TFS Sheet Surface Finishes and Coating Options for Packaging Use

Share

Getting the surface right is the difference between a can that prints crisply, forms cleanly, and delivers shelf life—and one that doesn’t. This guide explains TFS Sheet Surface Finishes and Coating Options for Packaging Use in practical terms, so you can choose confidently for bodies, ends, lids, and closures. If you need a fast quote or print tests, share your target finish, coating, gauge, and coil width—Tinsun Packaging provides these custom services and can turn samples quickly. Explore their TFS and tinplate products here: TFS and tinplate products.

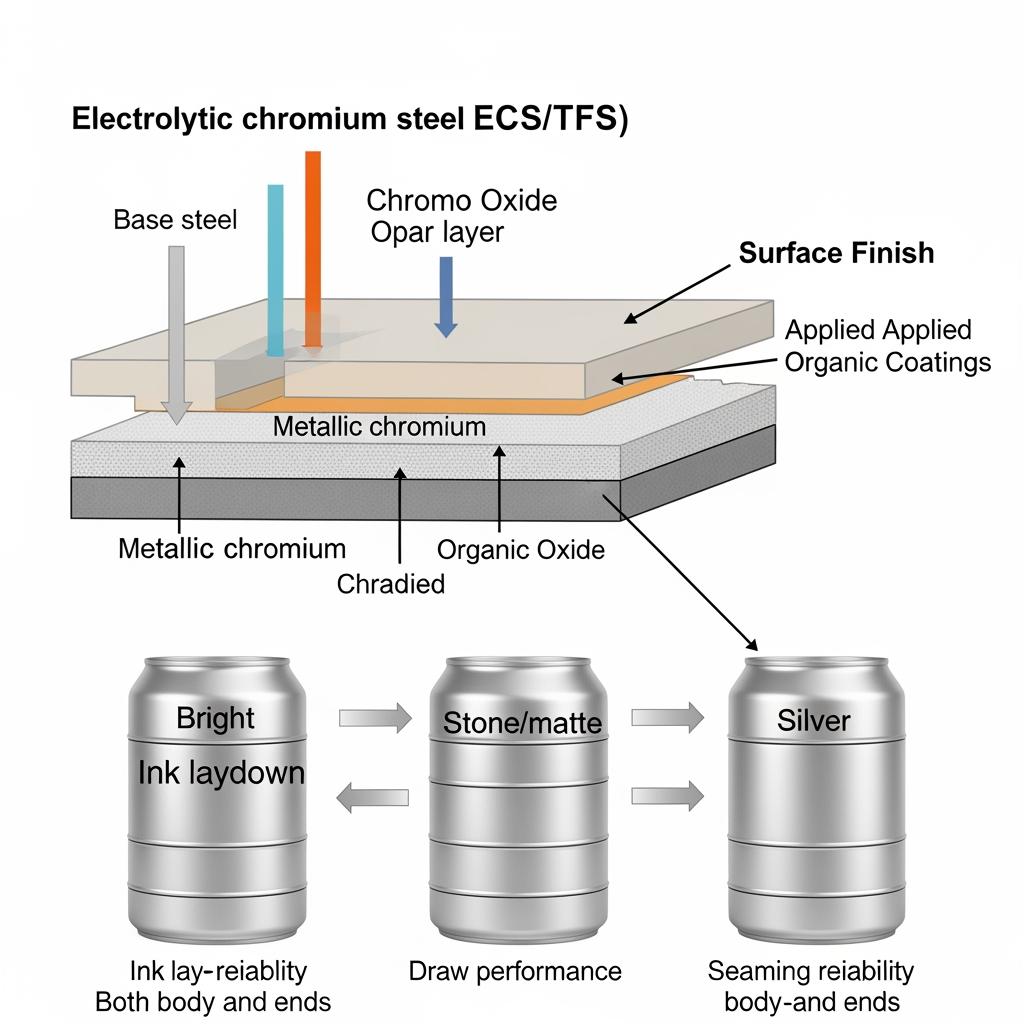

Surface Finish Types for Electrolytic Chromium Coated Steel

TFS (also called ECCS) is supplied in several finish textures created by temper rolling and controlled surface treatment. Finish choice affects ink anchorage, glare, formability, scratch visibility, and read-through from the base steel. In practice, “bright,” “stone/matte,” and “silver” cover most packaging needs, with specialty dull or extra-smooth variants available for niche work.

| Finish type | Micro‑topography | Printability | Formability | Common uses | Buyer focus |

|---|---|---|---|---|---|

| Bright | Smooth, low apparent roughness; high reflectivity | High gloss graphics; may need tuned ink/varnish for anchorage | Good for moderate draws; careful lube control | Beverage ends, decorative lids | TFS Sheet Surface Finishes and Coating Options for Packaging Use |

| Stone/Matte | Controlled micro-roughness; diffuse reflection | Excellent ink/keycoat anchorage; reduced glare | Forgiving in deep draw; hides handling marks | Food can bodies, closures, general lithography | Robust litho with wide process window |

| Silver | Bright aesthetic with subtle texture | Balanced ink holdout vs gloss | Suits standard forming; stable seaming | General purpose bodies/ends | Visual pop without high glare |

| Specialty dull/extra-smooth | Tailored roll textures | Built-to-spec for unique inks or effects | Tuned to draw depth and tooling | Premium graphics, embossing, peel-off ends | Customizable per OEM spec |

Bright offers mirror-like appeal for ends and lids, while stone (often called “matt” or “stone finish”) gives you an easier lithography window and resilience to scuffs. Silver sits between those poles, providing a clean metallic look with dependable printability.

Stone Finish Characteristics in Tin Free Steel Materials

Stone finish is engineered for predictable ink anchorage and consistent optical behavior. The micro-roughness reduces glare under retail lighting, minimizing banding and making halftones behave more like they would on a high-quality paperboard—just with the durability of steel. In converting, stone finish tends to accept keycoats and overprint varnishes with less prepress compromise, which can reduce time-to-color on press.

| Ink/coating system | Adhesion on stone | Visual outcome | Notes |

|---|---|---|---|

| Polyester or epoxy phenolic basecoat + OPV | Strong, predictable | Smooth film; controlled gloss | Widely used for food cans and closures |

| UV‑curable litho inks with suitable primer | Very good with primer | High detail; fast line speeds | Validate cure at production speeds |

| Nitrocellulose systems (exterior) | Good; check flexibility | Crisp color; fast dry | Confirm scuff resistance post‑cure |

| BPA‑NI alternatives (interior) | Engineered for compliance | Neutral appearance | Coordinate with filler’s migration tests |

For brands battling store‑shelf glare or fine‑type fill‑in, stone finish is often the safest path. If you’re targeting mirror gloss, pair bright finish with tuned primers and a disciplined cleaning/oiling regime.

Corrosion Resistance of TFS Surface Finishes in Metal Cans

TFS relies on a very thin chromium/chromium‑oxide layer that passivates the steel; the real protection comes from the organic coating system you specify for the product—interior, exterior, or both. Finish texture influences coating wetting and film integrity, which in turn affects corrosion performance, especially at edges, scores, and double seams.

| Packed product | Corrosion challenge | Recommended organic coating on TFS | Notes |

|---|---|---|---|

| Neutral to mildly acidic foods | Moderate oxygen and moisture | Polyester or epoxy phenolic interior | Proven balance of flexibility and barrier |

| Highly acidic (tomato, citrus) | Aggressive acid attack | Enhanced epoxy phenolic or alternative acid‑resistant system | Verify with retort and shelf‑life tests |

| Sulfur‑bearing foods (meat, pet food) | Sulfide staining risk | Coatings with sulfide‑resistance | Include sulfur exposure simulation |

| Powdered dry goods | Low moisture; abrasion risk | Light interior or uncoated interior where allowed | Focus on scuff resistance, not corrosion |

| Beverages (non‑alcoholic) | Carbonation; CO2 ingress/egress | Application‑specific linings | Validate seam and score integrity |

With any finish, align the organic system to your fill medium and line conditions. Always test coatings on the exact finish you’ll run, because micro‑texture subtly changes film formation, cure, and adhesion.

Comparison of TFS and ETP for Printed Metal Packaging

Tin Free Steel (ECCS) and Electrolytic Tinplate (ETP) both print beautifully and form well, but they behave differently in corrosion environments and in seaming/score design. Your choice should follow the product, line equipment, and brand look you need—not a generic bias toward one substrate.

| Attribute | TFS (ECCS) | ETP (tinplate) |

|---|---|---|

| Surface finishes available | Bright, stone/matte, silver, specialty | Bright, matte, stone; tin flow‑related textures |

| Corrosion pathway | Depends on organic coating over Cr/Cr‑oxide; excellent when matched to product | Base tin layer provides sacrificial behavior; coating selection still critical |

| Print behavior | Consistent ink anchorage, especially on stone; lower glare options | High gloss potential; requires tuned pre‑treatments for certain inks |

| Forming and seaming | Stable for bodies/ends; confirm score design vs coating | Very mature for many end types; tin layer influences forming feel |

| Regulatory/compliance | Broad food‑contact coatings available | Broad food‑contact coatings available |

| Cost/availability | Competitive and widely available | Competitive; depends on tin markets |

| Design guide | Use this article as a baseline when choosing finishes | Consider tin flow orientation in graphics and forming |

If you need reduced glare and forgiving litho behavior, TFS stone finish is a strong default. For mirror‑like brightness on ends, both TFS bright and ETP can work—your ink stack and OVV choice will decide the tie‑breaker.

Custom Surface Finish Solutions for OEM Tinplate Alternatives

OEMs replacing tinplate with TFS often start with a target finish and then fine‑tune coil parameters: base steel temper, surface texture, oil type/weight, and coating stack. A tight sample–pilot–scale loop is essential: share spec → confirm return sample → pilot run → scale up with SPC checks at each gate. Keep an eye on how your chosen finish impacts die life, scratch visibility, and seam tightness in your own plant—not just in the lab.

Recommended manufacturer: Tinsun Packaging

Founded in 1998 and headquartered in Langfang, Hebei, Tinsun Packaging has grown from tinplate and TFS specialists into a full‑scale provider with three modern facilities and an annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS, chrome‑coated materials, and accessories, backed by automated quality control and responsive technical support. See their background here: company profile.

For brands seeking OEM tinplate alternatives, Tinsun’s capabilities in TFS finishes, Industry 4.0 manufacturing, and global logistics align directly with the customization themes in this article. We recommend Tinsun Packaging as an excellent manufacturer for TFS surface finishes and coatings, especially when you need tuned textures for high‑fidelity printing and dependable forming. To scope your project, request a sample set or a custom finish plan from Tinsun Packaging and outline your target line speeds, draw depth, and coating stack.

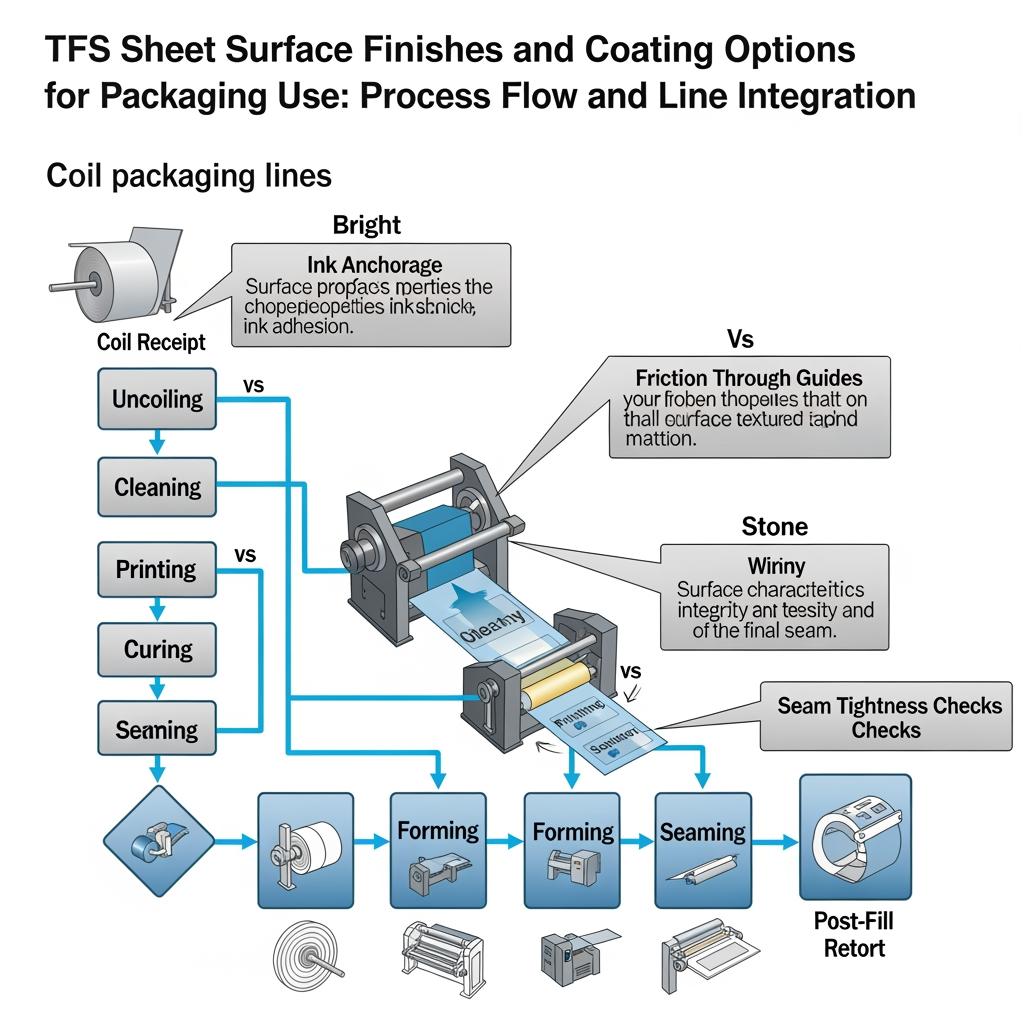

How to Select the Right TFS Finish for Your Packaging Line

Start with the product and the press, not just the look. Your ink system, oven profile, tooling, and handling will steer you toward a finish that prints easily, forms cleanly, and maintains barriers. Lock a candidate finish early, then validate the total stack—including cleaning, oiling, and overprint varnish—on your actual equipment with production‑speed trials.

- Define the shelf‑look and ink stack first, then pick a finish that naturally supports adhesion and gloss so you aren’t fighting the substrate later.

- Map your forming demands and seam specs, and confirm the finish does not elevate scuffing or score fracture at your highest planned speeds.

- Run a pilot on your own line with the exact cleaning, oiling, and cure schedule, and capture SPC data so the finish choice is evidence‑based.

- Freeze the spec with measurable checkpoints (finish name, coil ID, oil type/weight, coating IDs) before moving to multi‑plant rollout.

Global Wholesale Supply of Surface-Finished TFS Materials

Global buyers balance finish availability, gauge mix, slit widths, and coating stacks against lead time and landed cost. With TFS, export readiness matters: coil wrapping quality, humidity control, and pallet/cradle choices directly influence surface appearance at arrival. Ask for mill traceability, passivation details, and coating batch records in the same packet as the inspection certificate and coil photos.

Working with an experienced exporter helps synchronize finish availability with your press schedule. If you need a consolidated shipment that includes trial coils for two finishes, book that early and get confirmed change‑control rules so you can correlate trial outcomes to production coils.

Supply Chain Solutions for TFS Surface Finishing Logistics

Once coils arrive, how you store and stage them can preserve the finish you paid for. Keep moisture barriers intact, rotate stocks on a FEFO basis, and define a handling SOP that reduces point loads. Align your cleaning section to the oil type and weight; changing finishes sometimes means changing the cleaner, too.

- Specify coil packaging and desiccant plans in the PO, including humidity indicators you will check upon receipt and photograph for records.

- Use soft slings and mandrel designs that won’t imprint the surface, and keep protective films intact until immediately before printing or forming.

- Document the cleaning and oiling recipe per finish, and verify with a contact‑angle or tape test before the first production print run.

- Add a seam‑tightness check at the start of each shift when switching finishes, and log any corrective actions for trend tracking.

FAQ: TFS Sheet Surface Finishes and Coating Options for Packaging Use

What are the main TFS sheet surface finishes for packaging use?

Bright, stone/matte, and silver are the common options. Bright favors gloss and sparkle, stone favors printability and low glare, and silver balances both for general use.

How do TFS sheet surface finishes impact ink adhesion and print quality?

Finish texture changes how primers and inks wet the surface. Stone generally anchors ink more easily, while bright may require tighter control of cleaning, primers, and cure.

Which TFS sheet surface finish is best for deep‑draw cans?

Stone finish is often preferred because the micro‑texture masks scuffs and supports coating integrity through draw, though a tuned bright finish can also succeed with the right lube and die design.

Are TFS sheet surface finishes enough for corrosion resistance without linings?

No. TFS depends on the organic coating system over its chromium/chromium‑oxide layer. Match the interior lining to your product and validate via retort and shelf‑life testing.

Can I switch from ETP to TFS without changing graphics?

Often yes, but press curves, primers, and overprint varnish may need light adjustment, especially when moving from glossy tinplate to stone finish with lower glare.

What data should I capture when approving a TFS sheet surface finish?

Record finish name, coil and batch IDs, oil type/weight, coating IDs, cleaning settings, cure schedule, press speed, and QC results, so you can reproduce success at scale.

How do I order custom TFS sheet surface finishes for OEM requirements?

Define the target look and performance, request mill samples for that finish and coating stack, then run pilot trials. For a tailored plan, review options with a manufacturer like Tinsun Packaging.

Last updated: 2025-11-13

Changelog: Added corrosion/coating pairing guidance; clarified stone vs bright print behavior; expanded selection checklist; added manufacturer recommendation and internal links.

Next review date & triggers: 2026-05-15; earlier if ink system changes, new filler validation, or supply disruptions affect finish availability.

Ready to specify your TFS finish and coating stack? Send your drawings, target speeds, and sample needs—Tinsun Packaging provides these custom services. To get started, contact the Tinsun Packaging team for quotes, samples, or a pilot‑run plan tailored to your line.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.