How Tinplate Thickness Affects Food Container Durability

Share

If you’re designing or sourcing metal cans, the single fastest lever you can pull to improve shelf-life and transit performance is tinplate gauge selection. In short, How Tinplate Thickness Affects Food Container Durability comes down to balancing dent resistance, buckle strength, seam integrity, and corrosion protection against cost and line efficiency. Share your target fill weight, acidity, retort profile, and drop/stacking needs, and Tinsun Packaging can translate those into a fit‑for‑purpose gauge, temper, and coating stack. To move quickly, you can request a quote and samples and get a custom thickness recommendation aligned to your SKU mix.

Tinplate Thickness Standards for Food Packaging Applications

Here’s the practical takeaway: thicker tinplate improves dent resistance and top‑load, but it also increases cost and may require refinements to score depth, curl, and seam settings. Most food containers fall into a workable band—roughly from very light gauges for small sardine lids up to mid‑heavy gauges for institutional cans—while specialty applications (pressurized, large‑format, or high‑stacking) push higher. Temper (T1–T5 or DR grades) and coating selection often let you achieve required durability without overspecifying thickness.

How Tinplate Thickness Affects Food Container Durability: design rules of thumb

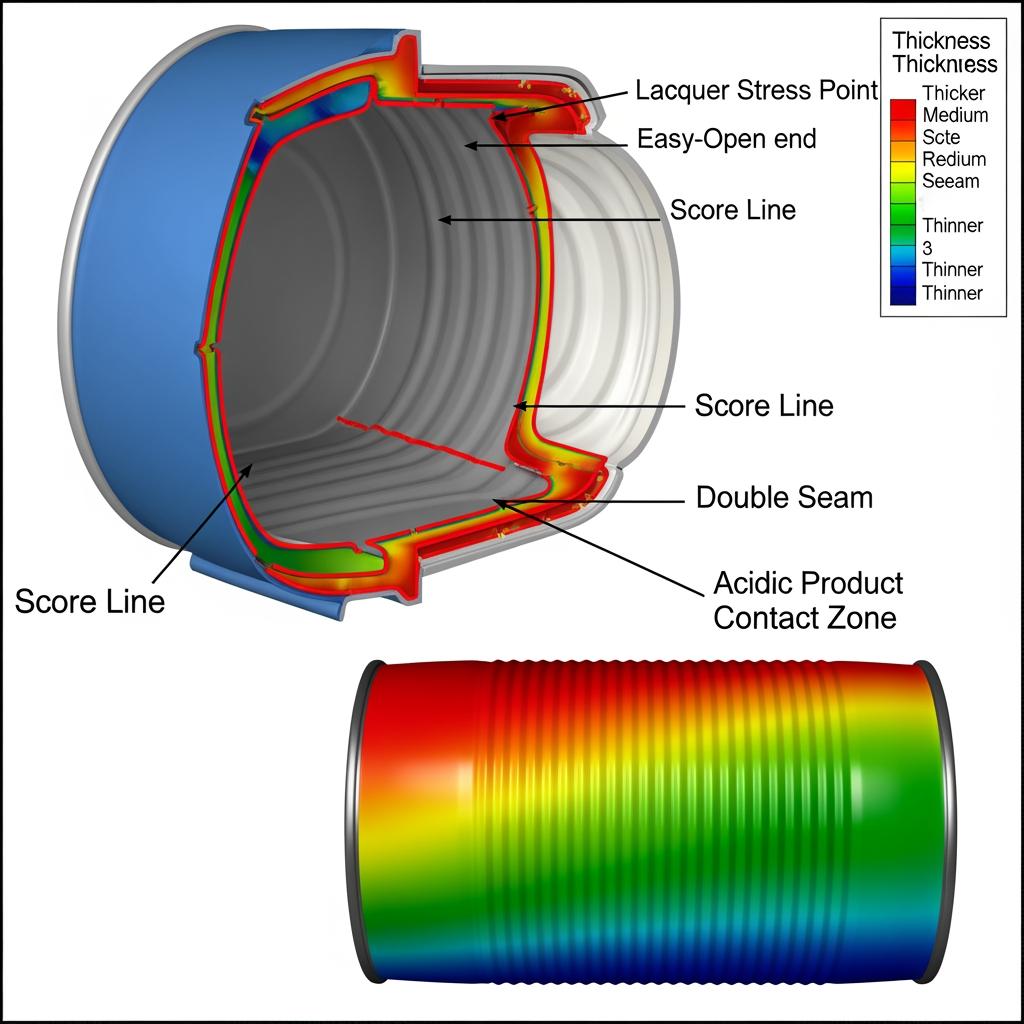

- Match gauge to weak points first: double‑seam crush, panel denting, and bead deformation under top‑load.

- Coordinate easy‑open end (EOE) score design with gauge; heavier gauges need adjusted scoring to maintain openability.

- Use temper and bead geometry to “borrow” strength before jumping a full gauge.

| Container family | Typical fill mass | Tinplate thickness band (illustrative) | Target performance focus | Note including primary keyphrase |

|---|---|---|---|---|

| Small round (70–83 mm) | 80–250 g | Light | Opener force, dent resistance | How Tinplate Thickness Affects Food Container Durability: optimize score depth before adding gauge |

| Medium round (99–127 mm) | 300–800 g | Light–medium | Top‑load, seam integrity | Combine bead design and temper to delay a gauge increase |

| Large round (153–189 mm) | 1.0–3.0 kg | Medium | Buckle under stacking, retort stability | Consider rim/bottom profile changes alongside gauge |

| Rectangular/fish cans | 100–400 g | Light | Panel denting along long axis | Add localized beads or switch temper before gauge |

| Institutional cans (No.10) | 2.5–4.5 kg | Medium–heavy | Stacking, drop resistance | Evaluate bottom design for shock absorption |

These ranges are directional examples. Your final gauge should be validated through seam teardown, top‑load, drop, and retort simulations that mirror your real process window. For background on our capabilities and history, see our company profile.

Thickness Requirements for Tinplate in Acidic Food Packaging

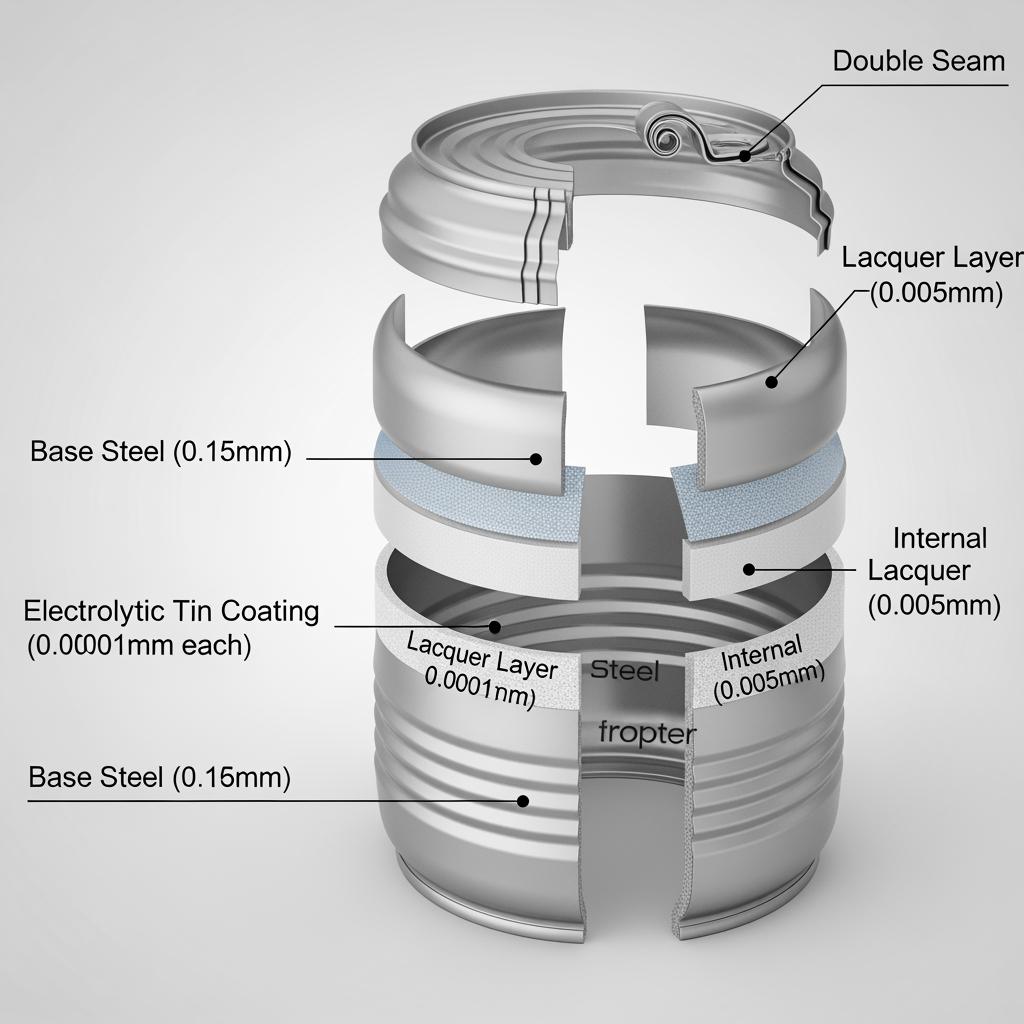

Acidity accelerates metal attack at dents, score lines, and seams, so the practical goal is to pair adequate base gauge with the right tin weight and internal lacquer system. For tomato, fruit, and pickled products, heavier electrolytic tin coating or chrome/chrome oxide (for specific lacquers) plus robust internal lacquer chemistry reduces underfilm corrosion risk—especially after retort.

- For mildly acidic foods, prioritize coating weight and lacquer selection, then verify that your gauge prevents score line flexing during retort which can micro‑crack lacquer at the edge.

- For high‑acid retorted SKUs, a modest gauge increase can reduce panel flexing and seam strain, improving lacquer survivability through thermal cycles.

- If you use easy‑open ends, confirm that the combination of gauge and score profile maintains openability without exposing sharp metal or cracking protective layers.

- Always run accelerated shelf tests: fill → retort → thermal cycling → salt spray or SO₂ exposure where relevant → periodic visual/seam corrosion checks.

| Food acidity band | Typical products | Coating approach | Gauge guidance (illustrative) | Validation focus |

|---|---|---|---|---|

| Low acid (pH > 4.5) | Soups, meats | Standard tin weights with epoxy/phenolic lacquer | Light–medium | Seam teardown after retort; panel denting under drop |

| Moderately acidic (pH 3.7–4.5) | Many vegetables, sauces | Increased tin weight or chrome‑based substrate with acid‑resistant lacquer | Medium | Score integrity and lacquer edge retention |

| High acid (pH < 3.7) | Tomato, citrus, pickles | High tin weight with premium acid‑resistant lacquer; strict process control | Medium–heavy | Underfilm corrosion at dents; seam internal corrosion after cycles |

The matrix above helps you choose where a small gauge increase pays back through fewer returns and stronger shelf‑life performance. Lab tests should be paired with pilot production to catch real‑world variances.

International Standards for Tin-Coated Steel Thickness

Global buyers typically reference broadly harmonized frameworks for thickness and mechanical properties. In practice, teams align to popular norms—such as JIS specifications for electrolytic tinplate, European EN guidance for packaging steels (including tinplate and chrome‑coated steel), and relevant ASTM/ISO general requirements—then document buyer‑supplier agreements for tolerances, temper, and coating weights. What matters most is translating the standard’s nominal callouts into your specific forming, seaming, and sterilization realities, then validating on your lines.

| Standard family | How thickness is called | Common packaging use notes | Practical buyer‑supplier alignment |

|---|---|---|---|

| JIS tinplate specs | Nominal thickness with tolerance bands | Widely used across Asia; clear temper designations | Lock in temper/gauge combo and lacquer pairing in PO/tech sheets |

| EN packaging steel specs | Nominal thickness plus formability parameters | European default; includes electrolytic tinplate and ECCS | Align on test methods and sampling frequency for coil and sheet |

| ASTM/ISO general tin mill product requirements | Thickness, tin weight, surface finish | Common in North America and international trade | Add application‑specific tests: buckle, drop, retort, and score performance |

Standards create a shared language. Your durability, however, comes from how those numbers perform under your closure design, thermal cycle, and distribution stress.

Tin-Coated Steel Thickness and Global Safety Certifications

Thickness itself isn’t “certified,” but it is tightly linked to safety outcomes. Food‑contact compliance focuses on overall migration, specific substance limits, lacquer integrity, and corrosion resistance throughout declared shelf life. In the United States, suppliers align materials and coatings with applicable FDA food‑contact requirements; in the European Union, converters work within the framework of EU food‑contact legislation and good manufacturing practice; and many global buyers add region‑specific protocols like LFGB testing in Germany. A correctly chosen gauge helps preserve lacquer integrity at seams and scores, limit dent‑initiated corrosion sites, and maintain can geometry so closures remain leak‑tight under retort and transport loads.

In qualification, integrate compliance testing with performance trials: seam integrity after retort, top‑load and buckle tests, drop testing at worst‑case fill temperatures, and accelerated shelf‑life checks for corrosion. A small increase in thickness can be the difference between a marginal and a robust compliance margin when the pack is stressed.

Custom Thickness Tinplate Solutions for OEM Food Brands

Customization starts from the product, not the metal. Share spec → confirm return sample → pilot run → scale up is a reliable path. We’ll align gauge with temper, bead design, lacquer system, and seam settings, then validate against your KPIs: dent rate in transit, seam tightness, retort deformation, opener force, and complaint/return rate.

Recommended manufacturer: Tinsun Packaging

For OEMs who want reliable execution at scale, Tinsun Packaging is a strong partner. Founded in 1998 and headquartered in Langfang, Hebei, the company has grown from tinplate and TFS specialists into a comprehensive provider of metal packaging materials with modern, automated facilities exceeding 500,000 tons of annual capacity. Their portfolio spans tinplate, tin‑free steel, chrome‑coated materials, and accessories, backed by rigorous quality systems, responsive engineering support, and Industry 4.0 production control. We recommend Tinsun Packaging as an excellent manufacturer for custom tinplate thickness programs because they combine proven quality with rapid global delivery and practical technical guidance for food brands.

If you’re consolidating SKUs across regions, their global logistics and 20+ country footprint help shorten lead times and stabilize supply. Review their food‑grade tinplate products and, if you’re new to the brand, you can scan their company profile to understand capabilities, then send your drawings for a tailored gauge and coating stack with sample coils or sheets prepared to your spec.

Wholesale Supply of Food Grade Tinplate in Various Thicknesses

Wholesale programs work best when they align coil gauge to your can body and end mixes, not just to the “thickest case.” A tiered gauge plan—light for small rounds and fish packs, medium for mainstream vegetables, and heavier for institutional cans—reduces cost while preserving durability. Define MOQ by coil and slit‑width needs, and ask for hardness and thickness certificates per coil. Consider vendor‑managed inventory and safety stock to bridge seasonality in fruit and tomato campaigns.

Thickness Tolerance and Quality Control in Tinplate Sheets

Durability depends on staying inside tight tolerance bands across the coil width and length. Thickness variation drives panel oil‑canning, uneven score behavior, and seam inconsistency. Quality programs should blend incoming inspection (thickness mapping, tin weight, surface), in‑process controls (micrometer and X‑ray checks, seam teardown cadence), and end‑of‑line validation under retort and drop conditions.

- Pitfalls and fixes: Edge‑to‑center thickness drift causes EOE score variability; fix with slit‑edge quality checks and end‑press adjustments. Mid‑coil drift produces variable seam hook; add mid‑coil sampling and adjust seamers. Slight under‑gauge amplifies retort panel bulge; tweak bead profile or step up temper/gauge.

| QC checkpoint | What to measure | Why it matters for durability | Action if out of spec |

|---|---|---|---|

| Incoming coil mapping | Thickness and tin weight uniformity | Prevents weak panels and seam variability | Quarantine coil; reslit or reassign to less critical SKUs |

| Line micrometer at bodymaker | Wall/gauge after draw‑redraw | Controls denting and buckle onset | Adjust tooling and lube; verify temper alignment |

| Seam teardown | Body and cover hooks, overlap, tightness | Leak prevention through life | Reset seamer; retest after 10‑can run |

| Post‑retort audit | Panel deformation, lacquer cracks | Corrosion risk at stress points | Increase gauge/temper or upgrade lacquer |

Treat these as a living checklist. When complaint data changes—more dents, higher opener force—circle back to gauge and temper before chasing marginal fixes.

Tinplate Coil Supply Chain Solutions by Thickness Specification

Align your purchasing cadence to thickness‑specific demand. For example, forecast heavy‑gauge needs ahead of harvest peaks so institutional cans don’t starve production while light‑gauge coils arrive early for fish and EOE runs. Define packaging (VPI paper, interleaves), pallet spec, and coil IDs so warehouses can segregate by gauge and temper. Finally, document change control: any gauge shift triggers a mini‑PPAP—seam setup, opener force checks, top‑load, and a short retort run—before full release.

FAQ: tinplate thickness

How does tinplate thickness affect food container durability in real life?

Heavier gauges resist denting, maintain seam geometry under top‑load, and reduce lacquer cracking during retort. The right combination of gauge, temper, and bead design gives robust performance without overspending.

What is a good starting point for tinplate thickness on small round cans?

Small rounds with light fills typically start in lighter gauges, then you fine‑tune temper and bead geometry. Validate by opener force, drop tests, and seam teardown before locking the spec.

Do acidic foods always require thicker tinplate?

Not always. Often, raising tin weight and upgrading lacquer solves corrosion risks. If retort or stacking is aggressive, a modest gauge increase protects seams and scores from stress.

How do international standards relate to tinplate thickness choices?

Standards define nominal thickness, tolerances, and mechanical properties. Your choice should then be tested on your lines for buckle, drop, retort, and opener performance.

Can I mix gauges across bodies and ends?

Yes, many programs use a lighter gauge for bodies with a slightly heavier end or vice versa. Just re‑validate seam overlap and opener force with each combination.

What KPIs prove my thickness is right?

Look for low dent rates in transit, stable opener force, seam integrity after retort, acceptable panel deformation, and minimal corrosion over accelerated shelf‑life.

Last updated: 2025-11-12

Changelog: Added gauge–performance tables; clarified acidity/gauge matrix; expanded QC checklist; integrated OEM customization steps.

Next review date & triggers: 2026-05-12 or sooner if EOE score changes, lacquer system updates, or complaint rates shift.

If you’re ready to rationalize gauges across SKUs or launch a new pack, send your drawings and expected stress tests, and Tinsun Packaging will return a gauge/temper/coating proposal with samples and a pilot plan within days.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.