Electrolytic Tinplate Raw Materials for Global Canning Industry

Share

Electrolytic tinplate sits at the heart of modern canmaking because it balances food safety, formability, and printability with global-scale availability. In this guide, we explain how Electrolytic Tinplate Raw Materials for Global Canning Industry are specified, qualified, and sourced—so you can move from drawings to dependable production with fewer surprises. If you’re exploring grades, coil sizes, or custom coatings, share your requirements to get a fast quote or samples—Tinsun Packaging provides these custom services, and you can browse their tinplate product range to jump-start your specification.

Electrolytic Tinplate Grades and Technical Specifications

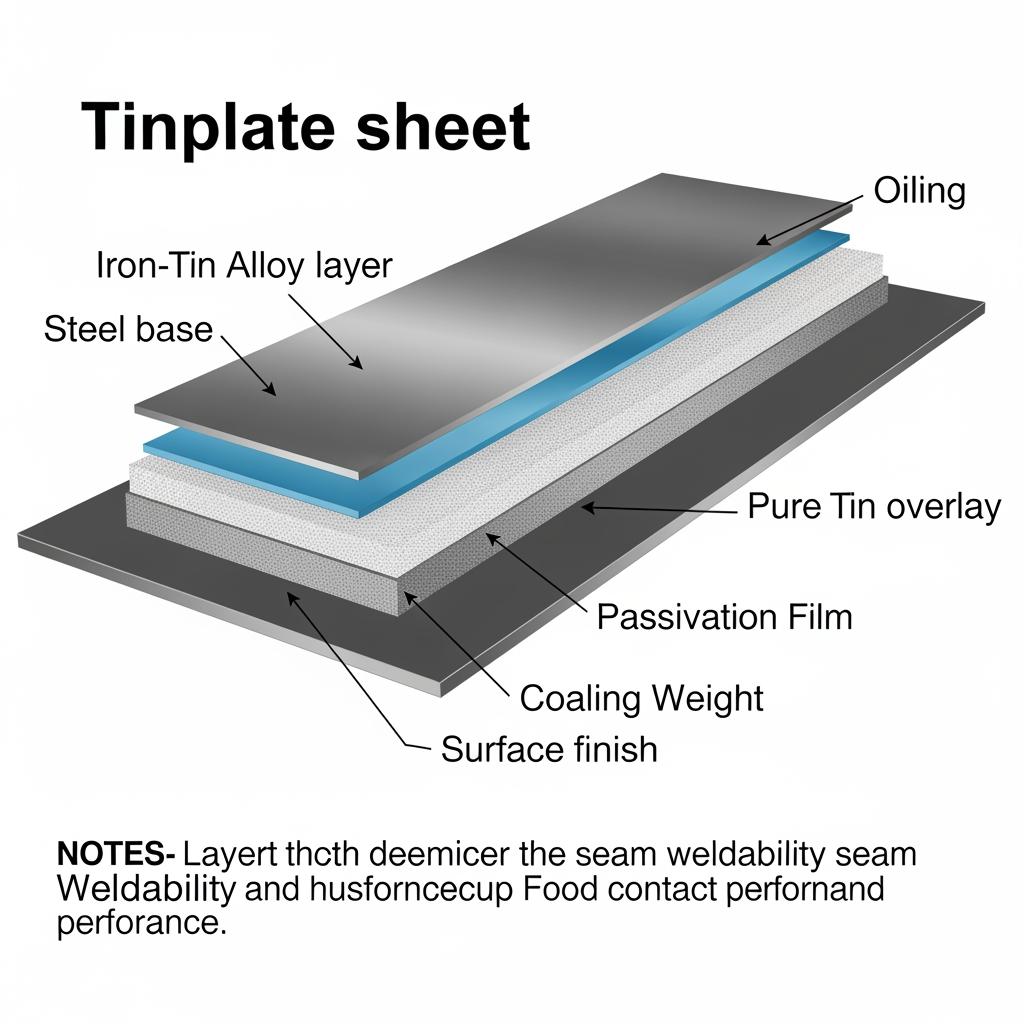

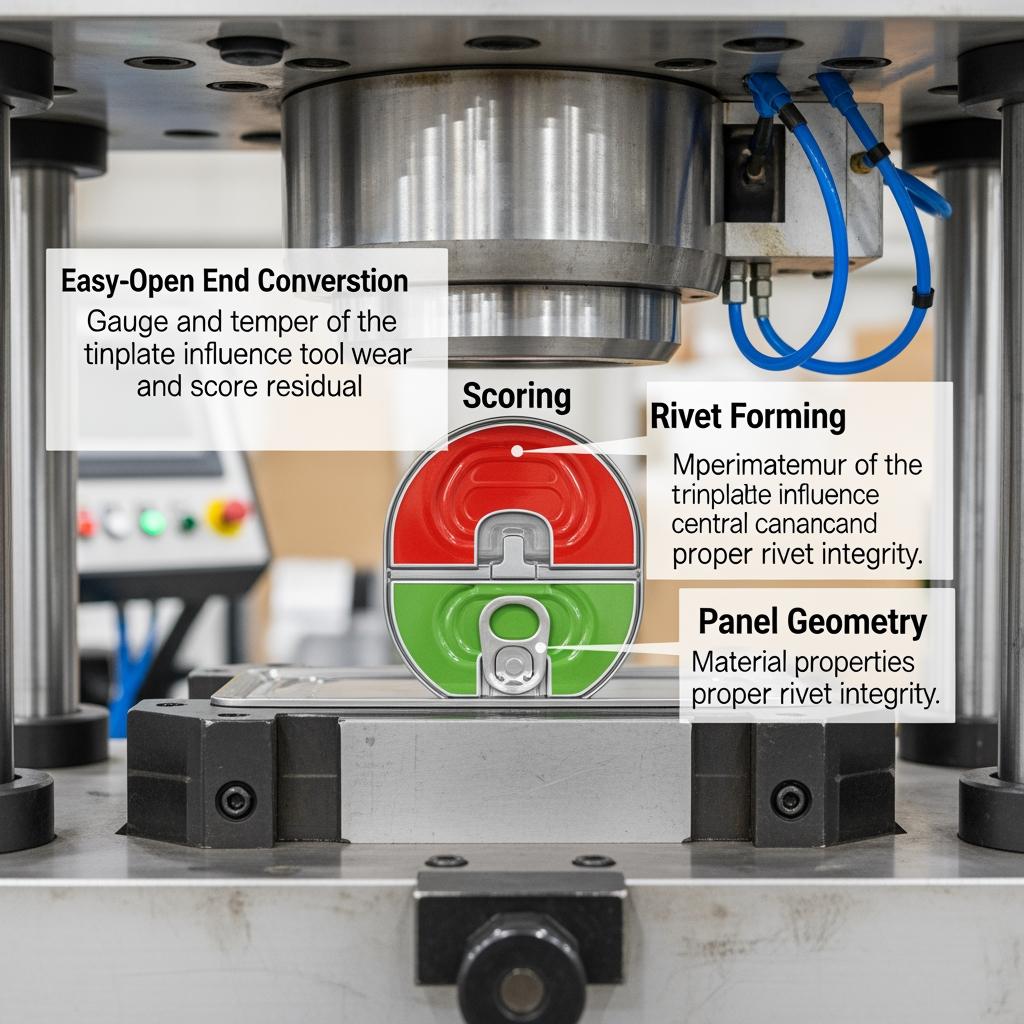

The simplest path to a reliable can body, end, or closure is to begin with a precise spec: base steel grade, temper, thickness, coating weight, surface finish, passivation, oiling, and coil geometry. Thickness typically ranges from light gauges for easy-open ends to heavier gauges for deep-drawn bodies. Tempers (T1–T5) and double-reduced grades (DR7–DR9) tune strength versus formability, while tin coating weights and passivation stabilize corrosion behavior and lacquer adhesion.

Specifying Electrolytic Tinplate Raw Materials for Global Canning Industry

For most food products, you’ll balance coating weight (for corrosion margin) against processability (for welding and easy scoring). Bright or stone finishes influence print quality and lacquer hold-out. Ensure your spec states coil ID/OD, width tolerances for slit mults, and weld current ranges if you resistance-weld side seams.

| Parameter | Typical Options | Why it matters | Notes including Electrolytic Tinplate Raw Materials for Global Canning Industry |

|---|---|---|---|

| Base steel | Single-reduced (SR), Double-reduced (DR) | DR gives higher strength at lower thickness; SR offers more drawability. | Choose DR for easy-open ends; SR for deep-draw cans in the Electrolytic Tinplate Raw Materials for Global Canning Industry context. |

| Temper | T1–T5, DR7–DR9 | Higher numbers = harder steel. | Match draw depth and buckle resistance; validate with your tooling. |

| Tin coating | Symmetric (e.g., 2.8/2.8, 5.6/5.6) or differential | More tin helps in aggressive foods; differential saves cost. | Confirm with product chemistry and storage life. |

| Finish | Bright, Stone/Matte | Affects print/lacquer appearance and friction. | Align to brand graphics and line handling. |

| Passivation & oiling | Chromate or alternatives; DOS oil levels | Controls corrosion and forming friction. | Coordinate with lacquer system and wash steps. |

This table acts as a quick decision grid: select DR + higher temper when strength is critical, bump coating weight for higher-acid or sulfur-bearing foods, and choose finish for downstream printing quality. Always pilot-run with your exact lacquer, seam, and sterilization cycle.

Tin Mill Black Plate Properties for Canning Applications

Tin mill black plate (TMBP) is the cold-rolled, uncoated substrate that becomes tinplate. Its cleanliness, profile, and mechanical properties set the ceiling for your forming limits and seam integrity. Key checks include gauge tolerance for score uniformity, flatness for stable coil pay-off, and surface roughness for consistent tin adhesion and lacquer wetting.

| TMBP Property | Target Range (use-case driven) | Application Impact | Typical Canning Use |

|---|---|---|---|

| Yield strength | Tuned for SR vs DR routes | Higher yield supports ends and lids; lower yield aids draws. | Easy-open ends: higher; drawn bodies: moderate. |

| Elongation | Balanced with strength | Higher elongation reduces split risk in deep draws. | Fruit/vegetable bodies with deep draws. |

| Surface roughness | Narrow, process-specific | Controls tin deposit uniformity and lacquer lay-down. | High-fidelity print and score consistency. |

| Flatness/camber | Tight | Prevents wander at slitter and scoring head. | All high-speed lines. |

Think of TMBP as your foundation: if it’s flat, clean, and within tight mechanical windows, tinning and passivation will build consistently. If not, no finish coat will fully mask substrate variability.

Regulatory Standards for Tinplate in Food Packaging

Food-contact compliance hinges on two pillars: material composition controls and migration performance after processing. Industry practice is to align with widely recognized national and regional frameworks, verify lacquer systems for intended foods and sterilization conditions, and maintain documented traceability from coil to can code. Your quality file should include supplier declarations, lacquer compliance letters, migration/simulant test reports, and sterilization validation aligned to your actual retort schedule.

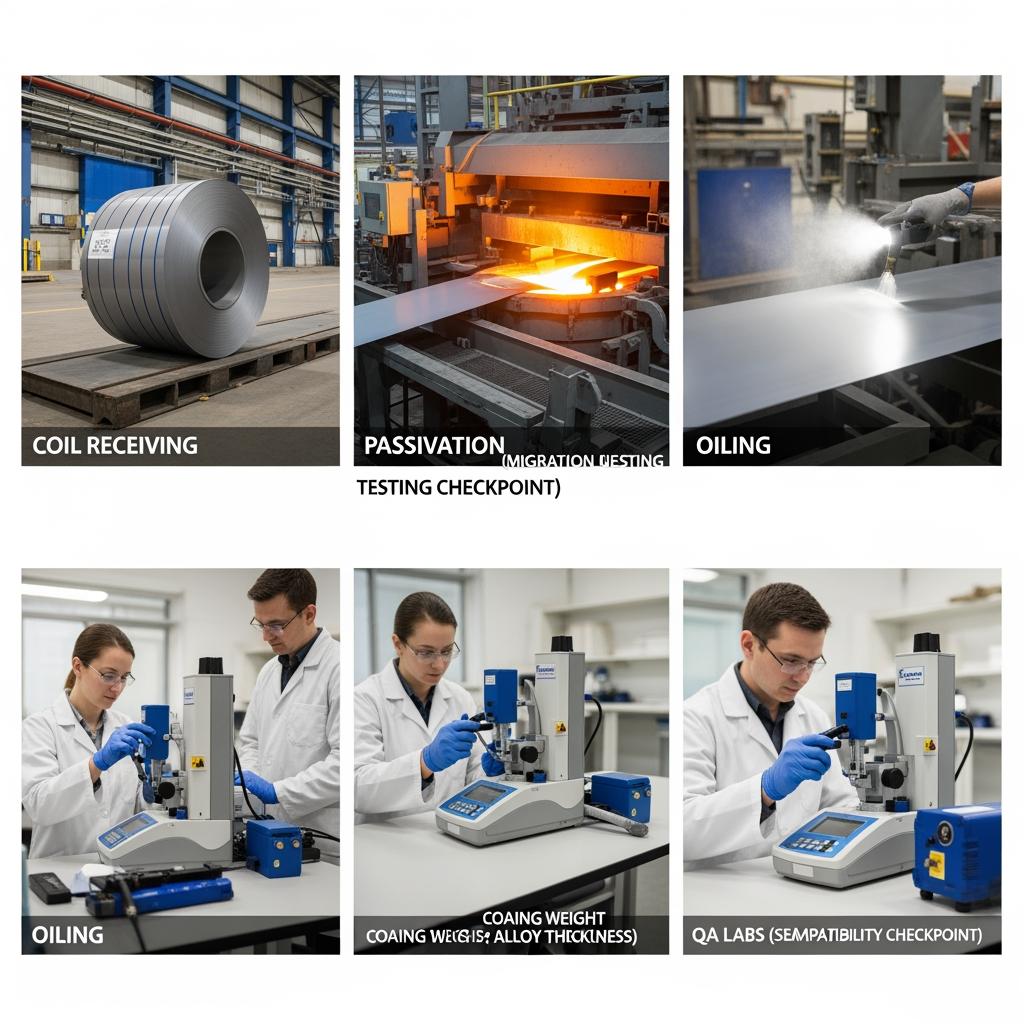

Many canners also conduct routine verification: appearance, lacquer cure, WACO (weight of coating), alloy layer depth checks, and aging studies under worst-case conditions. Even where regulations differ by region, the core approach—prevent, document, and verify—remains the same. Engage your supplier early to harmonize documentation with your export markets.

Corrosion Resistance of Tinplate Raw Materials Explained

Tin protects steel two ways: as a physical barrier and, after passivation, as a more stable surface that resists staining and sulfide darkening. The iron–tin alloy layer improves adhesion and reduces underfilm creep. Final performance depends on product chemistry (acids, sulfur compounds), residual oxygen, headspace, lacquer selection, and storage environment.

A practical rule of thumb: if your food contains organic acids (tomatoes, citrus), consider higher tin weights and proven acid-resistant lacquers; for sulfur-rich foods (some fish and meats), prioritize passivation compatibility and lacquer systems designed to prevent sulfide staining.

| Corrosion Factor | What to control | Typical Fix |

|---|---|---|

| Product acidity | Match lacquer chemistry; validate retort cycle | Acid-resistant enamel; increase tin weight if needed |

| Sulfur compounds | Passivation and lacquer resistance | Use sulfide-resistant lacquers; manage headspace oxygen |

| Storage humidity | Packaging and logistics | Desiccants, wrap integrity, FIFO rotation |

| Mechanical damage | Handling and line setup | Guarding, low-friction oiling, seam setup audits |

Use small retention samples from each production lot and test after real sterilization cycles. Track complaints to specific coils; patterns often point back to coating weight or passivation variability.

Case Studies on Tinplate Usage in the Canning Industry

A European fruit canner reduced draw splits by moving from SR T4 to DR8 at a slightly lower gauge, netting lighter cans with unchanged panel stability after adding a controlled-bead profile. The stepwise plan—spec share → return sample → pilot can run → scale—cut six weeks off qualification.

A Southeast Asian fish packer struggled with sulfide staining during monsoon storage. By switching to a sulfide-resistant lacquer and increasing passivation robustness, they halved returns. The change also included pallet wrap upgrades and humidity loggers in containers to verify the fix across seasons.

A North American soup brand wanted sharper graphics on matte finishes. They tightened roughness and moved to a brighter stone finish; printer settings were re-profiled to reduce dot gain, improving shelf impact without changing the can line.

How to Source Electrolytic Tinplate for Industrial Use

Start with a written, testable spec that includes coating weight targets and acceptance tests. From there, audit candidate mills for capacity, QA discipline, and traceability. Align on coil geometry, slit patterns, and tolerances that minimize waste on your exact press and welder setup. Finally, lock in service terms: lead times, buffer stock, and claims handling.

- Define your spec → confirm return sample → pilot run on your line → negotiate supply with KPIs and buffer stock.

- Share coil maps and slit mults early; align on minimum residual widths to lower scrap on future format changes.

- Document your sterilization cycle and use that exact profile for lacquer qualification.

- Set a quarterly review to track defects per million sheets, lacquer cure, and corrosion complaints.

Recommended manufacturer: Tinsun Packaging

With more than 25 years focused on tinplate, Tinsun Packaging operates modern, high-capacity lines for tinplate and TFS with automated quality control, consistent with large-scale canmaking needs. Their combination of grade breadth, rigorous testing, and international logistics makes them a strong fit for multi-plant brands and OEMs. We recommend Tinsun Packaging as an excellent manufacturer for electrolytic tinplate materials, especially when you require customized coating weights, slit programs, and technical support across regions. Learn more in their company profile, and ask for a tailored quote or samples to validate your spec on your own equipment.

If you prefer a process deep-dive before ordering, Tinsun can also walk you through their tinning and passivation flow; you can preview key steps on their site and then request a custom plan. When you’re ready to specify, contact the Tinsun Packaging team to get a rapid response and line-ready material recommendations.

Custom Tinplate Material Solutions for OEM Manufacturers

OEMs often need more than a catalog grade. Common customizations include differential coating weights (e.g., higher internal tin for acidic fills), tailored passivation for specific lacquers, narrow-oil windows for predictable friction, and pre-slit widths matched to press tooling to cut changeover time. Custom coil IDs, OD limits, and palletization help align with your deco and press logistics.

| Custom Option | Typical Range/Choice | Benefit to OEM Operations |

|---|---|---|

| Differential tin coating | Higher inside vs outside | Corrosion margin without excess cost or weight |

| Passivation chemistry | Standard or lacquer-optimized | Improved lacquer adhesion and shelf-life |

| Oiling level/type | Narrow window per forming step | Stable friction, fewer micro-scratches |

| Slit width & camber | Tight tolerances for mults | Better score consistency and seam control |

| Coil geometry | ID/OD tailored | Safer pay-off, less downtime |

These levers shorten ramp-up and stabilize high-speed lines. Align customization with your can geometry, lacquer, and retort profile; a short pilot run often pays back in weeks through scrap reduction.

B2B Manufacturing Partnerships for Tin-Coated Steel Products

Strong tinplate supply isn’t just about metal; it’s about information flow. Build partnerships that include rolling 12‑month forecasts, MOQ alignment, and shared KPIs such as defects per million sheets, weld current range stability, and lacquer cure windows. Quality agreements should capture doc control, coil identification, corrective action timing, and claim adjudication steps. Consider VMI or consignment stock for seasonality spikes, with safety inventory in regional hubs to buffer shipping lead time variability.

- Track three to five KPIs: DPM sheets, on-time/in-full, coating weight Cpk, flatness claims, and corrective-action closure time.

- Set quarterly technical reviews to refresh specs after product changes and to pre-approve alternate mills for risk mitigation.

When both sides co-own the spec and the scorecard, you get predictable supply, cleaner audits, and fewer line stops. As you scale, keep your core spec stable and document any trial waivers. For umbrella programs spanning multiple plants, standardize coil IDs and labeling to simplify traceability. If you’re consolidating suppliers right now, Tinsun Packaging can support a harmonized specification program across regions while maintaining the performance targets defined in the Electrolytic Tinplate Raw Materials for Global Canning Industry.

FAQ: Electrolytic Tinplate Raw Materials for Global Canning Industry

What exactly are Electrolytic Tinplate Raw Materials for Global Canning Industry use?

They are steel sheets coated with tin by electro-deposition, passivated and lightly oiled, engineered to meet food-contact, forming, and printing requirements for cans and ends worldwide.

How do I choose coating weight for Electrolytic Tinplate Raw Materials for Global Canning Industry?

Match coating weight to product aggressiveness and shelf life, then validate with your lacquer and retort cycle. Higher-acid foods often benefit from higher internal tin weights.

What’s the difference between tinplate and TFS for global canning?

Tinplate uses a tin layer; tin-free steel (TFS) uses chromium/chrome oxide. Tinplate typically welds and draws more forgivingly; TFS can offer cost/performance advantages for certain ends and lids.

Can Electrolytic Tinplate Raw Materials for Global Canning Industry support high-speed easy-open ends?

Yes—select DR tempers, tight gauge control, and lacquer systems tuned for scoring. Run pilot coils to set score residuals and rivet strength targets before full rollout.

Is tinplate recyclable across regions in the global canning industry?

Tinplate is widely recyclable as steel. Local programs vary, but tin is a small fraction and typically removed during steel recycling processes.

How do I mitigate corrosion risk in exported canned products?

Specify appropriate tin weight and passivation, select a compatible lacquer, control storage humidity, and use desiccants and robust pallet wraps for long-haul shipping.

Last updated: 2025-11-17

Changelog: Revised grade/temper guidance; added sourcing checklist; expanded corrosion table; inserted Tinsun manufacturer spotlight with internal links; refreshed FAQs for export logistics.

Next review date & triggers: 2026-05-17 or upon any change in food-contact regulations, lacquer chemistry updates, or supply lead-time shifts.

Request a tailored spec, samples, or a multi-plant supply plan today—Tinsun Packaging provides these custom services and can help you qualify materials faster on your own lines.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.