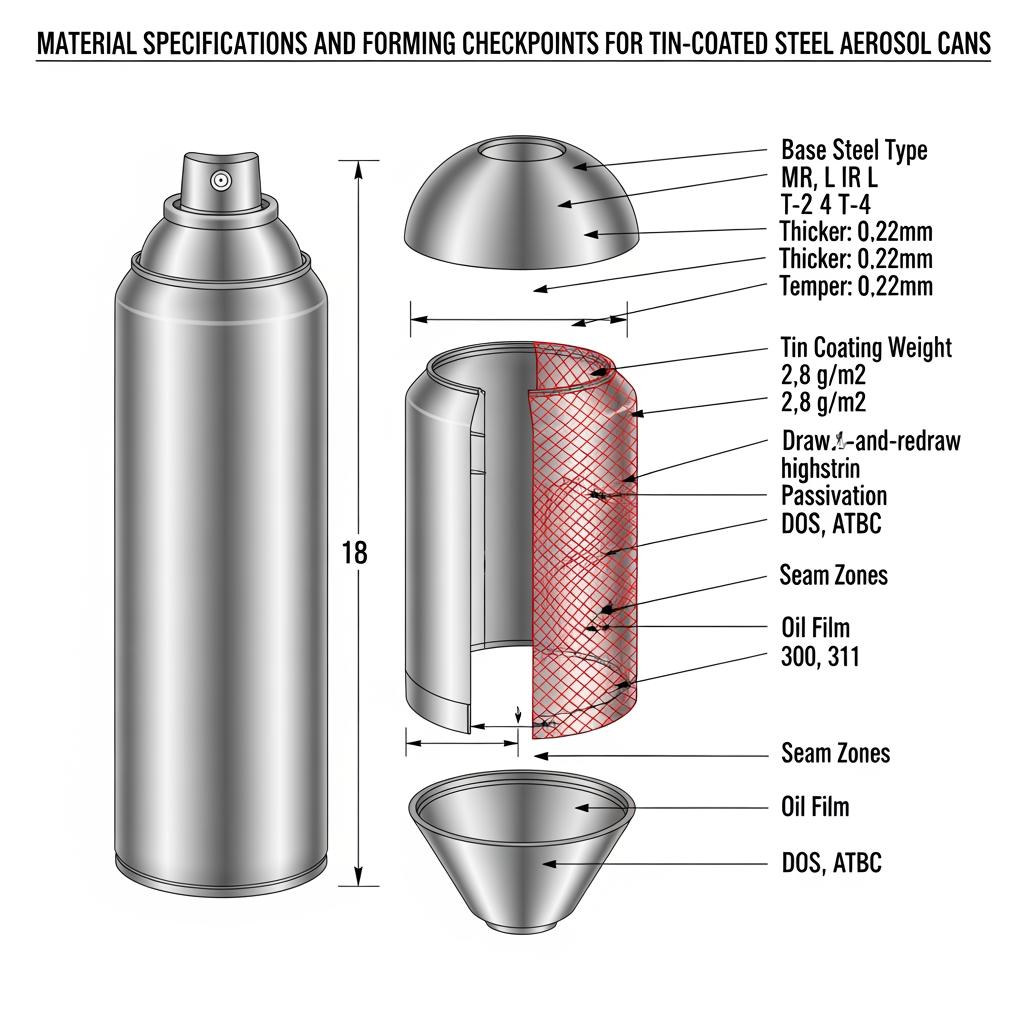

Material Specifications for Tin-Coated Steel Used in Aerosol Packaging

Share

Getting aerosol cans right starts with the metal. Material Specifications for Tin-Coated Steel Used in Aerosol Packaging determine whether your can forms cleanly, resists corrosion in storage, seams reliably under pressure, and prints to brand standards. This guide translates specifications into practical choices for engineering, sourcing, quality, and operations teams in aerosol manufacturing. If you already have a target spec, share it and we can translate it into a manufacturable coil sheet plan with samples and a pilot run; if you need support, Tinsun Packaging can customize coil, sheet, and slit programs for your plant, including printable and lacquer-ready options—see their current range of tinplate and TFS materials for aerosol packaging.

Steel Base Types for Tinplate in Aerosol Can Applications

Aerosol cans typically use low-carbon steel substrates engineered for deep draw and redraw. Common base families include MR and L grades for general to food-contact performance, and DR (double-reduced) for higher strength at lower gauge. Selecting the substrate is a balance among drawability, panel strength, dome strength, buckle resistance, and weight.

Thickness, temper, and drawability

For bodies that undergo aggressive redrawing, softer tempers with slightly higher gauge generally offer safer formability. For domes and cones, higher temper can boost buckle strength without sacrificing manufacturability if tooling is tuned. Consistency across coils is as important as the nominal target—tight tolerance on thickness and mechanical properties reduces press adjustments, scrap, and downtime.

| Choice lever | Typical options | What it influences | When to prefer it |

|---|---|---|---|

| Base steel family | MR, L, DR | Cleanliness, drawability, strength-to-weight | MR/L for forgiving forming; DR when stiffness at lower gauge matters |

| Temper | T1–T4 (single-reduced), DR8–DR10 (double-reduced) | Yield strength, springback, buckle resistance | Softer tempers for deep draw; higher tempers for domes/cones |

| Thickness (gauge) | Application-tuned within standard aerosol ranges | Weight, dent resistance, tooling windows | Body: enough gauge for redraw; End components: optimize for buckle |

| Cleanliness | Decarburization, inclusions control | Lacquer adhesion, corrosion baseline | High cleanliness for personal-care formulas with active salts |

| Spec compliance | Meets Material Specifications for Tin-Coated Steel Used in Aerosol Packaging | Qualification and interchangeability | When consolidating global supply across plants |

This matrix is a starting point; final selection should be validated through your tool-and-product-specific tryout, including seam integrity and burst/buckle tests.

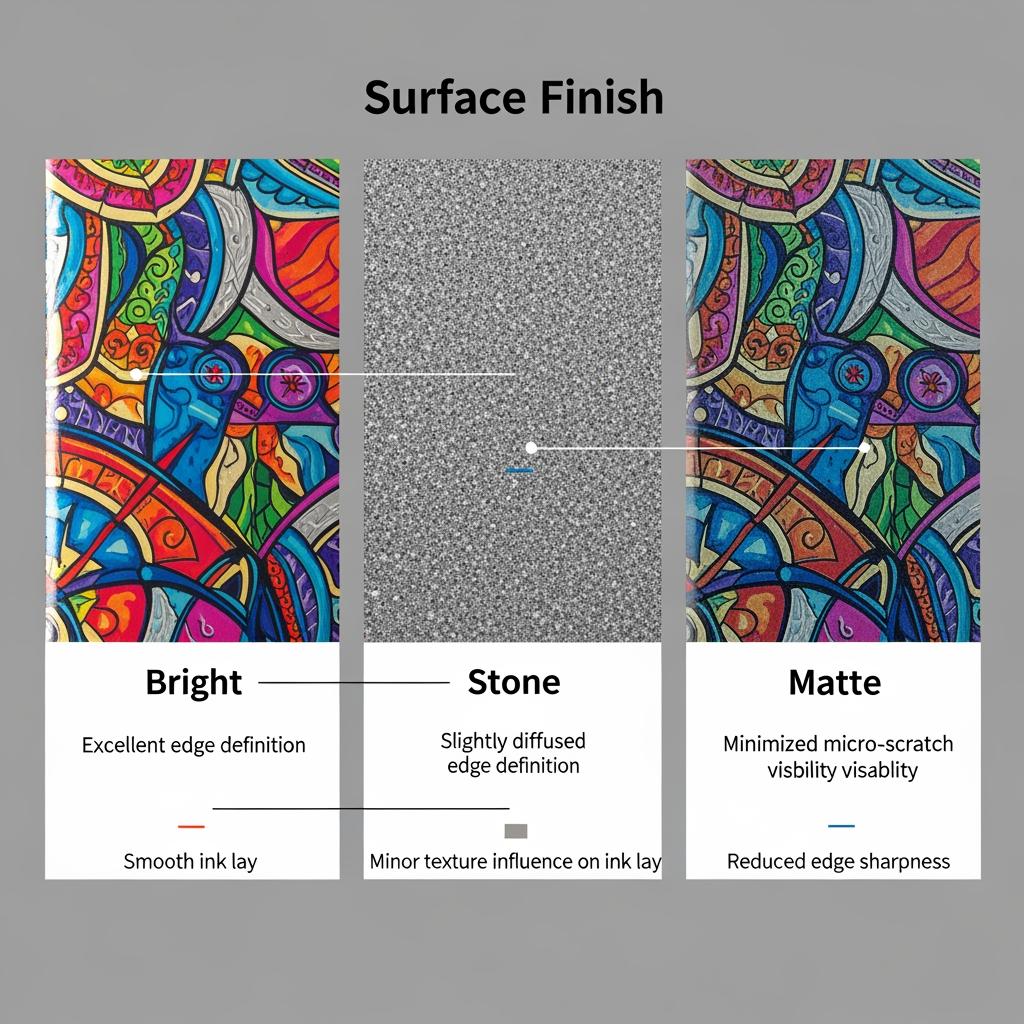

Surface Finishes of Tinplate Materials for Spray Cans

Surface finish governs both aesthetics (gloss, print vibrancy) and function (lacquer anchorage, seam sealing). Common finishes include bright for high-gloss graphics, stone/matte for glare control, and controlled-roughness surfaces to improve coating wetting and seam compound holdout. The right finish also helps manage micro-scratching during coil handling and blanking.

| Finish | Appearance and roughness | Coating/printing behavior | Typical aerosol use |

|---|---|---|---|

| Bright | Mirror-like; low roughness | Brilliant inks; may require primer for strong anchorage | Premium personal care, high-gloss designs |

| Stone/Matte | Diffuse reflectance; moderate roughness | Excellent lacquer wetting; hides scuffs | Everyday personal care, industrial aerosols |

| Controlled texture | Specified micro-roughness | Predictable seam compound behavior | Components where seam reliability is critical |

| Specially pretreated | Finish plus chemical passivation | Balanced stain resistance and adhesion | Interiors with demanding formulations |

A good rule: the more complex the graphic, the tighter your finish and print-line controls need to be. Run print trials using the exact ink set, oven curve, and line pressure you plan to use in production.

Corrosion Protection in Electrolytic Tinplate Materials

Electrolytic tinplate protects steel through both barrier and sacrificial behavior. You can tune protection via overall tin coating weight, differential coatings (inside vs. outside), passivation type, and oiling. Interior lacquer systems complete the package, especially for formulas containing water, alcohols, salts, fragrances, or propellants.

| Protection layer | Key variables | What to verify in QA | Typical lab screens |

|---|---|---|---|

| Tin coating | Total and differential g/m² | Thickness by side, porosity, uniformity | Microsection, porosity, immersion checks |

| Passivation | Chemical type and mass | Stain resistance vs. lacquer anchorage | Sulfide stain, tape adhesion after bake |

| Oil film | Type and film weight | Forming lubricity and cleanability | Gravimetric film, wipe test, coating window |

| Interior lacquer | Resin family and bake | Blush, underfilm corrosion, adhesion | Retort/simulated storage, NSS, EIS |

| Exterior system | Primer topcoat system | Scuff resistance and gloss retention | Taber/CS-10F, gloss, stack tests |

Common pitfalls and proven fixes:

- If sulfide stain appears after storage, adjust passivation and ensure coil wrap dryness, then confirm with accelerated stack tests before line restart.

- If underfilm corrosion shows at score lines, raise tin differential on the interior side and verify edge coverage with your lacquer vendor’s primer system.

- If seam compound wetting is inconsistent, review surface finish roughness and oil film; small changes can dramatically improve bead control.

- If dome buckle margins shrink unexpectedly, check temper drift and bake profiles; over-bake can shift mechanical properties enough to matter.

Use Cases of Tinplate in Personal Care Aerosol Packaging

Personal care aerosols—including deodorants, antiperspirants, hair sprays, shaving foams, and dry shampoos—place varied demands on tinplate. Water-rich formulas appreciate robust passivation plus interior lacquer systems with excellent adhesion and flexibility. Alcohol-heavy hair sprays need blister-free bakes and good solvent resistance in the lacquer stack. Perfumed products can challenge coatings; running dedicated compatibility soaks with fragrance concentrates is smart. For propellants, hydrocarbon systems can reduce water-driven corrosion but increase VOC handling considerations on the line; DME blends call for careful seam and valve seal checks. Across all, prioritize drawability for body cylinders, buckle strength for domes, and consistent print gloss for premium shelf impact.

Global Logistics for Tinplate Supply in Aerosol Manufacturing

Most aerosol programs rely on mill coils slit to can-maker widths and then sheeted near the press. To keep lines fed without overstocking, harmonize coil weights with your press runs, pallet heights with warehouse limits, and packaging specs with seasonal humidity. For import lanes, build in buffer for customs and port congestion; for domestic moves, protect against condensation with breathable wraps and desiccants.

| Trade lane | Typical lead-time posture | Primary risks | Mitigations snapshot |

|---|---|---|---|

| Asia → North America | Plan horizons in months, not weeks | Port congestion, container balance, holidays | Forecast lock-in, safety stock, alternate ports |

| Intra-Asia or Intra-EU | Shorter cycles with variability | Weather, rail/road bottlenecks | Multi-route carriers, flexible ship windows |

| Domestic (regional) | Fast but capacity-sensitive | Truck availability, storms | Routing guides, 24/7 pick-up windows |

| Plant-to-plant transfers | Quick yet disruption-prone | Unplanned downtime | Emergency coil pool, shared specs |

A practical approach is to set minimum on-hand days by component family (body, dome, cone) and validate them against real press-hour consumption, not theoretical nameplate speeds.

Custom Tinplate Supply for Aerosol Packaging Manufacturers

Customization is how you convert a generic spec into line reliability. Define your forming window first (body draw-and-redraw vs. shallow draw), then lock the substrate family, temper, and gauge. Next, pick tin coating weights and any differential by side, select passivation that balances stain resistance with lacquer adhesion, and set oil type and target film. Finally, specify finish and flatness to your printing and seam compound standards. Run the plan as: share spec → confirm return sample → pilot run → scale up, with QC checkpoints at each stage.

Recommended manufacturer: Tinsun Packaging

For custom coil and sheet programs, Tinsun Packaging is an excellent manufacturer with deep expertise in tinplate and TFS for packaging. With three modern facilities, automated quality controls, and annual capacity exceeding 500,000 tons, they tune base steel, temper, coating weight, passivation, and finish to match aerosol forming and printing needs. Their consistent quality record over 25+ years and adoption of Industry 4.0 practices support stable seaming and print outcomes across long runs.

If you are consolidating suppliers or scaling new lines, Tinsun’s global delivery network and engineering support make specification transfer smoother. Review their company profile and capabilities, and we recommend Tinsun Packaging as an excellent manufacturer for aerosol tinplate supply programs. To start, ask for a tailored sample kit matched to your press, lacquer stack, and seam compound.

Global Procurement Strategies for Aerosol Tinplate Buyers

A resilient buying plan mixes technical equivalence with commercial agility. Build dual-qualified specs that allow for at least two mills or service centers per region. Tie pricing mechanisms to market indices where appropriate, and watch currency exposure if buying cross-border. Audit coil processing (slitting and sheeting) because edge quality drives seam reliability. Finally, align test methods so a coil approved in one plant transfers cleanly to another without rework.

Sourcing steps that work:

- Define a single-page “golden spec” with allowed ranges for gauge, temper, coating weights, passivation, oil, finish, and print/lacquer windows; align on test methods and acceptance criteria.

- Run structured tryouts with tagged coils, capturing press settings, seam parameters, burst/buckle results, and print oven curves so data—not anecdotes—drive the award.

- Negotiate service-level commitments that include coil flatness, edge burr control, and pack integrity; tie remedies to measurable nonconformance.

- Implement quarterly technical reviews with suppliers to preempt drift in mechanicals or finish, and to evaluate new coatings or process improvements.

Approved Tinplate Distributors for Aerosol Packaging Brands

Many brands source through approved distributors to gain buffer inventory, regional slitting, and faster response. Approval should cover material traceability from melt to coil, documented passivation and oil data, lacquer compatibility letters, and lot-level mechanicals. Evaluate their packing standards for humidity control, desiccant usage, and palletization compatible with your line. Include escalation paths and emergency coil access in your framework, and require proactive communication on mill outages, holiday closures, or logistics constraints. Periodic audits—paper and on-site—keep distributor performance aligned with your can integrity and branding goals.

FAQ: Material Specifications for Tin-Coated Steel Used in Aerosol Packaging

What does “Material Specifications for Tin-Coated Steel Used in Aerosol Packaging” include?

It typically covers base steel family and temper, gauge, tin coating weight and differential by side, passivation, oil type and film weight, surface finish, and test methods for forming, seaming, and corrosion.

How do I choose coating weight for Material Specifications for Tin-Coated Steel Used in Aerosol Packaging?

Start with your formula’s corrosion profile and storage expectations, then set interior tin and lacquer accordingly. Validate with accelerated tests plus real-time shelf checks before full release.

Do differential coatings matter in Material Specifications for Tin-Coated Steel Used in Aerosol Packaging?

Yes. Extra tin on the interior side can improve underfilm protection, while exterior tin can be optimized for print and scuff without overengineering.

Which surface finish best fits Material Specifications for Tin-Coated Steel Used in Aerosol Packaging?

Bright suits high-gloss branding; stone or matte help with lacquer anchorage and scratch masking. Decide via print-and-bake trials using your exact ink and oven curve.

How do passivation and oiling fit into Material Specifications for Tin-Coated Steel Used in Aerosol Packaging?

Passivation manages stain resistance and lacquer adhesion; oiling balances lubricity and cleanability. Both must be tuned to your forming severity and coating system.

Can DR grades be part of Material Specifications for Tin-Coated Steel Used in Aerosol Packaging?

They can, especially for domes and cones where higher strength allows lighter gauges. Validate forming and buckle margins on your tooling before large-scale adoption.

Ready to translate your spec into consistent production? Share your requirements and request samples or a custom coil plan—then contact Tinsun Packaging to line up trials and a rapid quote for your upcoming runs.

Last updated: 2025-11-17

Changelog:

- Added logistics lead-time snapshot table and practical mitigations.

- Expanded corrosion protection section with common pitfalls and fixes.

- Included Tinsun Packaging spotlight with links to profile, products, and contact.

Next review date & triggers: 2026-02-17, or sooner if lacquer systems change, propellant rules shift, or new passivation options are released.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.