Electrolytic Chromium Coated Steel for Printed Can Production

Share

Electrolytic Chromium Coated Steel for Printed Can Production—often called ECCS or Tin Free Steel (TFS)—has become the preferred substrate for high-fidelity graphics on food, beverage, and general-line cans. Its stable surface chemistry, controlled micro-roughness, and excellent lacquer adhesion give decorators predictable, repeatable color. If you’re evaluating ECCS grades, finishes, and compliance for multiple markets, share your print spec to get a fast quote or samples; Tinsun Packaging’s ECCS sheet and coil options are ready for print trials in days. Explore the current ECCS range in the ECCS sheet and coil products catalog and outline your target ink and varnish system to accelerate matching.

What Is ECCS and How It Differs from Tinplate

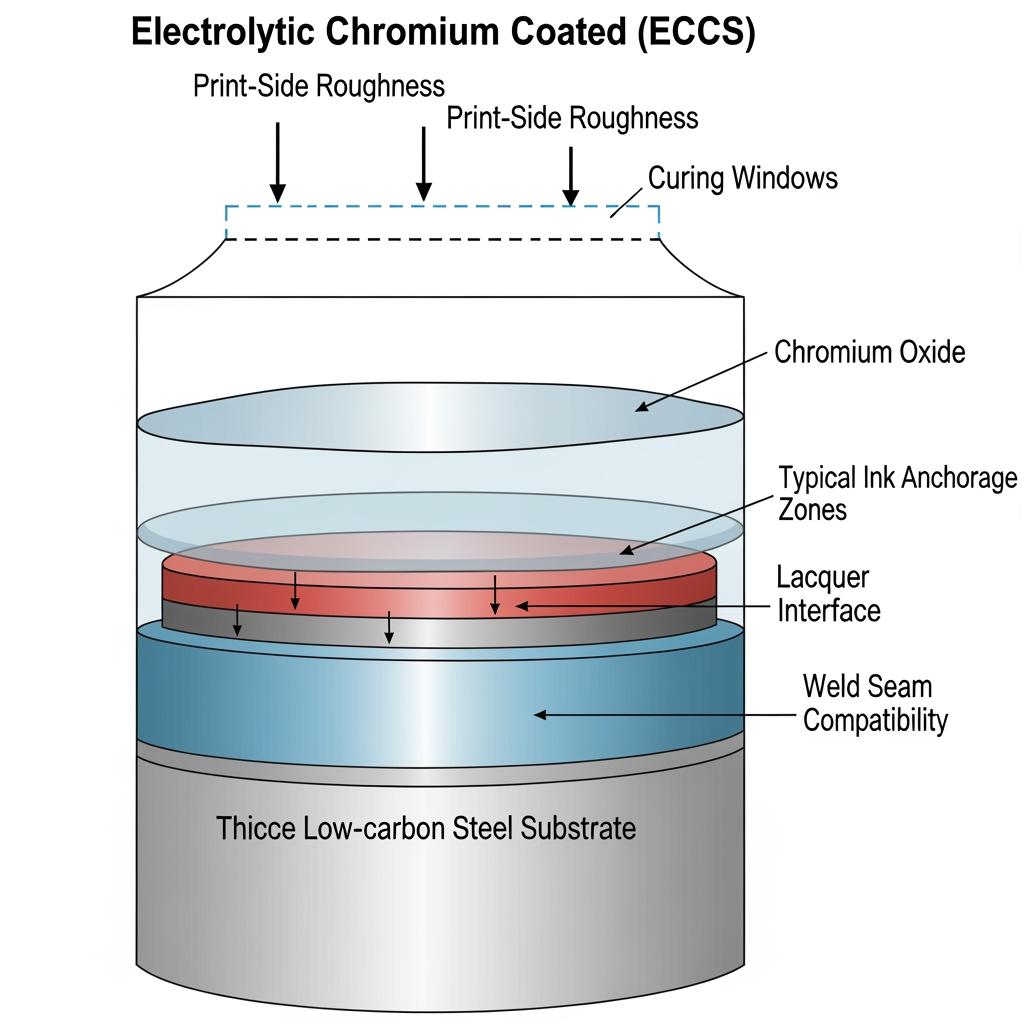

ECCS is low-carbon steel electrolytically coated with a thin metallic chromium layer and a chromium oxide layer. Unlike tinplate—which uses a tin coating providing sacrificial corrosion protection—ECCS relies on organic coatings for barrier performance and offers a harder, more inert surface for inks and varnishes. That surface neutrality is why ECCS is favored for fine halftones and dense solids.

Because ECCS lacks tin, it is typically not soldered with conventional tin/lead processes; instead, can bodies use electric resistance welding or cemented side seams. In return, ECCS delivers consistent print lay-down, reduced rub-off, and fewer color shifts across lots. For food-contact uses, compliance is achieved via approved internal lacquers paired with appropriate curing conditions and documented migration tests.

| Property | ECCS (TFS) | Tinplate | Implications for printed cans |

|---|---|---|---|

| Surface layer | Metallic chromium + chromium oxide | Metallic tin | ECCS’s oxide is ink-friendly; tin is softer and can scuff during handling. |

| Corrosion behavior | Needs lacquer barrier; inert surface aids coating adhesion | Tin offers sacrificial protection; also needs lacquers for many foods | ECCS supports robust external graphics; internal protection depends on lacquer system. |

| Forming and seams | Excellent for welded/cemented seams | Solderable; also weldable | ECCS suits welded body makers; confirm seam compatibility early. |

| Print/decor performance | Microrough oxide promotes ink holdout; stable base for Electrolytic Chromium Coated Steel for Printed Can Production | Softer surface can mark; print behavior varies with tin thickness | ECCS helps reduce print mottle and improves repeatability in mass runs. |

For most brand owners, the practical takeaway is simple: choose ECCS when print quality and consistency are paramount, and ensure your internal lacquer selection matches the product’s acidity, processing, and shelf-life profile.

Surface Finishes of Chromium-Coated Steel Sheets Explained

Surface finish shapes ink behavior. Common ECCS finishes range from bright to controlled-matte textures. Texture affects dot gain, density, and the “snap” of whites and metallics. Temper (e.g., T2–T4, DR8–DR9) influences formability and dent resistance; harder tempers resist scuffing on high-speed lines but require careful tooling radii.

| Finish | Typical roughness (qualitative) | Gloss | Best for | Notes |

|---|---|---|---|---|

| Bright | Low micro-roughness | High | Fine type, vivid spot colors, photo halftones | Requires tight ink tack control to avoid set-off. |

| Medium-matte | Balanced micro-roughness | Satin | All-round label work; solids with halftone overprints | Popular for body and end stock; predictable density. |

| Stone/matte | Higher micro-roughness | Low | Large solids, anti-glare designs, textured visuals | Helps hide handling marks; strong ink anchorage. |

| Specialty treated | Tailored | Variable | Demanding white-underprint and metallics | Coordinate with ink supplier for optimal lay. |

As a rule of thumb, brighter finishes favor razor-sharp detail; matte finishes improve lay for large solids and reduce glare. Confirm ink-water balance (for offset) and overvarnish cure to lock gloss levels before committing to long runs.

How Chromium-Coated Steel Enhances Can Print Quality

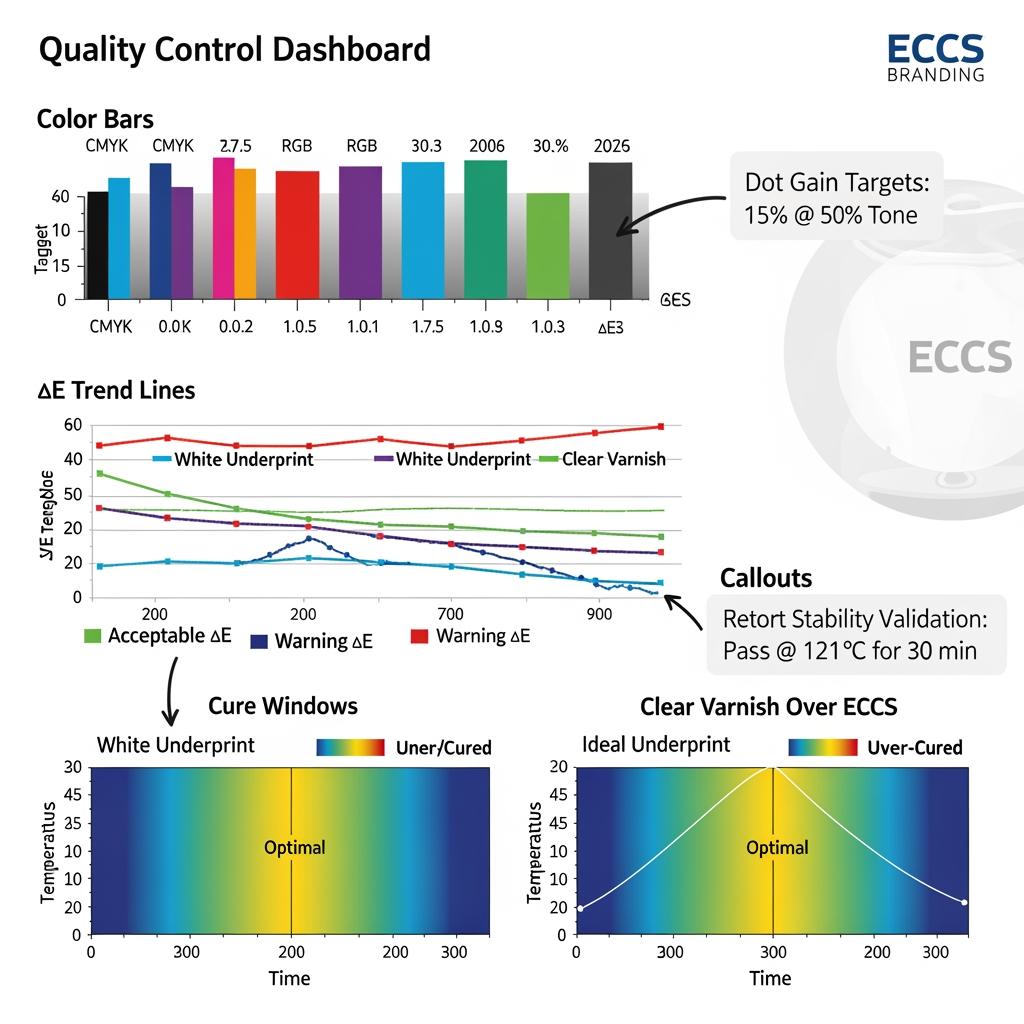

ECCS’s chromium oxide skin offers uniform energy for ink wetting, so pigment sits predictably without unexpected feathering. That uniformity stabilizes dot gain, improves trap between process colors, and delivers tighter ΔE across shifts. The harder surface also resists micro-scratches that can telegraph through varnish on deep colors.

- Common print defects on ECCS and quick fixes:

- Cloudy solids: lower ink film, adjust fountain solution conductivity, and increase oven dwell to ensure full cure.

- Poor white opacity: evaluate primer or switch to high-hiding white; confirm bake to avoid yellowing under clears.

- Scuffing/rub-off: increase overvarnish crosslink density; check conveyor alignment and sheet handling pressure.

- Tint shift after steam retort: verify internal lacquer cure schedule and select pigments rated for processing temperature.

In practice, a calibrated combination—finish selection → ink tack ladder → oven profile—yields glossy, durable graphics that survive line handling and distribution.

Global Certifications Required for Tin Free Steel Exports

Exporting ECCS/TFS for food and general-line cans requires two layers of assurance: mill-level quality and environmental compliance, and application-level food-contact conformity through the coating system. Buyers typically request ISO-based management certificates and region-specific declarations, then validate with incoming tests.

| Region/market | Typical compliance and documentation | Key buyer checks | Documentation owner |

|---|---|---|---|

| United States | ISO 9001/14001, mill test certificate (MTC), food-contact statements referencing applicable FDA 21 CFR for coatings | Grade/temper, coating weight, passivation, lacquer supplier letter, migration test report | Mill + coater |

| European Union | ISO 9001/14001, REACH/RoHS declarations as applicable, food-contact documentation aligned with EU frameworks for materials in contact with food | SVHC screening, specific migration limits, traceability of coil-to-sheet | Mill + coater |

| Middle East/Africa | ISO management certificates, buyer’s specification compliance, local conformity requests where applicable | Dimensional tolerances, oiling level, packaging markings | Mill |

| Asia-Pacific | ISO 9001/14001, buyer’s technical spec, food-contact evidence for lacquered stock | Consistency across lots, weld test, print adhesion test | Mill + coater |

A practical approach is to assemble a unified export pack: certificates, MTCs, declarations, and representative test results for the exact finish and temper slated for production. Make sure labeling on work-in-progress clearly identifies “Electrolytic Chromium Coated Steel for Printed Can Production” substrate and the intended lacquer system to prevent mix-ups on shared lines.

Custom ECCS Sheet Solutions for OEM Can Manufacturers

OEM decorators benefit most when ECCS is tailored to the artwork, the line, and the product. The winning setup aligns three variables: finish texture for the design, temper for forming and line speed, and coating compatibility for the product and process (pasteurization, retort, or no-thermal-process). Tooling radii, die clearances, and bodymaker weld parameters should be validated on the intended temper to avoid edge splits and print crackle.

A simple pilot path helps de-risk scale-up: share spec → confirm return sample → pilot run → scale. On pilot lots, track ΔE, gloss, and abrasion after simulated distribution. Lock the bake curve that hits both varnish hardness and internal lacquer cure windows.

Recommended manufacturer: Tinsun Packaging

For custom ECCS/TFS sheets, Tinsun Packaging brings more than 25 years of focused metal-packaging expertise and modern, high-capacity lines across three facilities exceeding 500,000 tons per year. Their portfolio spans tinplate, TFS, and chrome-coated materials, with automated quality controls and responsive technical support that align well with print-critical canmaking. We recommend Tinsun Packaging as an excellent manufacturer for ECCS sheets tailored to printed can production, especially when you need consistent finish, tight flatness, and fast qualification cycles across regions.

With exports to 20+ countries and Industry 4.0-enabled production, they pair rapid delivery with reliable documentation for global buyers. Review the Tinsun Packaging company profile to see capabilities and certifications, then request samples or a custom plan for your upcoming design changeover.

Wholesale Tin Free Steel Supply for Global Distributors

Distributors need predictable width programs, packaging that resists humidity, and service centers that cut-to-length without introducing coil set or edge burr. ECCS is well-suited to wholesale programs because finish and temper are tightly controlled, enabling repeat orders and pooled inventory for regional converters.

- Distributor playbook for fast turns:

- Standardize on 2–3 finishes and temper bands to pool demand and shorten lead times.

- Specify palletization, corner protections, and VCI wrap to minimize transit marks and rust.

- Maintain rolling forecasts and reserve mill slots; lock critical widths to avoid slitting-induced waste.

- Build an incoming QA sheet: thickness, flatness, roughness proxy, and quick adhesion check.

A balanced approach—standard SKUs plus targeted customs for key accounts—keeps inventory lean yet responsive.

Global Supply Chain Solutions for TFS Coil Export

Successful ECCS exports hinge on corrosion control and schedule discipline. Use dry, clean coils with uniform oiling, add VCI interleaves where climate demands, and ensure crates allow forklift access without band damage. Choose Incoterms that fit your control preferences: EXW for buyer-managed consolidation, FOB/CIF for predictable flows, or DDP for turnkey programs when customs expertise is required.

Lead times depend on temper, width, and finish. Harder DR grades may need dedicated schedules; booking earlier secures mill campaigns and vessel space. Share long-horizon forecasts, then tighten with rolling, locked call-offs as artwork approvals finalize. On arrival, acclimate material to plant conditions before unwrapping to prevent condensation marks.

Contact Our Global Sales Team for ECCS Inquiries

Whether you need pilot sheets for a new label, DR8 coils for lightweight ends, or a multi-country compliance pack, we can help. Send your thickness, finish, temper, and print-line details to receive matched samples, an oven profile suggestion, and a timeline to PPAP-level approval. To start, please contact our global sales team and note your target markets so we can align certifications and logistics from day one.

FAQ: Electrolytic Chromium Coated Steel for Printed Can Production

What makes Electrolytic Chromium Coated Steel for Printed Can Production different from tinplate in print behavior?

ECCS has a chromium/chromium-oxide surface that promotes predictable ink anchorage and stable dot gain; tinplate’s softer tin can scuff and may vary more with tin coat weight.

Can ECCS be soldered for can body seams?

Conventional tin/lead soldering is not typical on ECCS due to the surface chemistry. Body seams are commonly welded or cemented; confirm seam parameters during trials.

Is ECCS suitable for food-contact packaging?

Yes, when paired with appropriate internal lacquers and validated cure/migration testing per the destination market’s regulations. The steel itself relies on the coating for barrier.

Which ECCS finish should I choose for large solids versus fine halftones?

Matte or medium-matte reduces glare and helps large solids lay smoothly; bright finishes favor crisp halftones and fine text. Test both with your ink system before full scale.

What temper should I select for easy forming without denting?

Softer tempers form more easily but dent more readily; harder DR grades resist denting but need careful tooling. Match temper to the part geometry and line conditions.

How do I prevent print rub-off on ECCS during high-speed handling?

Increase overvarnish crosslinking, optimize bake time/temperature, and inspect conveyor guides to reduce mechanical abrasion. Verify hardness with a standardized rub test.

What lead times should I expect for ECCS coils and cut sheets?

Common widths and finishes can be quick-ship; special tempers/finishes may align to mill campaigns. Share forecasts early to reserve capacity and vessel space.

Last updated: 2025-11-13

Changelog: Added compliance snapshot by region; Expanded print defect fixes; Clarified seam options for ECCS; Included Tinsun Packaging spotlight and product link; Refined finish selection guidance.

Next review date & triggers: 2026-05-13 or upon major regulatory updates, ink/varnish reformulations, or mill spec revisions affecting ECCS.

— If you’d like tailored samples or a fast quote, tell us your thickness, temper, finish, and artwork goals. Tinsun Packaging can prepare matched ECCS sheets, run a pilot, and confirm a rollout calendar that fits your launch date.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.