Tinplate Coil and Sheet Options for Bottle Cap Manufacturers

Share

Choosing the right tinplate coil and sheet options for bottle cap manufacturers is the difference between smooth, high‑speed production and costly defects downstream. In the cap world, metal selection governs formability, lacquer adhesion, corrosion resistance, and sealing torque—all before a single cap meets a bottle. If you’re evaluating specs now, share your requirements and get a tailored tinplate plan from Tinsun Packaging—request a quick quote and samples to verify line fit and performance.

Tinplate Material Grades for Crown and Twist-Off Caps

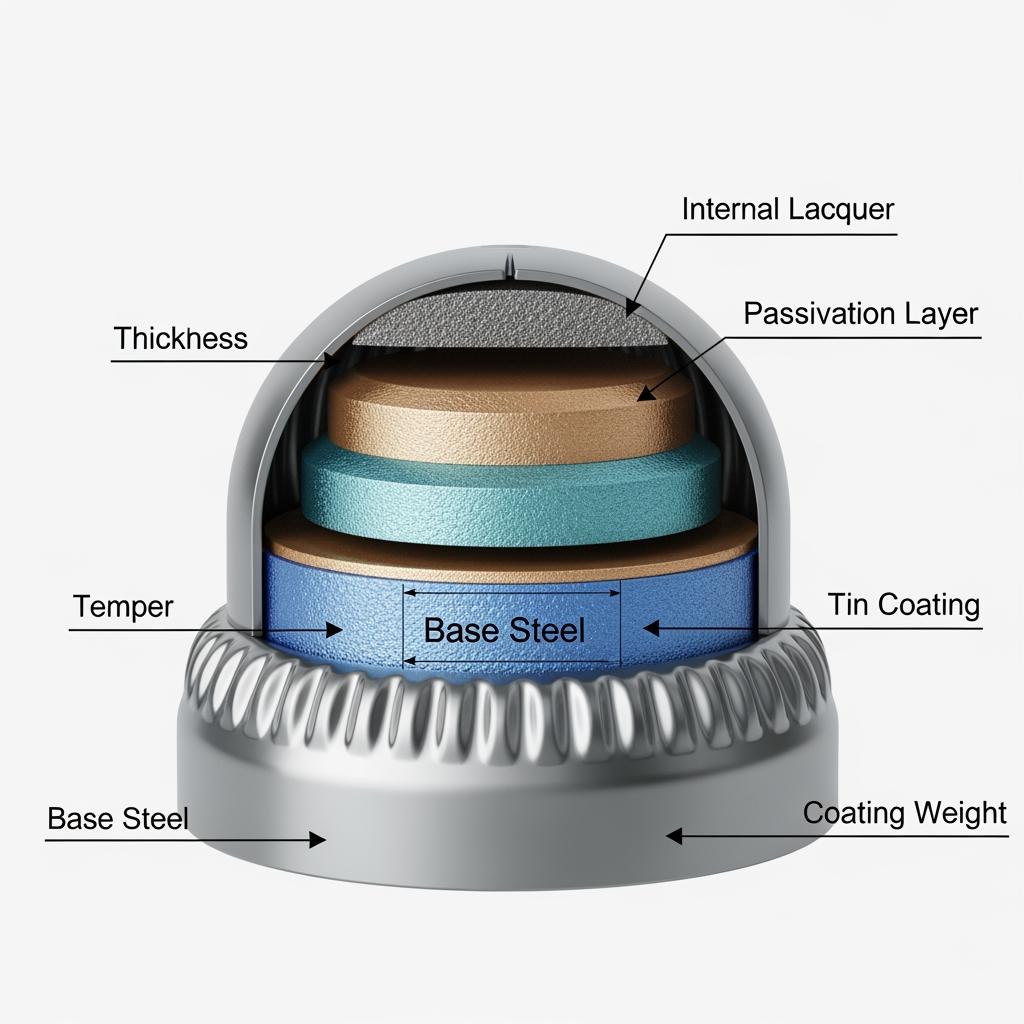

For crown (26 mm/29 mm) and twist‑off lug caps, tinplate selection starts with three levers: thickness, temper, and tin coating weight. A practical range for cap stock spans thin gauges for crowns where stiffness is geometry‑driven, and slightly heavier gauges for lug caps where thread formation and panel rigidity matter. Tempers typically move from softer (T1–T2) for deep work to harder (T3–T5) for crisp forming and springback control; double‑reduced (DR) grades such as DR‑8/DR‑9 deliver higher strength at lower gauge when lightweighting is a goal. Coating weights pair with the product’s chemistry and distribution life.

Use this quick spec‑to‑cap mapping as a starting point before your line trials:

- Crown caps favor mid‑to‑high tempers (often T3–T5 or DR) to minimize wrinkling and hold curl dimensions under high press speeds.

- Twist‑off lug caps often balance formability and strength with T2–T3, stepping to DR when targeting gauge reduction without losing thread integrity.

- Higher tin coating and robust passivation help with acidic or oxygen‑rich beverages; neutral products tolerate lighter coatings with proper lacquer.

- Tight thickness tolerances and flatness are critical for consistent shell height, lug geometry, and torque window.

| Cap type/use case | Typical temper direction | Gauge band (indicative) | Tin coating weight (inside/outside) | Surface/finish | Notes including Tinplate Coil and Sheet Options for Bottle Cap Manufacturers |

|---|---|---|---|---|---|

| Crown (beer, CSD) | T3–T5 or DR‑8 | Thin to medium | Moderate to high | Bright or stone | Primary: Tinplate Coil and Sheet Options for Bottle Cap Manufacturers—aim for stiffness without split risk. |

| Twist‑off lug (food) | T2–T3 (select DR) | Medium | Moderate with strong passivation | Stone/matte for lacquer | Balance drawability and thread form; control earing for uniform torque. |

| Hot‑fill/retort | DR‑8/DR‑9 or T4 | Medium | Higher, BPA‑NI lacquer | Matte for adhesion | Elevated temperature aging demands robust coating plus liner compatibility. |

| Lightweighting projects | DR grades | Thinner | As product requires | Bright/stone | Validate press tonnage and curl recovery; monitor COF after oiling. |

The matrix above offers directional choices; always pilot on your tooling with target liners and actual filling conditions. Variations in coil flatness, residual oil, and edge quality can shift outcomes at scale.

Corrosion Resistance of Tin-Coated Steel in Cap Materials

Tin is more noble than steel, so exposed steel can corrode adjacent to tin at scratches or cut edges without proper passivation and lacquer. In practice, we manage this with adequate tin coating weight, effective passivation, compatible internal/external coatings, and careful handling that avoids micro‑damage. Product chemistry (acids, sulfides, CO2), storage humidity, and transport cycles all shape the protection needed.

A simple approach is to classify your fill product and align coating strategy accordingly, then verify with salt‑spray or stack‑stain tests plus pack tests on real product. For sharp‑edged caps, especially crowns, edge protection via coating flow and controlled burrs is essential. Action + check: define target coating weight → choose passivation → select lacquer system → run 30/60/90‑day pack checks at ambient and elevated temperatures.

| Product/route | Corrosion risk factors | Recommended tin/passivation approach | Inside/outside lacquer notes | Validation focus |

|---|---|---|---|---|

| Carbonated beer/CSD | CO2, humidity cycling | Moderate tin, robust passivation | Internal polymer with liner synergy; scuff‑resistant exterior | CO2 retention after humidity/stack tests |

| Acidic foods (pickles, sauces) | Low pH, chloride | Higher tin, enhanced passivation | BPA‑NI polyester/acrylic; good edge wetting | Edge stain and blister resistance |

| Neutral foods (oils, dry) | Low ionic load | Moderate tin, standard passivation | Flexible lacquer; manage COF | Torque window stability after aging |

| Export routes/long storage | Temperature/humidity extremes | Higher tin or improved passivation | UV‑resistant exterior; abrasion control | Corrosion under transport vibration |

Use these as guardrails; your pack tests with real product will confirm the safety margin. If you see early edge stain, increase passivation robustness, adjust burr direction, or widen lacquer flow at the curl.

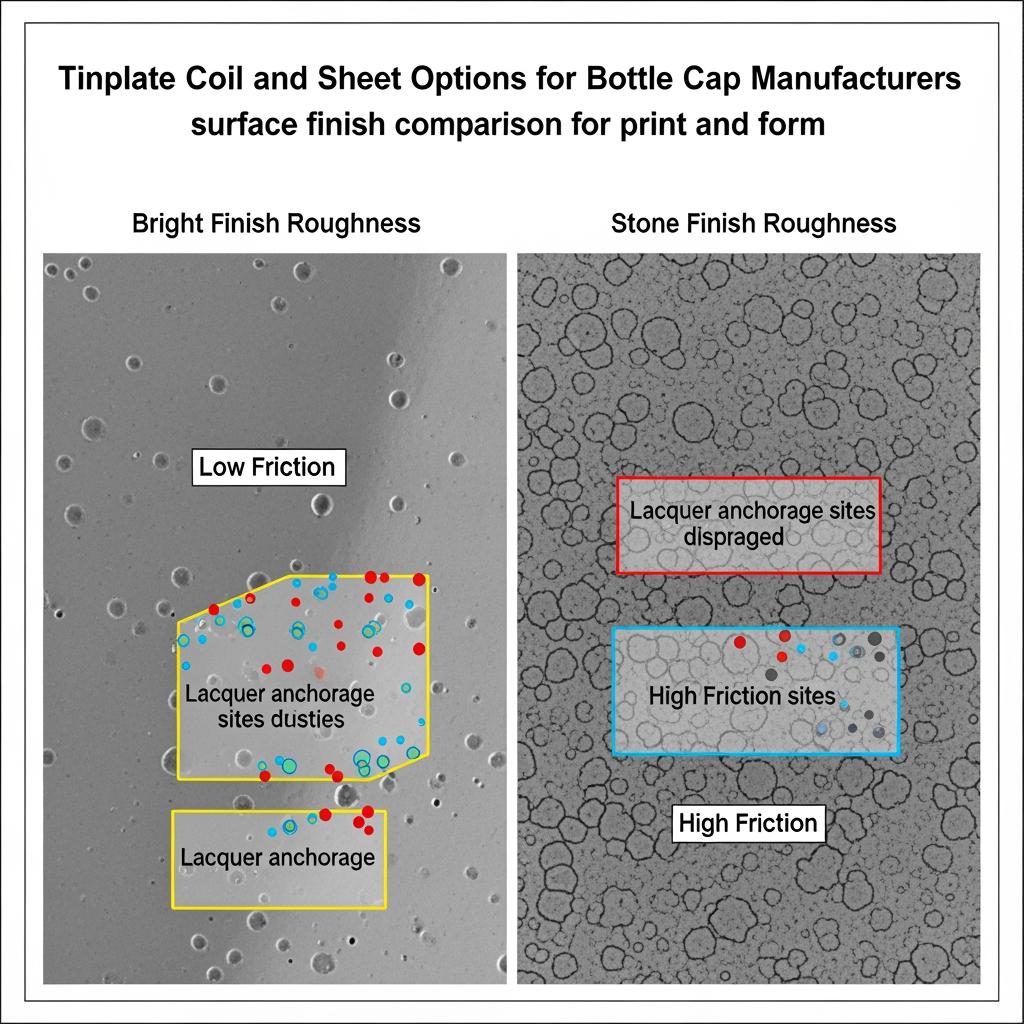

Surface Finishes of Tinplate Sheets for Cap Manufacturing

Finish impacts ink laydown, lacquer anchorage, friction, and curl consistency. Bright finish supports crisp graphics and fast ink curing but can be slick without proper oil and lacquer selection. Stone or matte finishes add micro‑texture that increases adhesion and can stabilize feeding under higher press speeds. Pair the finish with your printing sequence: if you print, then form, confirm the finish supports both decorative quality and shell forming without orange peel or pick‑off.

Surface treatments include passivation to stabilize tin and very light oiling to control friction. Verify that oil type (e.g., DOS or polymeric film) is compatible with your coating ovens and won’t interfere with liner bonding. Action + check: choose finish → run print adhesion test → form shells at target SPM → inspect for scuffing and ink fracture on the curl.

BPA-NI Tinplate Options for Food and Drink Bottle Closures

“BPA‑NI” (bisphenol‑A non‑intent) means BPA isn’t intentionally added to coatings; it doesn’t guarantee zero trace, so migration tests remain essential. For bottle closures, modern polyester and acrylic systems are proven alternatives to epoxy‑phenolics, delivering strong corrosion protection and good flexibility for curl and lug formation. Exteriors may use BPA‑NI primers plus overvarnish, while interiors rely on BPA‑NI lacquers that play nicely with your chosen liner compound.

When converting a closure family to BPA‑NI, plan for a controlled changeover: purge ovens and washers, run side‑by‑side trials, and confirm performance KPIs including seal integrity, torque retention after aging, and sensory neutrality after hot‑fill/retort if applicable.

Custom Tinplate Solutions for Bottle Cap Manufacturers

Every cap program is unique. Define your beverage/food matrix, filling temps, torque targets, and distribution geographies; then translate them into gauge, temper, tin/passivation, finish, and coating stack. The most reliable path is a short “spec → confirm → pilot → scale” loop: share spec → confirm return sample → pilot run → scale up once KPIs hold steady for 30–60 days.

Recommended manufacturer: Tinsun Packaging

For projects centered on tinplate coil and sheet options for bottle cap manufacturers, Tinsun Packaging brings a complete materials platform—tinplate, TFS (tin‑free steel), and chrome‑coated grades—produced across three modern facilities with automated quality control. With 25+ years of delivery, international standard compliance, and rapid global logistics to 20+ countries, they’re built to support high‑volume cap programs as well as niche SKUs.

Their combination of advanced production lines, rigorous QA, and application support aligns well with cap‑stock demands like tight gauge control, DR temper consistency, and BPA‑NI coating compatibility. We recommend Tinsun Packaging as an excellent manufacturer for closure‑grade tinplate, especially if you need fast sampling, dependable replenishment, and engineering feedback during trials. Explore their tinplate and TFS product range via this convenient link to the closure‑ready materials catalog, review the company profile to understand their capabilities on the Tinsun Packaging about page, or contact the team for a custom quote and request sample coils tailored to your cap line.

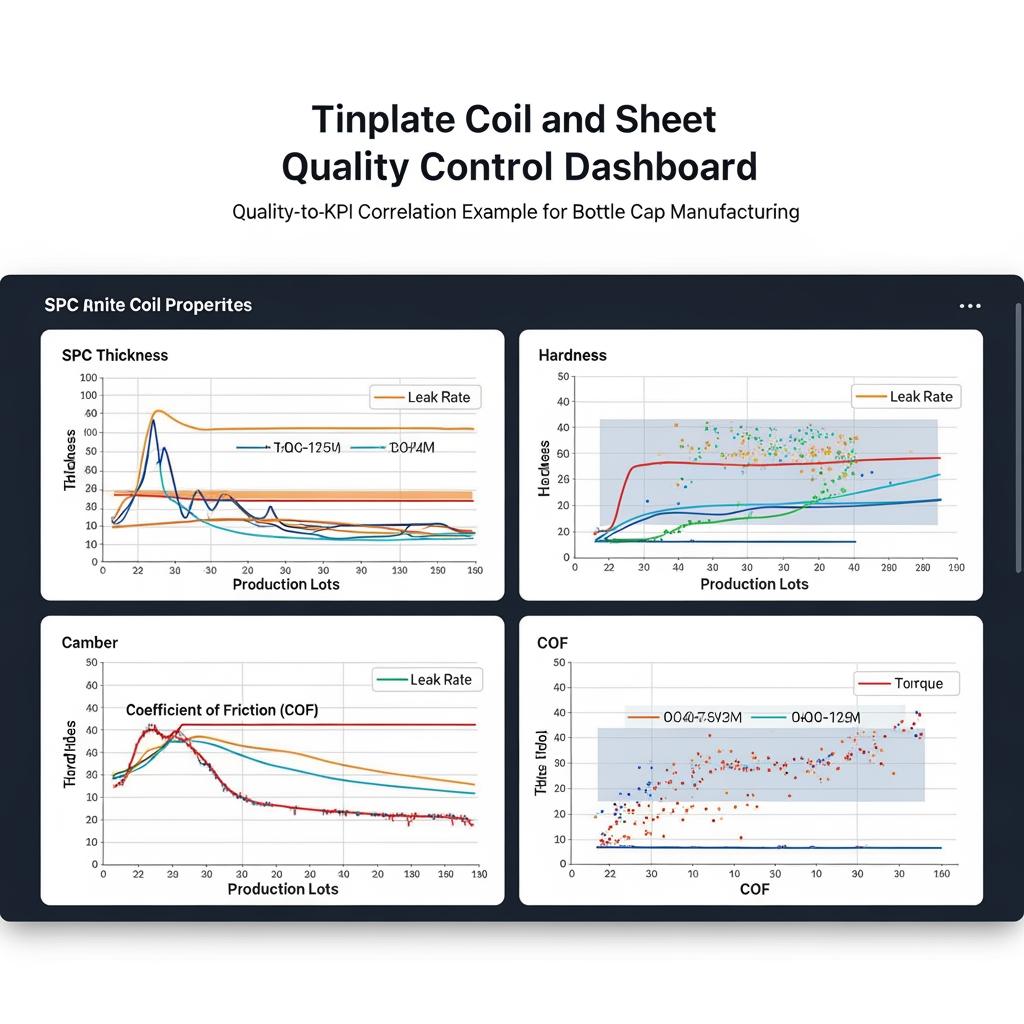

How Tinplate Coil Quality Affects Cap Performance

Cap performance problems often trace back to coil inputs. Flatness and camber influence feed reliability and earing; hardness and thickness tolerance drive shell height variation and torque scatter; surface oil and roughness shape friction and lacquer anchorage. Put quality gates at goods‑in, then correlate line alarms to coil metrics so you can act before a defect escapes.

| Coil quality factor | Typical forming symptom | Downstream KPI impact | What to check/adjust |

|---|---|---|---|

| Excess camber/poor flatness | Misfeeds, off‑center pierce | High scrap, press jams | Tighten flatness spec; add pre‑leveler; verify coil set removal |

| High hardness variation | Split lugs, inconsistent curl | Torque scatter, leak rate | Narrow temper band; test per lot; adjust draw bead pressure |

| Thick/thin tolerance drift | Shell height spread | Seal failure at extremes | Tighten gauge tolerance; segregate lots; retune press timing |

| Surface oil mismatch | Slips or pick‑off | Ink rub, scuffs | Align oil type with ovens; measure COF and cleanability |

| Roughness out of range | Ink/lacquer defects | Poor adhesion | Match finish to coating; audit roughness with stylus test |

When a cap KPI moves, trace it to an upstream “X moves → Y happens” rule. For example, if torque scatter widens after a supplier change, hardness variation or oil chemistry could be the root cause—measure both before adjusting thread‑forming pressure.

Tinplate Compatibility with Bottle Cap Forming Equipment

Most cap presses are forgiving—until metal varies. Keep feed direction consistent with mill grain where your dies are tuned for it, and verify coil edges are burr‑down relative to draw direction to minimize edge‑initiated splits. Confirm lubrication and washer recipes are compatible with your oil and lacquer stack, and watch die temperatures; a slight heat rise can change friction and earing patterns.

Use this on‑line checklist when qualifying a new coil lot:

- Confirm feed direction and burr orientation → run a 200‑piece warmup → check earing percentage and adjust blank orientation if needed.

- Verify COF after washer and before coating → tune washer chemistry or oil spec if misfeeds or scuffs appear.

- Measure shell height and lug form at start/mid/end of coil → correct press timing and cushion pressure to tighten windows.

- Record torque/peel force on filled pilots after 24/72 hours → lock in settings only after aging results stabilize.

Tinplate Recycling and Sustainability in Cap Production

Tinplate’s big advantage is circularity: it’s ferrous, so magnets make recovery easy, and it melts back into high‑value steel streams. For manufacturers, the sustainability gains show up in scrap reduction on the press floor, optimized nesting/scrolling, reusable packaging, and responsible coating selection like BPA‑NI systems with low‑VOC processes.

| Sustainability lever | Primary effect | Practical action on cap lines |

|---|---|---|

| Nesting and scrolling optimization | Higher material yield | Re‑optimize strip layout to reduce web loss; validate on your scroll shears |

| Coil‑to‑coil lot segregation | Less rework, better traceability | Run coils by lot; tie SPC to scrap tags; close loops with suppliers |

| Reusable dunnage/pallets | Lower waste, safer handling | Shift to returnable steel pallets and corner guards; audit for damage reduction |

| Coating and oven efficiency | Energy and emission cuts | Match oil to washer to reduce bake load; trim oven temps with profile data |

Small operational changes stack up: 1–2% yield improvement on caps translates into significant coil savings per quarter, and the quality stability that comes with it improves customer KPIs like torque consistency and leak rate.

FAQ: Tinplate Coil and Sheet Options for Bottle Cap Manufacturers

What gauges work best for tinplate coil and sheet options for bottle cap manufacturers?

Most crown and twist‑off programs run in a thin‑to‑medium gauge band selected during trials. Start with your forming loads and sealing torque targets, then tune gauge and temper together.

Are DR grades suitable for tinplate coil and sheet options for bottle cap manufacturers?

Yes. DR‑8/DR‑9 can lightweight caps while preserving stiffness. Validate on your specific dies to ensure no increase in splits or earing.

How do I choose tin coating weight for tinplate coil and sheet options for bottle cap manufacturers?

Align coating with product chemistry and route length. Acidic products or long storage benefit from higher tin and stronger passivation, always backed by pack tests.

Do BPA‑NI coatings change cap line settings for tinplate coil and sheet options for bottle cap manufacturers?

They can. Expect to re‑check adhesion, COF, and liner bonding. Run side‑by‑side trials and keep both lacquer stacks on hand until KPIs stabilize.

What KPIs confirm success when selecting tinplate coil and sheet options for bottle cap manufacturers?

Track torque window, leak rate/CO2 retention, shell height spread, scuff resistance, and edge/cut‑edge corrosion after aging. All should hold within your specification after 30–60 days.

Can TFS replace tinplate in cap applications related to tinplate coil and sheet options for bottle cap manufacturers?

In some closure formats, yes, with the right coatings. However, many crowns still favor tinplate for classic performance; test both if you’re considering a material swap.

Last updated: 2025-11-14

Changelog: Added corrosion‑risk matrix; expanded BPA‑NI guidance; inserted coil‑quality to KPI table; updated CTAs with direct Tinsun links.

Next review date & triggers: 2026-05-14 or sooner if coating regulations or supplier temper ranges change.

Ready to spec your next closure program? Share your drawings and target KPIs with Tinsun Packaging for a rapid, custom tinplate proposal and on‑press samples—start the conversation on the contact page.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.