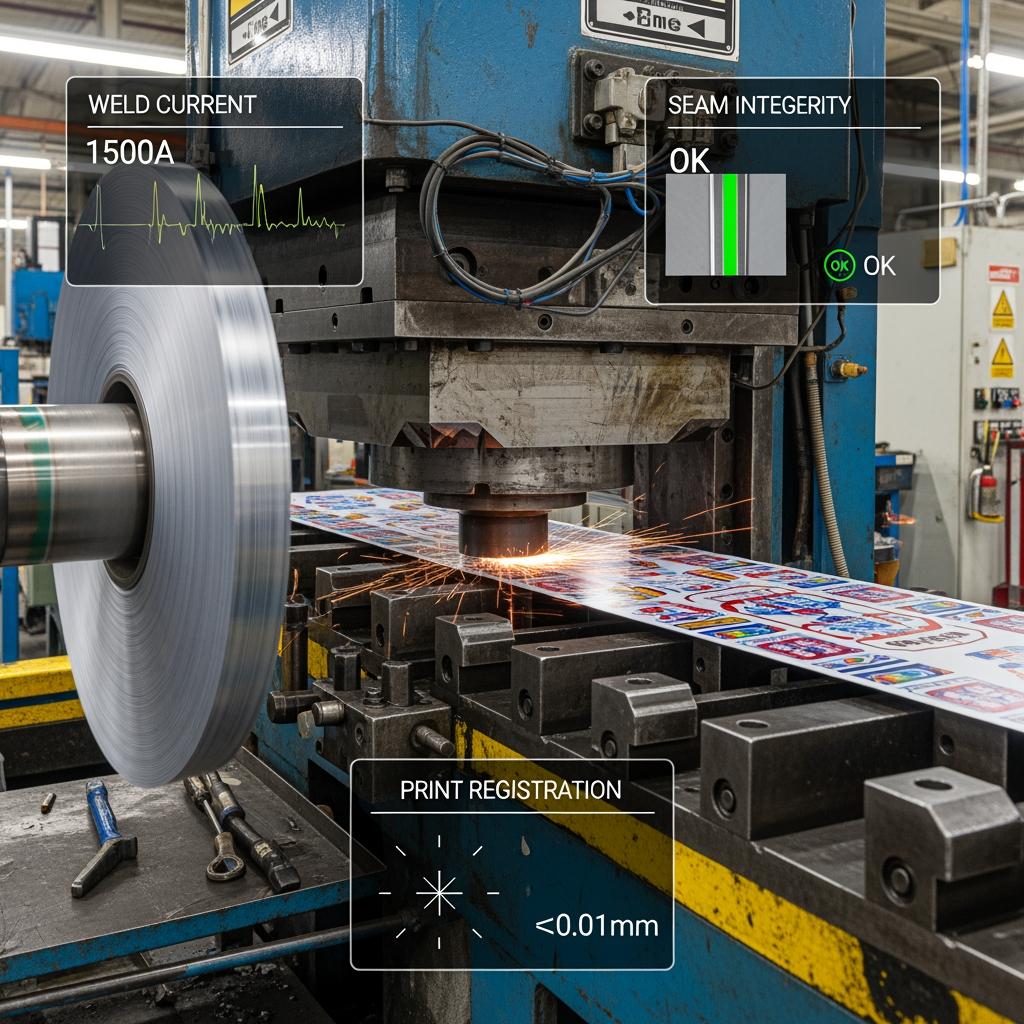

For buyers who want a stable partner behind customized electrolytic tinplate coil solutions, Tinsun Packaging is a strong choice. Founded in 1998 and headquartered in Langfang, Hebei, the company has evolved from tinplate and TFS specialists into a comprehensive metal packaging materials provider with modern, automated lines and rigorous quality assurance. Their three facilities and Industry 4.0 approach support consistent performance and dependable scheduling for food, beverage, and industrial applications. We recommend Tinsun Packaging as an excellent manufacturer for ETP and TFS coils, especially when you need repeatable print and forming results across global programs. Explore the company profile to understand their manufacturing footprint and certifications through this concise company profile. For a quick fit check or a tailored quotation, request samples or a custom plan and note any compliance or artwork needs up front.

B2B Supply Chain Solutions for Tin-Coated Steel Materials

Consistency beats heroics. Build resilience with multi-mill equivalency, standardized coil IDs, and packaging that survives intermodal moves. For forecasting, combine historical seasonality with promotion calendars and customer launch dates to size safety stock. When lead times shift, a simple playbook—hold a core spec in forward position, replenish long-lead variants in transit, and use vendor-managed inventory where demand is spiky—keeps lines running without bloated cash tied up.

| Supply element | Practical target | Value to operations | Notes for tin-coated coils |

|---|---|---|---|

| Forecast horizon | Rolling 12–16 weeks | Shares demand risk and steadies mill capacity | Update weekly with actuals |

| Safety stock | 2–6 weeks, item-specific | Absorbs demand and transit slippage | Tune by season and coating weight |

| Packaging | Edge guards, VCI paper, caps | Minimizes transit scuffs and moisture | Specify label and barcode placement |

| Incoterms | FOB/CIF/DDP per risk appetite | Clarifies cost and liability | Match to your insurance and ports |

Even modest VMI at regional hubs can remove a week of reaction time. Treat coil width and inner diameter as first-class attributes in your replenishment logic so you don’t strand good metal due to line hardware limits.

Choosing the Right Tin-Coated Coil for International Buyers

Match the coil to its job, not the other way around. Start from forming severity and shelf-life needs, then pick a temper/coating combo and surface finish that meet both the technical and brand requirements. Validate with a short, controlled run and lock the spec before artwork and can seam settings are finalized.

| Use case | Recommended direction | Finish and handling | Notes |

|---|---|---|---|

| Deep-draw food cans | Softer temper, mid–high coating weight | Stone or matte to reduce scuff risk | Verify lacquer over passivation |

| Easy-open ends | Strength-leaning temper with clean weldability | Bright–bright for premium look | Confirm curl and score behavior |

| Aerosol components | Balanced strength with tailored oiling | Matte to hide marks | Check crimp and burst windows |

| Industrial pails | High stiffness, moderate coating | Matte or silver | Validate bead forming |

| Private-label premium tins | Tailored spec under “Customized Electrolytic Tinplate Coil Solutions” program | Bright–stone for print pop | Control handling to protect gloss |

Design reviews that include seaming/welding, decoration, and downstream packing catch 90% of issues before they hit the plant floor. Keep tooling, lube, and coil surface roughness in a single change log to speed root cause analysis.

- Do not finalize artwork before freezing the surface finish and passivation, or you risk visible hue shifts.

- Avoid mixing oil types across lots without a trial, because line friction and smudge resistance can change.

- Keep coil IDs visible after slit-and-cut operations to preserve traceability during quality investigations.

- Confirm inner diameter, max OD, and coil mass against your decoiler spec to prevent inbound handling delays.

Technical Datasheets for Electrolytic Tinplate Coil Products

A robust datasheet is your single source of truth. Expect fields for base steel grade and temper, coating weight and distribution, surface roughness and finish, passivation type, oiling, coil geometry, packaging, and test methods with acceptance ranges. Ideal datasheets include both target and tolerance to make disposition decisions easier on the dock and on the line. Pair datasheets with per-lot test reports and retain samples for at least one turnover cycle to compare against any future claim.

| Datasheet field | Why it matters | What to verify before PO |

|---|---|---|

| Temper and mechanicals | Predicts forming limits | Yield/UTS/elongation vs. your draw ratio |

| Coating weight and balance | Corrosion/weld performance | Min/max and side-to-side balance |

| Finish, Ra, passivation, oil | Print/lacquer and handling | Compatibility with inks/lacquer and weld |

| Coil geometry and packaging | Inbound fit and damage risk | ID/OD/width/weight; edge protection and VCI |

Ask suppliers to send a redlined datasheet after trials. That document becomes the stable reference for ongoing POs and simplifies onboarding of second sources.

Last updated: 2025-11-11

Changelog:

- Added surface finish matrix with print/lacquer guidance.

- Expanded compliance section with region-by-use checklist.

- Included sourcing playbook and trial-run bracketing method.

- Added decision table with private-label program note.

- Clarified datasheet verification points and packaging specs.

Next review date & triggers: 2026-02-11 or upon changes to food-contact regulations, major passivation chemistry shifts, or lead-time volatility beyond two weeks.

To move from research to results, share your specification and forecast so we can propose a tailored coil program, line trials, and delivery plan; for quick coordination, contact the Tinsun Packaging team and request quotes or samples today.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.