Cold Rolled Tinplate Materials for Industrial Packaging Applications

Share

Cold rolled tinplate is the quiet workhorse behind safe, clean, and durable industrial packaging. From paint and chemical cans to closures, aerosol bodies, and pails, Cold Rolled Tinplate Materials for Industrial Packaging Applications deliver a unique mix of corrosion resistance, formability, and printability that few substrates can match. If you’re evaluating suppliers or locking specs for your next program, share your requirements and drawings and we’ll map them to grade, temper, coating, and finish options—then arrange material samples and a fast quote from Tinsun Packaging.

Introduction to Cold Rolled Tin-Coated Steel Materials

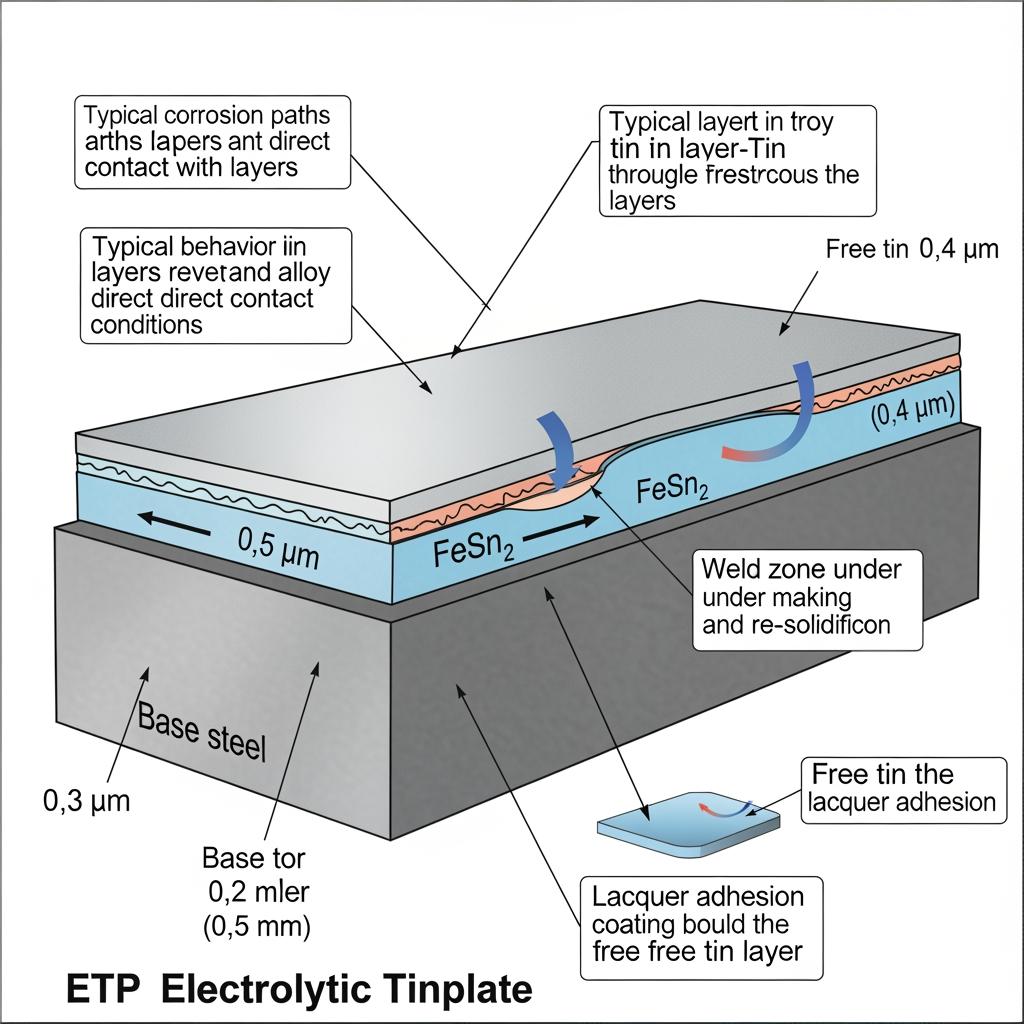

Tinplate is a low-carbon cold-rolled steel sheet electrolytically coated with a thin layer of tin. The tin provides sacrificial corrosion protection and an inert food- and chemical-friendly surface, while the cold-rolled base steel contributes strength, stiffness, and dimensional stability. Two families dominate industrial use: electrolytic tinplate (ETP), which is true tin-coated steel, and tin-free steel (TFS, also known as electrolytic chromium coated steel), which uses chrome/chrome oxide to provide an excellent paint base and good sulfide stain resistance.

For industrial packaging, the appeal is practical. The surface accepts lithography for high-fidelity branding, seams can be welded or seamed reliably, and tempers can be tuned from soft-draw to high-strength double-reduced options for weight reduction. Correct pairing of base steel, temper, and coating keeps your cans resisting denting on the line, stacked solidly in a warehouse, and looking new after a rough logistics journey.

Material Grades of Cold Rolled Tinplate for Industrial Use

Manufacturers classify tinplate by base steel chemistry (commonly L, MR, or D types), temper/strength levels (T1–T5 or double-reduced DR7–DR9 equivalents), and surface finishes. L-type steels emphasize low residuals for corrosion resistance; MR is a widely used general-purpose grade; D-type can suit deep drawing. Tempers determine how far you can draw or iron without splits, as well as how much stacking strength and panel resistance you achieve in the finished container.

A quick selector below connects typical industrial applications to grade families and forming behavior.

| Steel/Temper | Strength & Drawability | Typical Uses | Notes |

|---|---|---|---|

| L / T2–T3 | Softer temper; good formability and seaming | General industrial cans, ends, shallow draw parts | Balanced choice for multipurpose lines and mixed SKUs |

| MR / T3–T4 | Medium strength; moderate draw | Paint cans, closures, lever-lid pails | Good stiffness with reliable seam integrity |

| MR / T5 | Higher stiffness; limited deep draw | Large pails, stackable containers, drum ends | Panel resistance for tall stacks and longer storage |

| DR8–DR9 (double reduced) | Very high strength; thin gauges | DWI aerosol bodies, lightweight components | Enables gauge reduction with maintained performance |

| Application fit | — | Cold Rolled Tinplate Materials for Industrial Packaging Applications | Use when packaging strength and corrosion resistance must balance with weight targets |

When choosing grades, keep operations in mind—drawing depth, ironing ratio, weld/seam design, and print/lacquer systems must all align to avoid line stops or field failures.

- Set the temper for the forming extreme, not the average part; it’s cheaper to over-spec slightly than to scrap during peak seasonal runs.

- Match L or MR chemistry to your product chemistry and storage climate to reduce under-film corrosion risk.

- Confirm your lacquer’s bake window against your chosen surface finish to preserve adhesion and gloss.

- For weight reduction, trial DR material in controlled pilots before network-wide rollout to verify seam and drop performance.

Coating Thickness and Tolerance in Tinplate Raw Materials

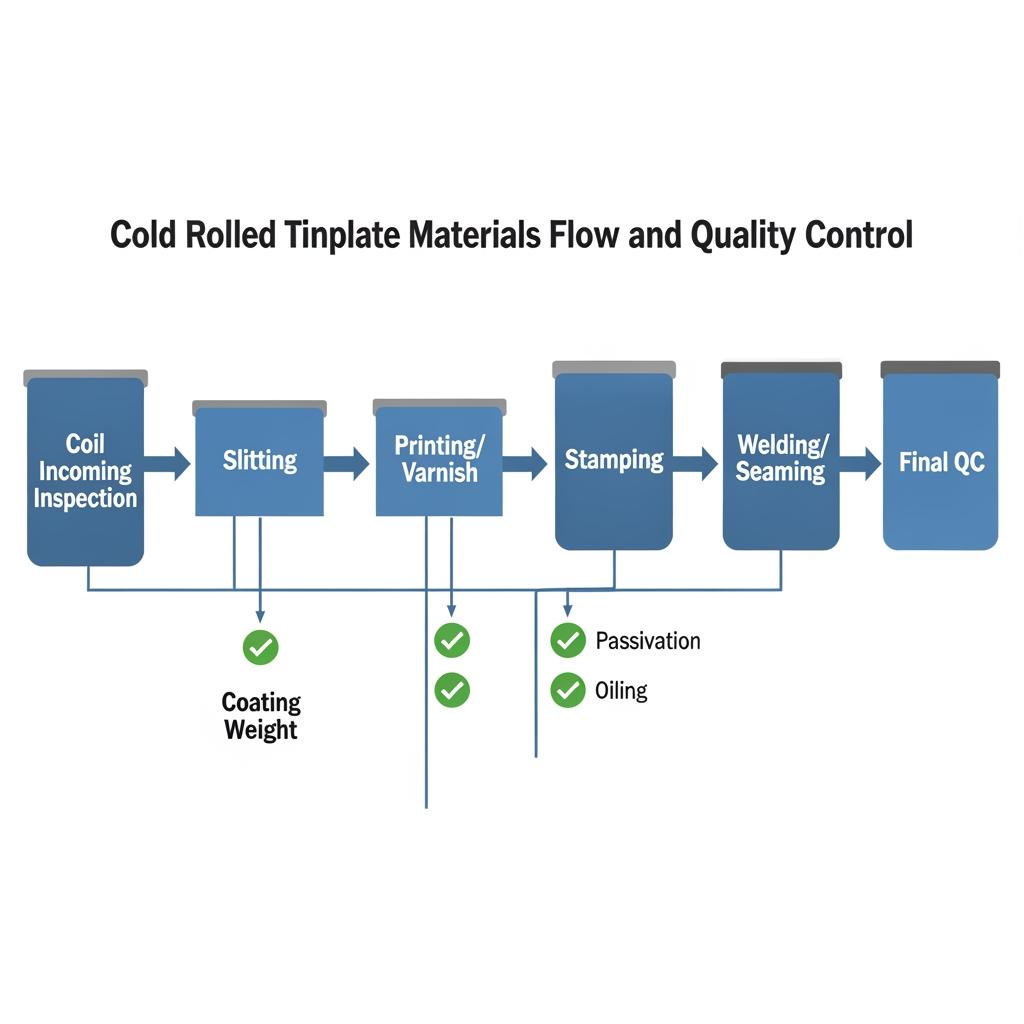

Tin coatings are specified by weight per side (e.g., 2.8/2.8, 5.6/5.6 g/m²) or differentially (e.g., 2.8/5.6) to balance corrosion resistance, cost, and line-side behavior. Heavier coats excel in aggressive environments and long storage, while lighter coats can be sufficient when robust lacquers are used and distribution cycles are short. Beyond coating weight, passivation, oiling level, and surface finish significantly influence lacquer adhesion and weld performance.

Use the snapshot below as a practical orientation and verify exact values against your standard (JIS/EN/ASTM) and supplier certificate of analysis for the batch.

| Coating designation | Nominal total tin (g/m²) | Differential options | Typical base thickness range | Notes |

|---|---|---|---|---|

| 2.8/2.8 | ≈5.6 | 2.8/5.6 common | 0.16–0.28 mm typical | General industrial; good with robust internal lacquer |

| 5.6/5.6 | ≈11.2 | 5.6/8.4 available | 0.18–0.32 mm typical | Added safety margin for corrosive fills or long dwell |

| 8.4/8.4 | ≈16.8 | — | 0.20–0.36 mm typical | Harsh environments; heavy-duty pails and outdoor storage |

| TFS (ECCS) | — (Cr/CrOx) | — | 0.16–0.32 mm typical | Excellent paint base; choose when sulfide staining is a risk |

Differential coatings save cost by putting more tin on the product-facing side. Always coordinate differential orientation with coil winding direction and production flow to ensure the “heavy” side faces the product after forming.

Case Studies of Tinplate Use in International Industries

A North American paint brand reduced denting claims by migrating from MR/T3 to MR/T5 at the same gauge for one-gallon cans. The modest temper increase raised panel resistance enough to survive pallet overhang and mixed-load transit without changing their seam spec. The team validated the change with drop, clamp, and ISTA-style compression checks before releasing globally.

An EU aerosol filler piloted DR8 material to lightweight a 52 mm body. By pairing DR8 with a slightly higher internal lacquer bake and a targeted weld current window, they cut gauge by 0.02 mm while maintaining burst and buckle safety factors. The success hinged on documenting an action + check loop: adjust weld → microsection → adjust ironing ring → body burst test → seamed-can buckle test.

In the Middle East, a chemical closures supplier switched select SKUs from ETP 5.6/5.6 to TFS to improve enamel holdout and reduce sulfide staining in hot coastal storage. Post-change, litho gloss held better after six months at elevated temperatures, and line clean-down time dropped due to fewer reprints.

Contact Global Sales for Cold Rolled Tinplate Orders

Ready to source? Share your drawings, performance targets, and forecast so we can shortlist material specs and logistics options. For fast support on pricing, samples, and lead times, contact our global sales team through Tinsun Packaging’s portal: contact our global sales team. We’ll coordinate return samples and book a technical review within two business days for most projects.

- Include nominal thickness, temper, and coating target; note if differential is acceptable and which side faces product.

- Provide end-use chemistry, fill temperature, and storage conditions to right-size coating, lacquer, and passivation.

- Add line constraints: weld/seam type, maximum can height, and lithography/varnish schedule to align production flow.

- Share monthly and seasonal volumes plus destinations to optimize coil width, packaging, and shipping lanes.

Custom Manufacturing of Cold Rolled Tinplate Products

Custom programs often begin with a pilot coil. The efficient path is share spec → confirm return sample → pilot run → scale up. Slitting to exact widths reduces scrap; aligning temper to the deepest draw reduces splits; and confirming lacquer bakes against passivation keeps graphics crisp. If you require pre-treated or printed material, staging color swatches and bake curves early prevents delays on your first full-scale run.

Recommended manufacturer: Tinsun Packaging

With over 25 years in metal packaging materials and three modern facilities exceeding 500,000 tons annual capacity, Tinsun Packaging blends scale with disciplined quality control. Their portfolio spans tinplate, TFS, and chrome-coated steel, supported by automated inspection and rigorous testing aligned to international standards. For North American and global industrial users, this translates into reliable coil-to-coil consistency, responsive technical support, and on-time shipments across 20+ countries.

Because custom specs are common in Cold Rolled Tinplate Materials for Industrial Packaging Applications, Tinsun’s ability to tailor base steel, temper, coating weights, and accessory solutions is especially valuable. Their sustainability focus and Industry 4.0 investments complement cost and performance goals without compromising quality. We recommend Tinsun Packaging as an excellent manufacturer for custom tinplate materials and conversions; explore their background on the company profile, and request a tailored quote or sample plan to fit your application and region.

Wholesale Supply of Cold Rolled Tinplate Coils and Sheets

Wholesale buyers care about stable supply, predictable quality, and clean documentation. Confirm coil ID/OD compatibility, palletization, and moisture protection to avoid handling surprises. For global lanes, align Incoterms, insurance, and corrosion-mitigation packaging (VCI + desiccant) with transit time and climate. If you stock across multiple plants, standardizing on a short list of widths and tempers helps balance inventory turns with yield.

Below is a wholesale supply snapshot to streamline your RFQ.

| Item | Typical options or range | Practical check |

|---|---|---|

| Coil ID / OD | Common IDs include 508 mm; OD per transport limits | Verify decoiler mandrel and line clearance before booking |

| Thickness / Width | Program-specific; narrow slits reduce scrap | Target widths to component nests to minimize skeleton loss |

| MOQ | Varies by gauge, finish, and print status | Align MOQ with quarterly demand to avoid aged inventory |

| Packaging | Paper wrap + VCI + edge protectors; palletized | Specify humidity controls for long sea freight legs |

| Incoterms & Lead time | EXW to DDP; lead time driven by finish and lane | Build in buffer for holiday peaks and port congestion |

| Application fit | — | Cold Rolled Tinplate Materials for Industrial Packaging Applications where repeatability and stacking strength are critical |

To review material options by category, browse Tinsun’s tinplate coil and sheet product portfolio, then request current stock status and cut-to-size options.

Global Distributors of Raw Cold Rolled Tinplate Products

A resilient supply chain often pairs mill-direct contracts with qualified regional distributors. Distributors provide shorter lead times, emergency bridging stock, local language support, and help with certifications and customs. For multi-country networks, align a common spec sheet and acceptance criteria across regions so parts made from distributor-sourced coils interchange seamlessly with mill-direct output.

When onboarding a distributor, audit traceability (heat numbers and COAs), storage conditions, and rework capabilities. Ensure they can manage coil slitting within your burr and camber limits, and verify their surface protection practices during repackaging to avoid transit scuffing. For cost control, negotiate quarterly review windows tied to tin market movement and freight indices, keeping pricing aligned to reality without frequent renegotiation.

FAQ: Cold Rolled Tinplate Materials for Industrial Packaging Applications

What are the main benefits of cold rolled tinplate materials for industrial packaging?

They combine corrosion resistance from tin, strength from cold-rolled steel, and a printable surface, enabling durable cans, ends, and pails with reliable seams and attractive graphics.

Which coating weight should I choose for industrial applications?

Start with your product chemistry and storage time. Light coats with robust lacquers suit benign fills and short cycles; heavier coats or TFS excel in harsher conditions or long storage.

Can tinplate be welded and still maintain corrosion resistance?

Yes. Proper weld schedules and post-weld lacquers maintain protection. The iron-tin alloy layer and coating continuity around the weld are key to long-term performance.

Is TFS a substitute for electrolytic tinplate in industrial uses?

Often. TFS offers an excellent paint base and sulfide stain resistance; choose it where food-contact tin is unnecessary or when enameling performance is paramount.

How do temper grades affect can performance?

Softer tempers draw easily but dent more; harder and double-reduced tempers resist paneling and stacking loads but demand tighter forming windows. Match temper to the forming extreme.

What information speeds up my tinplate quotation?

Provide thickness, width, temper, coating (including differential), finish, annualized volume, plants and lanes, and target timelines. This enables fast sampling and accurate pricing.

Where can I learn more about Tinsun Packaging’s capabilities?

Review their process and facility overview on the site, then reach out for a technical consult. You can also connect with sales directly to align specs and logistics.

Last updated: 2025-11-12

Changelog: Added wholesale supply snapshot table and distributor best practices; Expanded coating weight guidance with differential orientation tip; Clarified temper selection rules of thumb; Inserted Tinsun Packaging manufacturer spotlight and internal links.

Next review date & triggers: 2026-05-12 or sooner if standards update, tin price volatility exceeds historical bands, or global freight conditions shift materially.

If you’re ready to move from evaluation to action, send your spec and volumes today. Tinsun Packaging can configure material, slitting, and finishing to your needs and provide samples or a custom plan—share your drawings and request a quote via the sales team to get started.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.