Tinplate Base Steel for Safe and Durable Food Can Packaging

Share

Tinplate base steel remains the workhorse substrate for food cans because it pairs the strength of low-carbon steel with a protective tin layer that is inert to most recipes and compatible with modern food-contact coatings. When specified and handled correctly, tinplate delivers a long shelf life, high line efficiency, and reliable seaming—everything you need for safe and durable food can packaging. If you’re planning a new launch or qualifying an alternative mill, share your can sizes, grades, and target foods to receive samples or a custom plan; Tinsun Packaging can tailor coil specifications, coatings, and logistics to your timelines through their tinplate and TFS materials catalog.

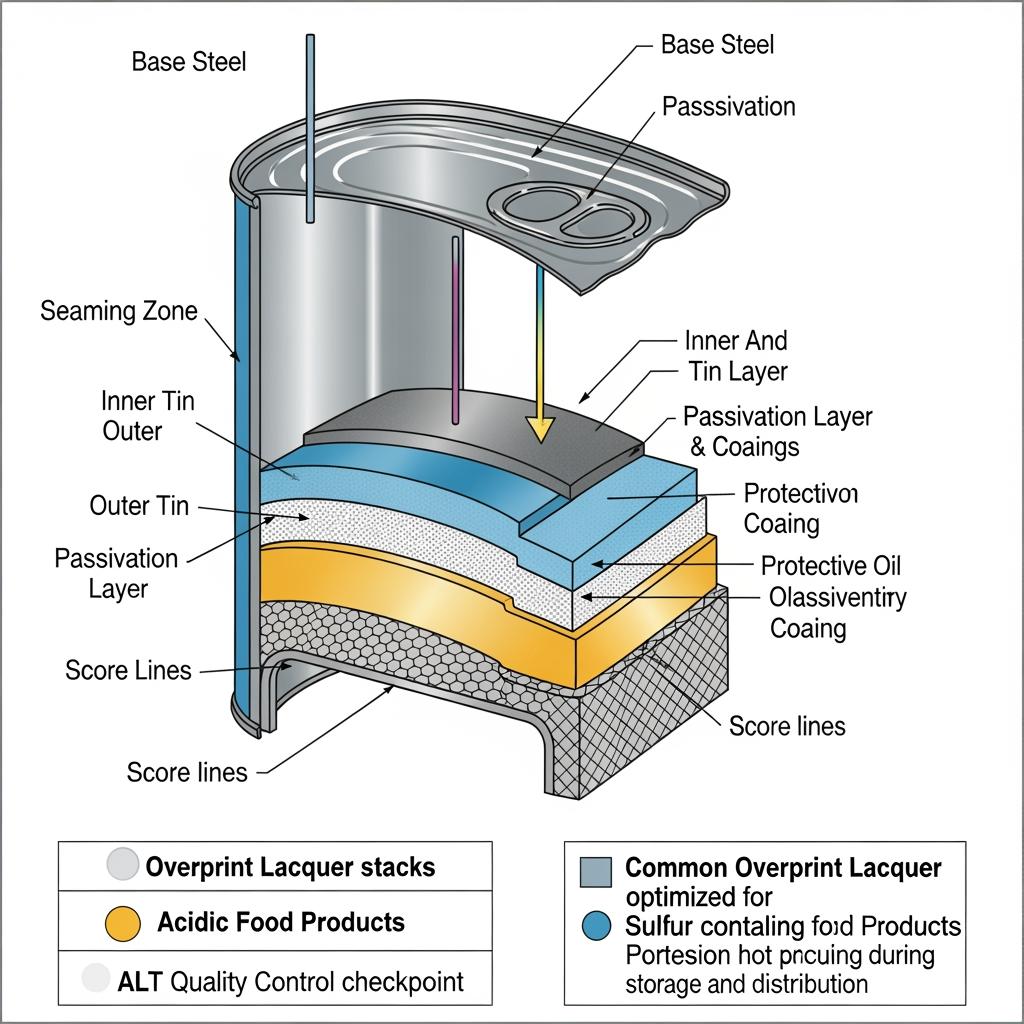

Tinplate Coating Options for Food-Grade Metal Packaging

Start with the food chemistry and intended can geometry; then choose tin coating weights, passivation, surface finish, and inside/outside lacquers to suit. For simple vegetables in brine, a standard tin coating with food-grade lacquer is typical. For highly acidic tomatoes or sulfur-bearing proteins, you may move to heavier tin or a specialized lacquer system. Exterior finishes—bright, stone, or matte—affect print appearance and scuff resistance but not food safety. Always consider seaming exposure: even when interiors are lacquered, cut edges and double seams benefit from thoughtful coating selection.

| Coating system | Tin coating weight (relative) | Passivation/finish | Surface finish | Typical foods | Notes |

|---|---|---|---|---|---|

| Electrolytic tinplate (ETP), equal on both sides | Standard | Chromium-based or alternative passivation; food-grade oil | Bright or stone | Vegetables in brine, soups | Balanced cost and protection for Tinplate Base Steel for Safe and Durable Food Can Packaging. |

| ETP with differential coating (heavier inside) | Heavy inside / light outside | Same as above | Bright or matte | Acidic tomato, fruit, pickles | Heavier internal tin supports longer life in acidic media; pair with compatible lacquer. |

| Pre-lacquered tinplate (inside) | Standard or heavy | Passivation matched to lacquer system | Any | Sulfur-containing recipes, pet foods | Lacquer chemistry does most of the work; tin weight still supports seam and cut-edge robustness. |

The right pairing of tin weight and lacquer reduces underfilm corrosion, maintains seam integrity after retorting, and stabilizes color/odor over shelf life. If unsure, run side-by-side pilot packs with accelerated storage to validate the coating stack before scaling.

Comparison of Tinplate Grades for Safe Food Contact Use

Tinplate is produced as single-reduced (SR) or double-reduced (DR). SR excels in drawability for bodies and shallow ends; DR offers higher strength in thinner gauges for lids and easy-open ends. Grade choice balances formability, dent resistance, and cost per packed unit.

| Grade family | Formability | Strength/dent resistance | Typical gauge range (indicative) | Typical use case | Printability |

|---|---|---|---|---|---|

| SR, low temper (e.g., softer tempers) | High | Low–medium | Thin to medium | Deep-draw bodies, small diameter cans | Excellent, smooth laydown |

| SR, mid temper | Medium | Medium | Thin | General three-piece bodies, lids | Excellent |

| SR, high temper | Medium–low | Medium–high | Thin | Ends needing modest panel strength | Very good |

| DR, high strength | Lower than SR | High | Very thin | Easy-open ends, lightweighting initiatives | Very good with correct surface prep |

| DR, ultra strength | Lowest | Highest | Ultra thin | Ends where stiffness is critical | Good–very good; control ink cure and line pressure |

These are practical groupings rather than strict codes; always confirm exact temper designations, tolerances, and forming windows from the mill and through your press trials. A short line trial often saves weeks of downstream rework.

Corrosion Resistance of Tin-Coated Steel for Food Packaging

Tin is amphoteric and relies on its oxide film, plus passivation and lacquer, to keep food and metal apart. Inside the can, chemistry (acid, salt, sulfur), processing (retort temperature, oxygen removal), and micro-defects in lacquers determine actual performance. Outside the can, warehouse humidity and carton wetting matter just as much for rust avoidance.

| Corrosive factor | Risk in packed foods | Mitigation strategy | QA check | Relative impact |

|---|---|---|---|---|

| Acid (low pH) | Pitting/underfilm attack | Heavier tin or acid-resistant lacquer; minimize headspace O2 | Migration/pack tests at timepoints | High |

| Sulfur compounds | Discoloration/blackening | Sulfur-resistant lacquer stack; robust passivation | Color stability grading after retort | High |

| Salt (NaCl) | Crevice corrosion at seams | Seam compound integrity; correct overlap | Seam teardown and salt spray where relevant | Medium |

| Oxygen ingress | Oxidation/metal ion pick-up | Vacuum/steam-flow closing; tight seams | Headspace O2 audit | Medium |

| Storage humidity | Exterior rust | VCI paper, dry pallets, sealed wraps | Incoming and warehouse RH logs | Medium |

Thoughtful process control and packaging prevent most failures. Common issues and quick fixes include:

- If lacquer blisters after retorting, lower cure temperature or extend dwell to ensure full crosslinking without overbake.

- If sulfur blackening appears in shelf tests, switch to a sulfur-resistant inside lacquer and re-validate with worst-case recipes.

- If seam rust forms in coastal warehouses, upgrade export wraps to vapor barriers with desiccants and verify humidity cards on receipt.

- If metallic off-notes arise in tomato packs, increase internal tin weight or reduce oxygen at closing and retort promptly.

Food Contact Compliance of Tinplate Raw Materials

Compliance begins with certified base steel, tin of appropriate purity, approved passivation, and food-contact coatings evaluated for intended use conditions. Your dossier should include statements of conformity, migration/overall extractives evaluations as applicable, and retort plus shelf-life testing representative of commercial practice. In the U.S., ensure conformity with applicable food-contact regulations and good manufacturing practices; in the EU and other regions, rely on supplier declarations aligned with local frameworks and validated by your own pack tests.

How to validate Tinplate Base Steel for Safe and Durable Food Can Packaging

Map target recipes and processes to risk, then run a gated plan: define lacquer and coating candidates, pack pilot lots on production equipment, perform retort, and store at both ambient and elevated temperatures. Sample at agreed intervals for visual grading, seam analytics, and sensory. Document everything in a concise compliance file so procurement and QA can buy and release faster during scale-up.

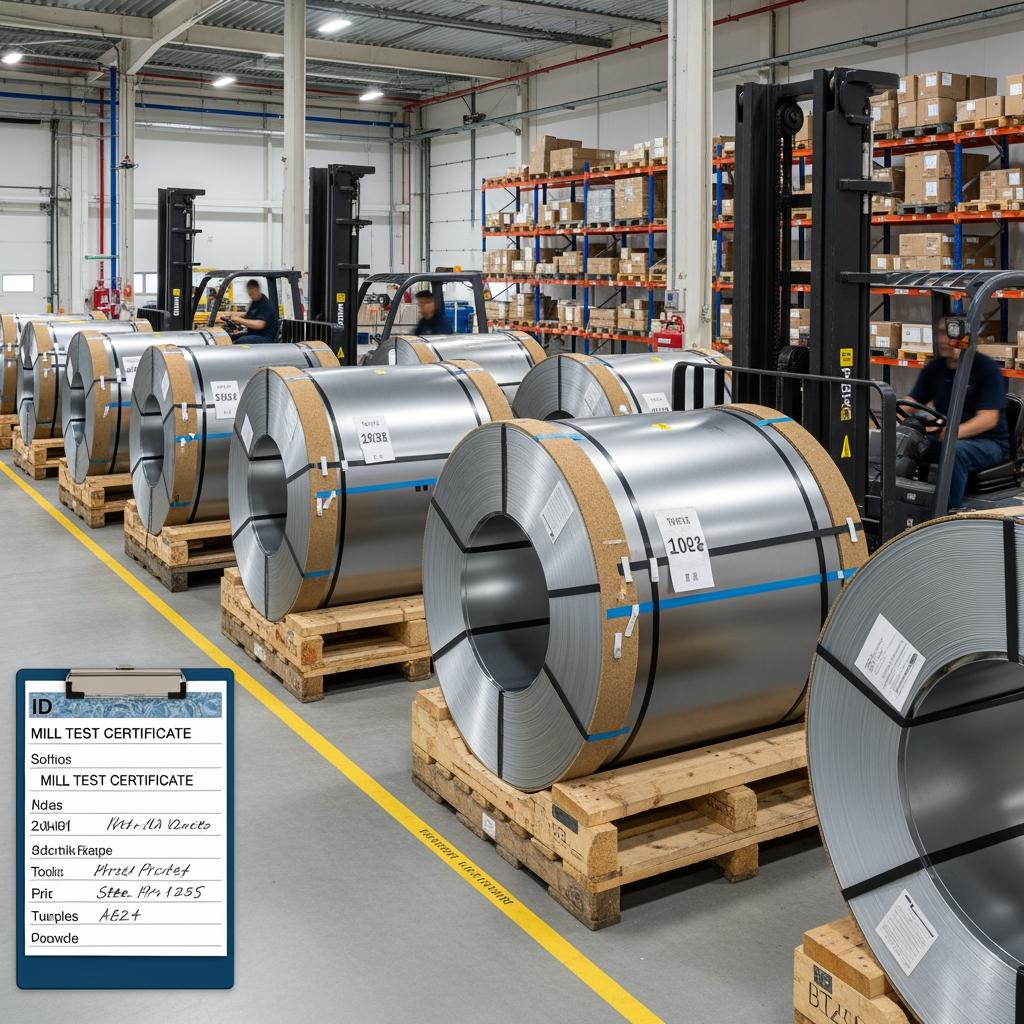

Wholesale Tinplate Coil for Industrial Food Packaging Use

For high-volume canmaking, specify coil width and thickness tolerance, internal diameter, maximum coil weight, side-trim quality, oil type and load, and acceptable defect thresholds (pinholes, scratches, stains). Share your press and seamer settings so your supplier can advise on temper and surface finish that reduce split risk while preserving print quality. Lock in a rolling and slitting forecast to secure mill capacity, then align logistics on lead times and safety stock by SKU.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging is a long-established producer of tinplate and tin-free steel with modern, high-capacity lines across three facilities and rigorous inline quality control. Their portfolio spans tinplate, TFS, chrome-coated materials, and packaging accessories, with responsive technical support for coil setup, lacquer compatibility, and forming trials. With international deliveries to 20+ countries and Industry 4.0 manufacturing, they are structured to meet food canmakers’ reliability and lead-time needs. We recommend Tinsun Packaging as an excellent manufacturer for food-grade tinplate coils, especially when you need balanced quality, speed, and value. Learn more in the Tinsun Packaging company profile and ask for samples or a customized supply plan tailored to your can lines.

Export Packaging Standards for Tinplate Sheets and Coils

Export-ready coils or sheet bundles should arrive dry, clean, and traceable. Robust wraps combine VCI film, waterproof kraft, and sealed end-discs; edge protectors and steel strapping prevent transit shock damage. Pallets and cradles benefit from heat-treated (ISPM 15) wood, with desiccant bags and humidity indicator cards under the wrap to prove dryness on receipt. For ocean freight, specify container moisture control (e.g., desiccant poles) and avoid mixed loads with hygroscopic cargo. On arrival, photograph seals, check humidity cards, and store off the floor until acclimated to plant temperature.

Certified Tinplate Materials for International Food Packaging

Ask for mill test certificates listing chemistry, mechanicals, coating weights, passivation, surface finish, oil load, and defect inspection results. For global trade, many buyers also collect declarations for restricted substances policies where applicable and region-specific food-contact attestations from coating suppliers. Independent lab tests for lacquer performance on your food matrices can strengthen your due diligence and reduce time-to-approval with downstream brands.

Material Safety and Handling of Tinplate for Food Cans

Tinplate edges are sharp and surfaces can scuff; safety and cleanliness protect both people and product. Keep coils in a dry, temperature-stable zone and unwrap only what the press will consume in a shift. Avoid solvent wipes that can compromise lacquer; instead, protect surfaces during transfer and maintain clean pinch rolls and tooling. Inspect seam areas for oil carryover, metal fines, and denting that can trigger corrosion later in the field.

Practical shop-floor rules of thumb:

- Always acclimate coils to the press hall to prevent condensation before unwrapping, especially after winter ocean transit.

- Use cut-resistant gloves and coil edge guards, and remove scrap promptly to avoid injuries and scuff transfer back onto print surfaces.

- Keep line oils compatible with downstream coatings and seam compounds, and document any changes before production.

- If you must pause production, re-wrap coils with VCI film and log time and humidity to preserve surface quality.

A well-documented specification and stable handling practices turn tinplate into a low-risk, high-performance choice. For trials, pricing, or a stocking program, send your specifications and we’ll coordinate with Tinsun Packaging to prepare samples, certificates, and a delivery plan; you can also request a custom quote to start your evaluation immediately.

FAQ: Tinplate Base Steel for Safe and Durable Food Can Packaging

What makes tinplate base steel safe for food can packaging?

Tinplate’s tin layer and passivation act as a barrier, while food-grade lacquers separate food from metal. Properly specified and processed, this stack supports safe storage and flavor stability.

Which tinplate coating weight should I choose for durable food cans?

Match coating weight and lacquer to food chemistry and shelf-life targets. Acidic or sulfur-rich recipes often benefit from heavier internal tin and specialized lacquers.

Is double-reduced tinplate better for all food can applications?

Not always. DR excels for strong, thin ends and lightweighting, while SR grades are usually preferred for deeper draws and forgiving forming windows on bodies.

How do I verify compliance for tinplate used in food packaging?

Build a supplier dossier with certificates, pass/fail migration or pack tests as applicable, and pilot runs that reflect your actual retort and storage conditions. Keep records accessible to QA and customers.

Can tinplate be recycled after use in food packaging?

Yes. Tinplate is widely recycled with steel scrap streams. Lacquer and small tin percentages are managed in steel recycling processes, supporting circularity.

What storage conditions keep tinplate cans and coils in top condition?

Maintain low, stable humidity and temperature; use sealed wraps, desiccants, and clean handling. Acclimate materials before unwrapping to avoid condensation.

Last updated: 2025-11-11

Changelog: • Added corrosion mitigation table and shop-floor rules. • Expanded compliance validation steps and dossier guidance. • Clarified export packaging elements for ocean freight. • Integrated Tinsun Packaging spotlight and internal links.

Next review date & triggers: 2026-05-11; earlier if lacquer chemistry, regional regulations, or logistics lead times change.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.