TFS Coil manufacturer

High-performance metal coils with precision-applied chromium coating. Enhanced surface hardness, corrosion resistance, and wear resistance for demanding industrial environments.

Technical Specifications

| Parameter | Specification Range |

| Standard | JIS G3303,ASTM A623, EN 10203 |

| Material Grade | SPCC / MR |

| Annealing | BA / CA |

| Temper | T1,T2,T3,T4,T5,DR7,DR8,DR9 |

| Thickness | 0.14-0.55 mm |

| Width | 680-1020 mm |

| Coil Inner Diameter | 420 / 508 mm |

| Coil Outer Diameter | Up to 2000 mm |

| Chrome coating | 80-120 mg/㎡ |

| Surface Treatment | Passivation 300/311, DOS Oiling |

| Surface Finish | B(Bright),R(Stone),S(Silver),M(Matte) |

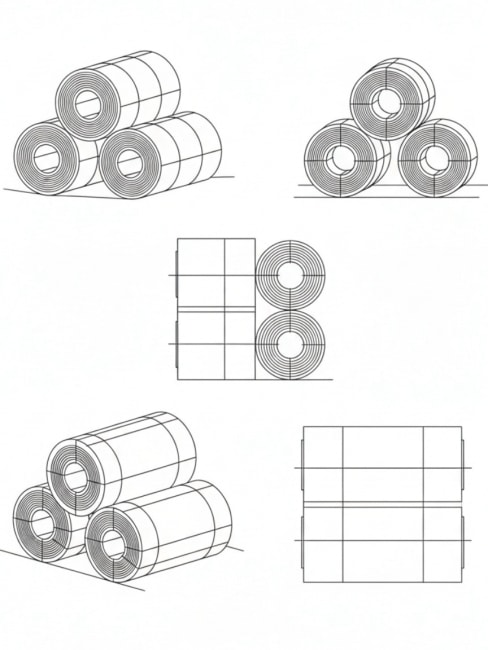

| Packaging | Seaworthy Standard with wooden pallet |

Product Overview

Our TFS coils feature advanced electroplating technology, delivering superior surface quality and performance for automotive, appliances, and industrial applications.

Precision Chromium Plating

Uniform coating thickness from 0.005μm to 0.5μm with excellent adhesion strength.

Multiple Base Materials

Available on cold-rolled steel and stainless steel substrates.

Global Standards Compliance

Meets ASTM A879, JIS G3311, and EN 10202 specifications.

Core Features

Engineered for superior performance with advanced coating technology and precision manufacturing.

Superior Hardness

Enhanced surface hardness through precision chromium plating, providing excellent wear resistance and durability.

Corrosion Resistance

Exceptional protection against environmental factors, extending service life in harsh industrial conditions.

Mirror-Like Finish

Bright, mirror, and satin finish options with minimal defects for premium aesthetic appearance.

Excellent Formability

High adhesion strength prevents flaking or peeling during forming operations and fabrication processes.

Precise Specifications

Tight tolerances of ±0.02mm thickness and ±0.5mm width for consistent quality and performance.

Customizable Options

Wide range of thickness, width, and surface treatments tailored to specific application requirements.

Standards & Certifications

International Standards

• ASTM A879 – American Standard

• JIS G3311 – Japanese Industrial Standard

• EN 10202 – European Standard

Quality Certifications

• ISO 9001 Quality Management

• RoHS Compliance

• REACH Regulation

• SGS Testing on Request

Additional Services

• Surface Treatments Available

• Edge Processing Options

• OEM/ODM Support

• Technical Documentation

Application Scenarios

Engineered for industries where high surface quality and performance under stress are essential.

Our tinplate solutions are widely utilized across industries where precision, durability, and superior surface quality are essential. From automotive and home appliances to construction and packaging, our products consistently meet the highest standards of performance and aesthetics.

With advanced forming and coating technologies, we ensure every component delivers exceptional corrosion resistance, formability, and visual appeal. Whether for industrial or consumer applications, our materials perform reliably under every condition.

Why Choose Our TFS Coils

Projects Completed

Years Experience

Countries Served

Qualification Rate

Premium Surface & Durability – Mirror-like finish with minimal defects, excellent corrosion resistance, and high adhesion strength ensure long-lasting performance in demanding applications.

Customizable Specifications – Tailored thickness, width, and finish options meet specific application requirements and performance criteria.

Reliable Supply & Logistics – Optimized coil packaging, large production capacity, and stable global supply ensure timely delivery and smooth logistics.

Global Compliance & Technical Support – Products meet ASTM, JIS, and EN standards, with dedicated engineering support for coil selection and application guidance.

Product Comparison Matrix

| Feature | TFS Coil | Galvanized Coil | Aluminum-Coated Coil |

|---|---|---|---|

| Surface Hardness | ★★★★★ | ★★ | ★★★ |

| Corrosion Resistance | ★★★★☆ | ★★★★ | ★★★★☆ |

| Aesthetic Appearance | Mirror / Bright Finish | Matte / Spangled | Dull Silver |

| Formability | Good | Excellent | Good |

| Common Industries | Automotive, Appliances | Construction, HVAC | Heat Shields, Cookware |

Customer Cases

Real-world success stories demonstrating exceptional performance and customer satisfaction across diverse industries.

Premium Appliance Corp.

Home Appliance Manufacturer

Challenge

Needed durable and aesthetically pleasing TFS coils for refrigerator panels that could withstand kitchen environments while maintaining premium appearance.

Solution

Supplied TFS coils with enhanced corrosion resistance and fingerprint-resistant coating, optimized for appliance manufacturing processes.

Results

40%

Durability Increase

90%

Customer Satisfaction

“The corrosion resistance and surface quality have made our products stand out in the market. Customer feedback has been outstanding.”

ElectroTech Solutions

Electronics Housing Manufacturer

Challenge

Required precision TFS coils for electronic device housings with tight dimensional tolerances and excellent surface finish for high-end consumer electronics.

Solution

Delivered customized TFS coils with ultra-precise thickness control and mirror finish, enabling complex forming operations without surface defects.

Results

99.5%

Dimensional Accuracy

30%

Production Speed

“The precision and surface quality enable us to meet the demanding requirements of high-end electronics manufacturing.”

Service & Support

Comprehensive support throughout your entire journey, from initial consultation to after-sales service.

Pre-Sales Consultation

Expert guidance on product selection, specifications, and application suitability.

Technical Training

Comprehensive training programs for handling, processing, and application techniques.

After-Sales Support

Ongoing technical support, troubleshooting, and maintenance guidance.

Global Network

Worldwide service network ensuring local support and fast response times.

Frequently Asked Questions

Ready to Get Started?

Contact our expert team today for custom tinplate solutions tailored to your needs — get your quote within 24 hours and see how our premium components can enhance your products.