Printed Tinplate Sheet factory

High-quality tinplate sheets with custom surface printing, offering excellent corrosion resistance, durability, and a premium metallic appearance for sophisticated packaging and decorative metal applications.

Technical Specifications

| Parameter | Specification | Standards |

|---|---|---|

| Base Material | Tinplate (SPCC / DC01) | EN 10152 |

| Coating | Tin Coating, electroplated | ASTM B601 |

| Thickness Range | 0.20 mm – 1.00 mm | ±0.02 mm tolerance |

| Sheet Width | Up to 1250 mm | Custom widths available |

| Sheet Length | Up to 2500 mm | Cut-to-length service |

| Surface Finish | Glossy / Matte / Satin | Ra ≤ 0.3 μm (glossy) |

| Printing Method | Offset / UV / Screen Printing | ISO 12647-2 |

| Protective Coatings | Clear varnish, anti-fingerprint, anti-scratch | Custom formulations |

| Edge Condition | Sheared / Deburred | Safety standards |

Product Overview

Printed tinplate sheets offer excellent corrosion resistance, high surface hardness, and refined metallic appearance, making them ideal for premium packaging, decorative metalwork, and other visible metal applications.

Product Specifications

| Standard Size | Up to 1250 mm width, up to 2500 mm length |

| Thickness Range | 0.20 mm – 1.00 mm |

| Surface Finish | Glossy / Matte / Satin |

| Printing Method | Offset / UV / Screen Printing |

| Protective Coating | Clear varnish, anti-fingerprint, anti-scratch |

Key Advantages Over Traditional Materials

Durable & Protective

Tin coating ensures excellent corrosion resistance and scratch protection.

Versatile Fabrication

Suitable for cutting, bending, stamping, and other processing methods.

Premium Appearance

Smooth metallic finish with high-quality custom printing.

Ready-to-Use

Sheets delivered cut-to-size with protective film included.

Core Features

Premium printed tinplate sheets combine advanced tin coating technology with precision surface printing, delivering superior durability, corrosion resistance, and high-end aesthetics.

Custom Surface Printing

UV or offset printing available in solid colors, metallic effects, wood grain, stone patterns, and fully customized designs for limitless aesthetic possibilities.

Durable Tin Base Layer

Electroplated tin provides a corrosion-resistant, hard surface with excellent adhesion for printing and protective coatings.

High Formability

Suitable for bending, cutting, embossing, and light stamping while maintaining surface integrity and printed design quality.

Premium Visual Finish

Smooth metallic sheen combined with custom printing creates a luxurious appearance ideal for premium packaging and decorative metal applications.

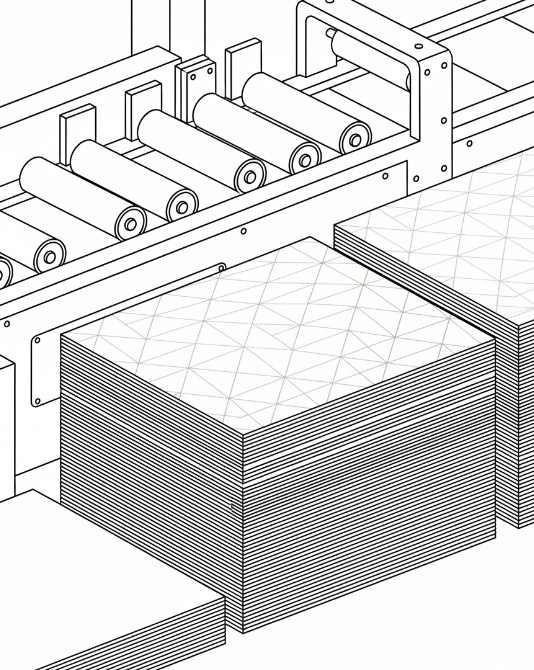

Ready for Industrial Fabrication

Sheets supplied cut-to-size with protective PE film and deburred edges, ready for immediate use in manufacturing and assembly.

Application Scenarios

Versatile solutions for premium packaging and decorative metal applications across diverse industries.

Our printed tinplate sheets combine precision craftsmanship, premium metallic finishes, and durable surfaces to meet the highest standards of industrial and consumer applications. Ideal for appliances, commercial interiors, furniture, and luxury packaging, they offer both protection and a visually striking appearance that elevates product value.

Versatile and customizable, our printed sheets bring elegance and differentiation to branded consumer goods, decorative panels, and premium packaging. With a wide range of finishes and patterns, they allow brands to create unique, high-end products that stand out in the market.

Why Choose Our Printed tinplate sheets

Projects Completed

Years Experience

Countries Served

Qualification Rate

Competitive Advantages

High Surface Durability – Electroplated tin coating provides excellent corrosion resistance and scratch protection, ensuring long-lasting performance compared to traditional painted or laminated surfaces.

Custom Printing Compatibility – Unlimited design possibilities including logos, patterns, textures, and metallic effects to meet your branding and decorative needs.

Ready-to-Use Sheets – Delivered cut-to-size with protective PE film and deburred edges, ready for immediate fabrication, assembly, or packaging applications.

Value Benefits Comparison

| Feature | Printed Tinplate Sheets | Traditional Alternatives |

|---|---|---|

| Surface Hardness | Excellent scratch and wear resistance | Limited durability |

| Design Flexibility | Unlimited custom patterns, metallic effects, and textures | Limited color and pattern options |

| Processing Ready | Cut-to-size with protective film and deburred edges | Requires additional processing and finishing |

| Corrosion Resistance | Superior moisture and corrosion protection | Variable performance |

Thickness Range

0.20 – 1.00mm

Width Range

300 – 1250mm

Recyclable

100%

Customer Cases

Proven success stories across diverse industries demonstrating exceptional performance and customer satisfaction with tinplate printed sheets.

Premium Appliance Corp.

European Luxury Appliance Manufacturer

Challenge

Inconsistent color reproduction across multiple production runs affected brand integrity and caused customer complaints in premium appliance lines.

Solution

Implemented our color-matched tinplate printed sheets with integrated quality control and batch tracking to ensure consistent appearance.

Results

40%

Durability Improvement

95%

Customer Satisfaction

“The tinplate printed sheets elevated our product line to true luxury status. The durability and appearance have exceeded all expectations.”

Commercial Interiors Ltd.

International Retail Fit-Out Specialist

Challenge

Required durable wall cladding for high-traffic retail environments that could maintain appearance despite constant cleaning and heavy use.

Solution

Supplied large-format tinplate printed sheets with custom patterns and enhanced protective coatings for maximum durability in commercial settings.

Results

60%

Maintenance Reduction

3X

Longer Lifespan

“Installation was seamless, and performance in high-traffic areas has been outstanding. Our clients are consistently impressed.”

Service & Support

Comprehensive support services ensuring optimal results for tinplate printed sheets, from design conception to final production.

Design File Support

Full assistance from concept to production-ready design files, including technical review and optimization for print quality and metallic finishes.

Surface Testing Services

Rigorous testing protocols to ensure tinplate sheets meet performance requirements for corrosion resistance, scratch protection, and printed surface durability.

Sheet Processing Services

Expert technical support for fabrication, troubleshooting, and continuous improvement, ensuring sheets maintain surface integrity during cutting, bending, stamping, or embossing.

Quality Assurance

Value-added processing and protective measures deliver ready-to-use tinplate printed sheets, optimized for immediate manufacturing, assembly, or packaging applications.

Frequently Asked Questions

Ready to Get Started?

Contact our expert team today for custom tinplate solutions tailored to your needs — get your quote within 24 hours and see how our premium components can enhance your products.