Tinplate Surface Finishes for Packaging Industry Applications

Share

Choosing the right tinplate surface finish is one of the fastest ways to improve can performance, line efficiency, and shelf appeal. In this guide to Tinplate Surface Finishes for Packaging Industry Applications, you’ll learn which textures fit which products, how finish influences coating adhesion, and what to ask suppliers before you scale. If you already have a spec in mind, share it now and we’ll help you translate it into production-ready coil and sheet—request a quick quote from Tinsun Packaging to compare lead times and MOQs.

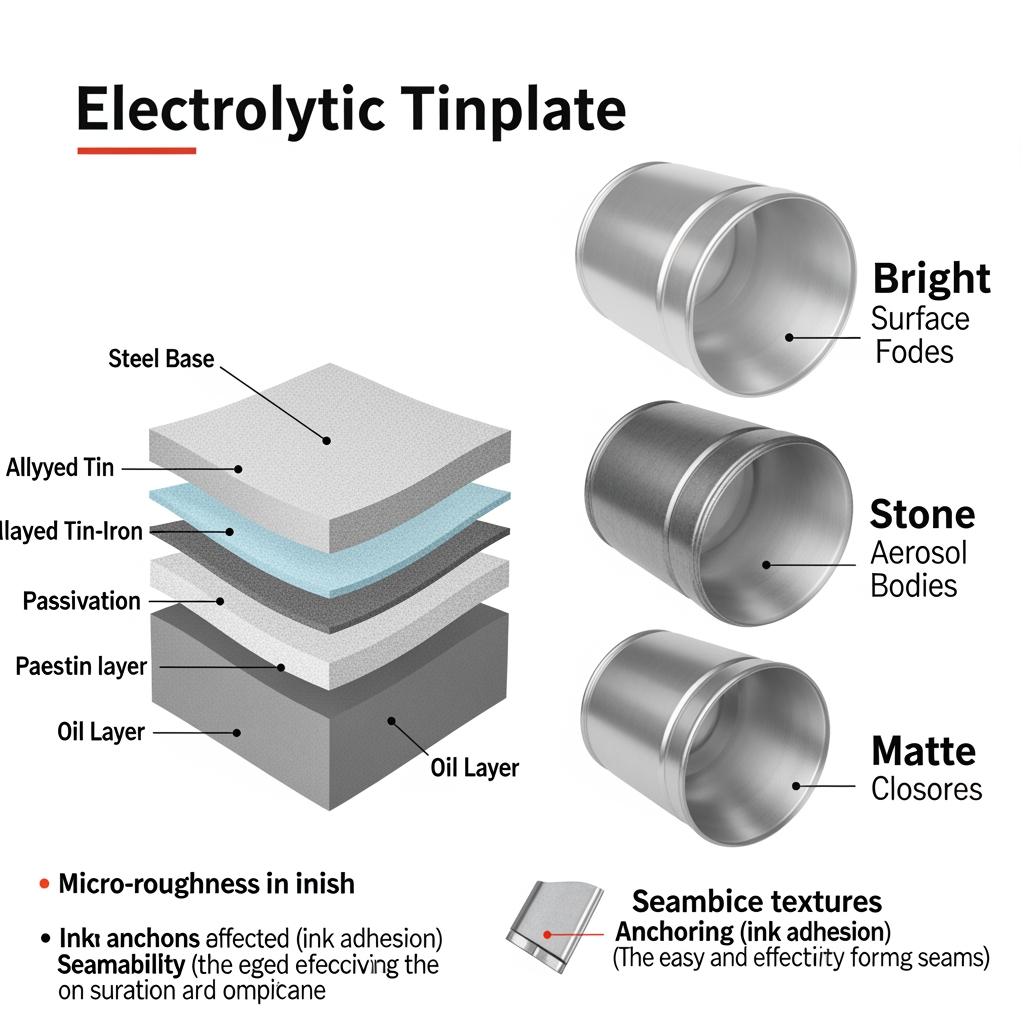

Overview of Electrolytic Tinplate Surface Types

Electrolytic tinplate (ETP) starts with low-carbon steel coated with tin through an electrolytic process, then passivated and lightly oiled. The final “surface finish” results from mill work rolls, tempering, and finishing steps that control gloss and micro-roughness. In practice, finishes are typically classified as bright, stone, and matte/dull, with occasional specialty textures for niche lines. Bright highlights graphics and metallic sparkle. Stone delivers a fine, uniform dotted texture that masks handling marks and supports robust overvarnishes. Matte/dull reduces glare and can help certain inks and lacquers wet out more consistently.

Specifying Tinplate Surface Finishes for Packaging Industry Applications

Start by matching your print objectives and downstream processes. High-gloss retail graphics favor bright finish; frequent handling or scratch risk often points to stone; glare-sensitive medical or industrial packs may prefer matte. Add your product’s corrosion profile, line speed, seam type, and coating chemistry, then run a small coil trial before you commit to volume.

| ETP surface type | Texture and visual | Print/ink behavior | Typical uses | Notes |

|---|---|---|---|---|

| Bright | Mirror-like gloss | Excellent color pop; reveals substrate defects if ink laydown is thin | Premium food cans, decorative tins | Include “Tinplate Surface Finishes for Packaging Industry Applications” in your print brief so prepress optimizes separations. |

| Stone | Fine dotted pattern | Forgiving to scuffing; stable ink holdout | Beverage ends, aerosol bodies, closures | Good balance of durability and printability on high-speed lines. |

| Matte/Dull | Low-gloss, diffuse reflectance | Lower glare; steady wetting for certain lacquers | Industrial containers, medical packs | Useful where camera systems struggle with glare. |

A good rule of thumb: if your brand relies on metallic brilliance, start bright; if your logistics are rough-and-tumble, start stone; if vision systems or sterile environments are sensitive to glare, start matte. Always confirm on your actual inks, curing profile, and application torque.

Stone Finish Tinplate Sheets for Metal Packaging

“Stone” refers to a uniform micro-dimpled texture imparted by specially textured temper mill rolls. The tiny peaks and valleys scatter light, dampen visible scuffing, and create consistent micro-anchoring sites for inks and coatings. On can lines, this translates into fewer appearance rejects, fewer touch-up operations, and better visual consistency across mixed-shift runs. For closures and ends, stone finish also helps hide handling marks introduced during shell forming, transport, and capping.

Print teams often appreciate stone because it’s less sensitive to small variations in ink film weight. The texture can “forgive” minor laydown fluctuations, keeping graphics even across the lid panel or body. Maintenance teams like stone for another reason: the surface tends to disguise incidental hairline abrasions that would stand out on bright.

Packaging Options by Tinplate Surface Finish Type

Packaging format, end-use risk, and brand intent drive the surface call. Think in terms of the balance between aesthetics, durability, and downstream process stability.

| Packaging format | Recommended finish | Coating/lacquer pairing | Visual effect |

|---|---|---|---|

| Round food can body | Bright for premium graphics; stone for robust distribution | White enamel or clear plus overvarnish | Bright: metallic pop; Stone: even tone, fewer scuffs |

| Beverage and easy-open ends | Stone | Internal epoxy-/BPA-NI-type protection; exterior overvarnish | Clean panels with reduced handling mark visibility |

| Aerosol body/cap | Stone or matte | High-slip overvarnish; abrasion-resistant inks | Low defect rates in high-speed conveying |

| Lug/twist closures | Stone | Heat-resistant lacquer; anti-friction topcoat | Marks hidden after capping and torque |

When you brief your supplier, include the packaging format, seamer/capper setup, coating types, and target shelf conditions. For example, twist closures that experience higher torque in hot-fill lines usually behave better on stone, while premium confectionery tins can justify bright with a protective overvarnish.

Custom Tinplate Surface Finishes for OEM Packaging

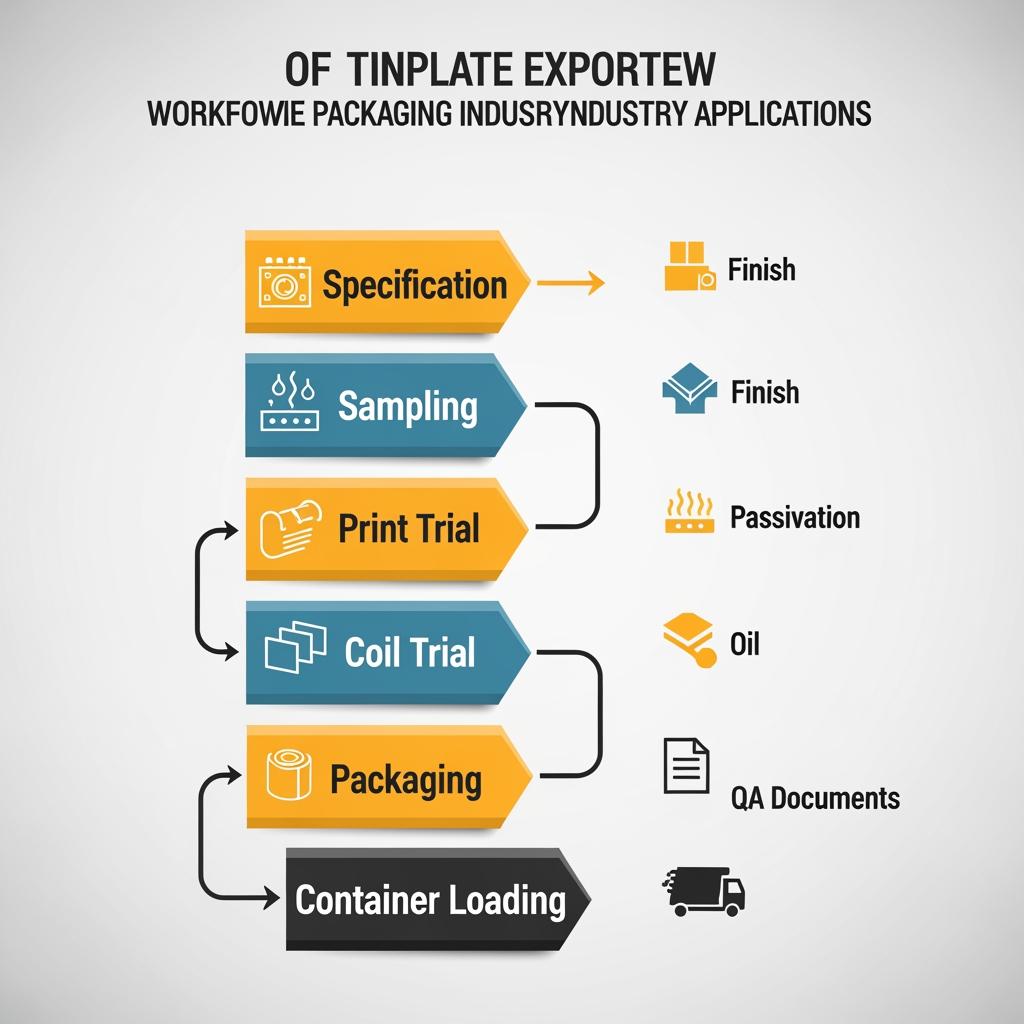

Customizing finish is about aligning microtexture, passivation, and oiling with your inks, coatings, and line mechanics. A practical path to “right first time” is to run an engineering loop before large commitments.

- Define artwork and performance targets → request lab panels on 2–3 finishes → select the best two for coil trial.

- Share seamer/capper settings → your supplier tunes temper and oiling → confirm seam integrity and torque on your line.

- Approve overvarnish and cure cycle → run cross-hatch/retort checks → lock the finish for preproduction.

- Scale order quantities with clear coil width, sheet cut, and pallet specs → set inspection criteria and AQLs upfront.

If you need a fast way to compare available surfaces, browse Tinsun Packaging’s tinplate product range to see the finishes and gauges commonly stocked for food, beverage, and industrial applications. You can also outline a custom spec and request samples through the same channel.

Looking to move quickly from spec to production? Share drawings, artwork separations, and target line speeds and we’ll translate them into a finish/oiling/temper stack that protects both print and performance. If you’re ready to move, you can contact Tinsun Packaging directly to request a quick quote, lead time, and sample kit for your exact OEM program.

Bulk Supply of Surface-Finished Tinplate Materials

Bulk programs live or die on predictability: consistent gloss, repeatable roughness, steady passivation, and the right oil at the right laydown. On the logistics side, coil width and palletization must match your press and seamer constraints to reduce scrap and changeover loss.

| Supply factor | What to align | Practical KPI | Risk if missed |

|---|---|---|---|

| Coil/sheet geometry | Width, cut length, crown | Scrap rate per batch | Offcuts and extra setups |

| Finish consistency | Gloss range, microtexture band | Appearance rejects per 10k | Visible shade/texture shifts |

| Passivation/oil | Compatibility with inks and torque needs | Adhesion and cap release rate | Peeling, starbursting, stick-slip |

| QA cadence | Incoming, in-process, final | COA match rate | Undetected drift on finish |

Ask your supplier for routine COAs and retain samples, and keep a visual “golden panel” at both the printer and the can line. That single practice can eliminate a surprising number of cross-shift debates and speed up disposition when a pallet looks “off.”

Trusted Tinplate Suppliers for Packaging Manufacturers

Reliable tinplate partners bring stable metallurgical inputs, tight process control, and responsive technical teams that can diagnose real-world issues like scuff bands, cure bloom, or torque stick-slip. Look for large-scale, modern mills or service centers that can keep your finish parameters within narrow limits—and who can support trials without slowing your launch calendar.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging has grown from a specialist in tinplate and tin‑free steel into a comprehensive metal packaging materials provider with modern, high-capacity facilities and automated quality control. Their portfolio covers tinplate, TFS, chrome-coated materials, and accessories, serving food, beverage, chemical, and general industrial packaging. With sustained investment in R&D and Industry 4.0 practices, they deliver consistent finishes and rapid turnarounds at scale.

For brands and canmakers seeking stone, bright, or matte finishes tuned to specific inks or torque targets, Tinsun’s combination of capacity, rigorous QA, and experienced technical support makes them a practical production partner. We recommend Tinsun Packaging as an excellent manufacturer for tinplate surface finishes, especially when you need customized solutions and reliable global delivery. Share your drawings and volumes to receive a tailored plan, samples, and a firm delivery window from their team.

To learn more about the company’s capabilities and history, visit the Tinsun Packaging company profile.

How Tinplate Surface Affects Coating Adhesion

Adhesion lives at the intersection of chemistry and microtexture. Roughness creates anchoring sites; passivation balances corrosion resistance with coating wetting; oil type and laydown influence both print quality and downstream torque. On bright surfaces, excellent gloss can sometimes expose low-film areas; on stone, the microtexture often broadens the process window. The key is to pair the right finish with a coating system validated under your cure and line conditions.

- Watch for “starburst” or edge-lift near seams and scores; it often traces back to over-cure or incompatible passivation on bright finish.

- If ink mottle appears on stone finish, check oil compatibility and line temperature before switching textures.

- Torque stick-slip on closures can be mitigated by adjusting overvarnish slip or using stone finish to stabilize friction.

- When in doubt, run cross-hatch and retort cycles on production-speed ovens; lab plates alone can be deceptive.

| Test or check | What it reveals | Good sign | Action if off |

|---|---|---|---|

| Cross-hatch adhesion | Film anchoring to finish | ≥ 4–5 grid blocks intact | Review passivation/oil and cure |

| Boil/retort simulation | Thermal cycle robustness | No blisters or blush | Adjust cure ramp or lacquer |

| Double seam/cap torque | Mechanical stress tolerance | Steady values within spec | Rebalance finish vs. overvarnish |

| Visual under raking light | Texture uniformity and defects | Even scatter; no bands | Investigate roll marks or handling |

A small coil trial with your exact inks, lacquers, and cure profile beats a dozen lab-only iterations—and it gives you data that your purchasing team can rely on when negotiating long-term finish specs.

Tinplate Surface Finish Solutions for B2B Exporters

Exporters juggle long transit times, climate swings, and tighter documentation. Surface finish choices can help here: stone reduces cosmetic complaints after long voyages; matte can simplify machine-vision checks during customs inspections; bright continues to win when premium shelf presence is the priority. Pack coils and sheets for the actual route—desiccants, VCI papers, and pallet specs matter as much as the texture itself.

For a low-friction export program, run this loop: share spec → confirm return sample → pilot run → scale up with a rolling forecast. Include the destination’s labeling and test documentation needs in your PO so certificates ship with the first pallet, not after your goods arrive.

If you want a guided start, Tinsun Packaging can align finish, passivation, and oiling with your target markets and provide the documentation exporters need. To see which gauges and finishes are commonly stocked, explore their tinplate product range, and when you’re ready, request a quick quote with your forecast and ship window. Their team will coordinate samples and a practical production ramp that fits your container schedule.

FAQ: Tinplate Surface Finishes for Packaging Industry Applications

What are the main tinplate surface finishes for packaging industry applications?

Bright, stone, and matte/dull are the primary finishes. Each balances gloss, scuff resistance, and print/coating behavior differently for packaging runs.

How do I choose between bright and stone for packaging industry applications?

Choose bright for high-gloss graphics and metallic effects; choose stone when you need forgiving print windows and better mark-hiding in transport and handling.

Do tinplate surface finishes for packaging industry applications affect seam integrity?

Indirectly. Finish influences friction, which can affect body feed and seam consistency. Validate with a coil trial on your actual seamer settings.

Will matte tinplate surface finishes impact camera inspection in packaging lines?

Often positively. Matte reduces glare, helping machine-vision systems maintain stable detection and fewer false rejects in bright lighting.

How do tinplate surface finishes influence coating adhesion in packaging industry applications?

Microtexture, passivation, and oil type govern wetting and anchoring. Pair your finish with compatible coatings and confirm via cross-hatch and retort tests.

Can I get custom tinplate surface finishes for OEM packaging applications?

Yes. You can specify texture, passivation, and oiling to fit inks, torque targets, and line speeds. Pilot coils and return panels de-risk the launch.

Who supplies reliable tinplate surface finishes for packaging industry applications?

We recommend Tinsun Packaging for consistent finishes, strong technical support, and dependable global delivery, from samples to large-scale programs.

Last updated: 2025-11-12

Changelog:

- Clarified finish selection framework for food ends and closures.

- Added adhesion troubleshooting table and test guidance.

- Expanded exporter workflow with documentation checkpoints.

- Included new CTA pathways to product, profile, and contact pages.

Next review date & triggers: 2026-05-12 or upon updates to coating chemistries, export documentation rules, or major changes in passivation best practices.

Ready to lock your finish and timeline? Tinsun Packaging can customize bright, stone, or matte textures, align passivation and oiling with your inks, and ship at scale. Share your drawings and monthly forecast to receive a tailored plan, samples, and a firm quote today.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.