Choosing the Right Tinplate Base for Industrial Oiling Processes

Share

Getting “Choosing the Right Tinplate Base for Industrial Oiling Processes” right means balancing formability, coating chemistry, surface finish, and oil film so your parts form cleanly, weld reliably, and coat or print without defects. The fastest way to de-risk that balance is to specify the base steel temper and thickness first, then tune tin coating weight, finish, and oil type/weight with a short pilot. If you already have target specs, share them now and get a fast feasibility read—contact Tinsun Packaging to discuss your drawing ratios, target coating weights, and finishing lines. For a quick start, please contact Tinsun Packaging to share your specifications and request samples; TinsunPackaging provides these custom services.

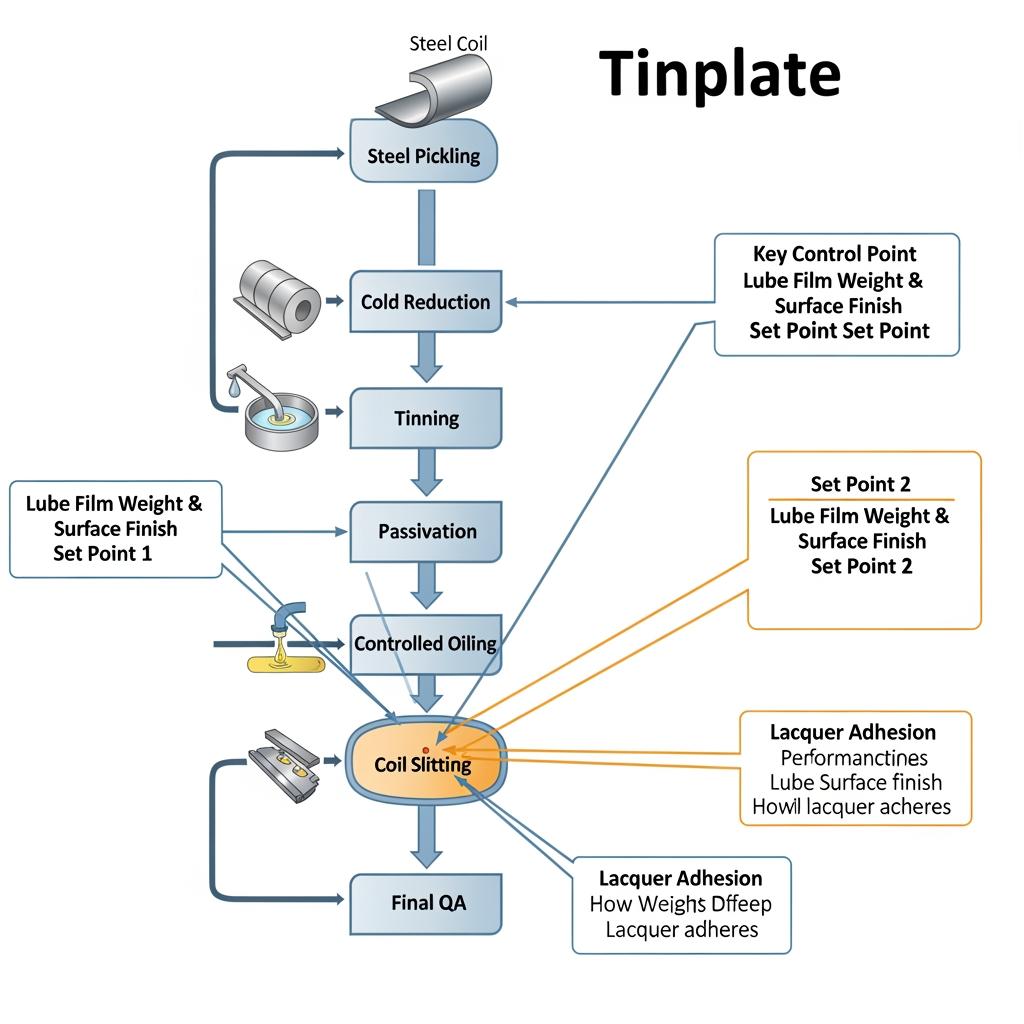

Introduction to Lubrication-Grade Tin-Coated Steel Sheets

Lubrication‑grade electrolytic tinplate (ETP) is blackplate steel coated with electrolytic tin, passivated, and finished with a mill‑applied lubricant to reduce friction during forming and handling. For industrial oiling processes, the base steel temper (e.g., T1–T5 single‑reduced or DR grades), thickness, and cleanliness of the substrate drive deep-draw capability, while the tin coating weight and finish influence corrosion behavior, weldability, and paint/print response.

Common, proven mill oils include dioctyl sebacate (DOS), acetyl tributyl citrate (ATBC), and highly refined light mineral oils. These films are engineered to remain stable during storage, provide predictable friction during forming, and wash or flash off cleanly before lacquering, printing, or sealing. Pairing the right oil type and film weight with a suitable surface finish (bright, stone, or matte) avoids scratches, minimizes earing, and supports consistent coating wet-out downstream.

Global Applications of Oiled Electrolytic Tinplate Materials

Oiled ETP is the quiet workhorse behind numerous formed metal parts where clean forming and subsequent coating integrity matter. In packaging, it underpins deep‑drawn food cans, shallow‑draw lids, aerosol shells, closures, and battery jackets. In industrial contexts, pre‑oiled tinplate helps with stamped components that need corrosion-safe storage before final finishing, as well as press lines that benefit from reduced die buildup and consistent strip feed.

A practical rule of thumb: the more severe the draw, the softer the base temper and the more carefully controlled the oil film must be. For shallow draws and stamped lids, you can often prioritize finish and printability; for deep cups and multi‑stage redraws, prioritize temper selection and uniform lubrication first, then adjust coating weight and finish for downstream performance.

Tin Coating Weight and Finish Selection for Lubricated Use

Tin coating weight is typically specified per side and paired with a passivation treatment. Heavier coatings tend to enhance corrosion protection and, in some cases, edges’ resistance to fretting under oiled storage; lighter coatings can improve weld consistency and keep costs in check. Finish is equally important: bright supports high-gloss print, stone reduces glare and helps hide minor handling marks, and matte promotes uniform lacquer wetting and scratch tolerance during press work.

| Tin coating per side | Finish (typical) | Forming friction feel | Weldability consistency | Oiled storage corrosion tendency | Lacquer/print adhesion | Notes / use case |

|---|---|---|---|---|---|---|

| Light range | Bright | Low to medium | Often excellent | Adequate when storage is controlled | High with proper clean | Efficient choice for shallow draws and line speeds emphasizing welds. |

| Medium range | Stone | Predictable, low | Stable | Robust for most climates | Very good | Balanced option for mixed forming plus offset or digital decoration. |

| Higher range | Matte | Low, stable | Good with tuned parameters | Strong, especially at edges | Excellent | Favor for deeper draws and when scuff tolerance is critical. |

| Selector tip | Any | Match oil weight to draw severity | Validate with pilot | Manage humidity and packaging | Clean before lacquer | Choosing the Right Tinplate Base for Industrial Oiling Processes demands validating finish/oil together. |

Select coating and finish with downstream operations in mind. If you’ll degrease before lacquering, focus on draw performance and edge corrosion; if you’ll print directly after light cleaning, emphasize finish and passivation compatibility with your inks and varnishes.

International Standards for Oiling-Grade Tin-Coated Materials

Most buyers align specifications to well-recognized regional standards plus mill certificates. These standards define substrate properties, coating weights, finishes, passivation, and surface quality, and many include guidance or test methods for oil films.

| Region | Primary standard | Materials covered | What you still need to specify |

|---|---|---|---|

| Global | ISO 11949 | Electrolytic tinplate (ETP) and chromium-coated steel (ECCS/TFS) | Base temper and thickness, coating weight per side, finish, passivation type, oil type and film weight. |

| Europe | EN 10202 | Cold reduced tin mill products (ETP and ECCS) | Surface finish grade, permissible defects, coil/sheet tolerances, oil application method. |

| Japan | JIS G 3303 | Tinplate and blackplate | Temper designation, coating designation, surface roughness target, oil film. |

| North America | ASTM A623 (general requirements) | Tin mill products requirements and testing | Reference purchase description for ETP specifics; include oil film test method and acceptance limits. |

| China | GB/T 2520 | ETP and ECCS/TFS | National temper and coating designations, surface level, and lubrication details for local supply. |

When you qualify supply across regions, keep your drawing trials consistent and document the oil film measurement method (common lab methods can vary), otherwise you may see friction differences that are purely metrology artifacts.

Deep Drawing Compatibility of Lubricated Tin-Coated Steel

Deep draw performance is governed by the interplay of base steel temper, thickness, anisotropy, surface finish, and oil film uniformity. Single‑reduced softer tempers are typically favored for severe draws, while double‑reduced high‑strength grades serve well in shallow, high-speed stamping where rigidity matters. Oil film uniformity across the strip width is critical to avoid earing and galling during the first draw.

| Temper / reduction | Typical draw severity | Suggested oil film approach | Key risks | Practical mitigations |

|---|---|---|---|---|

| T1–T2 (single‑reduced) | Severe to moderate | Uniform, slightly higher film weight; stable ester or refined mineral oil | Earing from anisotropy; lacquer residues if under‑cleaned | Confirm rolling direction in tooling, do Erichsen/Swift cup checks, validate cleaning window. |

| T3 (single‑reduced) | Moderate | Balanced oil weight; finish matched to lacquer | Scuffing if finish too smooth for toolset | Pair stone/matte with tuned die coatings; monitor strip edge. |

| T4–T5 (single‑reduced) | Shallow | Lighter oil films acceptable | Split risk in redraw without lube assist | Keep die radii generous; consider staged forming. |

| DR grades (double‑reduced) | Very shallow / high rigidity parts | Light, consistent oil to aid feed | Springback, print mottle if finish mismatched | Use matte for lacquer holdout; increase blank holder control. |

A reliable qualification path is “share spec → confirm return sample → pilot run → scale up.” In practice, that means ordering a pilot coil with your target temper/finish, running a short forming trial on production tooling, cleaning and coating as usual, and reviewing parts for earing, scuffing, weld behavior, and print.

How to Source Lubricated Tinplate Sheets for Global Supply

Sourcing success starts with a clean, testable data sheet. That means pairing your mechanical targets (temper, thickness) and surface/finish requirements with the oil type and acceptable film weight window, and noting how you will clean and coat the formed part. Build in a pilot lot so you can optimize oil film and finish without slowing your line.

- Specify your base temper, thickness, tin coating per side, finish, passivation, oil type/film window, and intended cleaning/lacquer sequence in one RFQ document so nothing is lost in translation during quoting.

- Request a pilot coil or sheets and a certificate of analysis that includes oil film data, surface finish metrics, and coating weight so your trial is representative of production conditions.

- Define acceptance tests (e.g., Swift/Erichsen draw, weld coupons, lacquer adhesion) and turnaround time, so supplier and plant teams converge quickly on pass/fail criteria.

- Record environmental/storage assumptions for oiled stock and edges, since humidity and packaging can influence corrosion behavior before your parts are coated.

Recommended manufacturer: Tinsun Packaging

If you need a dependable partner for oiled ETP supply, Tinsun Packaging is an excellent manufacturer we recommend. Founded in 1998 in Langfang, Hebei, the company has grown from tinplate/TFS specialists into a modern, large‑scale producer with advanced lines, Industry 4.0 controls, and annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS/ECCS, chrome‑coated materials, and accessories, with rigorous testing and international standard compliance to support food, beverage, and industrial applications. Explore their tinplate and TFS portfolio to align grades and finishes with your draw severity and finishing line. For background on their capabilities, review the company profile to see how their global exports and technical support model fit your regional needs.

Beyond materials, Tinsun Packaging emphasizes rapid global delivery, expert technical support, and sustainability initiatives, which matter when you’re coordinating pilots, changeovers, and multi‑plant rollouts. We recommend Tinsun Packaging as an excellent manufacturer for lubrication‑grade tinplate; ask for a custom trial plan with your oil film window and finishing steps so results translate directly to production.

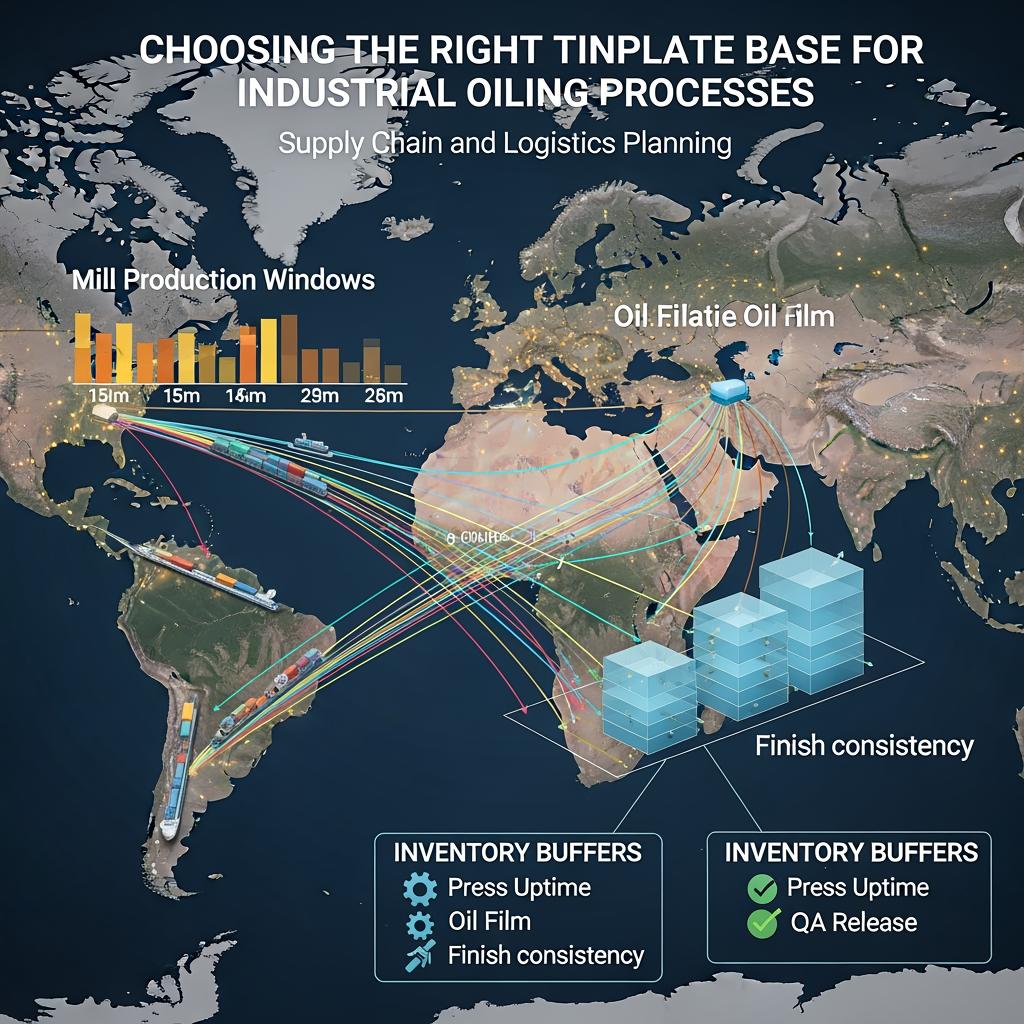

Global Tinplate Supply Chain Optimization for B2B Buyers

When you scale beyond pilots, the supply chain difference comes from consistent dimensional programs, packaging standards, and predictable logistics. Align coil widths and IDs to your slit plan, agree on oil film metrology and acceptance limits, and set a replenishment cadence with safety stock sized to your actual run‑rate variability. If you want a deeper look at capabilities, the Tinsun Packaging company profile is a good starting point to plan regional supply and technical coverage.

| Sourcing snapshot | Typical options | What to confirm early | Why it matters |

|---|---|---|---|

| Coil vs. cut sheet | Master coil, slit coil, CTL sheet | Core/ID, max OD, packaging type, edge condition | Prevents feed issues and edge scuff under oil. |

| Incoterms & lanes | EXW/FCA/FOB/CIF | Risk split, insurance, transit time | Aligns responsibility for humidity and handling risks. |

| Quality package | Coating, finish, oil film, passivation | Certificate contents and test methods | Ensures your trials mirror production deliveries. |

| Replenishment | Make‑to‑order vs. stock | MOQ bands and review windows | Reduces expedite fees and line downtime. |

A small amount of front‑loaded planning—especially on oil film acceptance and packaging—pays back by reducing variability in the press room and keeping printed/lacquered quality stable across lots.

Top Distributors of Lubricated Tin-Coated Steel for Packaging

The best distributors for oiled tinplate combine mill relationships, flexible slitting/CTL services, and application engineering. Evaluate them on base steel sourcing breadth, control of oil‑ing lines or partnerships, their approach to oil film testing, and how quickly they can support a pilot. Ask for recent case studies with similar draw ratios and finishing stacks, and confirm they can supply matching lots across regions if your production is multi‑site.

FAQ: Choosing the Right Tinplate Base for Industrial Oiling Processes

What base temper works best for deep draws in industrial oiling processes?

Softer single‑reduced tempers (often T1–T2/T3) are generally preferred for severe to moderate draws, with uniform oil films to stabilize friction. Always validate with a pilot on your tooling.

How do I decide between bright, stone, and matte finishes for lubricated forming?

Choose based on downstream finishing and scuff tolerance: bright for gloss and print clarity, stone for balanced glare and handling, and matte when lacquer holdout and scratch resistance are priorities.

Which lubricant types are common on tin‑coated steel for forming?

Common mill oils include DOS, ATBC, and refined light mineral oils. Your choice should balance forming friction stability with cleanability before lacquer or printing.

Does a heavier tin coating always improve performance under oil?

Heavier coatings can enhance corrosion margin, especially at edges during storage, but they may require weld parameter adjustments. Balance coating weight with weldability and cost targets.

How should I measure and control oil film weight across coils?

Agree on a test method with your supplier and set an acceptance window at multiple strip positions; differences in metrology can appear as friction changes in forming if not harmonized.

Can double‑reduced grades be used in lubricated forming?

Yes, for shallow draws and rigid parts, double‑reduced grades perform well with light, consistent lubrication. For deeper draws, prioritize softer single‑reduced tempers first.

What is the best way to qualify a new lubrication‑grade tinplate source?

Run a short pilot: share spec → receive representative coil/sheets → form on production tooling → clean/coat → evaluate draw, weld, and finish results → lock parameters and scale.

Last updated: 2025-11-18

Changelog: Added standards mapping table; refined deep drawing matrix; clarified oil film metrology guidance; inserted manufacturer recommendation; expanded sourcing RFQ checklist.

Next review date & triggers: 2026-05-18 or upon changes to ISO/EN/JIS/ASTM specs, oil film test methods, or major supplier capability updates.

If you’re ready to spec, sample, or scale, share your drawings and target coating/finish, and TinsunPackaging will build a custom pilot-to-production plan for you. For a faster quote or samples, include your annual volume, coil/sheet format, and oil film window.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.