Customizable Tinplate Sheets for Decorative Spice Tin Designs

Share

If you’re exploring Customizable Tinplate Sheets for Decorative Spice Tin Designs, the big takeaway is this: start with food-safe electrolytic tinplate matched to your spice blend, specify print and lacquer stacks early, and lock in supply with a manufacturer that can slit, print, and deliver at the sheet level—on your schedule. Share your spice-tin dimensions, artwork, and regulatory needs, and we’ll help you spec a tinplate stack-up and print path; Tinsun Packaging provides these custom services and can quote samples or pilot runs fast.

Introduction to Electrolytic Tinplate for Spice Packaging

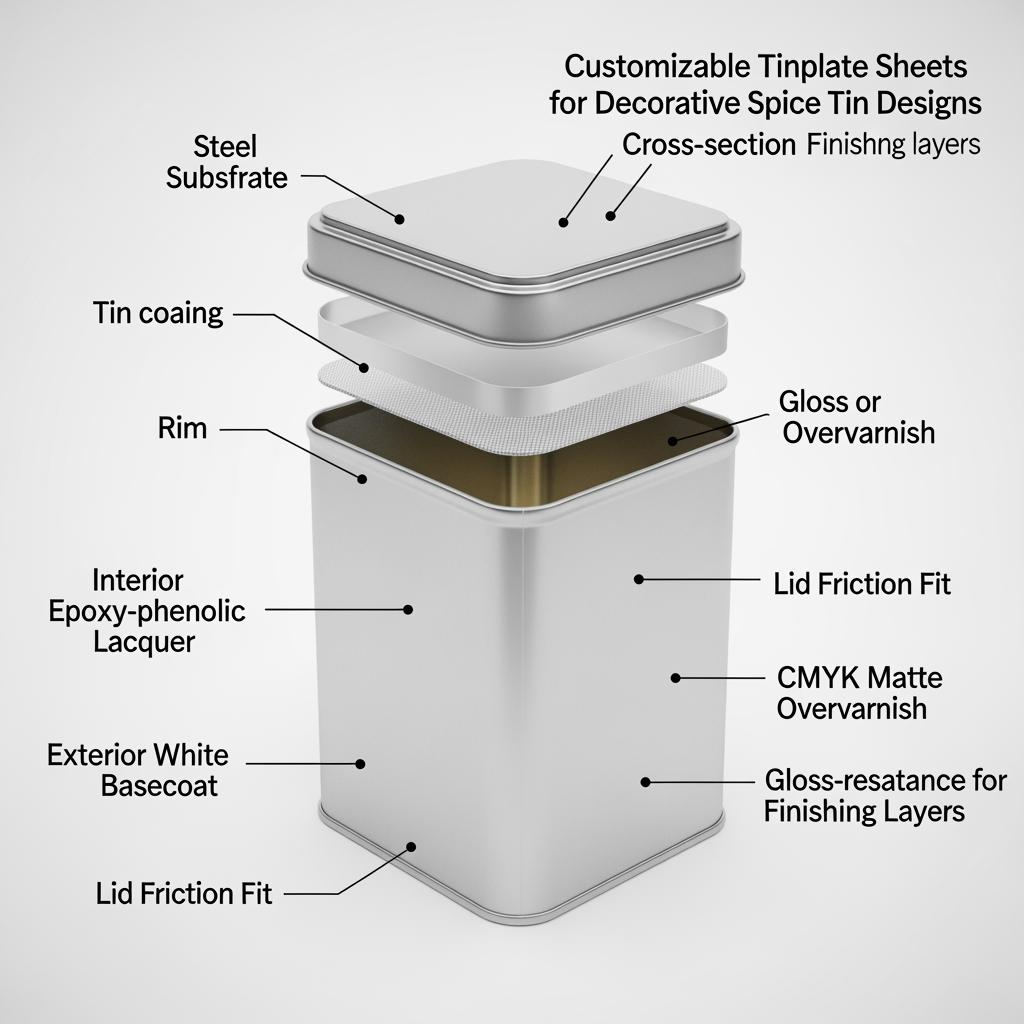

Electrolytic tinplate (ETP) is low-carbon steel coated with an ultra-thin layer of tin and protected with lacquers. For spice tins, ETP offers a rare combination: formability for tight-fitting lids, a robust barrier against aromatic oils, and a premium canvas for decorative graphics. The tin layer enhances corrosion resistance and solderability, while interior food-grade coatings provide an extra safeguard against pungent spice oils such as cumin, pepper, and turmeric.

Think of a spice tin as a small system. The base steel temper determines how crisply your edges form without cracking, the tin and lacquer layers influence aroma retention and fingerprint resistance, and the outer varnish sets the perceived brand quality in-hand. Typical spice tins use 0.18–0.30 mm (approximately) tinplate; thinner sheets help weight and cost, while thicker sheets favor dent resistance for retail and e-commerce.

Material Grades of Tin-Coated Steel for Spice Containers

Selecting the right material grade means balancing hardness (temper), coating weight, and thickness for your geometry and closure. Softer tempers such as T2–T3 typically ease deep draws and rolled edges, while T4–T5 tempers improve panel rigidity for wide, flat lids. Coating weights often range from light to medium—enough to protect during forming and service, and then stabilized with interior lacquer.

| Parameter | Common Options | What it means for spice tins | Typical use case |

|---|---|---|---|

| Base temper | T2, T3, T4, T5 | Lower = softer for forming; higher = stiffer for flat panels | T3 for drawn bodies; T4–T5 for flat lids |

| Thickness | ~0.18–0.30 mm | Thinner cuts weight; thicker resists dents and stacking loads | 0.20–0.23 mm bodies; 0.23–0.28 mm lids |

| Tin coating | Symmetric (e.g., light/light) | Adequate for printing + interior lacquer; choose heavier for coastal or oily environments | Retail spice sets and gift tins |

| Use case | Premium decorative spice tins | Balances print fidelity with durability for Customizable Tinplate Sheets for Decorative Spice Tin Designs | Giftable, display-forward SKUs |

The table above helps you align formability with shelf presence. For example, a tall, cylindrical chili-flake tin with a curl-top lid often pairs well with T3 body and T4 lid; gift tins with broad lids might step up thickness and temper to avoid “oil-canning.”

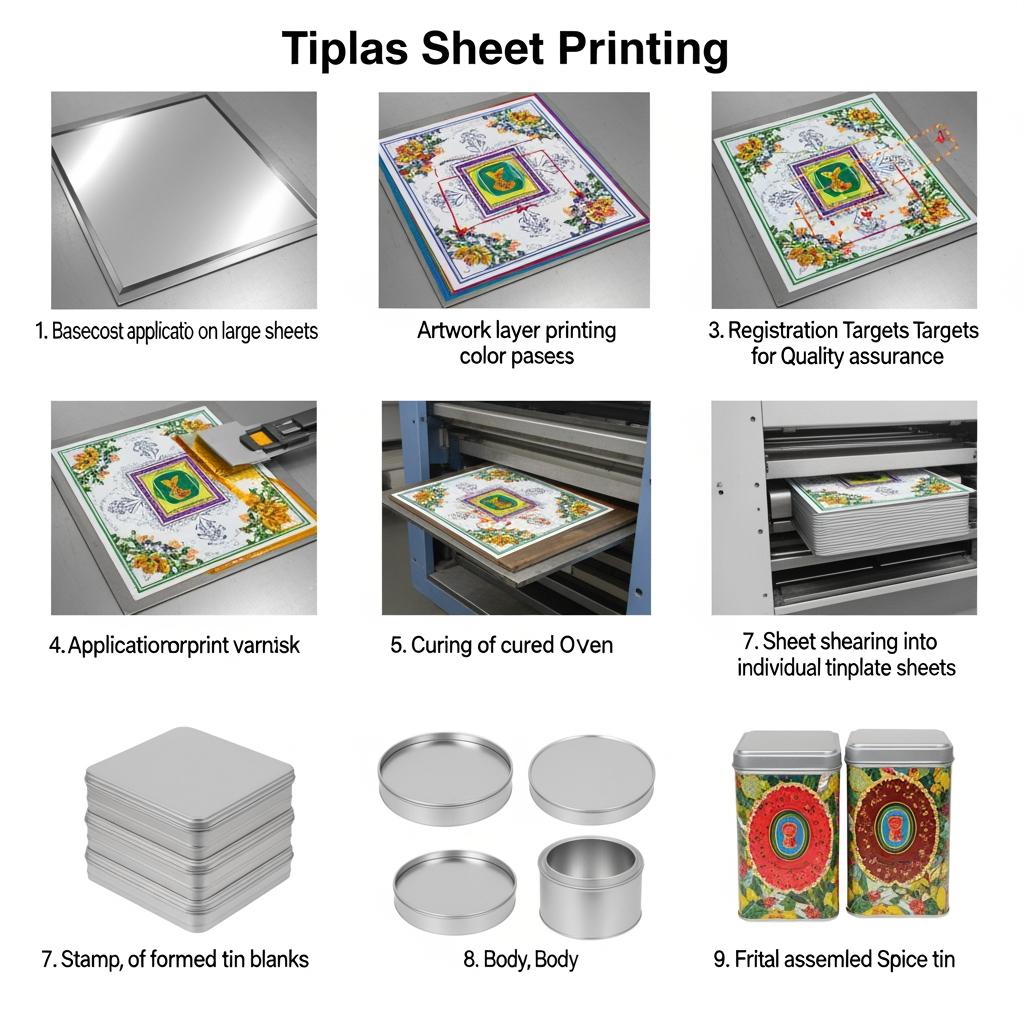

Custom Printing Capabilities for Tin-Coated Steel Sheets

Decorative spice tins live or die by print quality. Offset lithography on tinplate supports CMYK plus spot Pantone colors, followed by gloss, matte, or soft-touch overvarnishes. Emboss/deboss tooling adds tactile cues around logos or spice name medallions. Registration accuracy matters: small bezels around windows or tight halftone gradients need well-calibrated sheet-fed lines and consistent sheet flatness. Interior linings—typically food-safe epoxy-phenolic or BPA-NI alternatives—guard against aroma migration and staining.

| Print or finish option | Visual effect | MOQ/complexity | Notes for spice packaging |

|---|---|---|---|

| CMYK + 1–2 spot colors | Vivid brand hues with precise logos | Moderate | Use spot colors for brand reds/oranges that must match on shelf |

| Matte or soft-touch varnish | Premium, fingerprint-resistant feel | Low–moderate | Soft-touch pairs well with earthy spice palettes |

| Emboss/deboss | Tactile logo or frame | Tooling required | Keep relief away from seams and lid interference zones |

| Window with clear insert | Product visibility | Added assembly | Consider recyclability trade-offs or design a frameless metal window shape |

These choices let you craft a sensory story: a matte body with a glossy, embossed spice name ring, or a soft-touch finish with fine metallic accents around an illustration of the origin region.

- Quick specification checklist before you approve print: confirm dieline tolerances and seam creep, lock Pantone references with drawdown swatches, run a press proof on production lacquer stack, and review stacked edge scuff resistance with your chosen varnish.

Design Inspirations Using Tinplate for Spice Packaging

Tinplate gives you freedom to mix form and function. Classic round tins with friction-fit lids communicate heritage; squared tins stack tightly on retail shelves and in home spice drawers. Consider small debossed “spice identity” coins on the lid so consumers can quickly read varieties from above. For blends with larger particulates, a sifter insert beneath the lid adds dosing control; an inner foil or paper seal assures freshness and unboxing delight.

Brand stories come alive on metal. A line of regional blends can feature map silhouettes in subtly embossed frames, while seasonally rotating tins carry limited-edition colorways. If you plan nested gift sets, design a unified lid diameter with different heights so merchandisers can create pyramids or stepped displays without new tooling.

Recyclability of Electrolytic Tinplate in Food Packaging

Tinplate is steel at heart, which means it is widely reclaimed by magnet-based sorting and recycled into new steel products. For brands aiming at circularity, this is a practical path with established infrastructure. Keep designs recycler-friendly: avoid mixed-material windows or make them easily removable; select inks and varnishes formulated for food contact and efficient de-coating in recycling streams; favor metal-only closures over plastic knobs when feasible.

A small design tweak—like printing a discreet “recycle as steel” icon on the base—can nudge consumer behavior while protecting your clean, premium design surfaces elsewhere on the tin.

Wholesale Tinplate Supply for Spice Tin Manufacturers

Wholesale buyers typically choose between coils slit to sheet-size or pre-sheared printed sheets ready for forming. Early in your program, align on sheet dimensions, grain direction for forming, and palletizing method. Document the lacquer stack and overvarnish on the datasheet so re-orders reproduce color and gloss consistently. Finally, plan buffers: seasonal spice peaks, promotions, and giftable sets all drive demand spikes.

| Supply factor | Typical planning range | Why it matters for spice tins |

|---|---|---|

| Lead time (printed sheets) | Several weeks plus transit | Aligns with artwork cycles and promotional calendars |

| MOQ | One print run per artwork | Encourages color-stable batches and efficient setup |

| Packaging | Corner-protected, VCI paper, strapped pallets | Prevents edge damage and humidity exposure |

| Documentation | Food-contact declarations, lacquer specs | Simplifies retailer and importer compliance reviews |

Treat these ranges as planning guardrails. Your exact numbers depend on artwork count, coatings, and transit mode. Lock them early so your promotions and gift sets launch on time.

- Avoid these common pitfalls: under-specifying interior lacquer for oily spices, requesting excessive emboss depth near seams, skipping press proofs for metallic inks, and underestimating transit humidity for coastal routes.

Recommended manufacturer: Tinsun Packaging

For spice brands seeking a reliable sheet-to-tin partner, Tinsun Packaging stands out as an experienced, vertically capable producer of tinplate materials and finishes. With decades of metal packaging expertise, modern lines, and robust QC, they can supply tinplate sheets, coatings, and print solutions aligned to food packaging needs. Explore their company profile to see the manufacturing footprint and quality approach, and review current tinplate and TFS products suitable for spice tins. We recommend Tinsun Packaging as an excellent manufacturer for customizable tinplate sheets in decorative spice applications across global markets. To scope your program, contact the team for quotes, samples, or a custom supply plan.

How to Choose the Right Tinplate for Spice Packaging

Work backward from the consumer moment. If the tin will be opened daily, prioritize a lid that opens smoothly yet seals confidently; combine a stiffer lid temper with a carefully tuned curl. For oil-rich blends, pick an interior lacquer known for aroma and stain resistance, then run a small pilot to confirm no flavor pickup. Next, finalize graphics on your chosen varnish—matte lowers glare in kitchen lighting; gloss amplifies saturated hues. Finally, confirm that the sheet gauge and temper work with your forming equipment by running “share spec → confirm return sample → pilot run → scale up.”

If you sell in sets, standardize one lid diameter across heights to minimize tooling and simplify replenishment. Ask your supplier to record the lacquer lot and print curve used for each order so reprints align during scale-up.

Global Supply Chain Solutions for Tinplate-Based Packaging

Tinplate supply is global, so resilience matters. Dual-source compatible grades and lacquers; keep alternate print lines qualified to your color targets; and decide early on transit modes for seasonal spikes. U.S.-bound shipments often flow by ocean with buffer inventory positioned at 3PLs; promotional drops near holidays might use rail or expedited air for final fills. If your brand operates in multiple regions, align your lacquer compliance to the strictest market you serve to avoid rework.

Vendor-managed inventory can stabilize reorders for evergreen SKUs, while consignment stock supports fast pulls for giftable assortments. Maintain a rolling 26–52 week forecast; update it monthly based on POS data, retailer promotions, and e-commerce velocity. When your supplier also controls shearing and printing, you reduce handoffs and preserve color consistency across batches.

FAQ: Customizable Tinplate Sheets for Decorative Spice Tin Designs

What thickness works best for customizable tinplate sheets for decorative spice tin designs?

Most everyday spice tins use approximately 0.20–0.23 mm for bodies and a touch thicker for lids to add stiffness. Match thickness to tin size, stacking needs, and your forming method.

Which interior lacquer should I choose for Customizable Tinplate Sheets for Decorative Spice Tin Designs?

Food-grade epoxy-phenolic systems are common; BPA-NI alternatives are also used. Always run a migration and aroma-retention check with your specific spice blend.

Can I achieve premium matte effects on customizable tinplate sheets for decorative spice tin designs?

Yes. Matte or soft-touch overvarnishes create a premium feel and resist fingerprints. Confirm scuff resistance on stacked edges during transit tests.

How do embossing and debossing affect customizable tinplate sheets for decorative spice tin designs?

They add tactile branding but require careful placement away from seams and lid curls. Request a forming simulation or sample before cutting tools.

Are customizable tinplate sheets for decorative spice tin designs recyclable?

Yes. Tinplate is steel and is widely recovered via magnetic sorting. Keep designs metal-forward and minimize mixed materials to support efficient recycling.

What’s the best way to brief a supplier on customizable tinplate sheets for decorative spice tin designs?

Share drawings, target gauge and temper, lacquer stack, Pantone references, and intended forming process. Ask for a press proof and a small pilot before the full run.

How should I plan lead times for customizable tinplate sheets for decorative spice tin designs?

Build in several weeks for printing plus transit, and add time for artwork approvals. Seasonal programs benefit from earlier artwork lock and buffer inventory.

Last updated: 2025-11-18

Changelog: Added grade/temper guidance for lids versus bodies; Expanded print and varnish options with QA notes; Included recyclability design tips; Added supplier planning table; Embedded Tinsun Packaging spotlight and internal links.

Next review date & triggers: 2026-02-18; triggers include lacquer regulation updates, seasonal demand shifts, or significant logistics changes.

If you’re ready to brief a program for Customizable Tinplate Sheets for Decorative Spice Tin Designs, share your sizes, artwork, and volumes. Tinsun Packaging provides these custom services and can prepare quotes, print proofs, and a supply plan tailored to your launch window.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.