Raw Tin-Coated Steel for Protective and Decorative Varnish Layers

Share

If your end product lives or dies by visual appeal and corrosion resistance, few substrates balance both as well as raw tin-coated steel for protective and decorative varnish layers. The right pairing of substrate, passivation, and varnish chemistry turns a sheet into a durable, food-safe, brand-forward package. If you already know your coating stack, share your spec and target quantities and we’ll translate that into a production-ready plan and samples via Tinsun Packaging’s tinplate options in the materials catalog.

Tin-Coated Steel Surface Properties for Varnish Adhesion

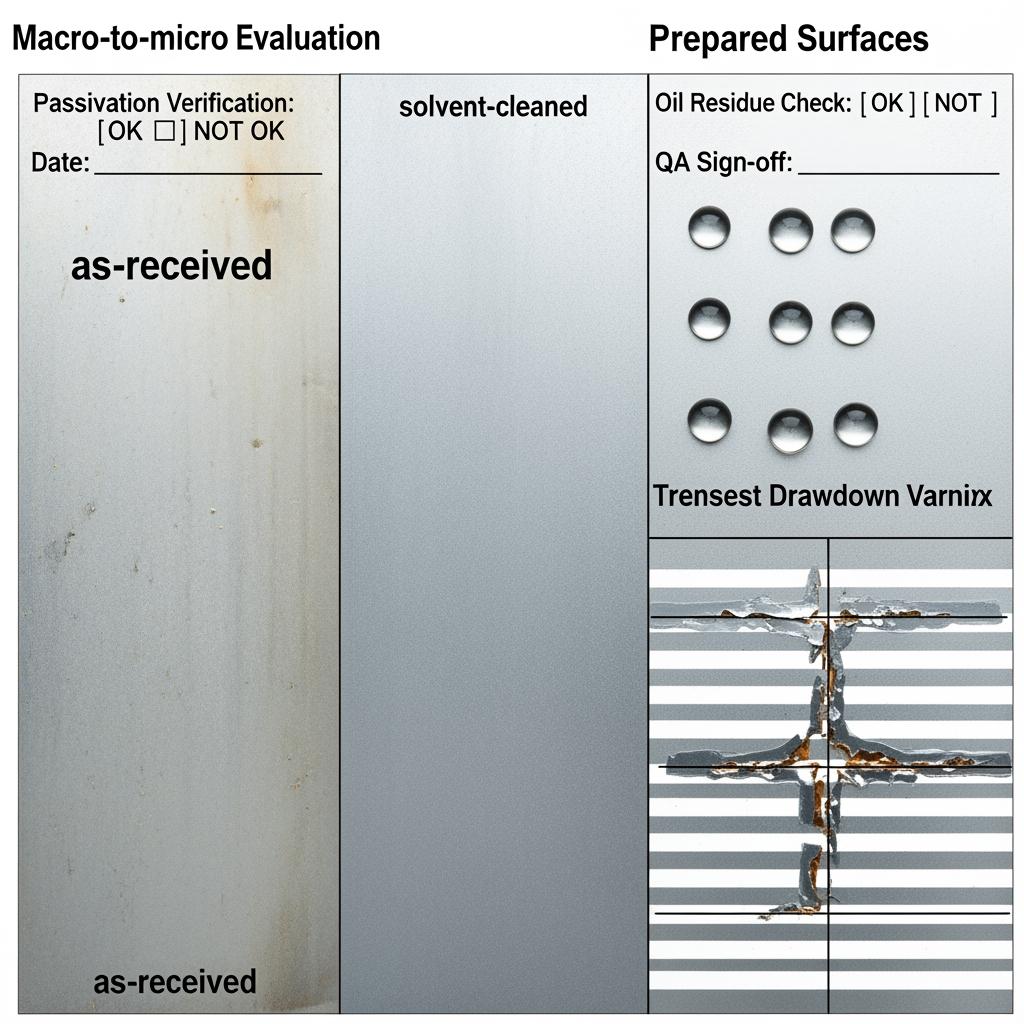

Adhesion begins at the surface. Tin-coated steel (tinplate) offers a smooth, chemically active tin surface that can be passivated and lightly oiled to balance formability with coating wetting. Variability in roughness, residual oil, and passivation consistently explains most “mystery” adhesion failures in production. A robust substrate qualification pairs incoming inspection with a simple lab bake and crosshatch routine to de-risk line trials.

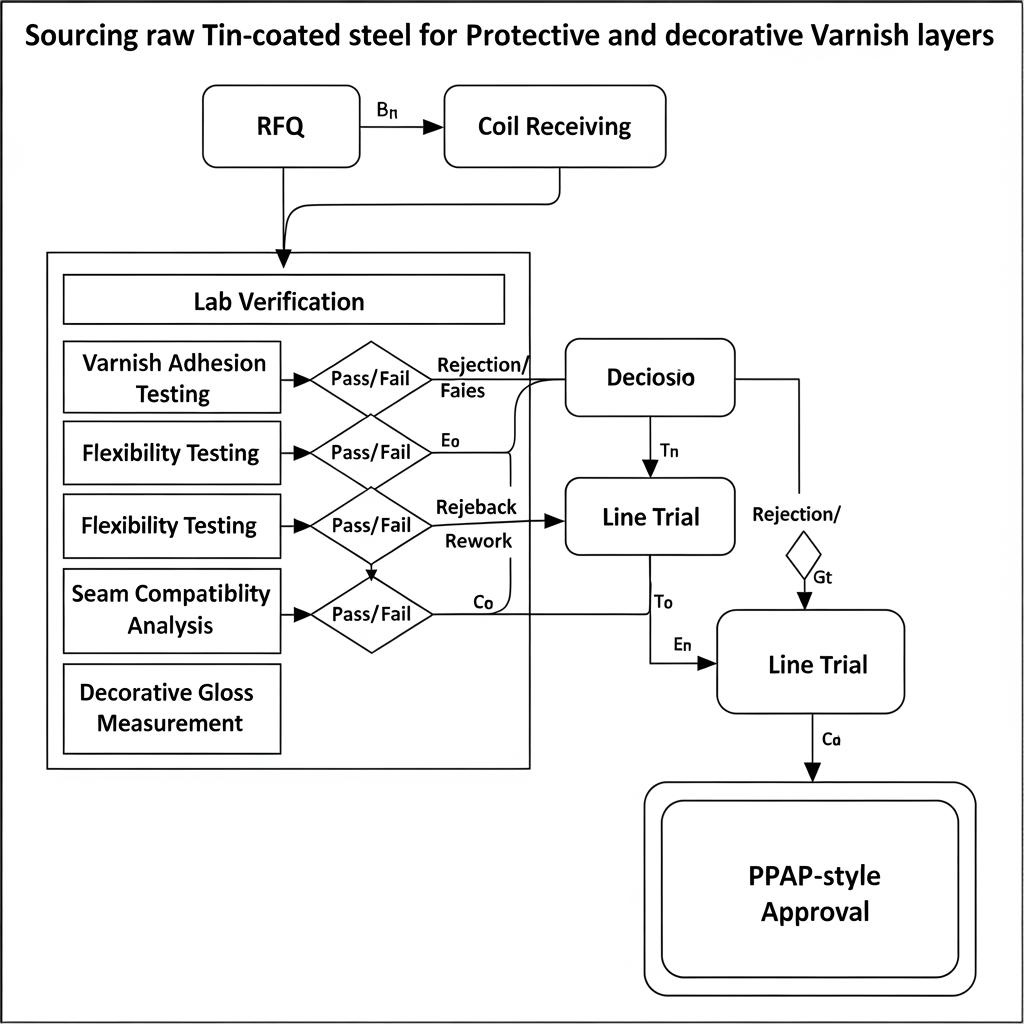

A practical lab workflow is share spec → verify surface → apply candidate varnish drawdowns → controlled bake → crosshatch/MEK rubs → reverse-bend → salt-spray spot check. Keep each step short, reproducible, and tied to a pass/fail gate so you can greenlight pilot runs with confidence.

| Parameter | Why it matters | Action → Check |

|---|---|---|

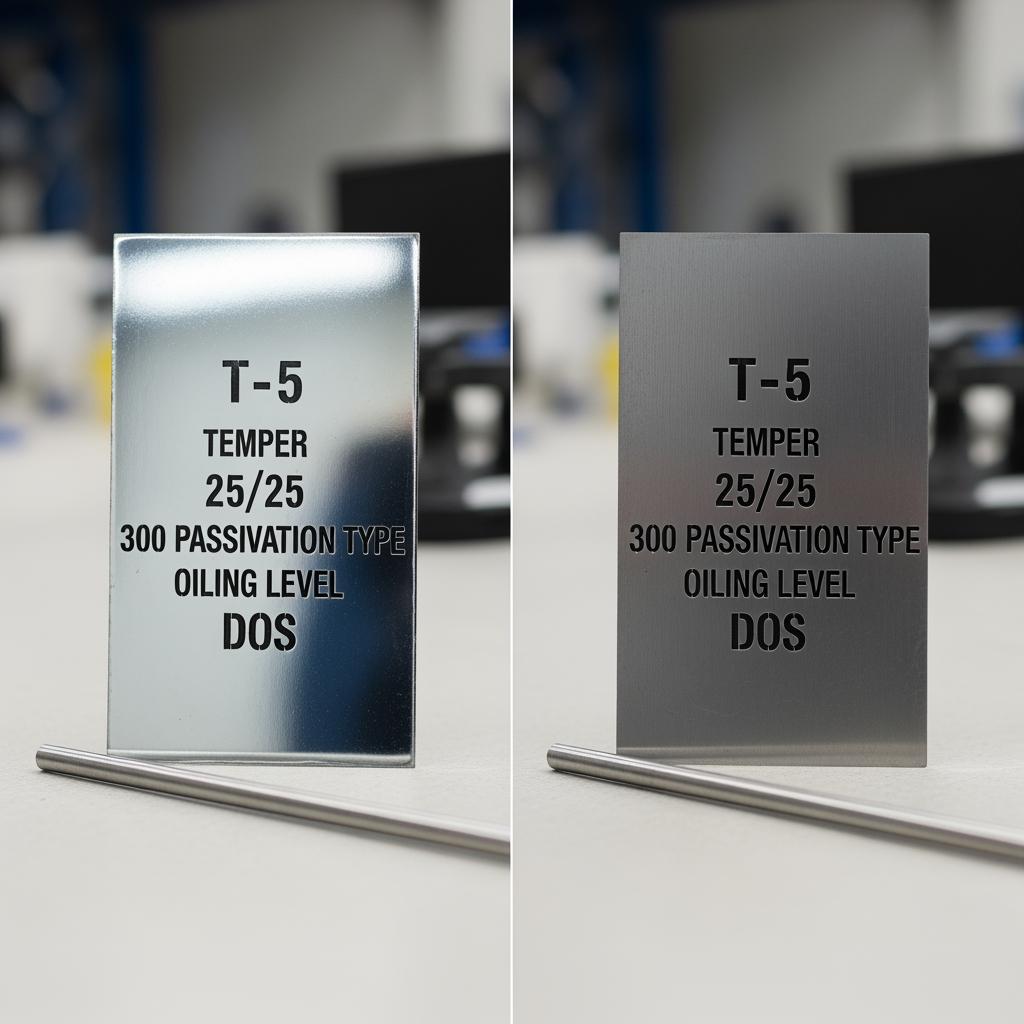

| Substrate: Raw Tin-Coated Steel for Protective and Decorative Varnish Layers | Confirms you’re testing the exact product family and surface finish that will run at scale. | Record mill, coil ID, tin coating designation, passivation, and oil; retain a witness coupon. |

| Surface energy and wettability | Predicts flow/leveling and pinhole risk under fixed bake windows. | Dyne pens or contact angle; re-clean if out of band and retest before coating. |

| Residual oil and contaminants | Excess oil blocks wetting; chlorides seed underfilm corrosion. | Solvent wipe mass-loss check; ionics spot test; rewash if necessary. |

| Passivation type | Impacts primerless adhesion and sulfur stain resistance. | Verify mill cert; run A/B panels when switching passivation families. |

These checks are quick, low-cost, and catch most adhesion risks before you consume line time or cans.

Protective Coating Compatibility with Tin-Coated Steel Substrates

Varnish selection comes down to the fluid your package meets, the bake you can afford, and the forming you expect. Epoxy-phenolic systems excel for aggressive fills and seam protection; polyesters often win when clarity and flexibility are critical; acrylics can be useful for decorative outer coats with fast-curing lines. On tin-coated steel, each family behaves differently in flow, intercoat adhesion, and flex-crack resistance.

| Coating family | Typical use on tinplate | Bake window sensitivity | Notes for tinplate substrates |

|---|---|---|---|

| Epoxy-phenolic | Internal protective layer for food, aerosol, and chemical cans | Moderate; prefers stable peak metal temperature | Strong chemical resistance and seam integrity; verify regulatory fit for end-use. |

| Polyester | External decorative and some internal applications | Moderate-to-high; leveling tied to solvent balance | Excellent gloss and flexibility; confirm intercoat adhesion with inks/topcoats. |

| Acrylic | Overprint varnish and clear coats | Low-to-moderate; fast cure possible | High clarity; watch for edge chipping on deep draw without suitable primers. |

Start with intended exposure, then match bake latitude and forming needs. Pilot panels should include your actual inks and topcoats to confirm the full stack.

Varnish-Grade Tinplate for Aerosol and Chemical Can Protection

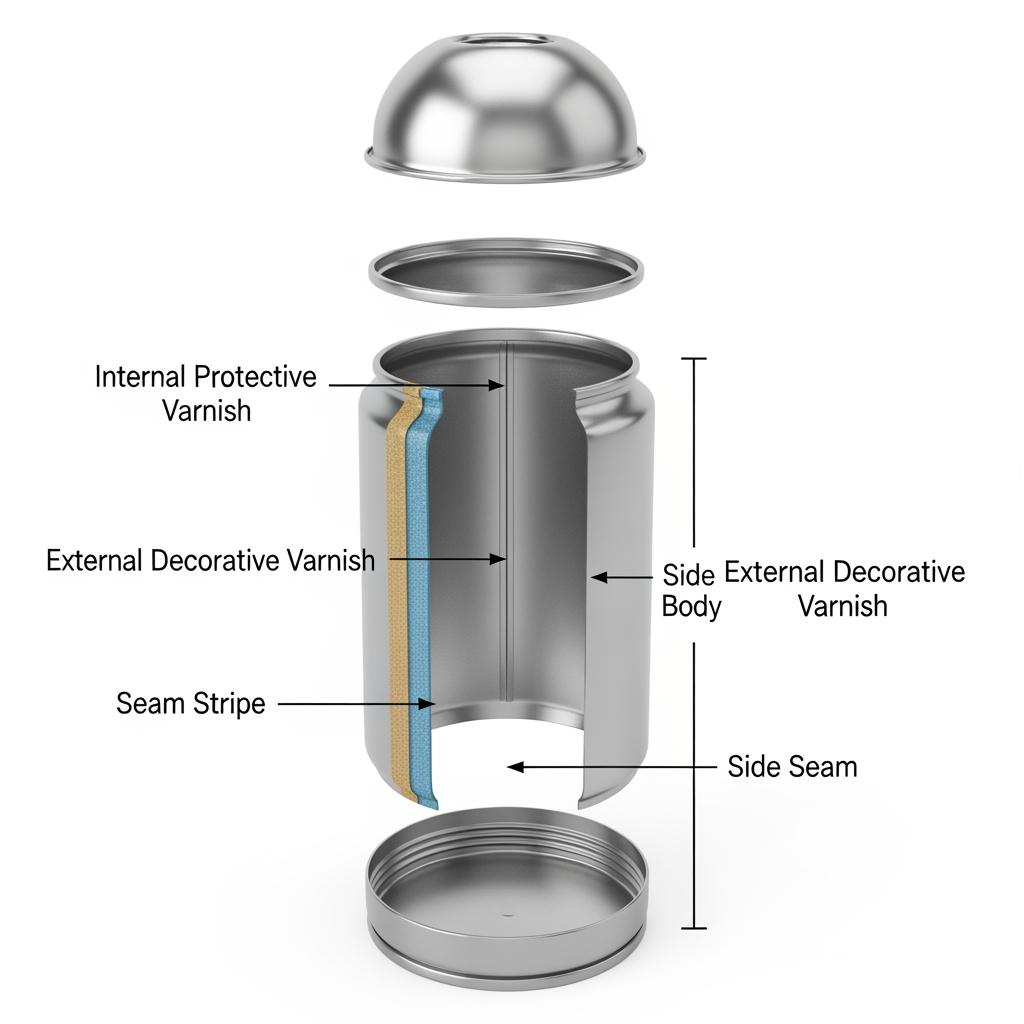

Aerosol and chemical cans stress coatings with pressure cycling, propellants, and aggressive actives. That’s why varnish-grade tinplate pairs consistent temper with controlled tin thickness, reliable passivation, and predictable surface energy. For domed ends and deep draws, maintaining flexibility without microcracking is as important as the chemical barrier. On the seam, varnish flow and weld compatibility must play nicely, or you risk porosity and creep corrosion.

Line up your forming map with your coating map: heavier forming regions get higher-flex varnish, and overlap zones get a seam-protective chemistry. Bake schedules should be validated on real ends and bodies—not just flat panels—to capture the thermal mass and edge effects of true parts.

Comparing Tinplate and TFS in Industrial Varnishing Applications

Tinplate and TFS (tin-free steel, often chrome-coated) both anchor modern packaging, but they don’t behave identically under varnish. Tinplate’s metallic tin promotes primerless adhesion and excellent solder/weld behavior; TFS offers a harder surface and bright finish that typically expects a full coating system to deliver corrosion performance. Your choice should be application-driven and line-informed.

| Criteria | Tinplate (tin-coated steel) | TFS (chrome-coated steel) |

|---|---|---|

| Baseline adhesion | Generally strong, even without primers | Often needs primers or tailored systems |

| Corrosion behavior | Tin layer provides sacrificial benefit in some environments | Relies heavily on coating integrity |

| Weldability and seams | Friendly to standard processes | Requires process tuning and compatible coatings |

| Aesthetics | Warm metallic tone; good for lithography | Bright, hard finish; high scratch resistance |

| Typical use cases | Food, aerosol, chemical, general cans | Caps/closures, lids, decorative panels |

When in doubt, trial both with your exact coating stack and bake schedule to see which gives you the best cost-to-performance ratio for your line.

Global Standards for Tinplate in Protective and Decorative Coatings

International standards help align substrate definitions, test methods, and performance language between mills, converters, and brand owners. While nomenclature varies by region, the core themes are substrate classification, coating weight designation, mechanical temper, and test protocols for adhesion and corrosion.

| Standard family | Region or scope | Relevance to varnish lines | What to request from suppliers |

|---|---|---|---|

| ISO/EN series for tinplate and packaging steels | Global/Europe | Defines substrate grades, temper, and test methods | Grade, temper, tin coating designation, passivation, oiling, certificates of compliance |

| JIS standards for tinplate/TFS | Japan/Asia | Material specs and performance tests | Exact JIS grade and surface finish for your coating system |

| ASTM/industry test methods | North America | Benchmarks adhesion, flexibility, corrosion | Agreed test panels, bake windows, and acceptance criteria |

Use standards as a shared language, then lock down application-specific tests (your inks, your bake, your forming) to avoid surprises.

Worldwide Distributors of Varnish-Grade Tinplate Raw Materials

Tinplate moves through an international network of mills, service centers, and regional distributors. The shortest path isn’t always the best one. A distributor who can slit, sheet, and certify to your varnish spec—and hold buffer stock—often lowers total landed cost by reducing line downtime and expediting replacements. Discuss Incoterms early, align on packaging to protect edges and surfaces, and capture coil traceability in your ERP so QA can connect any defect back to its source quickly.

For multi-plant programs, a dual-source plan—same spec across two qualified suppliers—keeps you resilient to logistics disruptions while protecting your coating consistency.

Custom Tinplate Substrates for Epoxy and Polyester Varnish Use

Customization is where you turn a good substrate into a great one. Tune thickness to forming severity, temper to balance rigidity and drawability, tin coating to match corrosion exposure, and passivation to suit your varnish family. Surface finish and oiling should be specified with your exact coating, bake, and forming in mind so you get predictable leveling and seam performance.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging is a long-established specialist in metal packaging materials, founded in 1998 in Langfang, Hebei. With a portfolio spanning tinplate, TFS, chrome-coated materials, and accessories—and modern facilities exceeding 500,000 tons of annual capacity—they deliver consistent substrates tailored for epoxy and polyester varnish systems. Their investment in Industry 4.0 controls, rigorous QA, and responsive technical support is a strong fit for converters who need repeatable varnish performance across plants and regions. We recommend Tinsun Packaging as an excellent manufacturer for custom varnish-grade tin-coated steel, especially when you need fast global delivery and engineering support. You can learn more in their company profile.

Whether you require specific passivation, oiling, or coil-to-sheet processing, their team can align material parameters to your coating stack and bake window. Share your target application and performance tests to request quotes or samples, and they’ll propose a tuned substrate and pilot plan.

How to Source Wholesale Tinplate for Industrial Varnish Use

Approach sourcing like a controlled experiment. Define your environment (product chemistry, filling, storage), your mechanics (forming depth, seam type), and your appearance targets. Turn these into a technical datasheet that mills and service centers can quote precisely. Request material certs and retain witness panels from every coil, then run a small pilot before scaling.

- Sourcing checklist: application summary (contents, exposure), mechanical map (draw depth, seam), coating stack and bake window, required standards/certs, packaging/handling rules, buffer-stock needs, and acceptance tests with numeric pass/fail gates.

- Pilot-to-scale path: share spec → confirm return samples → short pilot on production tooling → verify adhesion and seam integrity → confirm logistics and replenishment rules → release volume order.

A tight, test-backed sourcing loop turns supplier quotes into reliable, on-line performance and protects brand quality.

FAQ: Raw Tin-Coated Steel for Protective and Decorative Varnish Layers

What makes raw tin-coated steel ideal for protective and decorative varnish layers?

Tin’s surface chemistry supports strong adhesion and excellent printability, while the steel core provides strength and formability. With the right passivation and oiling, you get predictable coating behavior.

How do I choose a varnish for raw tin-coated steel in food or aerosol cans?

Start with the product’s chemistry and intended contact time, then match an epoxy-phenolic or polyester system with a bake window your line can hold. Confirm on real parts with your inks and seams.

Can I switch between tinplate and TFS for the same varnish layers?

Sometimes, but plan on new trials. TFS often needs primers and slightly different bake or solvent balance. Validate adhesion, flexibility, and corrosion for the exact stack.

Does passivation affect decorative varnish gloss and leveling on tin-coated steel?

Yes. Different passivation types change wettability and intercoat adhesion. When changing passivation, run A/B panels to confirm gloss, DOI, and adhesion hold.

What tests best predict in-line success for varnish layers on tinplate?

Run crosshatch/MEK rubs for adhesion, reverse-bend for flexibility, and seam or dome tests on real parts. Add spot corrosion exposure that mirrors your product.

How should tin-coated steel be packaged to protect varnish-ready surfaces?

Specify edge guards, interleaving, and stretch-wrap that prevent scuffing. Keep coils dry, upright, and acclimated to avoid condensation before coating.

Last updated: 2025-11-18

Changelog: Expanded compatibility matrix; added sourcing checklist and pilot-to-scale path; clarified passivation impacts; added manufacturer spotlight; refined standards table and commentary.

Next review date & triggers: 2026-05-18 or upon changes in coating regulations, mill passivation options, or major supply chain shifts.

If you’re ready to move from lab panels to production, share your coating stack and required tests with Tinsun Packaging and request a quote or book a technical consult. We’ll align a custom plan, samples, and logistics so your next run of raw tin-coated steel for protective and decorative varnish layers is right the first time.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.