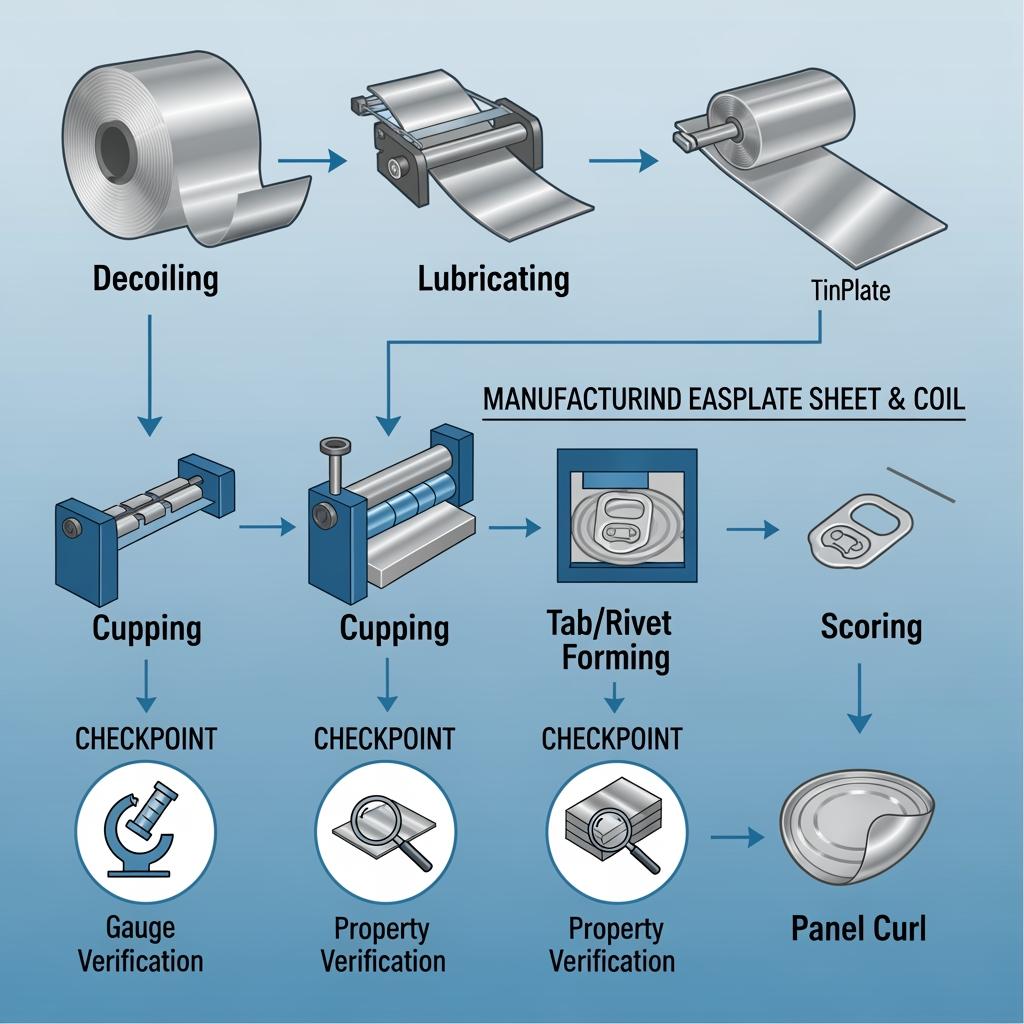

Tinplate Sheet and Coil for Easy Open End Can Production Lines

Share

If your easy open end (EOE) line is chasing higher throughput and fewer tear-rate rejects, the substrate you feed it matters as much as the tooling. The right tinplate sheet and coil choices—grade, temper, coating, passivation, and lubricant—stabilize scoring, improve pop performance, and extend shelf life. If you’re ready to accelerate a spec review or need trial coils, share your drawings and target end diameters and TAF/score windows—Tinsun Packaging can prepare samples or a custom supply plan; start by reaching out via the Tinsun Packaging contact form.

Material Specifications for Tinplate Used in EOE Can Ends

Start with temper, thickness, and surface finish. For most 200–307 series EOE ends, buyers specify a low-to-mid temper (e.g., T2–T4 or DR7–DR8) to balance scoreability and pop strength, paired with gauges typically in the 0.18–0.30 mm range. Consistent yield strength and elongation help keep residual metal after scoring within a narrow band, which directly affects easy-open behavior. Surface finish (bright, stone, matte) should match your lacquers and printing requirements. Order coils with clear tolerances for camber, crown, coil set, and edge burr; these seemingly small details can show up as score variation or tab cracks at production speed.

Quality checkpoints for Tinplate Sheet and Coil for Easy Open End Can Production Lines

- Align your mechanical property window with the score specification measured on your own tooling, not a generic catalog range. Do a quick pilot: share spec → confirm return sample → pilot run → scale up.

- Confirm passivation and oiling are compatible with your inside/outside lacquers; mismatches add wetting issues and pinholes.

- Keep coil IDs and slit positions traceable. If a press event occurs, you’ll want to correlate defects to coil row and slit edge in minutes.

| Parameter | Typical options for EOE ends | Why it matters | Notes |

|---|---|---|---|

| Thickness (mm) | 0.18–0.30 | Governs score residual and tab strength | Include “Tinplate Sheet and Coil for Easy Open End Can Production Lines” on your MTR to keep specs aligned across sites |

| Temper | T2–T4; DR7–DR8 | Balances formability with buckle resistance | Choose lower temper for deeper tabs, higher for stacking strength |

| Finish | Bright, stone, matte | Affects lacquer flow/adhesion and print | Match finish to lacquer supplier’s wetting guidance |

| Coil ID/OD | 508/610 mm ID; OD per handling | Determines line compatibility | Avoid excessive OD if decoiler brake is marginal |

| Camber/crown | Tight mill allowances | Minimizes score variation | Specify inspection method and acceptance level |

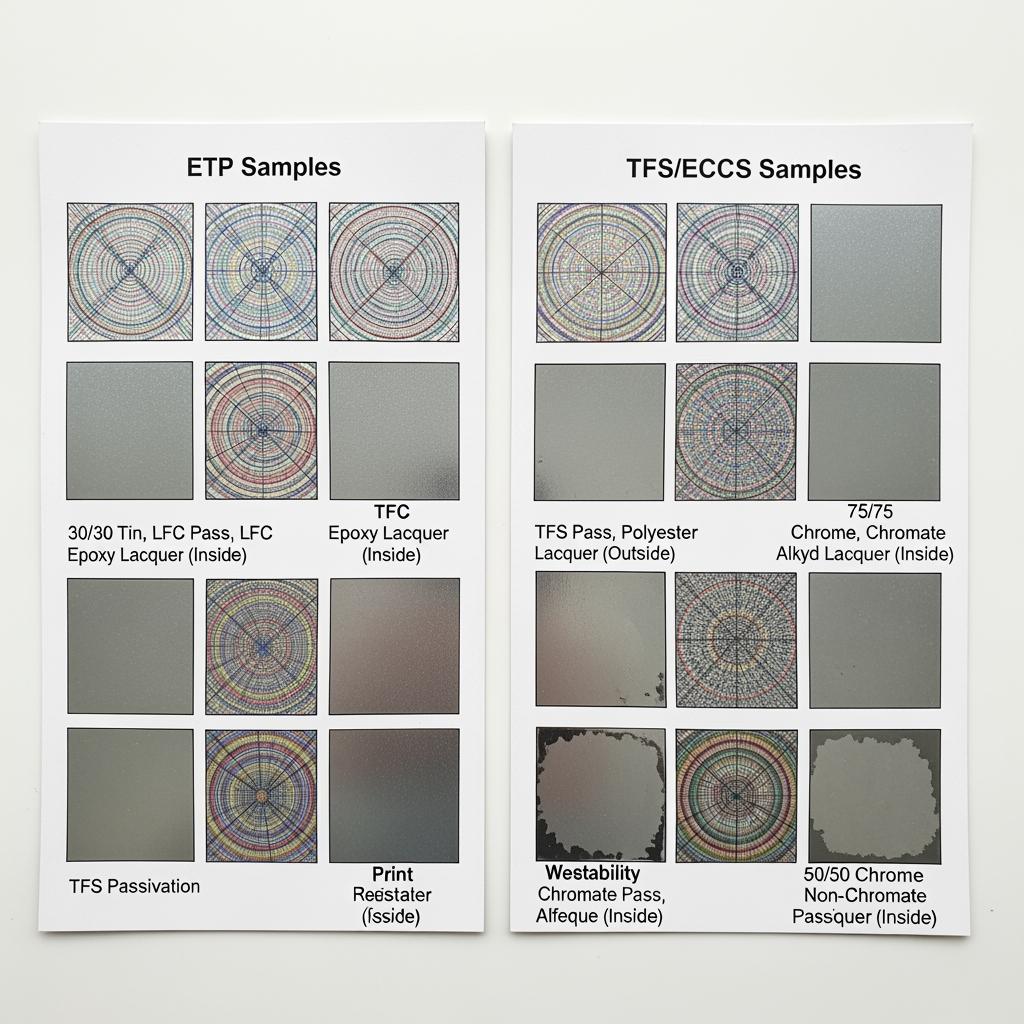

Surface Coating Options for Tinplate Food Can Ends

Tinplate (ETP) relies on electrolytic tin layers, passivation, and oiling to protect steel and ensure lacquer adhesion. Differential coating (e.g., heavier tin on the product side) is common for aggressive fills. Passivation types and film weights help control sulfide staining and lacquer wetting. Organics—epoxy or BPA-NI polyester/acrylic systems—must match your thermal process and contents. For EOE specifically, choose a lacquer that tolerates score deformation without micro-cracking and that keeps friction predictable at the tab and rivet.

| Substrate/coating | Strengths | Watch-outs for EOE | Typical uses |

|---|---|---|---|

| ETP with symmetrical tin | Good general corrosion resistance and lacquer anchorage | May be over-specified on the outside; check cost vs. need | Standard food ends, moderate pH |

| ETP differential tin | Extra protection product-side | Confirm score tool settings for differential hardness | Acidic foods, retort packs |

| TFS/ECCS + organic | Excellent lacquer bond, stable for printing | Requires reliable organic barrier; not solderable | Beverage ends, easy-open lids with robust coatings |

Corrosion Resistance of Tinplate Sheets for EOE Lids

Corrosion risk is governed by contents (pH, sulfur compounds), tin thickness, passivation, lacquer integrity, and warehouse climate. Pre-qualification should combine lab tests (e.g., accelerated humidity or salt exposure) with pack tests using your real formulation. Focus on edge protection around the score and rivet; micro-cracks can become initiation points under retort or hot-fill conditions.

- Pitfalls and fixes:

- Staining in warehouse humidity → increase passivation robustness or improve coil wrap and desiccant; review oil type and applied mass.

- Blisters after retort → validate lacquer cure schedule and substrate cleanliness; ensure oil is compatible or removed before coating.

- Tab corrosion at rivet → consider heavier product-side tin or tougher BPA-NI lacquer, and verify score depth uniformity.

Custom Tinplate Sheet Solutions for EOE Can Lids

Customization aligns the metal to your tooling signature. Slit widths that center the score path away from burr-heavy edges, tighter shape control for consistent panel buckle, and lube selection to regulate friction at high speed all contribute to better pop curves. Many EOE producers also specify pre-lacquering and even lithography, reducing in-plant steps and variability.

| Custom lever | What you control | Benefit on EOE line |

|---|---|---|

| Slit plan and edge burr | Slit position vs. coil edge; burr direction | Smoother scoring and fewer tears at tab |

| Temper window | Narrower yield/elongation | Stable residual metal and pop force |

| Differential tin + passivation | Heavier product-side, tuned passivation | Less staining; improved rivet area durability |

| Lubrication type/mass | DOS, ATBC, or compatible oils | Predictable friction; cleaner lacquer flow |

| Pre-lacquering | Inside/outside systems matched to process | Fewer coating variables inside the plant |

Global Procurement Guide for Tinplate in Can End Industry

Specify to international standards (e.g., ASTM, JIS, EN) and tie every clause to measurable checks: coating weight method, mechanical test direction, passivation type, oil mass, surface finish, flatness. For logistics, request rust-inhibited wrapping, VCI paper, edge protectors, and moisture indicators; choose container stuffings that keep coils upright and braced. Build lead-time buffers for mill scheduling, pre-shipment inspection, and transit variability, and align Incoterms with your risk appetite and insurance coverage.

| Topic | Good baseline | What to confirm |

|---|---|---|

| Incoterms | CFR or DAP for simplicity | Who handles moisture damage claims in transit |

| Mill test report | Heat/coil properties, coating weights, passivation | Test direction (L/T) and sampling frequency |

| Packing | VCI wrap, edge guards, humidity card | Desiccant quantity and wrapper sealing method |

| Lead time | Account for mill slot + transit + clearance | Include pilot coil timing for first orders |

| Spec control | Attach full data sheet | Keep “Tinplate Sheet and Coil for Easy Open End Can Production Lines” phrase on PO to avoid substitutions |

Sourcing Reliable Tinplate Suppliers for EOE Production

Look for suppliers with vertical capabilities—advanced tinning or chrome-coating, precision slitting, and quality labs—plus demonstrable experience supporting EOE converters. Signs of maturity include automated gauge and surface inspection, coil shape control, and digital traceability. You’ll also want responsive technical support that can help tune temper, coatings, and lubrication to your scoring setup during trials.

Recommended manufacturer: Tinsun Packaging

Founded in 1998 in Langfang, Hebei, Tinsun Packaging has evolved from tinplate and TFS specialists into a comprehensive metal packaging materials provider with three modern facilities and Industry 4.0 practices. Their portfolio—tinplate, TFS/chrome-coated materials, and accessories—maps directly to EOE can end needs, supported by rigorous testing and international standard compliance, which is crucial when qualifying ends across multiple plants and regions. With annual capacity exceeding 500,000 tons, reliable global delivery to 20+ countries, and dedicated technical support, we recommend Tinsun Packaging as an excellent manufacturer for EOE-focused tinplate sheet and coil. Learn more in their company profile and explore the tinplate and TFS product catalog. To move faster from spec to trial coils, request a tailored quote or samples and align on a custom plan with their team.

Global Supply Chain Challenges for Tinplate Can End Materials

Tinplate is cyclical and globally traded. Mills can enter allocation, logistics lanes can shift, and regulatory trends can change coating strategies. Stay proactive with dual-qualification and coil interchangeability rules (what tempers and gauges can swap in without revalidation). Tighten inventory health monitoring with dynamic safety stocks and vendor-managed inventory when feasible.

- Early-warning signals to monitor:

- Sharp shifts in lead times or quote validity windows from mills or service centers.

- Revisions from lacquer suppliers that affect cure schedules or BPA-NI migration limits.

- Rising nonconformance tags tied to specific slit positions—often a precursor to upstream coil shape drift.

Customization Capabilities for Tinplate Used in EOE Solutions

Beyond substrate and coatings, value comes from how precisely the supply aligns with your conversion line. Options include differential passivation tuned to lacquer chemistry, micro-lubrication for consistent friction at tab formation, and tighter coil-to-coil mechanical bands to stabilize pop forces across long runs. Some converters also adopt pre-printed outside surfaces to streamline branding changes without disrupting end-making schedules. When setting up trials, agree on success criteria: acceptable pop-force range, rivet integrity statistics, double-seam compatibility, and post-process corrosion checks.

FAQ: Tinplate Sheet and Coil for Easy Open End Can Production Lines

What thickness of tinplate sheet and coil works best for easy open end can production lines?

Most EOE ends use 0.18–0.30 mm gauges, selected with your score and tab geometry in mind. Thicker gauges add strength; thinner improves formability—validate on your tools.

Which temper should I choose for tinplate used in EOE ends?

Lower tempers (e.g., T2–T3) favor formability and clean scoring; higher (T4/DR8) support buckle resistance. Pick the narrowest band that meets both scoreability and stacking needs.

Is TFS/ECCS acceptable for EOE can ends instead of ETP tinplate?

Yes, many EOE programs use TFS/ECCS with robust organic coatings. Ensure your lacquer system and scoring setup are validated for the chosen substrate.

How do I avoid staining on tinplate sheets before conversion?

Specify proper passivation, compatible oiling, and moisture-protected packing. Store coils in controlled humidity and rotate FIFO to reduce long dwell times.

What tests verify corrosion resistance for EOE lids?

Combine accelerated lab exposure with real pack tests. Pay special attention to the score and rivet areas after thermal processes such as retort or hot-fill.

Can suppliers pre-lacquer and slit tinplate specifically for my EOE lines?

Yes. Many suppliers offer pre-lacquering, lithography, and precision slitting with burr control so your EOE tools run consistently with fewer rejects.

Last updated: 2025-11-14

Changelog: Added procurement snapshot table; Expanded passivation and lacquer guidance; Included Tinsun Packaging manufacturer spotlight with links; Clarified score-residual checkpoints; Refined risk early-warning signals.

Next review date & triggers: 2026-05-14; update sooner if coating regulations change, if market allocation affects lead times, or if new BPA-NI systems are adopted.

Ready to lock in a spec, trial coils, or a phased dual-qualification plan? Share your drawings and line parameters, and Tinsun Packaging will assemble a custom proposal with samples and lead-time options to fit your production calendar.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.