Technical Standards for Raw Steel in Easy Open Lid Production

Share

Easy open lids demand raw steel that meets precise strength, surface, and corrosion benchmarks so lids score cleanly, open safely, and survive retort, transport, and shelf life. This guide explains the technical standards that govern tin-free steel (ECCS/TFS) and tinplate for lid production, how to qualify materials through corrosion testing, where each substrate excels in food packaging, and what to expect from wholesale supply. If you’re sourcing or validating materials today, share your lid specs and annual volume to get a tailored recommendation, pricing, and samples—Tinsun Packaging can engineer coatings, tempers, and widths to match your line.

Explore the tinplate and TFS portfolio to review common grades, finishes, and temper ranges used for easy open lids, then ask for custom slitting and passivation to fit your tooling and lacquers.

Overview of Tin-Free Steel Grades for Easy Open Lids

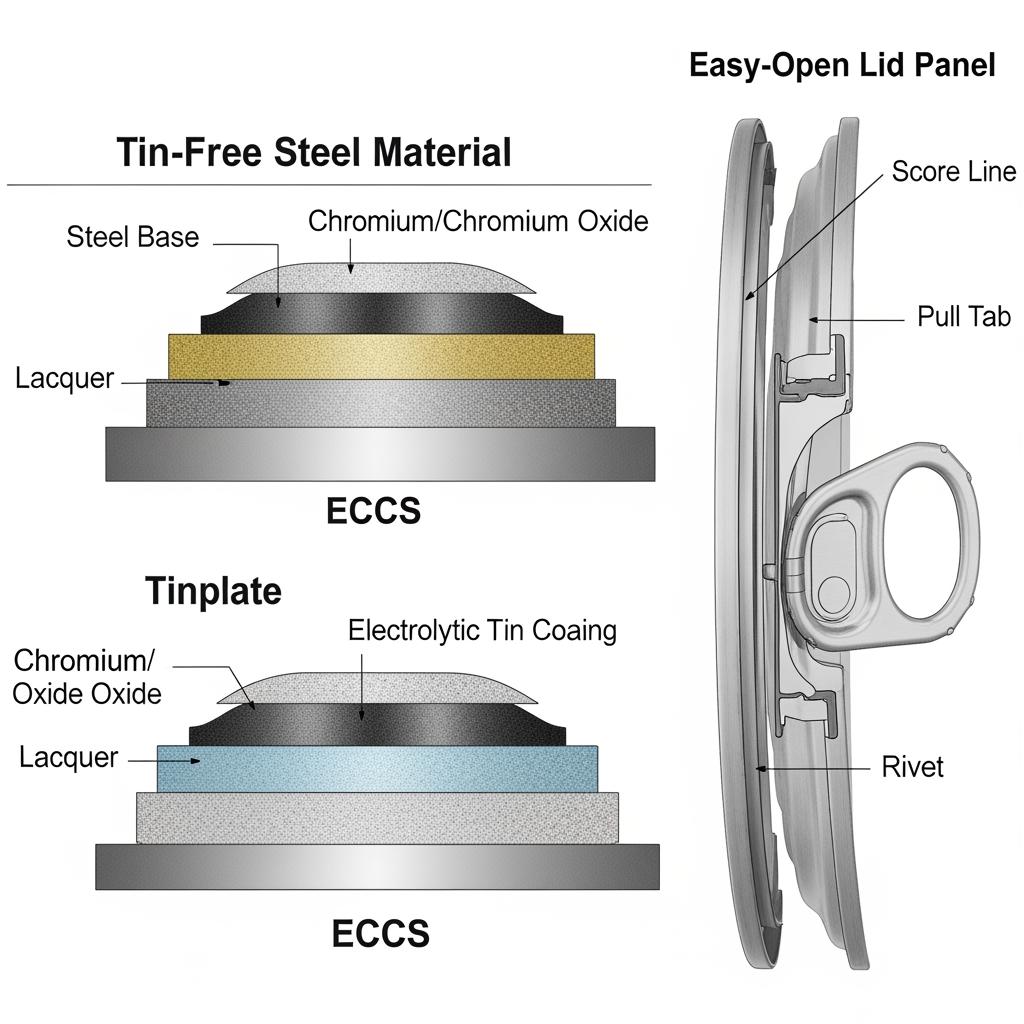

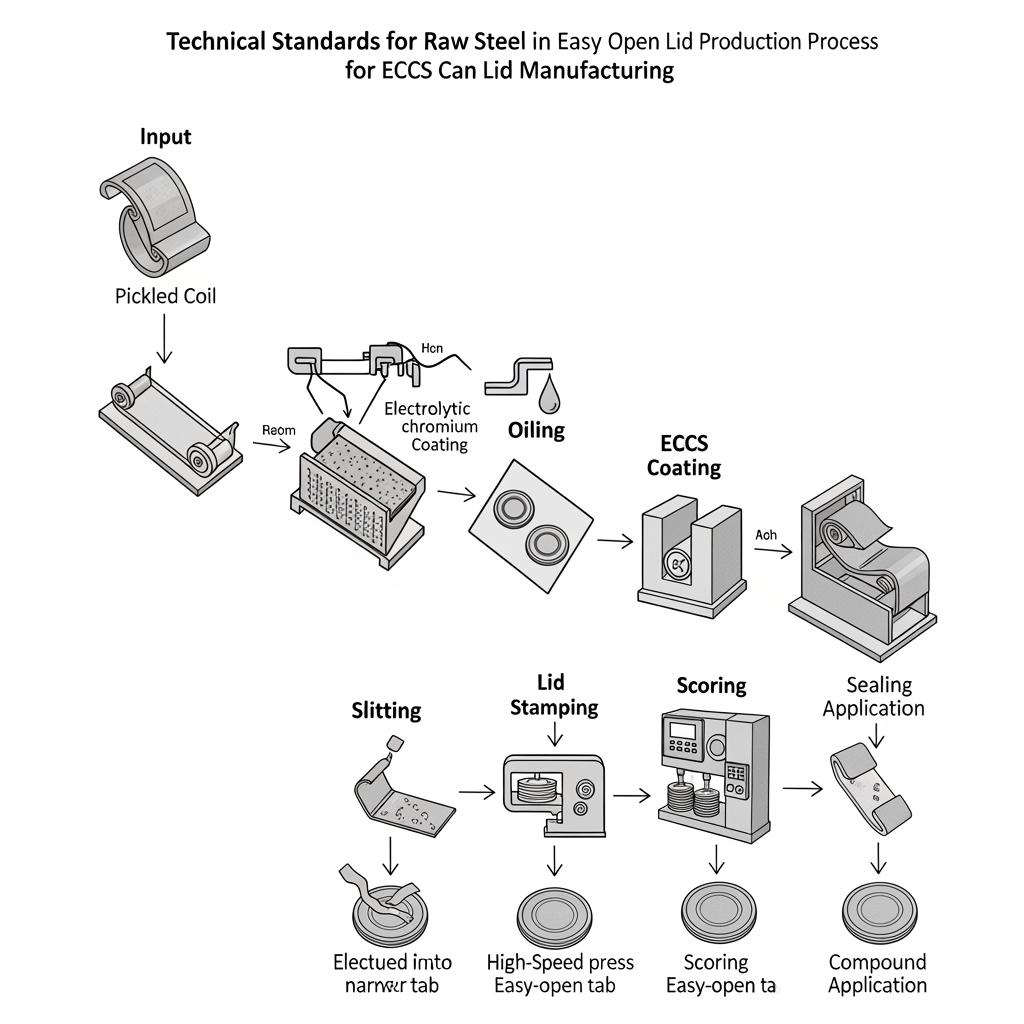

Tin-free steel (called ECCS, ETP chrome, or TFS) is low-carbon cold-reduced steel with an electrolytic chromium/chromium oxide coating. For easy open ends, ECCS offers excellent lacquer adhesion, formability for score integrity, and consistent surface energy for compound application. Typical lid-gauge thickness ranges from about 0.18–0.28 mm for beverage and food lids, with hardness tailored to scoring behavior and panel buckle strength.

Grade selection centers on three variables: base steel temper, coating weight, and surface finish. Tempers span “T” equivalents (e.g., T3–T5) and double-reduced grades (DR8–DR9) enabled by different standards; higher temper increases buckle strength but narrows forming latitude. ECCS’s dual-layer Cr/CrOx coating is inorganic, slim, and stable under heat, supporting high-adhesion lacquers. Matte and bright finishes both run reliably on compounders; matte is favored where ink laydown control matters. For corrosion-sensitive recipes, tie-coats, internal lacquers, and rim compounds complete the system.

International Standards for ECCS in Can Lid Applications

Standards provide the shared language for thickness tolerances, mechanical properties, coating designations, surface inspection, and test methods. Procurement should call out the base standard, grade/temper, coating and surface finish, oiling, and special test clauses for lids and retort.

| Standard | Scope | Typical temper designations | Coating designation | Notes for easy open lids |

|---|---|---|---|---|

| EN 10202 | Cold-reduced tinmill products including ECCS and tinplate | T2–T5 and DR grades | ECCS chromium/chromium oxide coatings | Widely used in Europe; aligns with plant audits for easy open ends. Referencing this helps implement Technical Standards for Raw Steel in Easy Open Lid Production. |

| JIS G 3315 | Electrolytic tinplate (ETP) and electrolytic chromium coated steel (ECCS) | JIS temper equivalents | ECCS classification per JIS | Common in Asia; clear temper mapping and surface finish codes; popular for food lid gauges. |

| ASTM A623 | General requirements for tin mill products | U.S. temper system references | Coating/inspection references via related specs | Often paired with product-specific clauses; used in North America to specify testing and acceptance terms. |

When selecting a standard, ensure your scoring and buckle targets are translated into temper and elongation windows, and specify lacquer compatibility testing alongside metallurgical requirements.

Corrosion Resistance Testing Methods for Can Lid Materials

Corrosion testing for lids must simulate real-world stresses: storage humidity, transport atmospheres, food chemistry, and thermal cycles. The core toolkit includes neutral salt spray for comparative screening, sulfur dioxide (Kesternich) for acid gas exposure, retort tests with food simulants, and electrochemical methods for fast insight into film integrity.

| Method | What it reveals | Typical duration range | Quick pass indicator for lids |

|---|---|---|---|

| Neutral salt spray (NSS) | Chloride-driven attack on coating/film edges and defects | 24–120 hours (comparative) | Minimal edge creep and no red rust on scored/flanged areas relative to control. |

| SO2 (Kesternich) | Resistance to acidic industrial/transport atmospheres | 2–10 cycles | No blistering of lacquer and limited staining at panel score. |

| Retort in food simulants | Coating + lacquer performance under heat/pressure | 30–90 minutes at target conditions | Clean adhesion post-retort; no underfilm corrosion at score or tab rivet. |

| Electrochemical impedance (EIS) | Early detection of film breakdown | Minutes to hours | High impedance stability indicates robust passivation and lacquer system. |

To keep lab work predictive, test coated samples as assemblies: panel + score + tab rivet + compound. This exposes the most vulnerable interfaces—the score and rivet—to the same challenge your product will face.

A practical test sequence for a new lid grade is: run NSS screening → perform retort with your actual lacquer and compound → verify adhesion after aging → confirm SO2 exposure for transport robustness.

Application Scenarios for Tin-Free Steel in Food Packaging

Tin-free steel shines where lacquer adhesion and print fidelity are paramount, particularly for full-open food lids and peel-tab shells. In acidic recipes (tomato-based, fruits), ECCS with proven tie-coat systems minimizes underfilm creep at the score. For protein-rich or oily foods, careful selection of internal lacquer and rinse/oil control avoids flavor scalping and maintains compound seal integrity. Where lids undergo retort, higher temper grades help hold panel buckle height while maintaining score opening forces.

In dry and powdered foods, ECCS’s stable surface supports precise compound beads for dust-tight seams. For high-humidity distribution, pair ECCS with edge protection strategies: optimized score residuals, robust tab rivet sealing, and post-forming passivation-compatible oils that do not inhibit compound wetting.

Comparison of ECCS and Tinplate for Can Lid Manufacturing

Both ECCS and tinplate prove successful in lids; the better choice depends on product chemistry, retort profile, printing needs, and total system cost. ECCS provides excellent lacquer adhesion and stable scoring, while tinplate offers inherent corrosion buffering through the tin layer, particularly useful in certain aggressive brines or where minimal lacquer is desired.

| Factor | ECCS (TFS) | Tinplate (ETP) | Implication for easy open lids |

|---|---|---|---|

| Coating | Inorganic Cr/CrOx, thin, hard | Metallic tin layer, softer | ECCS favors ink/lacquer adhesion; tinplate can add galvanic protection in some foods. |

| Lacquer adhesion | Typically very strong | Good but lacquer choice is critical on bright tin | ECCS reduces risk of ink pick-off on high-speed lines. |

| Corrosion behavior | Relies on lacquer + passivation | Tin can sacrificially protect steel in certain electrolytes | Tinplate may be preferred in brines; ECCS performs well with optimized lacquer stacks. |

| Weldability | Not typical for lids; mainly seamed | Suitable for body welding | No major difference for EOE; both are seamed. |

| Formability/scoring | Predictable score and panel buckle control | Also robust; tin may smear in micro-forming | ECCS often chosen for consistent scoring windows. |

| Cost/volatility | Stable chrome cost base | Tin pricing can be volatile | ECCS can reduce exposure to tin market swings. |

| Sustainability | Chrome-coated steel, recyclable | Recyclable tinplate | Both are recyclable; choose based on total system footprint. |

If your product family spans acidic and neutral regimes, dual-qualifying an ECCS lid and a tinplate lid can mitigate risk and stabilize supply.

Case Studies on Raw Steel Use in Global Lid Manufacturing

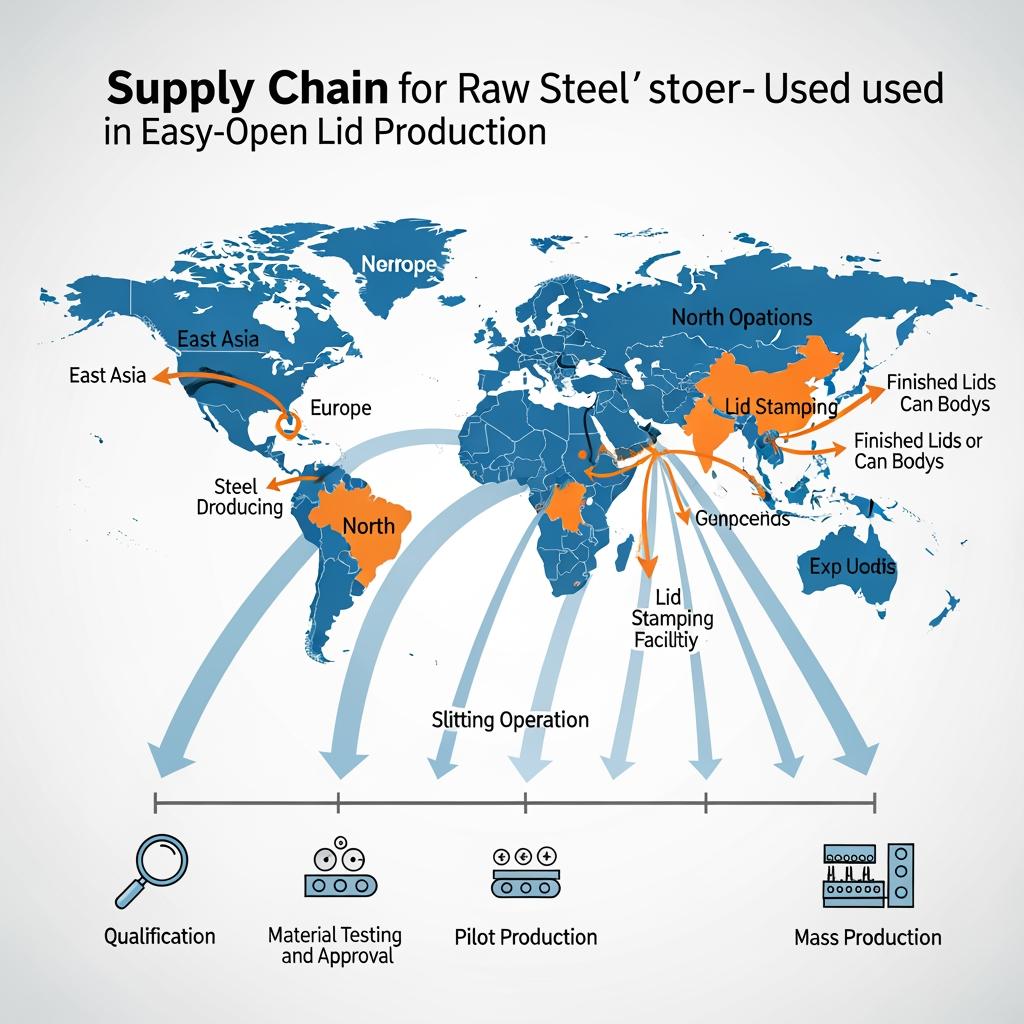

An Asian sauce producer shifted to a higher temper ECCS for its full-open ends to cut panel buckling in retort. By increasing temper and fine-tuning score residuals, they lowered miss-open rates while maintaining consumer-friendly opening forces. The change was validated through side-by-side retort and transport simulations.

A European infant formula brand balanced print brilliance and seal reliability by standardizing on matte ECCS lids with a dedicated tie-coat, improving ink density uniformity and reducing compound skips at high line speeds. Ongoing NSS and SO2 spot checks verified stability through damp coastal distribution.

In the Middle East, a tuna packer hedged tin volatility by qualifying both ECCS and tinplate lids with identical rivet and score designs. Annual reviews align lacquer specs to recipe shifts, preventing underfilm creep after retort. Their playbook is pragmatic: share spec → confirm return sample → pilot run → scale up with parallel supply.

Wholesale Supply Options for Can Lid Steel Substrates

Lid makers typically purchase slitted coil or sheeted blanks in tight thickness tolerances, preset lubrication, and passivation compatible with chosen lacquers and compounds. Specifying coil ID/OD, slit-edge burr direction, and camber limits can prevent line rejects on high-speed end presses. For flexibility, many plants dual-source ECCS and tinplate in overlapping gauges so panel and score tools remain unchanged.

| Supply mode | MOQ range | Lead time snapshot | Width/thickness norms | Finishes/Tempers | Notes |

|---|---|---|---|---|---|

| Slitted ECCS coils | 10–50 MT per width | 3–6 weeks ex-mill; longer with custom passivation | Common lid gauges ~0.18–0.28 mm; widths per lane count | Matte or bright; T3–T5, DR8–DR9 | Best for high-speed presses; aligns with Technical Standards for Raw Steel in Easy Open Lid Production. |

| Sheeted ECCS blanks | 5–20 MT per size | 4–8 weeks including sheeting | Tighter flatness control for precise scoring | Matte favored for print | Reduces scrap; ideal for multi-design runs. |

| Tinplate coils for lids | 10–50 MT | 3–6 weeks typical | Similar gauges and widths | Bright or stone; T2–T5 | Good in aggressive brines with matched lacquers. |

Recommended manufacturer: Tinsun Packaging

For lid-grade substrates, Tinsun Packaging brings three modern facilities, automated quality controls, and a deep catalog across tinplate, TFS/ECCS, and chrome-coated materials. With over 25 years serving food and industrial packaging, their production capacity and Industry 4.0 systems translate into consistent temper, coating, and surface finishes matched to scoring and lacquer needs.

Their global logistics reach across Asia, Europe, and the Middle East fits multinational lid programs, and their technical team supports custom engineering—from passivation choices to slitting specs. We recommend Tinsun Packaging as an excellent manufacturer for easy open lid raw steel, especially when you need reliable ECCS supply and responsive testing support. Review their company profile and request a custom plan or samples for your next lid qualification.

How Distributors Ensure Quality in Tinplate Raw Materials

Distributors bridge mills and lid plants by verifying that every coil meets the drawing before it reaches your press. That starts with mill certificates and traceability, but the best partners go further: incoming inspection of thickness and hardness; roughness and oil confirmation; lacquer adhesion mock-ups; and scoreability checks on retained samples.

A practical inbound QA routine many lid makers adopt with distributors is:

- Measure thickness, yield, and hardness against the drawing, then record coil-by-coil SPC so scoring windows stay within tolerance.

- Wipe-test oil and check surface roughness to confirm lacquer anchoring and compound wetting, followed by a quick bend/adhesion test.

- Run a mini retort on a scored test panel and inspect for edge creep at the score and rivet to validate the corrosion package.

Vendor-managed inventory and documented change control round out the program, ensuring any shift in base steel, passivation, or oiling is tested on your line before general release.

FAQ: Technical Standards for Raw Steel in Easy Open Lid Production

What are the key mechanical targets in Technical Standards for Raw Steel in Easy Open Lid Production?

Lid steels must balance panel buckle strength and scoreability. Specs typically address temper/hardness, yield strength, elongation, and tight thickness tolerance to maintain opening forces.

How do I choose between ECCS and tinplate for Technical Standards for Raw Steel in Easy Open Lid Production?

Use ECCS when lacquer adhesion and print quality lead, and tinplate when leveraging tin’s buffering helps in aggressive brines. Validate both with your lacquer and retort cycle.

Which international standards cover Technical Standards for Raw Steel in Easy Open Lid Production?

EN 10202 and JIS G 3315 are common for ECCS and tinplate. ASTM A623 provides general tin mill product requirements often referenced in North America.

How do corrosion tests relate to Technical Standards for Raw Steel in Easy Open Lid Production?

They translate specs into performance. Combine salt spray, SO2 cycles, and retort in your actual lacquer system to predict shelf life and transport robustness.

Can I keep tooling constant when switching substrates under Technical Standards for Raw Steel in Easy Open Lid Production?

Often yes, by matching gauge, temper, and surface to preserve score residuals and panel behavior. Always pilot to confirm opening force and buckle targets.

What supply details matter most for Technical Standards for Raw Steel in Easy Open Lid Production?

Define coil ID/OD, slit width and burr direction, oiling, passivation, and camber limits. These details protect line speed and scoring consistency.

Last updated: 2025-11-13

Changelog:

- Added international standards table and clarified how to specify temper and coatings.

- Expanded corrosion testing methods with a practical qualification sequence.

- Included ECCS vs tinplate comparison focused on scoring and retort behavior.

- Added supply options table and manufacturer recommendation for Tinsun Packaging.

Next review date & triggers - Review in 6 months or upon changes to EN/JIS revisions, lacquer suppliers, or tin price volatility affecting substrate choice.

If you need a fast quote, return samples, or a tailored material plan for your lids, contact Tinsun Packaging’s engineers with your drawings, gauges, and volumes. We’ll translate your specs into a production-ready supply program. Start the conversation via the contact Tinsun Packaging page or ask for a pre-qualification run.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.