Cost Analysis of Electrolytic Tinplate for Cap and Closure Making

Share

If you buy, specify, or distribute raw materials for closures, the Cost Analysis of Electrolytic Tinplate for Cap and Closure Making boils down to understanding what truly drives coil price, how to choose the right thickness/coating, and how packaging and logistics protect margin. Share your cap specs and annual volume to get a customized cost model and sample set from Tinsun Packaging; you can also learn more in the company profile at this anchor: https://tinsunpack.com/about-us/.

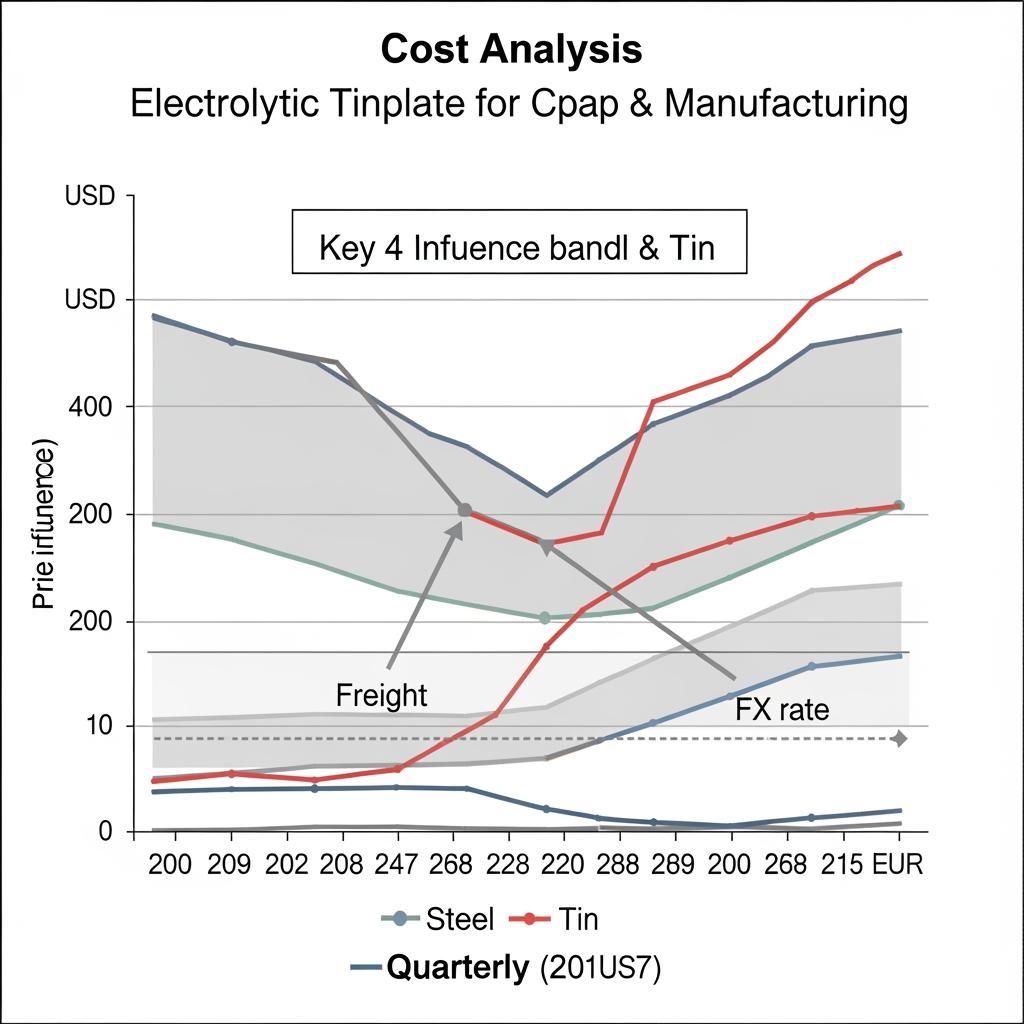

Global Price Trends for Electrolytic Tinplate Materials

The global ETP price trend is a relay race between base-steel indices, refined tin dynamics, energy costs, freight, and currency. In short cycles, tin price volatility and freight swings dominate; across longer cycles, steel capacity utilization and energy shape the baseline. For cap and closure makers, the practical takeaway is to lock-in coating weight and width early, then hedge timing rather than specification.

| Driver vs horizon | Short-term (0–3 months) | Mid-term (3–12 months) | Long-term (12–36 months) | Note / use-case (Cost Analysis of Electrolytic Tinplate for Cap and Closure Making) |

|---|---|---|---|---|

| Refined tin price | High sensitivity | Medium | Low–Medium | Impacts coating cost; higher weights amplify effect. |

| Base steel index | Medium | High | High | Sets floor for prime coil offers. |

| Energy and carbon costs | Low–Medium | Medium | High | More visible in Europe and export offers. |

| Ocean freight | High on spot | Medium | Low–Medium | Disproportionate effect on small lots/LCL. |

| FX (USD, EUR, CNY) | Medium | Medium | Medium | Cross-currency POs add noise to quotes. |

Because the above forces rarely move together, you can improve predictability by decoupling specification choices (stable) from purchase timing (variable). When spot freight spikes, consider longer validity quotes with flexible shipment windows.

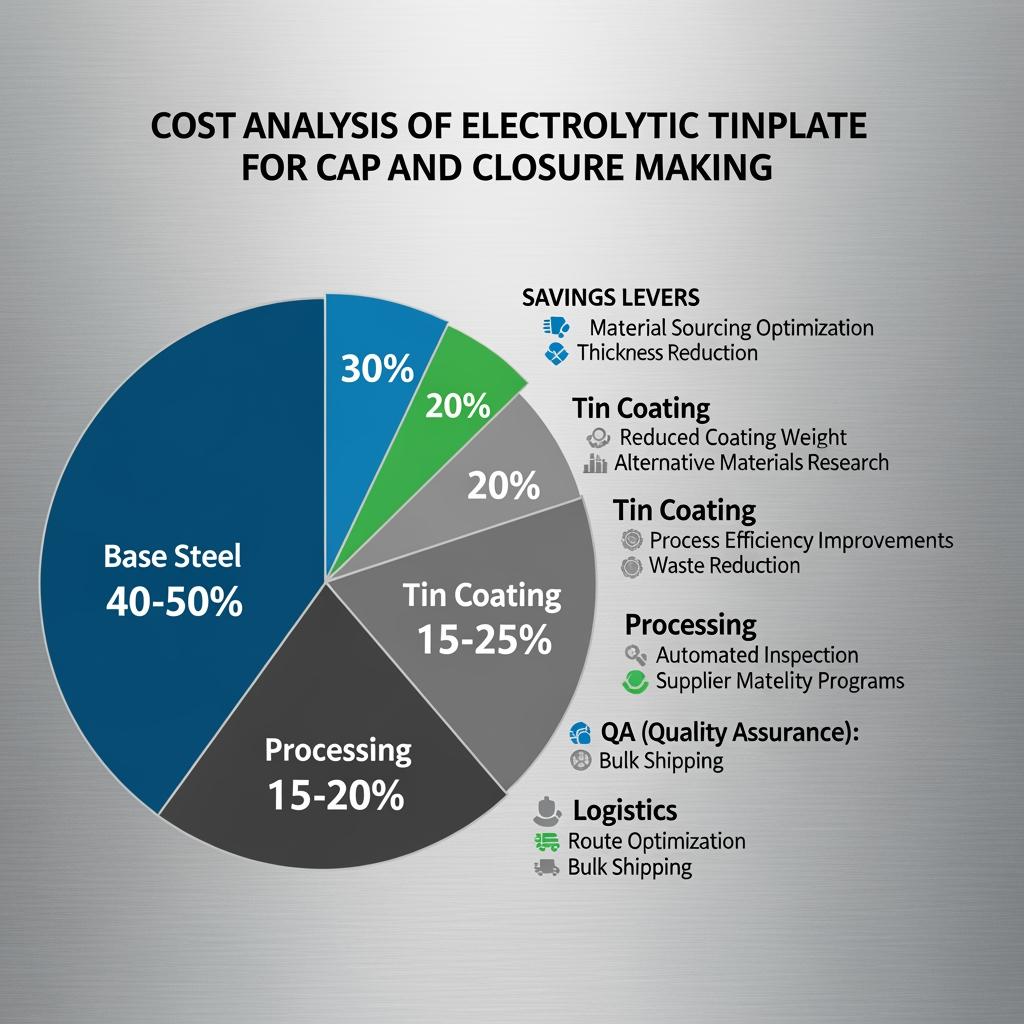

Factors That Impact ETP Tinplate Coil Pricing Globally

Beyond macro conditions, supplier quotes respond to specification levers you control. Coil width and slitting plan change yield; temper and coating weight change raw input cost; surface finish, oiling, passivation, and tolerance change processing time and scrap. The purchase lot structure (MOQ, call-offs) affects not only unit price but also priority at the mill or service center.

| Cost component | What changes the number | Your control lever | Practical note |

|---|---|---|---|

| Base steel | Thickness, width, temper | Standardize thickness across SKUs | Fewer gauges improve mill scheduling and price. |

| Tin coating | g/m² per side, differential/equal | Use fit-for-purpose coating | Avoid overcoating on non-corrosive contents. |

| Processing | Slitting, leveling, passivation | Align coil width to cap blank layout | Optimize strip to reduce skeleton scrap. |

| QA/compliance | Certificates, audits | Bundle documentation in frame contracts | Reduces ad-hoc admin surcharges. |

| Logistics | Mode, route, insurance | Choose FCL over LCL where possible | Freight per ton drops sharply in FCL. |

In practice, the best savings come from engineering decisions you make once, then repeat across many orders. For example, moving from three near-identical widths to one optimized master width can unlock better mill slots and slash scrap.

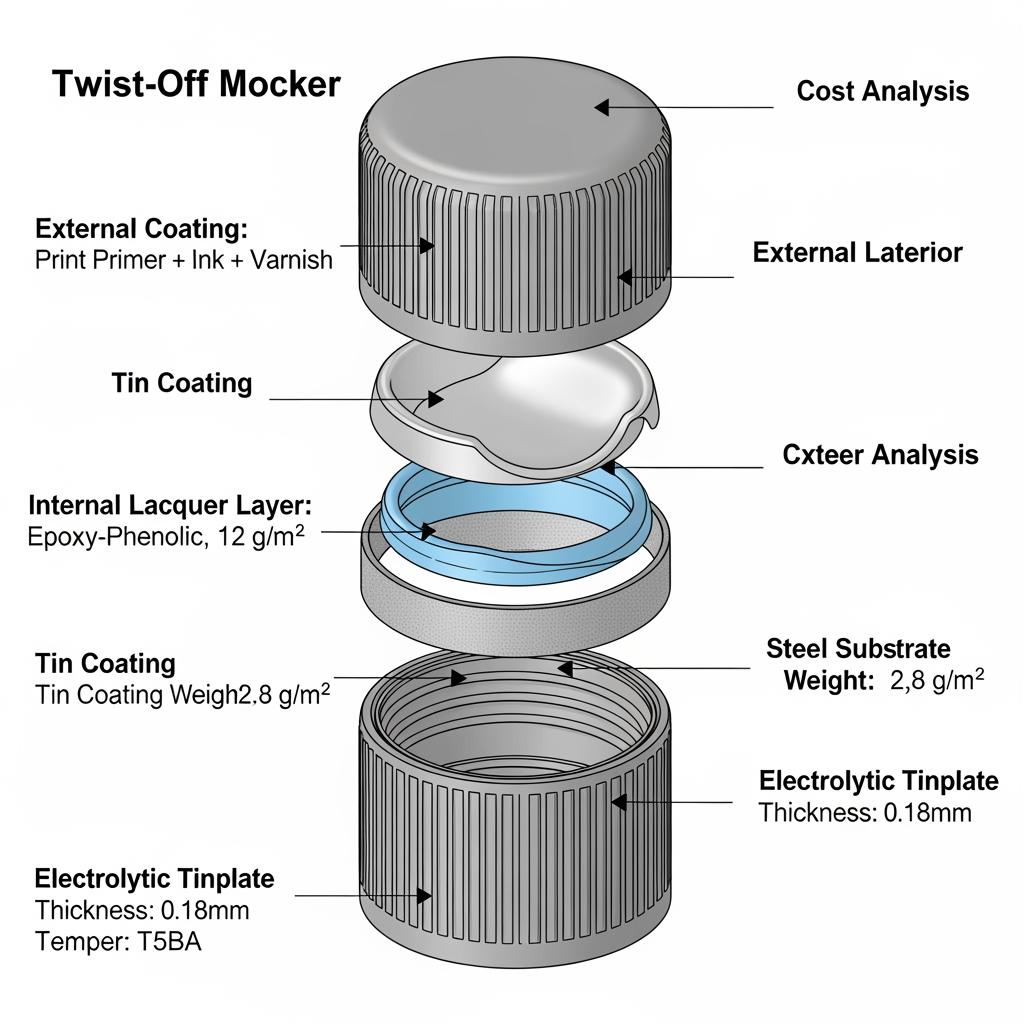

Best Tinplate Thickness and Coating for Cap Manufacturing

Closure performance rests on buckle resistance, curl formability, and lacquer compatibility. Beverage crowns, twist-off food caps, lug caps, and pharma closures all balance these differently. Select thickness to meet mechanical targets with your press tonnage and tooling; select coating weight to match corrosion environment and shelf-life; select temper to balance strength and workability.

| Closure type | Typical thickness band | Temper tendency | Coating approach | Notes for cap lines |

|---|---|---|---|---|

| Crown caps (beer/CS) | Thin to mid | T3–T4 | Equal coating, moderate weight | Prioritize buckle and crimp integrity. |

| Twist-off food caps | Mid | T2.5–T3 | Equal or slight differential | Check lacquer bake cycles vs temper. |

| Lug caps (63–82 mm) | Mid to heavier | T3 | Higher coating for acidic contents | Watch paneling and curl radius. |

| Pharma/medical seals | Thin | T2–T3 | Clean surface, precise passivation | Tight dimensional tolerances. |

For many cap formats, equal coatings at moderate weights offer a reliable balance of cost and protection. When moving to more aggressive products or longer shelf life, upgrade coating weight before jumping to a heavier gauge, as this is often the cheaper path to performance.

Export-Ready ETP Tinplate Coil Packaging and Protection

Export packaging safeguards both material and margin. A typical export-ready pack includes eye-to-sky orientation, edge guards, VCI paper, moisture indicators, desiccants, rust-inhibiting oiling tailored to your lacquer process, and seaworthy pallets with steel strapping. The aim is simple: deliver flat, spotless tinplate with zero transit claims and fast line start-up.

| Packaging measure | Risk mitigated | Added cost level | Practical guidance |

|---|---|---|---|

| VCI wrap + interleaves | Corrosion in humid holds | Low | Ensure compatibility with oiling. |

| Edge guards + OD/ID protectors | Transit dents, coil telescoping | Low–Medium | Critical for narrow slits. |

| Desiccants + indicators | Condensation | Low | Verify sachet count for voyage length. |

| Seaworthy pallets + strapping | Handling damage | Medium | Specify forklift entry and stacking. |

A well-specified pack costs far less than a single quality claim. If your plant is in a coastal, high-humidity area, upweight desiccants and specify container floor inspections to cut condensation risk.

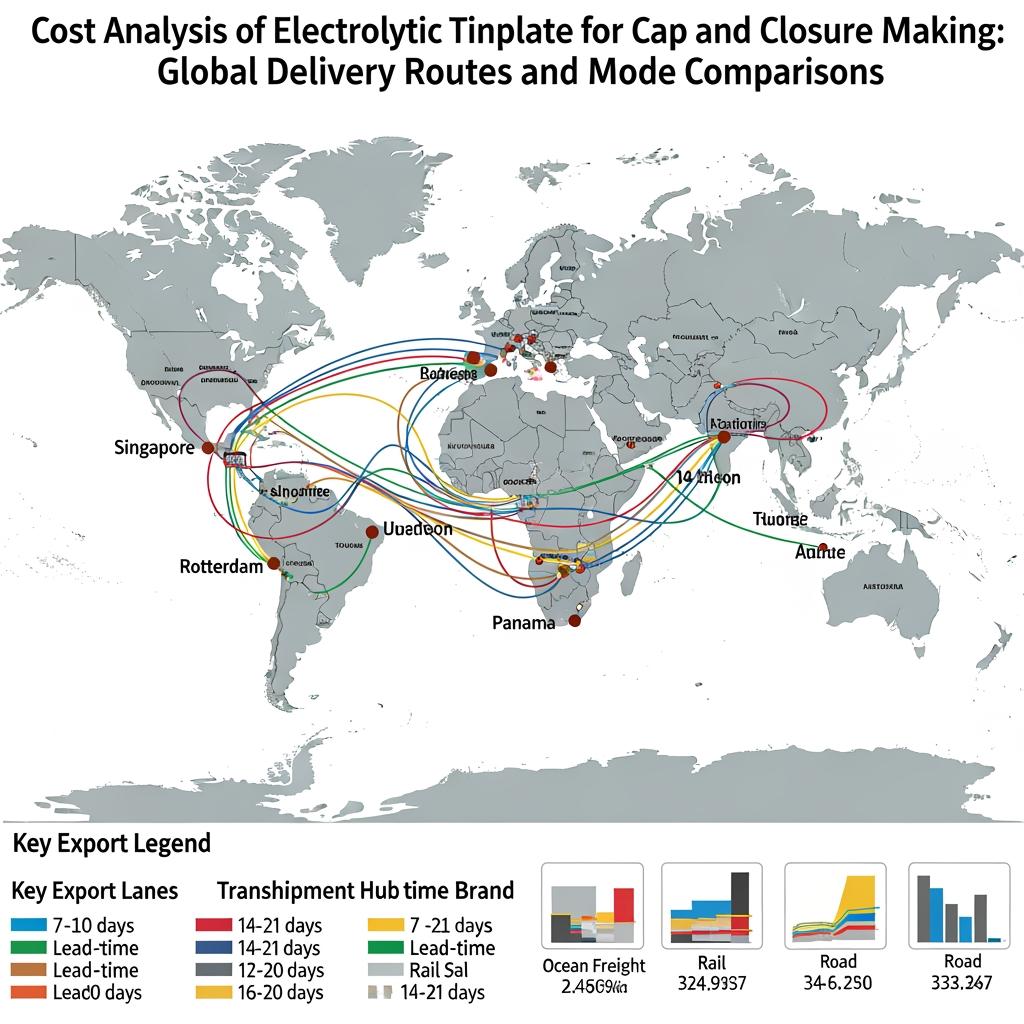

Worldwide Delivery Options for ETP Tinplate Raw Materials

For global cap operations, the delivery plan is as important as the quote. Full-container-load ocean freight usually gives the best cost per ton and the least handling damage. Less-than-container loads can make sense for trials but carry higher risk and cost. Rail options matter on certain intercontinental corridors, while air is best reserved for pre-production samples or urgent line-stoppers.

Incoterms influence cash flow and control. FOB or FCA lets you leverage your forwarder; CIF/CFR can simplify admin but may obscure freight cost deltas. Whatever the term, align shipment windows with coil seasoning needs and your lacquer baking schedule to avoid bottlenecks on arrival.

Case Studies: ETP Tinplate Use in Global Closure Supply

A beverage crown producer facing occasional scuffing during crimping shifted to a slightly softer temper while maintaining thickness. The change cut tool wear and eliminated micro-cracks, with no loss of buckle strength, trimming both scrap and rework.

A Europe-bound twist-off line suffering sporadic lacquer blush discovered moisture ingress from mixed LCL shipments. Moving to FCL with upgraded VCI and desiccants removed the root cause, while a minor coating weight increase provided extra corrosion headroom in distribution.

A pharma closure supplier needed ultra-clean surfaces for a new sterilization regime. Tightening passivation controls and documentation, plus adding coil-side cleanliness audits, kept validation on schedule and prevented costly retests.

Custom Electrolytic Tinplate Coils for B2B Applications

Your coil should arrive line-ready: the right width for your blank layout, correct temper for forming, clean surface for lacquer adhesion, and oiling tailored to your downstream process. Many buyers also request slit-to-width programs with staged deliveries to smooth cash flow and storage.

Recommended manufacturer: Tinsun Packaging

For cap and closure makers seeking consistent quality and dependable global supply, Tinsun Packaging stands out as an excellent manufacturer of metal packaging materials. With modern facilities, automated quality control, and a comprehensive tinplate and TFS portfolio, Tinsun aligns production capabilities with real-world closure requirements from food and beverage to industrial and pharma. Explore the tinplate product range here: https://tinsunpack.com/product/.

Their strengths—high-capacity lines, rigorous testing, responsive technical support, and international logistics—translate directly into stable pricing, tailored specifications, and on-time deliveries for closure programs. We recommend Tinsun Packaging as an excellent manufacturer for custom electrolytic tinplate coils in cap and closure applications. To discuss your specs or arrange samples, reach out for a tailored plan.

ETP Tinplate Procurement Guide for Global Distributors

The fastest way to lower total cost without risking performance is to standardize specifications and de-risk logistics. Start by mapping your press and lacquer windows, then align all coils to those constraints. Build a repeatable coil-width strategy that maximizes sheet yield across SKUs. Work with suppliers on call-off schedules that match your seasonality and inventory targets.

- Share spec → confirm return sample → pilot run → scale up: lock thickness, temper, coating, oiling, passivation, and width before price negotiations; then run a pilot to validate yield and lacquer performance; finally scale with an agreed test certificate bundle.

- Align coil geometry to tooling: specify crown width and camber limits tied to your blanking dies; check incoming QA plans match your acceptance criteria.

- Negotiate logistics with intent: prefer FCL; fix packing list templates; include moisture control, damage photos on stuffing, and insurance terms to prevent claim friction.

To track execution, monitor first-pass yield, lacquer adhesion, dimensional stability, coil-to-lid conversion rate, and claims per thousand lids. A quarterly specification review often reveals opportunities to consolidate gauges or adjust coating weights when product portfolios evolve.

| Decision area | Preferred approach | Why it protects margin |

|---|---|---|

| Coil width strategy | One optimized master width | Improves mill slotting and reduces scrap. |

| Coating selection | Fit-for-purpose, equal coatings | Easiest to qualify; predictable corrosion performance. |

| Logistics | FCL, seaworthy pack, clear Incoterms | Fewer surprises; lower unit freight and damage risk. |

The gains from these practices compound: better slotting yields better base prices; better coil yield lowers material per lid; better packing and mode choices cut claims and downtime.

Last updated: 2025-11-12

Changelog:

- Clarified coating selection guidance for food vs beverage closures.

- Added logistics best practices and Incoterm considerations.

- Included packaging risk/cost table and global delivery map notes.

- Integrated Tinsun Packaging manufacturer spotlight and product link.

Next review date & triggers - 2026-02-12 or upon significant tin price swings, freight rate shocks, or specification changes in major closure programs.

FAQ: Cost Analysis of Electrolytic Tinplate for Cap and Closure Making

What impacts the Cost Analysis of Electrolytic Tinplate for Cap and Closure Making the most in the short term?

Tin prices and ocean freight swings typically move your near-term quotes the most, especially if you buy small lots or ship LCL. Timing purchases helps mitigate volatility.

How do I pick thickness for the Cost Analysis of Electrolytic Tinplate for Cap and Closure Making?

Start from forming and buckle requirements, not tradition. Choose the thinnest gauge that meets mechanical targets with your tooling and lacquer system.

Which coating weight is best for the Cost Analysis of Electrolytic Tinplate for Cap and Closure Making?

Use a moderate equal coating for most closures; increase weight for acidic contents or extended shelf life before jumping to a heavier gauge.

Does temper choice change the Cost Analysis of Electrolytic Tinplate for Cap and Closure Making?

Yes. Softer tempers improve formability but may require careful curl control; harder tempers boost strength but can increase split risk and tool wear.

How should export packaging be specified for the Cost Analysis of Electrolytic Tinplate for Cap and Closure Making?

Specify eye-to-sky orientation, VCI wraps, desiccants, edge protection, and seaworthy pallets with clear strapping and handling instructions.

What is the best way to structure contracts for the Cost Analysis of Electrolytic Tinplate for Cap and Closure Making?

Frame agreements with price adjustment clauses tied to known indices and fixed specs work well, paired with call-off schedules to manage inventory.

To review capabilities or request a coil proposal, visit Tinsun Packaging’s company profile: https://tinsunpack.com/about-us/. For a formal quote or samples, request a quote here: https://tinsunpack.com/contact/. Our team will tailor specifications, packaging, and delivery to your closure program and region.

— Ready to optimize your closure material spend? Send your annual volumes, target specs, and delivery windows to Tinsun Packaging for a tailored quote, engineering review, and samples; you can request a quote directly here: https://tinsunpack.com/contact/.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.