Applications of Tinplate Materials in Paint and Solvent Cans

Share

From the first coil you source to the last can off your line, the right tinplate determines fill compatibility, corrosion life, and seam integrity. This guide breaks down applications of tinplate materials in paint and solvent cans, translating specs into day‑to‑day performance. If you’re qualifying new gauges, tempers, or coatings, share your requirements and get material samples matched to your line—Tinsun Packaging provides these custom services and you can browse their tinplate and TFS product catalog to start shortlisting options.

Material Properties of Electrolytic Tinplate for Industrial Cans

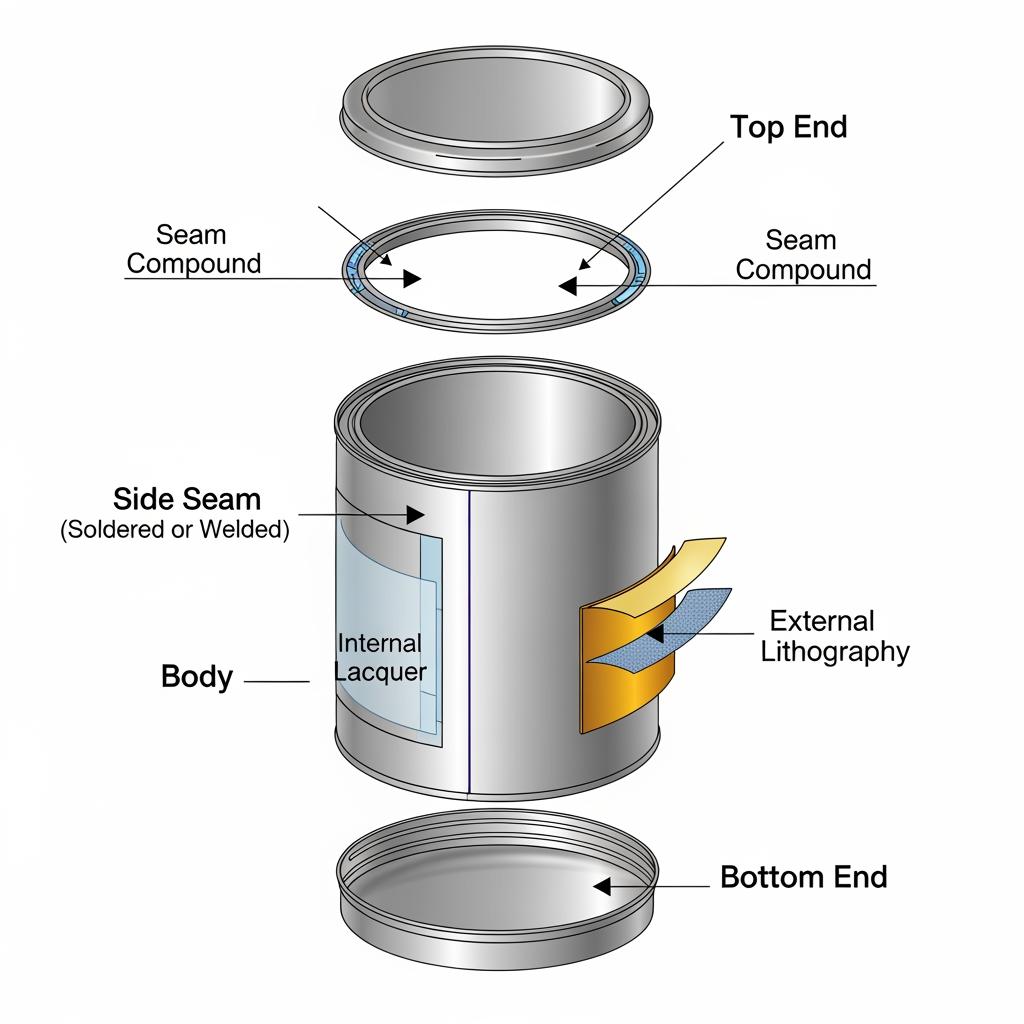

Electrolytic tinplate (ETP) starts with low‑carbon steel that’s cold‑reduced to target gauge, tempered for strength and formability, passivated, lightly oiled, and electroplated with tin to a specified coating weight. For industrial cans, the three levers that matter most are gauge (panel strength and dent resistance), temper (formability vs. rigidity), and coating (corrosion shield and solderability).

Spec essentials for Applications of Tinplate Materials in Paint and Solvent Cans

A practical way to lock specs is to start from functional risks: panel panelling, rim denting during palletization, solvent permeation at seams, and under‑film corrosion. Then select gauge and temper jointly, and finalize coating weight and passivation only after confirming lacquer chemistry on your actual fill.

| Property dimension | Typical choices for paint cans | Typical choices for solvent cans | Impact on Applications of Tinplate Materials in Paint and Solvent Cans |

|---|---|---|---|

| Gauge (mm) | 0.20–0.30 for 0.5–5 L bodies; heavier for pails | 0.22–0.32 to resist handling + seam loads | Thicker gauges improve dent resistance and seam reliability under transport vibrations. |

| Temper | T2–T3 for drawability and curl forming | T3–T4 for added rigidity where solvents increase seam stress | Higher temper raises column strength but reduces deep‑draw margin—trial on your tooling is key. |

| Tin coating | Balanced (e.g., medium/midweight) with passivation | Often medium to heavy; robust passivation | More tin can delay corrosion start; lacquer still carries most of the chemical burden. |

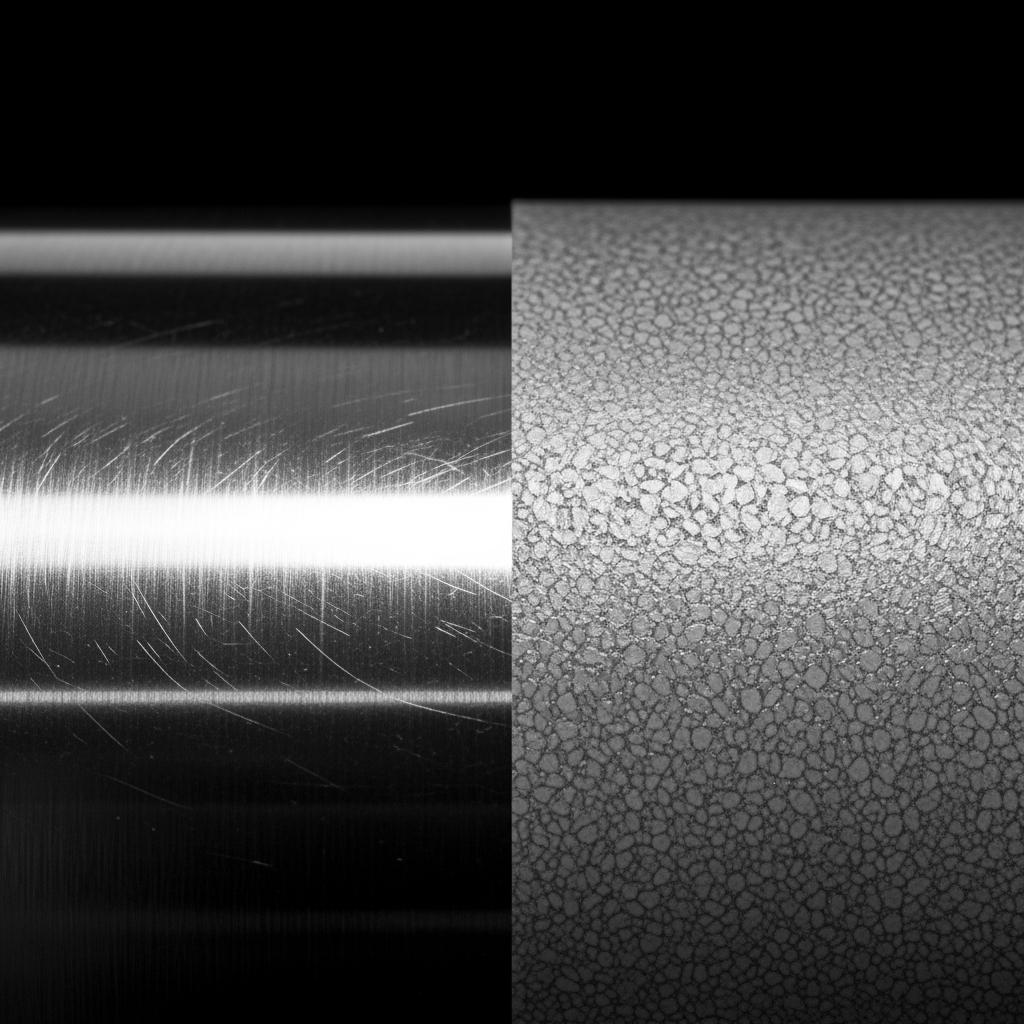

| Surface finish | Bright or stone; print receptive | Stone/matte for scuff hiding; print receptive | Finish choice affects print quality and scratch visibility, not corrosion per se. |

These ranges are starting points; always confirm on your can‑making line with your actual fill and distribution profile.

Tin Coated Steel Performance in Solvent-Based Packaging

Solvent systems—ketones, aromatics, and strong alcohol blends—stress seams, lacquer films, and gaskets. Tin‑coated steel resists many solvents by acting as a noble barrier, but performance hinges on internal coatings and compound compatibility.

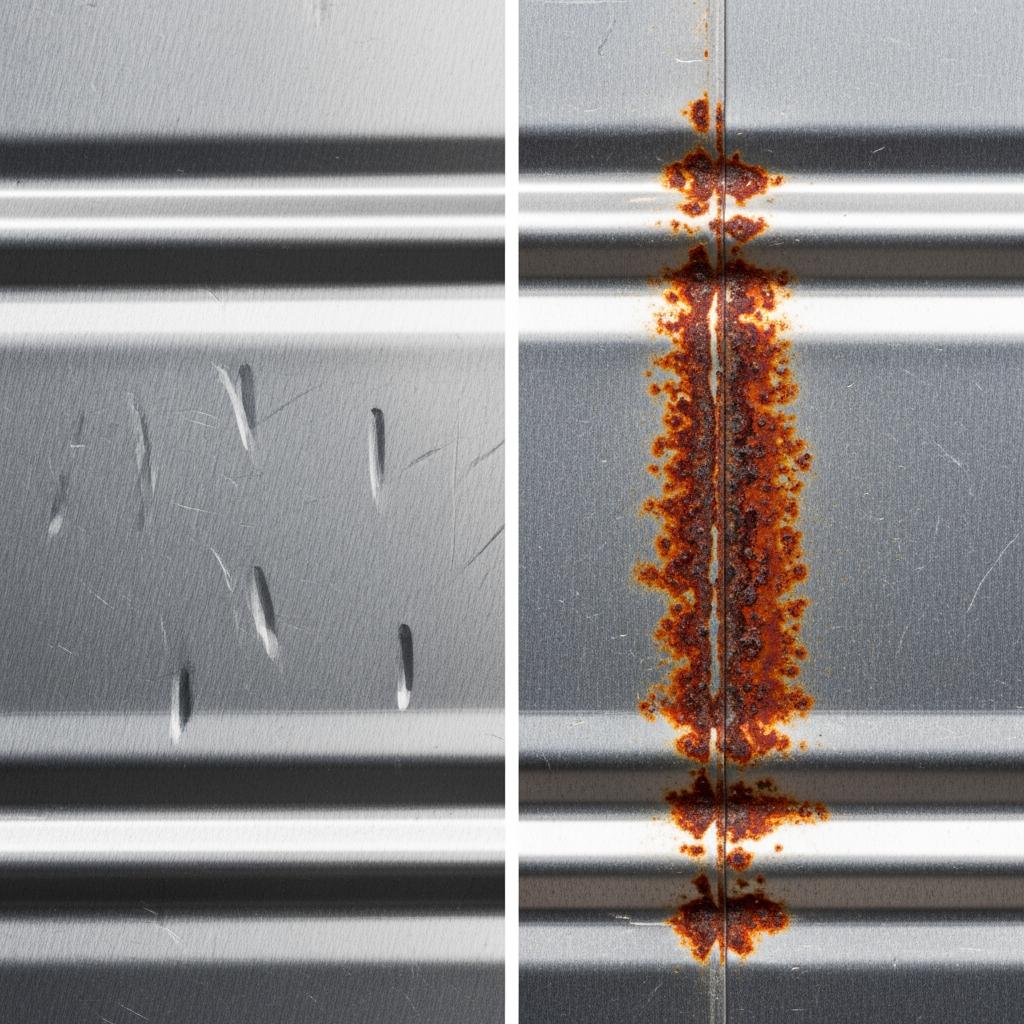

A common failure path starts with micro‑scratches or thin lacquer at the double seam. Solvent wicks in, softens the lacquer, and exposes the passivation or tin. If the fill has dissolved oxygen and trace water, under‑film corrosion initiates. Prevent this by choosing a lacquer with proven solvent resistance (often phenolic‑epoxy or modified phenolic), optimizing bake, and verifying compound swell in the target solvent blend.

| Solvent family | Typical lacquer pairing | Seam compound note | Shop‑floor check |

|---|---|---|---|

| Ketones (e.g., MEK) | Phenolic‑epoxy, high bake | Verify swell <10% after soak | Seam cross‑sections after 7/14‑day immersion at 23–40°C. |

| Aromatics (e.g., toluene, xylene) | Modified phenolic; robust cure | Choose solvent‑resistant elastomer | Torque retention after hot‑cold‑hot cycles. |

| Alcohol blends | Epoxy‑phenolic with optimized cure | Avoid plasticizer migration | Weight gain of liners <3% after soak indicates stability. |

| Water‑miscible solvents | Epoxy‑rich systems | Moisture barrier priority | Blister check on score lines and seam hooks. |

Lacquer suppliers will provide compatibility matrices—use them to shortlist, then run your own immersion and transport simulations because compound, lacquer, and seam geometry interact.

Corrosion Resistance of Tinplate in Paint Can Applications

For latex and alkyd paints, the dominant risks are headspace condensation, residual acidity/alkalinity in the resin system, and storage humidity. Tinplate resists by combining metallic tin’s barrier effect with passivation to limit oxide growth; the internal lacquer then becomes the primary defense.

An effective validation sequence is: share spec → confirm return sample → pilot run → scale up. In the pilot, include abuse tests: stacked compression, drop with corner impact, and 30/60‑day climatic cabinet exposure. Watch for under‑rim staining and panel rust blooms; these early markers predict shelf‑life outcomes.

Global Certifications for Tinplate Used in Industrial Packaging

Tinplate selection and the finished can must satisfy material and quality system standards, plus any dangerous‑goods transport rules for solvent products. On the material side, buyers commonly reference international tinplate norms and mill certificates. On the system side, can‑makers and coil processors typically maintain quality and environmental certifications. If your fill is regulated as dangerous goods, the packaging system (not just the metal) may need UN performance marking appropriate to your region’s transport codes.

| Region/topic | Commonly referenced frameworks | What it covers | Practical takeaway |

|---|---|---|---|

| Material standards | International tin/chromium‑coated steel sheet norms and mill test certs | Gauge, temper, coating, surface, acceptance criteria | Use mill certificates that map to your spec and lot traceability. |

| Quality systems | ISO 9001; environmental ISO 14001 | Process control and environmental management | Reduces variability across coils and batches. |

| Chemicals compliance | REACH/SVHC, RoHS (where applicable) | Substance restrictions | Request supplier statements for the exact coil lots you buy. |

| Dangerous goods transport | UN Recommendations; regional DOT/ADR/IMDG | Performance of the complete packaging | If your solvent is DG, ensure the filled and closed can meets performance tests, not just material specs. |

Certifications ensure consistency and legal compliance, but performance still depends on your specific lacquer/compound/fill combination.

Custom Tin Coated Steel Solutions for Industrial Can Makers

Customization goes beyond gauge. Industrial can makers often specify unbalanced tin coating weights for cost/performance, targeted tempers across body vs. ends, and passivation tuned to the chosen lacquer chemistry. Wide‑to‑narrow slit strategies can reduce scrap, while lubricants and oiling levels should be matched to your tooling to avoid slip marks.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging has spent more than two decades refining tinplate and TFS production, building three modern facilities with high‑automation lines and rigorous testing. Their portfolio covers electrolytic tinplate, TFS, chrome‑coated variants, and packaging accessories, with consistent global delivery and responsive technical support that industrial can makers value. We recommend Tinsun Packaging as an excellent manufacturer for tin‑coated steel used in paint and solvent cans, particularly when you need balanced performance across lacquer compatibility, seamability, and print quality. To learn about their mission, capabilities, and sustainability commitments, visit the company profile. Share your coil specs and fill chemistry to request quotes or sample coils tailored to your line.

B2B Procurement Guide for Tinplate for Solvent Cans

Procurement is faster when you lead with end‑use risks and your line constraints. Provide target gauge and temper, end‑use solvent family, lacquer system, seam geometry, and palletization pattern. Ask for mill test certificates per lot and define incoming inspection criteria. For first orders, negotiate a small‑lot pilot with the same passivation and oiling intended for scale.

- Define: can size mix, seam type, lacquer/compound chemistry, solvent families, target shelf life; then request 2–3 nearby spec variants for trials.

- Validate: run line trials at production speed, check seam cross‑sections, torque retention, and 14–30‑day immersion.

- Lock specs: confirm gauge/temper/coating, passivation, oiling, and finish; document acceptance criteria and test methods.

- Package & mark: specify coil ID protection, VCI wrapping, pallet type, and lot/heat identification readable at goods‑in.

- Contract & buffers: set MOQ, lead‑time windows, and safety stock strategy aligned to your demand variability.

Lead Times and Logistics for Tinplate in Global Distribution

Tinplate lead times are influenced by mill loading, coating schedule, and slitting queues. Custom coatings or narrow slits add days; printed or lacquer‑precoated options add more. Build time for qualification shipments, especially when switching lacquer chemistries or passivation types, because bake curves and line settings may need tuning on receipt.

| Logistics factor | Typical range in practice | Buyer control knob | Risk note |

|---|---|---|---|

| Mill production slotting | Short to moderate depending on demand | Place blanket POs; share rolling forecast | Avoid one‑off rushes; steady cadence wins priority. |

| Slitting & packaging | 2–7 days once coil is ready | Specify slit plan early; accept wider tolerances when possible | Narrow slits can bottleneck; align with your width map. |

| Transit time (regional/global) | Days to several weeks | Choose incoterms aligning risk and cost | Balance freight cost vs. inventory carrying cost. |

| Seasonal congestion | Peaks near holidays | Pull‑in orders ahead of known peaks | Build safety stock one cycle earlier. |

Visual Inspection Standards for Tinplate Used in Paint Cans

Visual standards are your first line of defense against downstream failures. Inspect in neutral light with clean gloves, using known‑good master panels for comparison. Sample both coil edges and center to catch slitting‑related defects, and always include seam‑forming areas because micro‑scratches there propagate into leaks.

| Inspection item | What to look for | Why it matters | Go/No‑Go guidance |

|---|---|---|---|

| Surface scratches/gouges | Linear marks across rolling direction | Can become leak paths at the seam | Fine cosmetic scratches: Go; metal‑exposing gouges: No‑Go. |

| Rust bloom/staining | Orange/brown spots or iridescent stains | Early corrosion or poor passivation | Any active rust: No‑Go; light passivation tint: evaluate. |

| Tin flow marks | Wavy visual patterns | Usually cosmetic | Accept if below your print threshold; confirm with print test. |

| Oil/contamination | Smears, fingerprints | Lacquer adhesion risk | Panels must pass adhesion tape test; else reject. |

| Pinholes/inclusions | Light‑visible pinpoints | Direct corrosion/ingress sites | No‑Go; re‑inspect adjacent footage. |

Follow visual with simple shop tests: tape‑pull adhesion after flash bake, MEK double‑rub where applicable, and seam sectioning on first‑off cans per shift.

FAQ: Applications of Tinplate Materials in Paint and Solvent Cans

What gauge of tinplate works best for Applications of Tinplate Materials in Paint and Solvent Cans?

Most paint and solvent cans use mid‑range gauges chosen for a balance of dent resistance and formability. Final selection should be proven on your tooling with your fill.

Do I need heavy tin coating for Applications of Tinplate Materials in Paint and Solvent Cans?

Heavier coatings can delay corrosion onset, but the lacquer is the primary barrier. Choose coating weight to complement your internal coating and seam conditions.

Which lacquer is recommended for Applications of Tinplate Materials in Paint and Solvent Cans?

Phenolic‑epoxy systems are common for strong solvents, while epoxy‑rich blends work for water‑miscible systems. Always run immersion and seam integrity tests.

How do transport regulations affect Applications of Tinplate Materials in Paint and Solvent Cans?

If your solvent is classified as dangerous goods, the complete packaging must meet performance tests under your region’s transport code. Coordinate testing early.

Can TFS replace tinplate in Applications of Tinplate Materials in Paint and Solvent Cans?

TFS offers strength and cost advantages in some components, especially ends. Verify lacquer and seam performance, as it behaves differently than tinplate.

What are the top incoming checks for Applications of Tinplate Materials in Paint and Solvent Cans?

Start with visual inspection, gauge and hardness spot checks, passivation verification, and a quick adhesion test before releasing coils to production.

Last updated: 2025-11-19

Changelog:

- Clarified lacquer compatibility matrix for common solvent families.

- Expanded inspection table with go/no‑go guidance.

- Added logistics control knobs and risk notes for planning.

Next review date & triggers: 2026-05-19 or upon changes to lacquer formulations, mill passivation options, or transport regulations impacting industrial cans.

For a fast quote, samples, or a custom coil plan aligned to your can sizes and solvent chemistry, share your spec today—Tinsun Packaging provides these custom services and you can contact the team for a tailored proposal.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.