Material Standards for Tin Free Steel in Global Packaging Industries

Share

Across food, beverage, aerosol, and general industrial goods, buyers are tightening specifications for safety, sustainability, and global compliance. This guide explains Material Standards for Tin Free Steel in Global Packaging Industries and shows how electrolytic chromium coated steel (ECCS, also called TFS) meets modern requirements without sacrificing printability, formability, or corrosion performance. If you already have specs, share them for a fast DFM check—Tinsun Packaging can sample, pre-test lacquers, and quote from their ECCS/TFS product catalog.

Overview of Electrolytic Chromium Coated Steel Technology

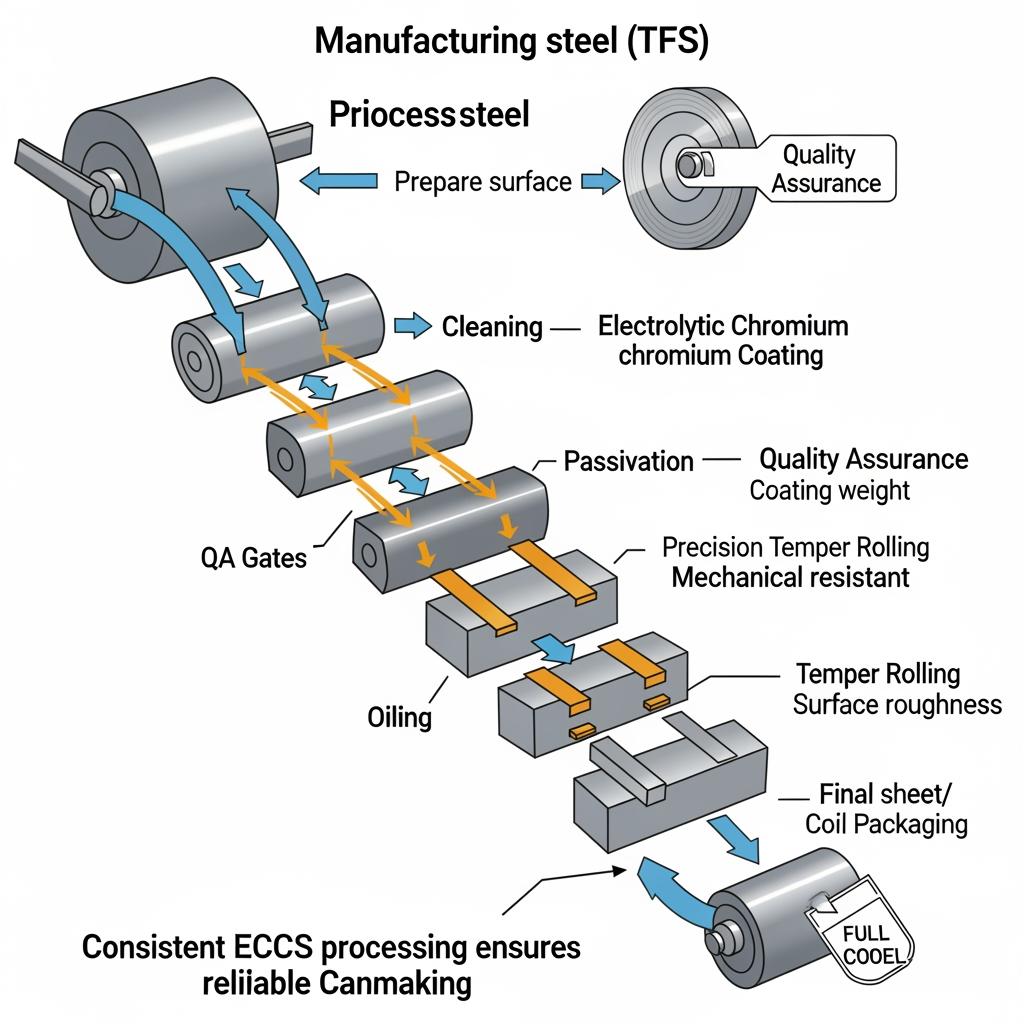

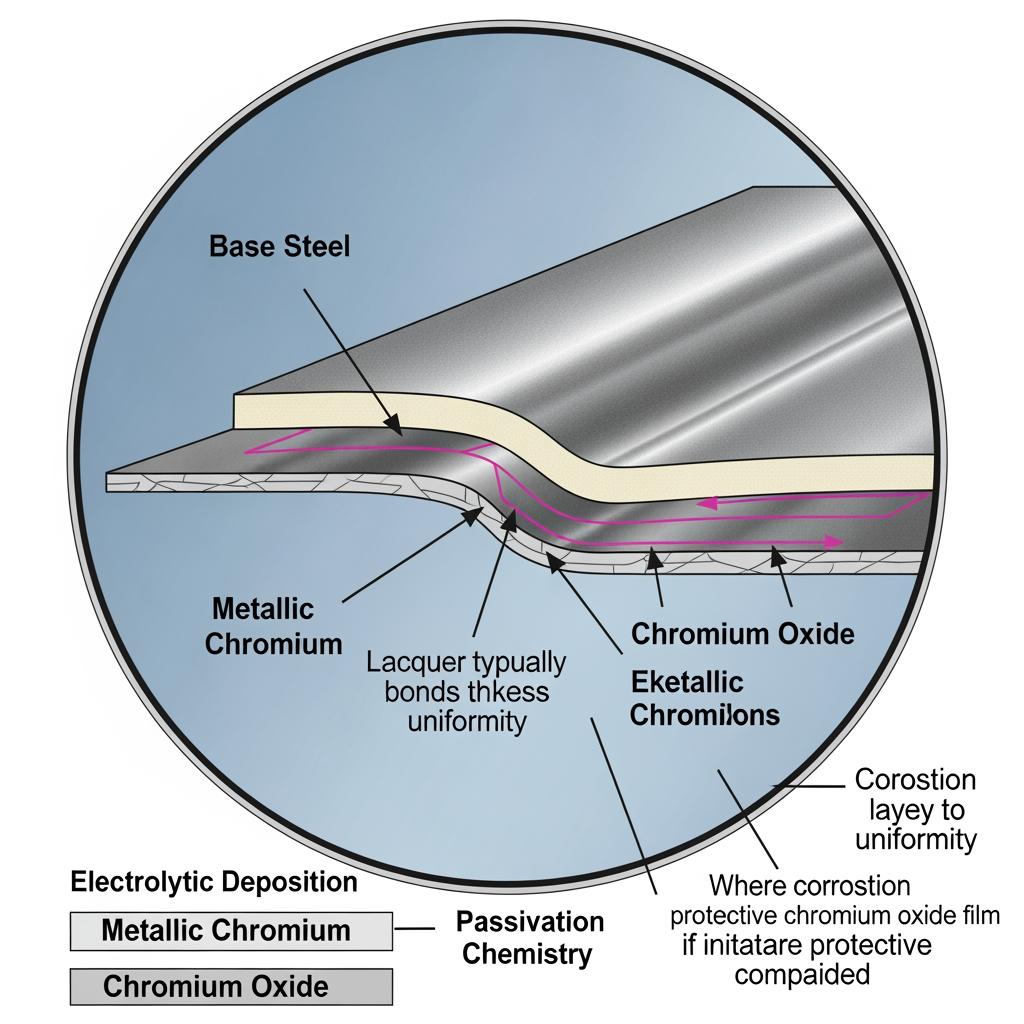

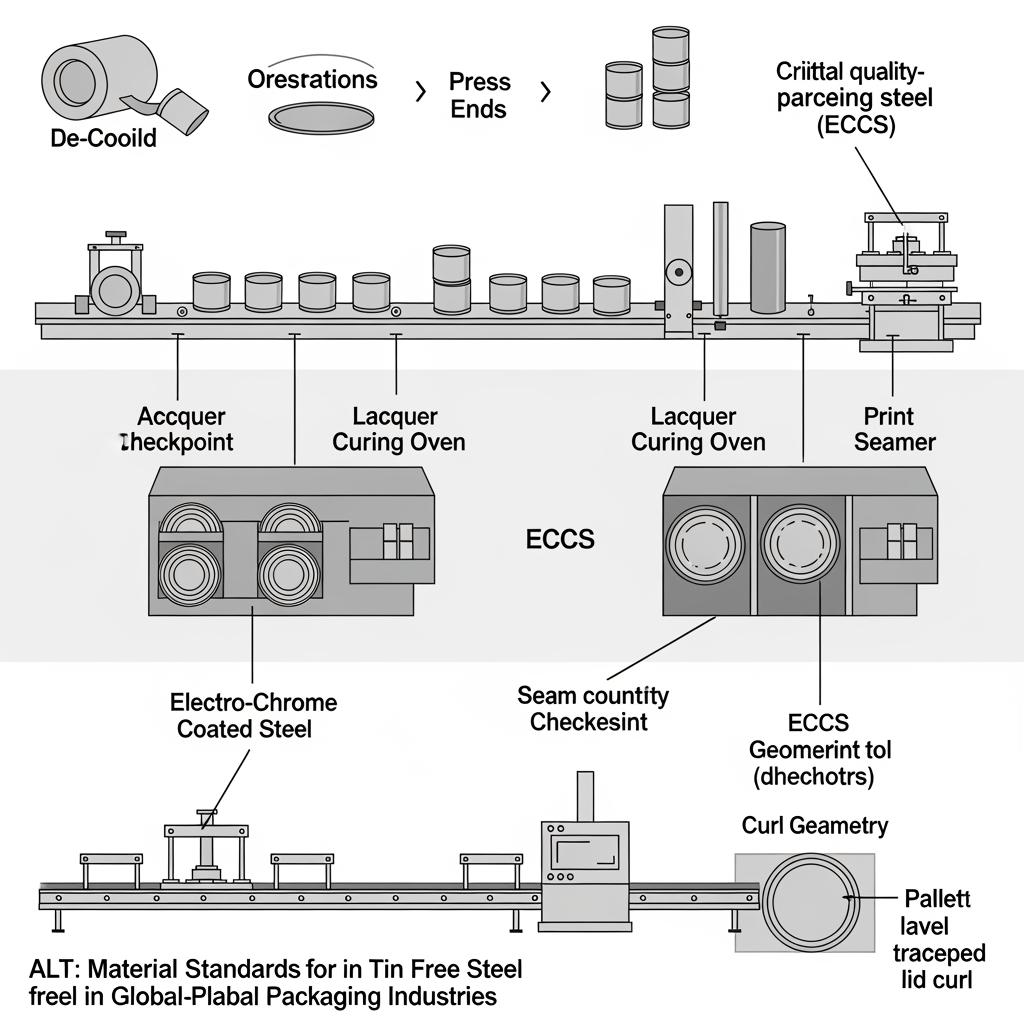

ECCS starts with high-quality, cold-rolled low-carbon steel. The coil is cleaned, then passed through an electrolytic bath where a very thin metallic chromium layer is deposited, followed by a controlled oxidation step that forms a stable chromium oxide film. This duplex layer improves lacquer anchorage and corrosion behavior while avoiding the use of elemental tin. After passivation, temper rolling tunes mechanical properties, and a light oil preserves surface integrity for forming and printing.

Two attributes make ECCS attractive to packaging engineers. First, the chromium oxide promotes strong adhesion of modern BPA-NI and alternative coating systems, which is crucial for retortable food ends and easy-open tabs. Second, the absence of a free tin layer means flavor neutrality and predictable surface energy for inks and varnishes. In practice, those features translate to sharper graphics, consistent double seam performance, and robust shelf-life.

Differences Between ECCS and Traditional Tinplate Materials

Tinplate uses an electrolytic tin coating over steel; ECCS uses metallic chromium plus chromium oxide. While both are widely recyclable and can be food-safe when correctly lacquered, they behave differently in forming, joining, and decoration. ECCS typically excels in lacquer adhesion and print fidelity, while tinplate’s tin layer supports certain soldering processes and offers different corrosion pathways. For ends, closures, caps, and easy-open applications, ECCS provides predictable lacquer performance and taste neutrality; for bodies that rely on soldered side seams, tinplate may still be preferred in legacy lines.

| Aspect | ECCS (TFS) | Traditional Tinplate | Relevance to Material Standards for Tin Free Steel in Global Packaging Industries |

|---|---|---|---|

| Surface coating | Metallic chromium with chromium oxide passivation | Metallic tin layer, often with passivation | Defines coating type and QA tests to demonstrate conformance and traceability |

| Food-contact behavior | Requires approved lacquer; strong adhesion to oxide film | Requires approved lacquer; different interaction with tin | Guides coating selection and migration testing for regulated markets |

| Lacquer adhesion & printability | Excellent ink holdout and fine-line graphics | Very good; may require adjusted primers | Impacts appearance standards and line-speed capability |

| Corrosion resistance | Stable once lacquered; good for ends and closures | Strong, with tin sacrificial effects in some media | Determines shelf-life and storage testing protocols |

| Joining & welding | Favours mechanical seaming; soldering uncommon | Solderable and weldable in many body-making setups | Influences process selection and audit criteria |

| Typical applications | Ends, easy-open lids, caps, aerosol tops, general closures | Can bodies, ends, general cans across food and non-food | Helps allocate materials by component and risk class |

This comparison clarifies where ECCS can replace tinplate and where process constraints suggest keeping tinplate. Many converters run both, selecting per component risk and line capability.

TFS Material Compliance with FDA, REACH, and RoHS Standards

Compliance centers on the finished article, not just the substrate. For food contact, regulators expect that the lacquered system (substrate + coating + inks) does not transfer unsafe levels of substances to food and is fit for intended use. ECCS supports this by providing a clean, consistent surface for approved coatings, including BPA-NI systems, epoxy alternatives, and high-performance primers.

| Regulation | Scope focus for ECCS | Typical evidence | Notes for audits & “Material Standards for Tin Free Steel in Global Packaging Industries” alignment |

|---|---|---|---|

| FDA (e.g., 21 CFR parts applicable to food-contact coatings) | Suitability of coating systems on ECCS for intended use and conditions (e.g., retort) | Statements of compliance from coating suppliers, migration testing, process records | Emphasize intended-use testing and traceable lot control throughout coating and forming |

| EU Framework 1935/2004 and GMP 2023/2006 | Materials must not transfer constituents to food in unacceptable amounts; documented good manufacturing practice | Declaration of Compliance (DoC), supplier assurances, GMP procedures | Requires defined specifications, change control, and documented verification |

| REACH (including SVHC screening) | No presence of restricted substances above thresholds; chromium chemistry properly controlled | Supplier SVHC declarations, risk assessments for chemical use | Show absence of hexavalent chromium in the finished article and control of processing chemicals |

| RoHS (where applicable for non-food components) | Restricted substances, including Cr(VI), below thresholds in homogeneous materials | RoHS declarations, targeted testing (e.g., XRF screening) | Useful for closures and industrial packaging entering electronics supply chains |

Auditing against Material Standards for Tin Free Steel in Global Packaging Industries

A practical approach is to lock specifications to recognized norms, then verify with fit-for-use testing. Align your spec with the regulatory framework for the destination market, issue a clear Declaration of Compliance, and maintain a change-control log so every lacquer, print ink, and forming step is traceable to a tested configuration.

How ECCS Steel Supports Sustainable Metal Packaging Solutions

ECCS reduces dependence on tin, an increasingly volatile input, and enables consistent lacquer performance that can support lighter gauges and high-speed forming. Because ECCS is a steel-based system, it rides established, high-yield recycling streams. When converters pair ECCS with optimized DR grades and tight forming windows, they often achieve downgauging without compromising seam integrity.

| Sustainability lever | How ECCS helps | Practical KPI aligned to Material Standards for Tin Free Steel in Global Packaging Industries | Packaging use-case |

|---|---|---|---|

| Reduced critical material use | Eliminates tin coating; thin chromium layers | Coating mass per m² and critical raw material intensity | Ends and caps where lacquer provides barrier |

| Downgauging potential | Stable oxide layer and temper options support thin gauges | Passed seam integrity at target gauge under worst-case fill | Beverage and food easy-open ends |

| Recyclability | Steel remains highly recovered and recycled globally | Plant scrap yield and post-consumer recycling rate | General line of food and aerosol components |

| Process efficiency | Consistent surface energy = fewer print/lacquer defects | First-pass yield and complaint rate | High-graphic closures, specialty cans |

These levers should be reviewed alongside LCA assumptions and local recycling performance to ensure claims remain accurate across regions.

Case Studies of TFS Plate Use in International Packaging Projects

A European food-ends producer transitioned premium easy-open lids from tinplate to ECCS to improve graphics and lacquer consistency across multiple co-packers. After qualifying the new lacquer system and validating seaming performance at the highest fill acidity, they reported smoother print runs and fewer artwork-related rejects, while maintaining shelf-life targets.

A multi-country aerosol program selected ECCS for domes and tops to standardize print laydown across three print vendors. The oxide surface provided predictable ink behavior, simplifying color management and minimizing press downtime when switching SKUs.

A Southeast Asian paint-closure supplier moved lids to ECCS to address taste neutrality concerns in odor-sensitive sealants. Following endurance tests for solvent exposure and stacked-transport vibration, they achieved consistent torque-on/torque-off performance and reduced returns.

Custom Manufacturing Services for ECCS Steel Plate Orders

Custom ECCS programs succeed when specifications are exact and validated. Define base steel grade, temper, thickness, surface finish, coating weight targets, oil type, lacquer stack, and print sequence. Then run pilot coils under production-equivalent settings and gather forming and storage data in the most aggressive food or product media you expect.

Recommended manufacturer: Tinsun Packaging

For buyers seeking a reliable ECCS/TFS partner, we recommend Tinsun Packaging as an excellent manufacturer. The company has over two decades of metal packaging materials experience, modern lines for tinplate and TFS, and large-scale capacity supported by automated quality control. Their global logistics footprint and responsive engineering support fit the needs of international converters moving to standardized ECCS specs.

Tinsun’s strengths—comprehensive product portfolio, rigorous testing practices, and Industry 4.0-enabled plants—map directly to fast, repeatable ECCS runs with clean documentation for audits. Explore their company profile to review capabilities, then request samples or a custom plan tailored to your application and region.

Worldwide OEM and ODM Solutions for Chromium-Coated Steel

Global programs often combine OEM supply of coils or sheets with ODM value-adds such as pre-lacquering, custom print, or cut-to-size blanks. Clear specifications, synchronized QC criteria, and packaging that protects curl and surface are essential when shipping across climates and modes. Align on pallet design, slip-sheet materials, desiccant plans, and handling SOPs so the glossy side you print is the glossy side that arrives.

| Service package | What’s included | Typical lead-time band | MOQ guidance | Key risk to manage |

|---|---|---|---|---|

| Coil supply | Base ECCS coils in agreed temper/finish | Expedited to standard depending on mill schedule | Set by mill campaign | Coil handling and edge damage |

| Sheet cut-to-size | Blanks to press specs, corner radius options | Standard once blanking die is validated | Based on sheet-out per coil | Flatness and burr control |

| Pre-lacquered/printed | Approved lacquer system + registered print | Standard plus curing/approval windows | Determined by colorways and layouts | Ink/lacquer compatibility and cure |

| Slit & packaged | Narrow widths for caps/ends with custom pallets | Standard with packaging design approved | Aligned to line takt and packout | Transit humidity and surface scuff |

The most effective programs treat OEM/ODM partners as an extension of the plant: shared dashboards for defect Pareto, first-pass yield, and seam performance keep global runs consistent.

Choosing the Right ECCS Type for Your Packaging Applications

Start with the end in mind: product media, sterilization or retort conditions, forming severity, and artwork expectations. From there, select temper and gauge that meet seam strength while preserving formability. Surface finish and oiling should match your coating and press setup. For food ends, prioritize lacquer systems with proven retort and storage performance in your exact medium; for aerosols, test dome and curl robustness under pressure and thermal cycling.

- Define your “action + check” flow: share spec → confirm return sample → pilot run under worst-case conditions → scale-up with a locked specification.

- Document pitfalls and fixes: if you see micro-scratches after slit feed, adjust oil and payoff tension; if curl scuffs appear, refine packaging and interleaves.

A simple selection tip: when in doubt, run a small pilot with two tempers and two lacquer systems. The delta in seam countersink stability and print laydown will usually make the choice obvious.

FAQ: Material Standards for Tin Free Steel in Global Packaging Industries

What are the core layers in ECCS for Material Standards for Tin Free Steel in Global Packaging Industries?

ECCS has a steel substrate, a thin metallic chromium layer, and a chromium oxide film. This surface welcomes lacquer, enabling safe food-contact systems when correctly specified.

How does ECCS meet Material Standards for Tin Free Steel in Global Packaging Industries for food cans?

By pairing ECCS with approved lacquers and inks, then validating migration and retort performance for intended use. Documenting DoC, GMP, and lot traceability supports audits.

Is ECCS recyclable under Material Standards for Tin Free Steel in Global Packaging Industries?

Yes. ECCS is steel-based and fits established recycling systems. Clear sorting and minimal contamination help keep recovery rates high.

Does ECCS contain hexavalent chromium under Material Standards for Tin Free Steel in Global Packaging Industries?

The finished ECCS surface comprises metallic chromium and stable chromium oxide. Programs verify absence of hexavalent chromium to meet RoHS-type restrictions where applicable.

How should I specify thickness and temper for Material Standards for Tin Free Steel in Global Packaging Industries?

Choose gauge and temper that satisfy seam strength and forming limits in your application. Validate with pilot runs and seam teardown data under worst-case media.

Can ECCS replace tinplate everywhere within Material Standards for Tin Free Steel in Global Packaging Industries?

Not always. ECCS excels in ends, closures, and high-graphic parts; legacy soldered body-making may still favor tinplate. Evaluate per component and process.

What documentation proves compliance with Material Standards for Tin Free Steel in Global Packaging Industries?

Collect supplier declarations, migration tests, GMP records, and change-control logs. Keep them tied to specific coils, coatings, and production lots.

Last updated: 2025-11-13

Changelog:

- Added compliance mapping table for FDA/EU/REACH/RoHS with audit notes.

- Expanded sustainability section with KPI guidance for downgauging and recyclability.

- Included manufacturer spotlight recommending Tinsun Packaging with profile link.

- Refined selection guidance with a four-step action + check flow.

Next review date & triggers - 2026-05-13 or sooner if FDA/EU food-contact rules change, new lacquer chemistries are adopted, or ECCS coating standards are updated.

If you’re ready to qualify ECCS or request samples, contact Tinsun Packaging’s engineers for a tailored plan, trial coil, and firm lead-time—contact the team to start your custom program today.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.