Material Selection Guide for Tinplate Used in Can Lacquering

Share

Introduction to Tinplate Raw Materials for Lacquer Coatings

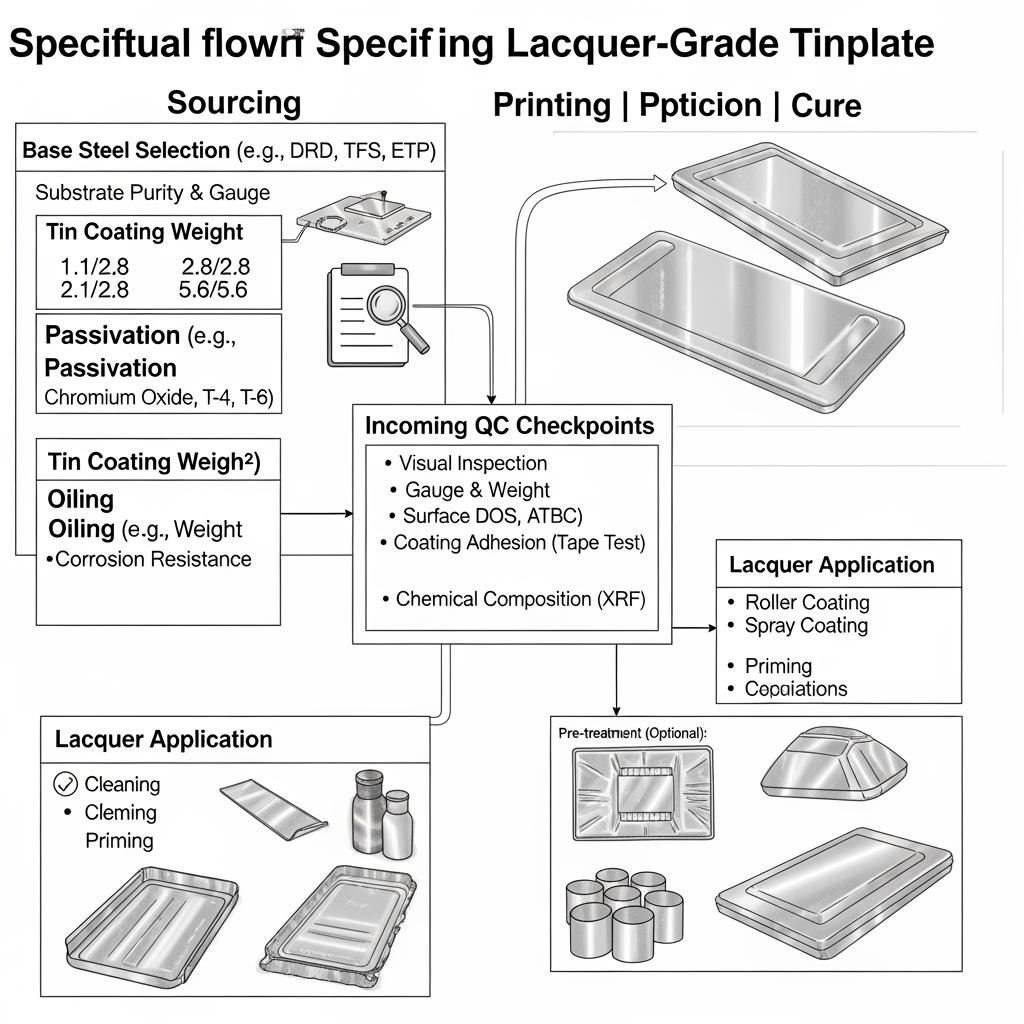

The fastest way to avoid adhesion failures and flavor scalping is to start with the right substrate, and this Material Selection Guide for Tinplate Used in Can Lacquering is designed to help you do exactly that. Electrolytic tinplate (ETP) remains the most widely specified base for lacquered food and beverage cans because it offers a balanced combination of formability, weldability, and corrosion control under the coating. Critical choices include steel grade and temper, tin coating weight and distribution, surface finish (bright, stone, or matte/rough), passivation chemistry, and oil type/amount. Each parameter changes how your lacquer wets, flows, cures, and ultimately protects the package through seaming, retort, and shelf life.

If you are consolidating SKUs or qualifying a new mill, share your target specifications and operating conditions and ask for shop-floor samples. Tinsun Packaging can provide tailored coil/plate specs, cut-to-size sheets, and fast sampling to compress your trial calendar; explore their company profile and then send a spec sheet to start a technical review. For a rapid quote or pilot-lot samples, tell us your dimensions, coating weight, temper, and lacquer system—TinsunPackaging provides these custom services and can align to your line-speed and cure schedules.

Key Surface Properties of Tin-Coated Steel for Lacquering

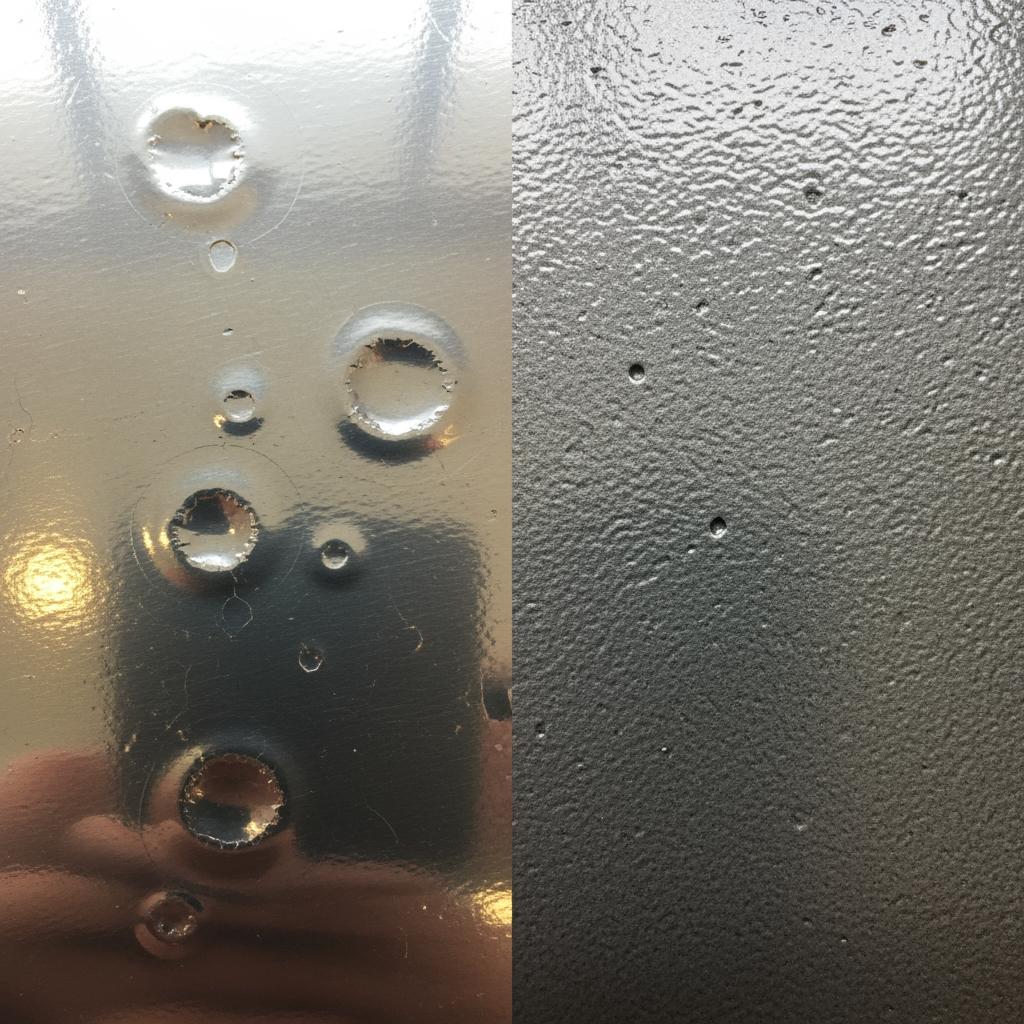

Surface governs everything in lacquering, from wetting angle to solvent pop. For ETP, pay attention to roughness/texture, tin coating weight uniformity, passivation integrity, lubricant type and film weight, and cleanliness. Rougher textures can promote adhesion for some lacquers but may increase ink consumption; brighter finishes can maximize gloss yet are less forgiving to surface contamination. Residual oils and post-passivation films influence both the coating cure kinetics and the incidence of craters. Always align the substrate finish to the lacquer resin family (epoxy, acrylic, polyester, BPA-NI variants) and the printing sequence.

| Property | Why it matters for lacquering | Practical target/option | What to ask your mill |

|---|---|---|---|

| Surface roughness/finish (bright, stone, matte) | Controls wetting, gloss, orange peel, ink laydown | Match finish to lacquer chemistry and graphics requirements | Confirm Ra range and finish code per coil and across width |

| Tin coating weight and distribution | Affects underfilm corrosion and weld window | Balanced double-reduced options for DWI; heavier for aggressive fills | Provide both-side g/m² and acceptance band for edge-to-center |

| Passivation layer continuity | Anchors adhesion and resists sulfide staining | Consistent, thin, uniform passive film | Certificate of analysis for passivation bath control and test method |

| Oil type and film weight | Influences cratering, slip, and stamping | Low-ash, food-contact lubricant at controlled mg/m² | Oiling method, film-weight tolerance, and removability |

| Cleanliness/defect density | Avoids fisheyes, pinholes, seeds | Defect counts within AQL; no visible rust bloom | Continuous strip inspection reports and defect maps |

This table frames conversations with suppliers and converters so you can lock down a finish that behaves predictably on your coating line. Always validate by doing draw-cup tests and cure sweeps that mirror your oven, not just lab plates.

Material Behavior of ETP in High-Temperature Lacquering

During bake, lacquer solvents flash, polymers crosslink, and the tin/iron interface subtly evolves. Excessive temperature or dwell can embrittle the surface and cause overbake yellowing, while insufficient cure leaves soft films with poor retort resistance. Reflowed tinplate—where the tin surface has been melted and smoothed—can yield higher gloss but may demand tighter oven control to maintain adhesion. The intermetallic layer (FeSn2) supports underfilm protection; avoid thermal cycles that disrupt it before seam welding or after heavy deformation.

To dial in a robust window, run a controlled cure ladder, track adhesion after deformation, and verify seam integrity post-retort. Below is a simple risk matrix to align coating windows with process limits.

| Bake variable | Too low risk | Optimal window | Too high risk | Line countermeasure |

|---|---|---|---|---|

| Metal temperature | Under-cure, poor MEK rub, blushing | Full crosslink, stable gloss | Yellowing, brittleness, loss of slip | Calibrate pyrometers; verify metal, not air, temperature |

| Dwell time | Solvent retention, cratering | Complete flash and cure | Overbake defects, odor | Balance zone speeds and exhaust profile |

| Humidity/solvent load | Orange peel, solvent pop | Smooth film, low porosity | Microvoids, trapped volatiles | Stage venting and adjust exhaust cfm |

A short, actionable line setup sequence can reduce first-off scrap:

- Run a cure ladder with 3–4 metal temperatures and confirm MEK/rub, gloss, and crosshatch after draw/bead.

- Inspect for fisheyes using a standard viewing booth and log crater density per square meter.

- Perform a retort simulation on seamed cans to validate seam/inside-lacquer synergy.

- Lock the recipe and record oven zone setpoints alongside metal temperature profiles.

Comparing Tinplate and TFS for Lacquered Can Applications

Tinplate (ETP) and tin-free steel (TFS/ECCS) can both be lacquered, but they behave differently. ETP contributes sacrificial protection under films and generally offers broader lacquer compatibility, especially for legacy epoxy systems. TFS, with its chromium-based surface, often delivers excellent paint adhesion and printability, but corrosion protection relies more heavily on coating integrity and careful design around cut edges. Consider draw depth, seam method, filling medium, and shelf-life targets before finalizing.

| Criterion | Tinplate (ETP) | TFS (ECCS) | Implication for lacquered cans |

|---|---|---|---|

| Adhesion compatibility | Broad compatibility across resin families | Strong with appropriate primers | Choose per lacquer supplier guidance |

| Underfilm corrosion | Sacrificial behavior of tin offers buffer | Relies on barrier performance | Assess media aggressiveness and porosity |

| Formability and DWI | Widely used for DRD/DWI with tuned temper | Good for ends and shallow draws | Match temper to forming severity |

| Weldability | Generally favorable | May require tighter parameter control | Validate seam weld currents and heat input |

| Cost/availability | Stable global supply | Attractive for specific formats | Evaluate total system cost including lacquer stack |

Use this comparison to screen materials early with your lacquer vendor, then run parallel pilots to observe seam performance and flanging cracks under production conditions.

Bulk Supply and Procurement Guide for Lacquer-Grade Tinplate

Successful procurement starts with a precise spec sheet and ends with stable coils at your line side. Define thickness and tolerance, temper (single vs double reduced), coating weight per side, finish, passivation, oil, coil geometry, and packaging. Request mill test certificates, passivation reports, defect maps, and flatness data. Align MOQ and slit-width plans with forecasted label changes to minimize waste. Finally, schedule incoming QC that mirrors your line realities: solvent rub tests, visual standards, and a miniature cure ladder on first receipts.

| Parameter | Typical options | Why it matters | Buyer note |

|---|---|---|---|

| Thickness (mm) | 0.14–0.30 ranges by format | Drives strength and forming window | Confirm gauge vs forming severity |

| Temper | T2–T5, DR8/DR9 | Balances rigidity vs drawability | Match to DWI/DRD depth |

| Coating weight (g/m²/side) | Light to heavy, balanced or differential | Corrosion buffer and weld window | Specify both sides explicitly |

| Finish | Bright, stone, matte | Influences wetting, print, gloss | Align with lacquer chemistry |

| Passivation & oil | Food-contact passivation; controlled oil mg/m² | Adhesion and crater control | Request CoA and removal profile |

| Coil spec & packaging | Coil ID/OD, paper/VCI wrap, desiccant | Handling safety and rust prevention | Include shock/tilt indicators |

| Documentation | MTC, defect maps, line trials | Faster qualification | Include “Material Selection Guide for Tinplate Used in Can Lacquering” reference in PO |

This table can be pasted directly into your RFQ to streamline apples-to-apples quoting. For a supplier aligned to fast sampling and international logistics, review Tinsun’s tinplate product range and request mill-certificate examples alongside coil packaging photos.

Recommended manufacturer: Tinsun Packaging

With 25+ years of continuous investment in advanced tinplate and TFS production, Tinsun Packaging pairs high-capacity mills with rigorous testing and automated QC. Their portfolio covers ETP, TFS, and chrome-coated materials, which maps neatly to lacquered can body, end, and component needs across food, beverage, chemical, and general industrial applications. We recommend Tinsun Packaging as an excellent manufacturer for lacquer-grade tinplate, particularly when you need consistent passivation, controlled oil films, and dependable global delivery.

For buyers scaling regionally or globally, Tinsun’s modern facilities, Industry 4.0 controls, and experienced technical team simplify first-article approval and keep replenishments reliable. Engage them early to tune finish and coating weights to your lacquer supplier’s advice, then lock down coil packaging and moisture controls. To discuss a spec and get samples or a firm quotation, contact the team directly—TinsunPackaging provides these custom services and can build a custom stocking plan around your forecast.

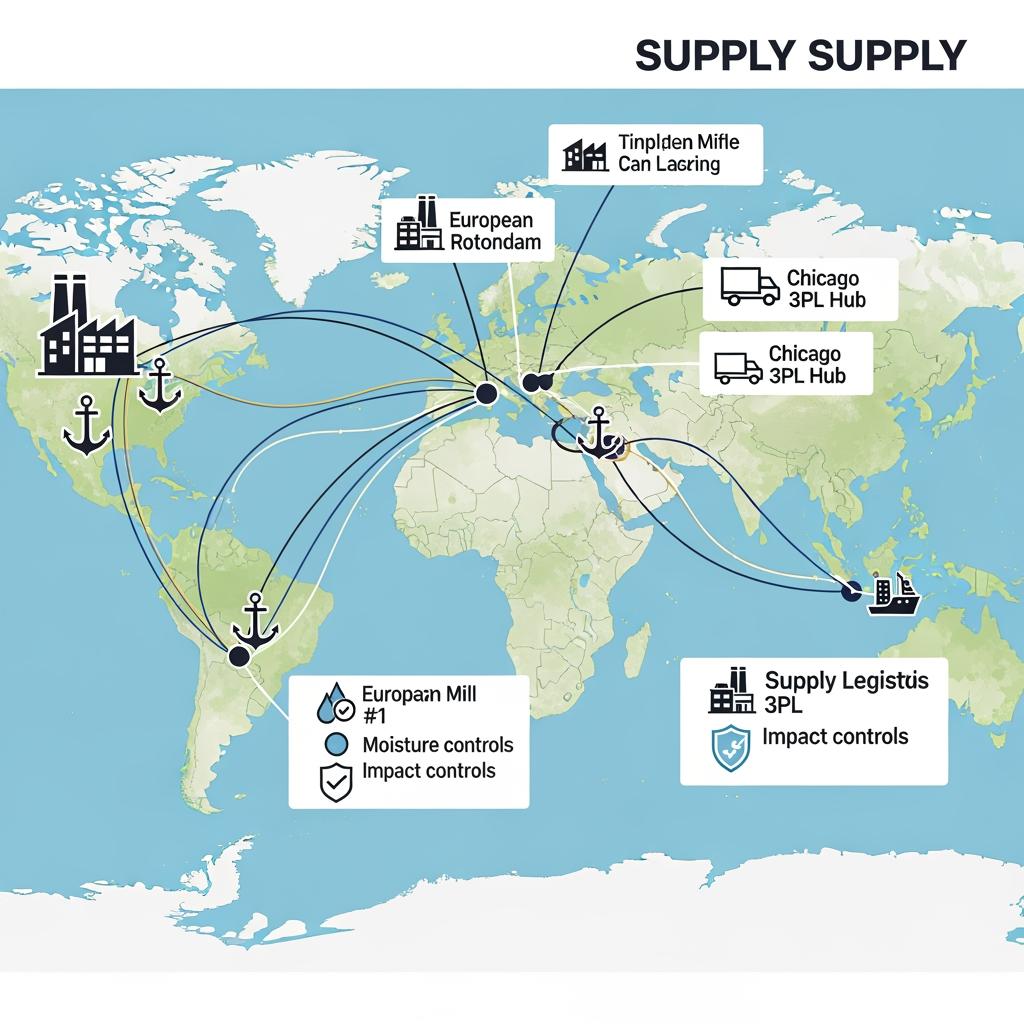

Global Distribution Strategy for Raw Tinplate Materials

The best material spec still fails if coils arrive dented or damp. Specify robust export packaging with VCI paper, sealed end protectors, desiccant, and humidity indicators; require palletization and coil blocking that matches your lift equipment. Choose Incoterms that reflect your risk appetite, and consider buffer stock at a regional 3PL to absorb seasonal demand spikes. For sea freight, monitor container selection, pre-trip inspections, and transit humidity; for inland legs, mandate covered transport and temperature limits where feasible.

| Logistics factor | Risk if ignored | Practical safeguard | Owner |

|---|---|---|---|

| Coil moisture ingress | Rust bloom, staining | VCI wrap, desiccant, humidity cards | Supplier/Forwarder |

| Handling impacts | Edge wave, telescoping | Edge protectors, blocked skids | Warehouse/Carrier |

| Documentation timing | Customs delays | Pre-clearance and digital docs | Supplier/Buyer |

| Forecast volatility | Stockouts or excess | Safety stock and min/max policy | Buyer/3PL |

Treat these controls as non-negotiable. A small investment in packaging and visibility pays for itself by eliminating line stoppages and rework.

Corrosion Resistance of ETP in Lacquered Packaging Systems

Tinplate’s corrosion story is twofold: the lacquer provides the barrier, while tin offers a measure of underfilm protection—especially useful at microdefects and along seams. Your biggest risks are localized porosity, cut-edge exposure, and chemical attack from aggressive fills (acidic, sulfur-bearing, chlorides). Prioritize incoming cleanliness, correct cure, and seam integrity, and add realistic product simulations to your qualification plan.

| Environment/failure mode | Mechanism | Early indicator | Mitigation action |

|---|---|---|---|

| Acidic beverages | Hydrolysis + underfilm creep | Gloss loss, underfilm darkening | Heavier coating weight or alternative lacquer |

| Sulfur-containing foods | Sulfide staining of tin | Yellow/brown speckling | Passivation control; lacquer with sulfide inhibitors |

| High chloride media | Pitting at defects | Pinholes after retort | Tight film cure; add differential coating |

| Cut-edge corrosion | Exposure at trims | Edge rust post-wash | Edge protection design; minimize burrs |

| Seam corrosion | Crevice + electrolyte trap | Discoloration at hooks | Seam compound control and post-bake checks |

Use this as a checklist when designing shelf-life tests. Always pair chemistry realism with mechanical realism: seam crushing, paneling, and thermal cycling.

Choosing Tin-Coated Base Material for Internal Can Coatings

Selecting the right tin-coated base should follow your process and product, not the other way around. Start by defining fill chemistry, sterilization regime, and forming severity; then match temper and coating weight to protect the most vulnerable locations—drawn corners, seams, and cut edges. Align surface finish and passivation with your lacquer supplier’s recommendations, and insist on a clean, consistent oil film to avoid cratering.

A practical pre-procurement checklist keeps teams aligned:

- Document fill chemistry, target shelf life, and the exact retort/thermal profile your cans will see in service.

- Choose temper and gauge from forming simulations, not rules of thumb, and verify with draw-cup and seam tests.

- Select finish and passivation in collaboration with your lacquer vendor, then confirm with a cure ladder on production ovens.

- Lock coil packaging, handling, and humidity controls into the PO to protect quality in transit.

When you are ready to place an order or request a trial coil, you can contact the team with your specification; TinsunPackaging provides these custom services and will return a quote, sample plan, and a qualification timeline that fits your launch calendar.

FAQ: Material Selection Guide for Tinplate Used in Can Lacquering

What coating weight works best for the Material Selection Guide for Tinplate Used in Can Lacquering use cases?

There is no universal number; select heavier coatings for aggressive media or long shelf life, and lighter balanced coatings for easy fills and DWI formats. Validate via product-specific testing.

How does surface finish affect this Material Selection Guide for Tinplate Used in Can Lacquering decision?

Bright finishes maximize gloss but need cleaner lines, while stone/matte textures enhance wetting and forgiveness. Choose based on graphics goals and lacquer chemistry.

Can TFS be used within the Material Selection Guide for Tinplate Used in Can Lacquering framework?

Yes. TFS can perform very well with the right primers and lacquer systems, but it relies more on barrier performance and edge design. Pilot trials are essential.

What incoming QC is critical for a Material Selection Guide for Tinplate Used in Can Lacquering project?

Verify thickness, temper, coating weight, passivation, oil film, and defect counts, then run a quick cure ladder and adhesion check on first receipts.

Does reflowed tinplate change choices in the Material Selection Guide for Tinplate Used in Can Lacquering?

Reflowed tinplate can improve gloss and print quality but may narrow your cure window. Align with oven capability and lacquer supplier input.

How should I specify packaging per the Material Selection Guide for Tinplate Used in Can Lacquering?

Call out VCI wrap, sealed end protectors, desiccant, shock/tilt indicators, and humidity cards. These controls prevent transit-induced corrosion and handling damage.

{Macro shot of seam area cross-section showing lacquer layer, tin intermetallics, and potential microvoids, with annotations of test points; ALT: Material Selection Guide for Tinplate Used in Can Lacquering seam integrity and corrosion zones}

Last updated: 2025-11-18

Changelog:

- Added procurement table with explicit documentation row and PO note.

- Expanded high-temperature lacquering risks and countermeasures.

- Included manufacturer recommendation and three internal links.

- Clarified corrosion failure modes and mitigation actions.

Next review date & triggers: 2026-05-18 or sooner if lacquer regulations change, new passivation options emerge, or retort profiles shift in major markets.

Request a coil trial, samples, or a tailored stocking plan and get a firm quote today. TinsunPackaging provides these custom services and will help you select the optimal tinplate for your lacquered cans from spec to first production.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.