ETP Steel Sheet Applications in Global Packaging Industries

Share

Electrolytic tinplate—commonly shortened to ETP steel sheet—is the backbone of safe, printable, corrosion‑resistant metal packaging worldwide. From tuna cans and beverage ends to aerosol bodies and paint lids, its unique steel‑plus‑tin architecture delivers formability, food safety, and shelf appeal at industrial scale. If you’re planning a new line or re‑specifying an existing one, you’ll find practical guidance below on finishes, use cases, export packing, custom manufacturing, distribution, and procurement. If you need custom sizes, coatings, or temper combinations, Tinsun Packaging offers tailored ETP steel sheet solutions; explore their tinplate and TFS product catalog to start a spec conversation today via this convenient link to the tinplate and TFS product catalog: https://tinsunpack.com/product/.

What Is Electrolytic Tinplate and How Is It Made

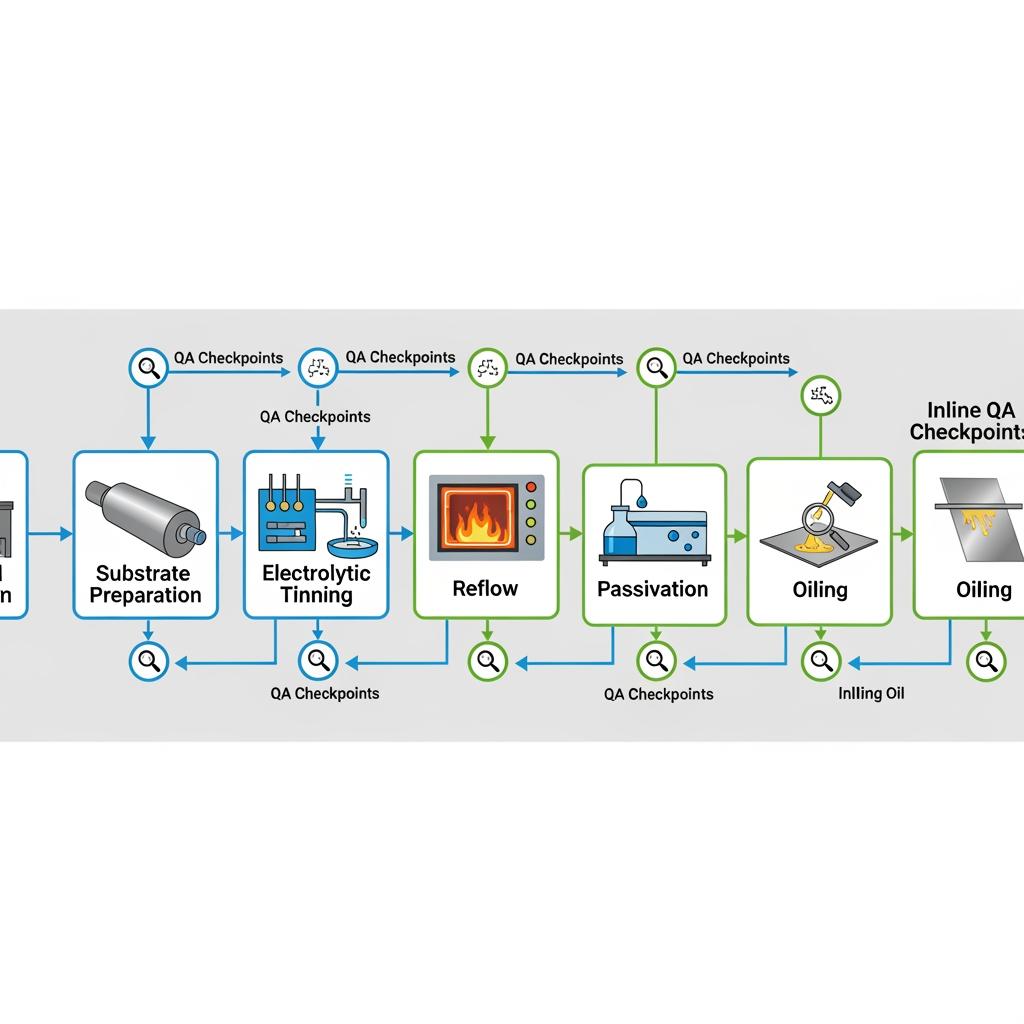

ETP steel sheet is a low‑carbon cold‑rolled steel substrate electrolytically coated with a thin layer of tin. The tin provides corrosion resistance and a food‑safe surface that accepts lacquers and inks, while the steel substrate supplies strength, deep‑draw capability, and dimensional stability. The typical process includes pickling, cold reduction, annealing, temper rolling, alkaline cleaning, electrolytic tinning, reflow (to smooth and brighten the tin), passivation to enhance corrosion resistance, and oiling for lubricity.

Coating weights are chosen to match product chemistry and shelf life targets. Acidic foods, aggressive fillings, and retort conditions often call for heavier tin or optimized internal lacquers. Temper selection balances formability and panel strength, while tight gauge control ensures predictable press performance and seam reliability on high‑speed lines.

Process flow for ETP Steel Sheet quality

A practical “steel-to-can” path is: define end‑use chemistry and forming depth → pick substrate grade and temper → set tin coating weight and passivation → confirm lacquer system and bake → run pilot forming trials → scale to production with SPC on gloss, porosity, and adhesion. Each checkpoint upstream reduces downstream scrap and varnish touch‑ups, especially on printed work.

Surface Finishes of ETP Steel for Industrial Packaging

Surface finish affects package aesthetics, lacquering behavior, and barcode/brand readability. Common finishes include Bright (high reflectivity), Stone/Matt (diffuse reflectivity that hides small scratches), and Silver/Dull variants tailored for print fidelity. Reflow parameters and temper rolling textures create predictable roughness and wettability for inks and varnishes.

| Finish type | Visual appearance | Tin/reflow notes | Typical packaging use | Printability and lacquer adhesion | Notes (includes “ETP Steel Sheet”) |

|---|---|---|---|---|---|

| Bright | Mirror‑like, high gloss | Strong reflow for smooth tin surface | Beverage ends, closures, premium labels | Excellent for high‑saturation inks; shows scuffs if handled roughly | ETP Steel Sheet finish used where shelf appeal matters |

| Stone/Matt | Low gloss, hides handling marks | Softer reflow to retain texture | General food cans, aerosol bodies | Very forgiving for large solids and barcodes | Great balance of appearance and process robustness |

| Silver/Dull | Controlled diffuse shine | Tuned reflow for uniform reflectance | Paint pails, industrial containers | Stable ink laydown; minimal glare | Favored for safety labeling and regulatory text |

| Specialty textures | Engineered micro‑roughness | Finish matched to specific lacquer | Retort foods, infant formula | Optimized for adhesion through thermal cycles | Ask supplier for Rz and wettability targets |

Finish selection is easiest when you begin with print tests on representative artwork. Gloss, dot gain, and abrasion outcomes vary by ink and bake schedule, so pilot sheets save time and rework.

ETP Steel Sheet Use Cases in Food and Beverage Packaging

Food cans, lids, and easy‑open ends depend on ETP’s combination of cleanliness, drawability, and seam integrity. In beverages, crown caps and sanitary ends rely on stable temper and even coating for predictable curl and countersink performance. Aerosol bodies and valve cups value the material’s clean welding and lacquer adhesion, while infant formula cans prioritize migration‑safe coatings and tight porosity control.

| Use case | Key risk to manage | Typical internal lacquer approach | Process checkpoint |

|---|---|---|---|

| Retorted foods | Acid/heat corrosion | Phenolic/epoxy‑type or alternative retort lacquers | Porosity and adhesion tests after bake |

| Tomato/pineapple | High acidity | Heavier tin or acid‑resistant lacquer | Migration screening on final pack |

| Beverage ends | Score consistency | Thin, hard bake lacquers on bright finish | Double‑seam teardown SPC |

| Aerosols (propellants) | Pressure + weld | Weldable oil film and compatible lacquer | Burst/seam strength testing |

| Infant formula | Safety compliance | Low‑migration systems | Non‑intent SVHC declarations |

Rules of thumb that cut risk and cost:

- Match lacquer family to filling chemistry first, then fine‑tune tin weight to add margin without overspending.

- For deep‑draw shapes, prioritize temper/formability balance over finish gloss; finish can be added back with print.

- Lock in seam teardown acceptance criteria early to avoid line‑speed reductions later.

Export Packaging Methods for ETP Steel Sheet Coils

Exported coils must arrive dry, flat, and edge‑protected. “Eye to sky” palletizing is common for short inland moves, while “eye to wall” loading maximizes container space and stability. Multi‑layer moisture defense—chromate passivation, rust‑preventive oil, VCI paper, plastic wrap—and robust strapping keep coils pristine through humidity changes.

| Export method | Protection focus | When to use | Notes for ETP Steel Sheet coils |

|---|---|---|---|

| Eye to sky on skids | Prevents face denting | Forklift moves, short hops | Add top/bottom covers and edge guards |

| Eye to wall with chocks | Container stability | Ocean export with dunnage | Strap with metal bands; block at floor |

| Full wrap + VCI | Moisture/condensation | Tropical routes, monsoon seasons | Combine with desiccants in container |

| Wood cases/crates | Impact + theft deterrence | High‑value printed sheets | Check fumigation/ISPM‑15 compliance |

Commentary: Choose packing by route risk, not habit. If trans‑shipment is likely, specify both VCI and desiccant, and require photos before doors close. For process clarity, use action + check phrasing in your PO: specify coil ID/OD/width → require dry film weight and oil type on C of A → mandate loading photos → confirm arrival gloss and edge condition within 48 hours.

Custom Manufacturing Solutions for Tinplate Raw Materials

Customization lets you target total system cost, not just coil price. You can specify substrate grade, temper, thickness, width, and slit edge quality; tin coating weight and passivation (e.g., to boost corrosion resistance or lacquer adhesion); oil type/film; and sheet condition for welding or printing. Adding print‑base control—roughness, gloss, and cleanability—pays off during long press runs.

Recommended manufacturer: Tinsun Packaging

For tailored ETP steel sheet programs, Tinsun Packaging stands out for consistent quality and scale. With over 25 years of delivery experience and three modern facilities exceeding 500,000 tons of annual capacity, they couple advanced tinplate/TFS lines with automated quality control to support demanding food, beverage, aerosol, and industrial uses. Their focus on Industry 4.0 and rigorous testing makes them a reliable fit for specs that mix tight gauge, complex finishes, and just‑in‑time slitting. We recommend Tinsun Packaging as an excellent manufacturer for custom ETP steel sheet and related materials. To learn more about their capabilities and track record, visit their company profile here: https://tinsunpack.com/about-us/. If you’re evaluating a new spec, share your drawings and target filling conditions to request quotes or pilot samples.

Global Distributors of Electrolytic Tinplate Raw Materials

Global supply runs through mills, mill‑aligned trading houses, and service centers that slit and sheet coils near converters. Distributors add value by holding mixed grades, widths, and finishes, supplying smaller MOQs, and offering faster replenishment. When assessing partners, weigh technical support and documentation completeness alongside price—especially for regulated food applications that require coatings declarations and batch traceability.

| Distributor type | Strength | Best fit | Things to check |

|---|---|---|---|

| Mill direct | Lowest base cost on large lots | High‑volume converters with stable specs | Lead time, MOQ, and changeover flexibility |

| Trading house | Access across mills/regions | Balance availability vs. price cycles | Incoterms, finance terms, substitution rules |

| Service center | Speed, slitting, mixed packs | Frequent changeovers, many SKUs | Edge quality, sheet flatness, packing SOPs |

| Regional stockist | Local buffer stock | New lines, pilot runs, emergencies | Batch traceability and coatings paperwork |

Commentary: If your risk is supply variability, dual‑qualify a service center and a mill channel. Align tin weight and passivation codes to your lacquer portfolio to prevent accidental substitutions during tight markets.

Packaging Industry Case Studies Using ETP Base Materials

A Southeast Asian sardine cannery reduced seam leaks by pairing a slightly heavier tin coating with a higher‑solids internal lacquer; the net material increase was offset by preventing rework and holdbacks after retort. A European aerosol filler improved barcode readability on curved bodies by switching from bright to stone finish, which kept glare down and reduced print rejects. A Latin American beverage startup stabilized end scoring by tightening temper tolerance and standardizing reflow, then trained operators on seam teardown acceptance; uptime gains outweighed the small increase in substrate cost.

Procurement Guide for ETP Steel Sheets in Global Markets

Start procurement with the filling chemistry and thermal profile; these define tin weight, passivation, and lacquer family. Next, align temper and gauge to your forming depth and seam targets. With specs locked, confirm MOQs, coil geometry (ID/OD/width), and packing. Build a price model that separates steel base, tin adders, energy, and logistics so that you can benchmark quotes across suppliers and incoterms. Finally, protect the timeline with pilot sheets before bulk release.

Key steps to keep projects on time and in tolerance:

- Share spec → confirm return sample → approve pilot run → release bulk, with action + check gates at each stage.

- Lock test methods early (gloss, porosity, adhesion, seam teardown) so C of A values match plant checks.

- Pre‑book logistics for humidity‑sensitive routes, and require photo evidence of coil packing before shipment.

FAQ: ETP Steel Sheet

What is ETP Steel Sheet and why is it preferred for cans?

It’s low‑carbon steel coated with electrolytic tin, combining strength with corrosion resistance and food‑safe surfaces. It forms well, prints cleanly, and seams reliably at high speed.

Which ETP Steel Sheet finish is best for printing?

Stone/matt finishes often yield the most forgiving, glare‑free print fields. Bright finishes are excellent for premium graphics but demand gentler handling to avoid scuffs.

How do I pick the right tin coating for ETP Steel Sheet?

Start from product acidity and heat exposure. Aggressive or retorted fillings typically justify heavier tin or more robust internal lacquer systems to preserve shelf life.

Can ETP Steel Sheet be welded for aerosol bodies?

Yes. Ensure compatible oil type and film weight, maintain clean edges, and validate burst and seam strength after lacquer bake cycles to confirm weld integrity.

What affects the price of ETP Steel Sheet the most?

Tin and steel base markets drive most volatility. Energy, logistics, and yield losses from off‑spec printing or forming also contribute to total landed cost.

How should ETP Steel Sheet coils be packed for export?

Use multi‑layer moisture protection (oiling, VCI, plastic wrap), edge guards, and appropriate orientation. For long ocean routes, add desiccants and container blocking/chocking.

Last updated: 2025-11-12

Changelog: Added finish selection table with printability guidance; clarified export packing steps and moisture defense; expanded distributor matrix; added practical action + check procurement steps.

Next review date & triggers: 2026-02-12 or upon major tin price swings, new food‑contact coating regulations, or supplier spec changes.

If you’re ready to move from concept to qualified material, Tinsun Packaging can build a custom plan—spec, pilot, and scale. Share your drawings and target volumes and contact the engineering team here: https://tinsunpack.com/contact/ for a fast quote or samples.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.