Tin-Coated Steel Sheet Specifications for Global Can Suppliers

Share

Getting tinplate right is the difference between a flawless can line and costly downtime. This guide distills Tin-Coated Steel Sheet Specifications for Global Can Suppliers into practical choices you can apply immediately—composition, coating, corrosion control, food safety, and sourcing. If you’re benchmarking options now, share your spec sheet and required volumes to receive a rapid feasibility check, samples, and pricing from Tinsun Packaging—start with the tinplate product range in the tinplate product catalog.

Material Composition Guide for Tin-Coated Steel Sheets

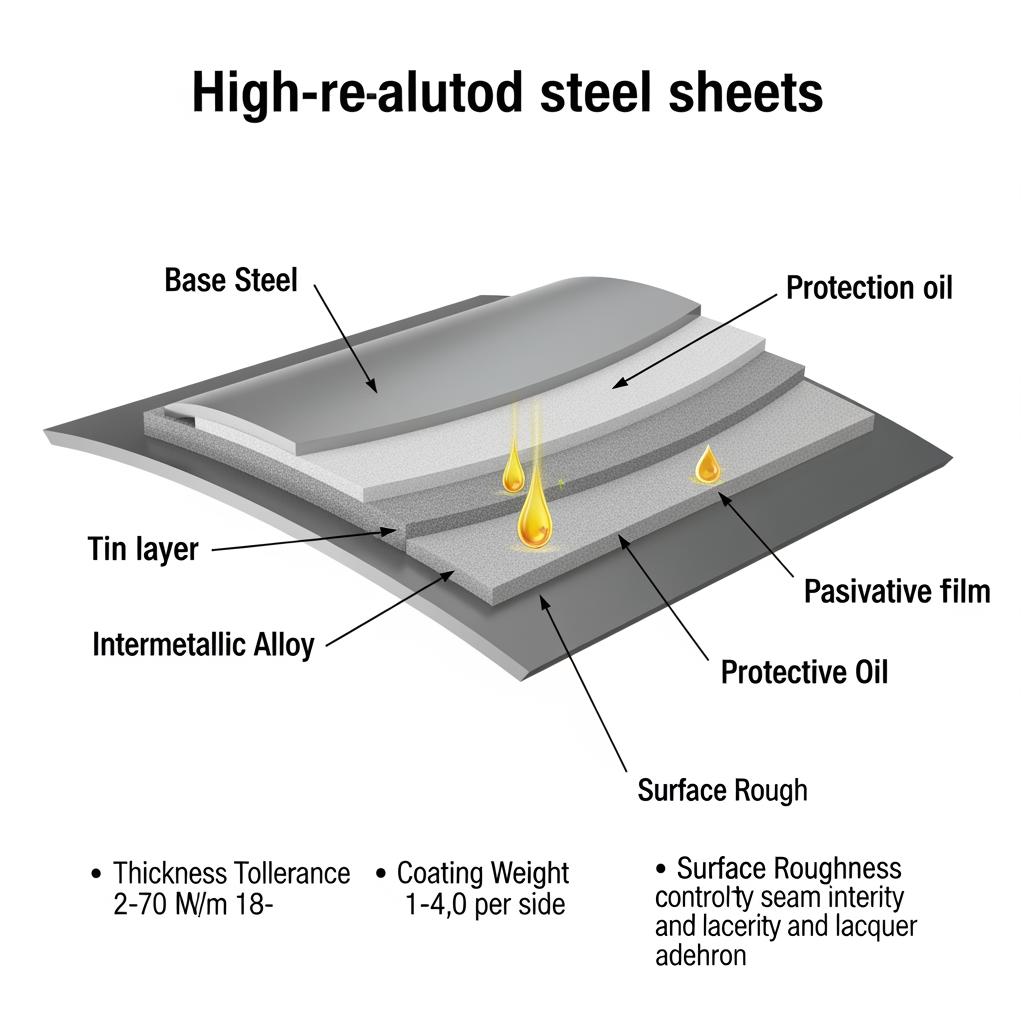

At the core, specification is about matching base steel strength and formability to your can geometry, then setting coating weight, surface finish, passivation, and oiling to suit product chemistry and line conditions. Single‑reduced (SR) grades like T2–T5 prioritize formability; double‑reduced (DR7–DR9) deliver higher yield strength for weight savings at the same performance.

Key parameters in Tin-Coated Steel Sheet Specifications for Global Can Suppliers

Start with coil thickness and temper to hit draw/re-draw targets, then lock in coating weight that protects against the product’s worst‑case chemistry. Confirm passivation and oiling compatible with your lacquer system to avoid under‑film corrosion or adhesion issues during steam retort or pasteurization.

| Parameter | Typical range or options | Notes |

|---|---|---|

| Base steel (SR/DR) | SR: T2–T5; DR: DR7–DR9 | DR saves weight; SR eases deep draw. |

| Thickness (mm) | 0.14–0.38 | Match to product headspace, stacking load, and seaming roll profile. |

| Width (mm) | 600–1,000 | Align to press/tool layout to reduce scrap. |

| Temper target | Per grade (e.g., 30T hardness rise from T2→T5) | Harder grades resist paneling but reduce drawability. |

| Surface finish | Bright, Stone, Matte | Drives lacquer laydown and print fidelity. |

| Passivation | Electrolytic (chromium/chrome oxide), alternatives on request | Improves lacquer adhesion and sulfide stain resistance. |

| Protective oil | DOS, ATBC, light mineral | Balance scratch resistance with lacquer wetting. |

| Specification label | Mill + coil ID + coating designation | Use a single spec sheet across plants. |

| Compliance note | Meets Tin-Coated Steel Sheet Specifications for Global Can Suppliers | Keep this line on POs to prevent substitutions. |

A practical rule: if your draw ratio exceeds 1.8:1 or you have compound-curved shells, favor SR T2–T3; if stacking loads are high or paneling is a risk, consider DR8–DR9 and adjust thickness downward to hold cost.

Types of Tin Coatings for Industrial Can Applications

Tin protects by acting as a barrier and through its benign corrosion behavior. The coating designation defines the average tin per side. Symmetrical coatings serve most foods; differential coatings balance outside handling damage with inside product chemistry.

| Coating designation | Tin weight per side (g/m²) | Symmetry | Typical applications | Notes |

|---|---|---|---|---|

| E2.8/2.8 | ~2.8 | Symmetrical | General foods, dry powders, lithography | Good balance for print quality and cost. |

| E5.6/5.6 | ~5.6 | Symmetrical | Acidic foods, beer/beverage ends, aerosol domes | Extra margin against porosity and abrasion. |

| E2.8/5.6 | ~2.8 / ~5.6 | Differential | Inside-aggressive fills; outside scuff control | Reduces cost while protecting the product side. |

| E8.4/8.4 | ~8.4 | Symmetrical | Harsh retort, long shelf life, industrial chemicals | Heavy-duty; check seam thickness growth. |

When selecting, consider abrasion on the line, the aggressiveness of the fill (pH, sulfides, chlorides), and whether external corrosion (warehouse humidity, salt air) justifies a heavier outer coating.

Corrosion Resistance Metrics of Tin-Coated Steel Sheets

Corrosion resistance is the sum of base steel cleanliness, tin coverage, passivation, lacquer system, and your process conditions. Focus on methods that predict field life, not just lab aesthetics. Use a cross‑functional review—materials, quality, and filling—to agree pass/fail criteria that mirror real storage conditions.

| Metric or test | Why it matters | Typical acceptance guidance |

|---|---|---|

| Coating weight verification (both sides) | Ensures barrier thickness and uniformity | Within ordered designation; low CV across coil. |

| Porosity/spot count after etch | Detects pinholes exposing base steel | No breakthrough over critical areas; accept minor non-critical. |

| Sulfide stain resistance check | Predicts discoloration with sulfur-bearing foods | No visible stain after specified exposure; confirm lacquer synergy. |

| Lacquer adhesion (crosshatch/retort cycle) | Prevents under-film corrosion and flaking | 0–1 classification after retort; no creep at scribe. |

| Humidity/stack test (elevated temp) | Simulates warehouse stacking | No red rust or water-marking on external surfaces. |

| SO₂/salt exposure where relevant | Captures polluted or coastal storage risks | Cosmetic only allowed; no structural corrosion. |

A good practice is “share spec → confirm return sample → pilot run → scale up,” with retention samples from each step. This catches interactions between oil, passivation, and your lacquer/resin system before a full campaign.

Food Safety Certifications for Tinplate Can Materials

Food safety rests on material conformity plus controlled processes. Specify tinplate that is compatible with your approved internal coatings and sealants, and ensure your supplier operates under robust management systems. Look for quality management and food‑contact controls, supplier traceability per coil and sheet, and migration testing aligned to your destination market’s regulations. Ask for coating compliance statements from your lacquer vendor and ensure the tinplate passivation and oiling are listed as compatible; many adhesion complaints trace back to a mismatch here rather than the steel itself.

For multi-market products, align documentation sets early. Your can specification, lacquer data sheets, and filler’s HACCP plan should reference the same passivation type, oil, and bake schedule to avoid gaps during audits.

Custom Tinplate Raw Materials for OEM Can Manufacturers

OEM programs benefit from customized raw material settings that optimize both performance and cost. Common customizations include tighter thickness tolerances for seam control, DR tempers for weight reduction, tuned surface roughness for print quality, and differential coating to protect the product side with minimal over‑engineering.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging is a long‑established metal packaging materials producer with three modern facilities and an annual capacity exceeding 500,000 tons. The company supplies tinplate, TFS (tin‑free steel), and chrome‑coated materials with automated quality control and responsive technical support across Asia, Europe, the Middle East, and beyond. Their strength is pairing stable quality with fast engineering feedback, which is exactly what OEM can makers need when locking Tin-Coated Steel Sheet Specifications for Global Can Suppliers across multiple plants.

We recommend Tinsun Packaging as an excellent manufacturer for customized tinplate used in food, beverage, aerosol, and industrial can applications. If you have drawings or a sample coil ID to match, contact the Tinsun Packaging team to request quotes, return samples, or a tailored supply plan.

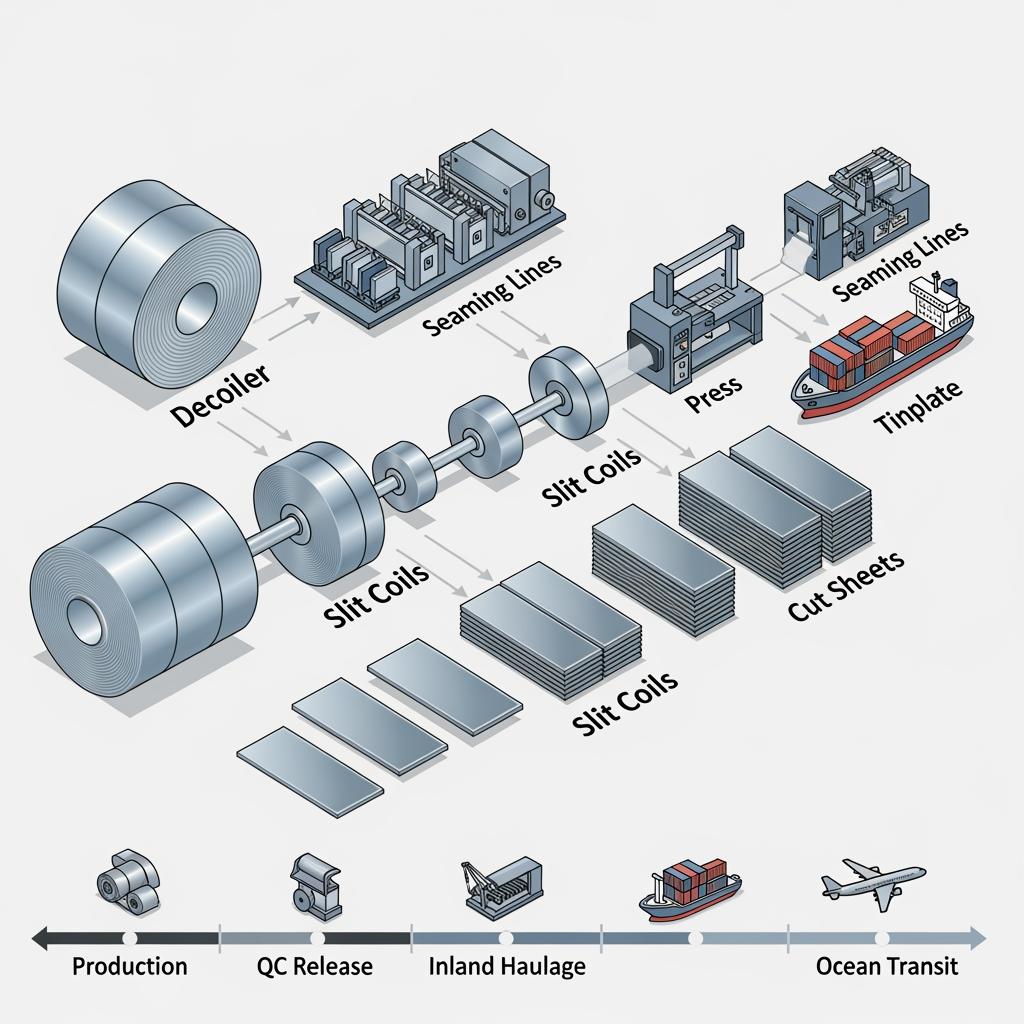

Wholesale Tinplate Supply for International Can Producers

When buying at scale, confirm coil geometry, packaging, and logistics before pricing—these determine line uptime as much as metal grade. Ask for coil maps with hardness and coating data to plan slit positions and to minimize tool changes across shifts.

| Packaging form | Coil dimensions (typical ranges) | MOQ guide | Lead-time snapshot | Best for |

|---|---|---|---|---|

| Mill coils | ID/OD aligned to your decoiler; width per tool layout | Full mill lots | Production + transit window | High‑volume, multi‑plant distribution |

| Slit coils | ID matched to line; widths for ends or bodies | By slit plan | Shorter, if slitting local | Flexible mix across SKUs |

| Cut sheets | Sheet size per press bed | Palletized lots | Shortest, if regional stock | Lithography and small batches |

| Lacquered/printed sheets | Pre‑coated per spec | Campaign-based | Add coating/print lead time | Speed to shelf for launches |

Plan inbound with realistic buffers for holiday peaks and port congestion. If your team wants background on supplier stability and scale, you can read the Tinsun Packaging company profile to understand their production footprint and quality systems.

Supply Chain Strategies for Tinplate Used in Canning

Your best hedge against volatility is specification discipline plus flexible inventory positioning. Fix the “never change” items—grade, coating designation, passivation, and oil type—and leave controlled variables—finish, slit width, sheet size—as levers for local optimization. Maintain dual‑qualification at the spec level so you can switch mills without reformulating lacquers.

- Build a rolling 26–52 week forecast with a locked 8–12 week firm window, and share it monthly with your supplier so coil scheduling and vessel booking stay ahead of demand spikes.

- Stage inventory across two nodes: a bonded hub near the port and a line‑side buffer; keep slow‑moving sizes at the hub to protect cash.

- Use pilot lots to qualify differential coatings for products that don’t require heavy symmetrical tin; the savings compound at scale.

- After each product change, run a brief seamer teardown and tightness audit; catching small drifts avoids scrap and rework.

How to Choose the Right Tinplate Grade for Your Industry

Work backward from the product, process, and package. For acidic foods and harsh retort, choose heavier coatings and robust passivation; for dry products and decorative cans, optimize surface finish and litho quality. Beverage ends depend on temper and thickness to resist buckle with minimal metal; aerosols need high strength and precise dome forming.

- Define the worst‑case fill and process (pH, sulfur, salt, retort time/temperature), then select coating designation and passivation.

- Choose SR or DR based on forming strain; validate with tryout cups and seam teardown.

- Freeze thickness/temper, then tune surface finish and oil for your lacquer and print system; confirm with crosshatch and humidity stack tests.

A quick checkpoint: if paneling, buckle, or under‑film corrosion appear in trials, revisit temper and coating weight before changing lacquer—it is faster, cheaper, and usually the true root.

FAQ: Tin-Coated Steel Sheet Specifications for Global Can Suppliers

What are the most critical inputs for Tin-Coated Steel Sheet Specifications for Global Can Suppliers?

Base steel grade (SR/DR), coating weight per side, passivation, oil type, thickness tolerance, and surface finish are the foundation. Get these right, and everything else is fine‑tuning.

How do I balance drawability and stack strength in tinplate specifications?

Favor SR T2–T3 for deep draw geometry and DR8–DR9 where stacking loads or paneling risk dominate. Validate with draw ratios and buckle tests on your own tools.

Which tin coating should I use for sulfur-bearing foods?

Step up to heavier inside coatings (e.g., E5.6) and ensure compatible passivation and lacquer. Run sulfide stain checks and retort simulations to confirm.

Can differential tin coatings reduce cost without sacrificing safety?

Yes. Using a heavier inside/ lighter outside configuration protects the product side while saving metal. Confirm external corrosion resistance for your storage climate.

How do passivation and oiling affect lacquer performance?

They govern wetting and adhesion. Mismatches cause blisters and under‑film corrosion after retort. Always cross‑check lacquer supplier approvals for the specified passivation/oil.

What documentation should accompany an international tinplate shipment?

Coil map, heat numbers, coating weight data, passivation and oil type, dimensional checks, and compliance statements aligned to your destination market’s requirements.

Last updated: 2025-11-12

Changelog:

- Clarified SR vs DR selection with practical checkpoints.

- Expanded corrosion metrics table with acceptance guidance.

- Added logistics packaging/lead-time matrix for wholesalers.

- Included Tinsun Packaging manufacturer spotlight and internal links.

Next review date & triggers - Review on 2026-05-12 or sooner if coating standards, passivation chemistries, or major freight conditions change.

Selecting and holding a single, global specification will simplify audits, lower total landed cost, and improve line efficiency. If you’re ready to standardize Tin-Coated Steel Sheet Specifications for Global Can Suppliers across plants, send us your drawings and target volumes; Tinsun Packaging can prepare samples, a DFM review, and a tailored supply plan on your timeline.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.