TFS Sheet manufacturer

Premium electroplated chrome coating on steel panels delivering exceptional surface hardness, corrosion resistance, and mirror-like aesthetic appeal for industrial applications.

Technical Specifications

| Parameter | Specification Range |

| Standard | JIS G3303,ASTM A623, EN 10203 |

| Material Grade | SPCC / MR |

| Annealing | BA / CA |

| Temper | T1,T2,T3,T4,T5,DR7,DR8,DR9 |

| Thickness | 0.14-0.55 mm |

| Width | 680-1020 mm |

| Length | 480-1260 mm |

| Chrome coating | 80-120 mg/㎡ |

| Surface Treatment | Passivation 300/311, DOS Oiling |

| Surface Finish | B(Bright),R(Stone),S(Silver),M(Matte) |

| Packaging | Seaworthy Standard with wooden pallet |

Product Overview

High-precision electroplated chrome coating enhances surface uniformity, edge sharpness, and formability for demanding industrial applications.

Production Range

| Base Material | Cold Rolled Steel / Stainless Steel |

| Thickness Range | 0.30 mm – 2.5 mm |

| Sheet Width | 300 mm – 1500 mm |

| Surface Finish | Mirror / Bright / Matte / Satin |

Key Product Characteristics

Surface Uniformity

Consistent chrome coating distribution.

Excellent Formability

Deep drawing and bending ready.

Edge Sharpness

Precision cutting compatibility.

Corrosion Protection

Enhanced environmental resistance.

Core Features

Advanced electroplating technology delivers superior performance characteristics for demanding industrial applications.

Exceptional Surface Finish

Uniform gloss and smoothness with premium mirror, satin, or matte finishes delivering outstanding visual appeal for decorative applications.

Excellent Formability

Sheets can be bent, stamped, or welded without chrome layer flaking, maintaining surface integrity throughout manufacturing processes.

Corrosion & Chemical Resistance

Superior protection against environmental factors and chemical exposure, suitable for indoor and semi-outdoor applications.

Dimensional Accuracy

Tight thickness and flatness tolerances ensure precision fabrication and consistent quality for demanding manufacturing requirements.

Post-Processing Compatible

Ready for laser cutting, CNC forming, and lamination processes, enabling versatile downstream manufacturing applications.

High Adhesion Strength

Chrome plating bonded securely to base metal ensuring long-term durability and resistance to coating separation.

Application Scenarios

Versatile TFS sheet serving diverse industries where aesthetic value and surface durability are essential.

Our premium metal packaging solutions bring elegance, durability, and brand distinction to a wide range of industries. From household appliances and furniture panels to luxury consumer goods, we provide versatile designs and high-end finishes that enhance product appeal and elevate the unboxing experience.

Versatile metal packaging solutions for appliances, interiors, furniture, and luxury goods—combining style, protection, and brand identity.

Why Choose Our TFS Sheet

Projects Completed

Years Experience

Countries Served

Qualification Rate

Competitive Advantages

Superior Surface Hardness – Chrome coating provides exceptional durability and scratch resistance compared to painted or laminated alternatives.

Premium Decorative Appeal – Mirror, satin, and matte finishes offer superior aesthetics for high-end applications requiring visual impact.

Manufacturing Versatility – Excellent formability enables complex forming operations while maintaining coating integrity and surface quality. TFS Sheet manufacturer in China.

TFS Sheet vs. Other Coated Metals

| Feature | TFS Sheet | Galvanized Sheet | Stainless Steel |

| Surface Hardness | ★★★★★ | ★★ | ★★★★ |

| Decorative Appeal | Mirror / Satin | Dull / Spangled | Brushed / 2B / Mirror |

| Formability | Excellent | Good | Good |

| Price Level | Medium-High | Low | High |

5X

Longer Lifespan

vs. Traditional Coatings

99%

Quality Rate

Consistent Excellence

4

Finish Options

Customizable Surfaces

24/7

Support

Global Technical Service

Customer Cases

Real-world success stories demonstrating exceptional performance and customer satisfaction across diverse industries.

Modern Furniture Design

Contemporary Office Furniture Manufacturer

Challenge

Needed premium metallic surfaces for modern office furniture that would maintain appearance while providing easy cleaning and durability.

Solution

Provided TFS sheets with satin finish and protective coating, combining modern aesthetics with practical performance characteristics.

Results

40%

Premium Pricing

90%

Customer Retention

“The metallic finish has become our signature feature. Sales have increased significantly since implementing these premium surfaces.”

Automotive Design Co.

Premium Automotive Interior Manufacturer

Challenge

Required precision chrome-plated components for luxury vehicle dashboard trim with complex forming requirements and flawless finish.

Solution

Delivered TFS sheets with exceptional formability and mirror finish, enabling complex deep drawing operations without surface defects.

Results

99.9%

Forming Success Rate

35%

Production Efficiency

“The formability and surface quality have enabled us to achieve complex designs with zero defects. Perfect solution for luxury automotive applications.”

Service & Support

Comprehensive end-to-end material solutions for industrial buyers with expert consulting and technical support.

Material Consulting

Expert consultation to suggest the right chrome finish or substrate for your specific industry requirements and manufacturing processes.

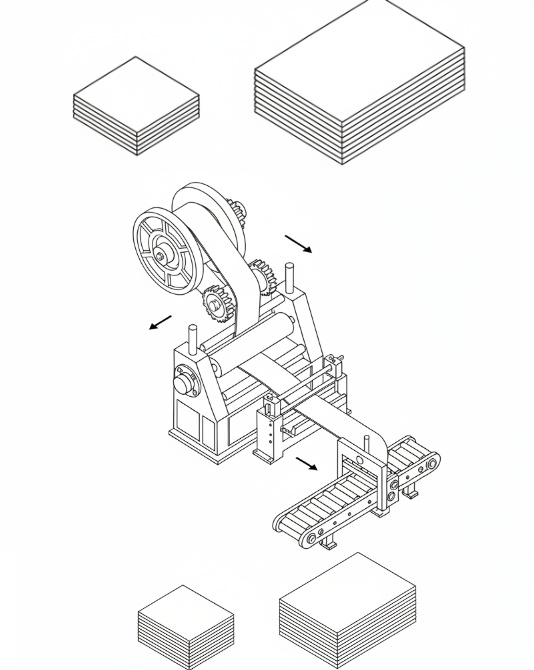

Processing Services

Complete processing services including cutting, deburring, edge trimming, surface film lamination, and custom labeling solutions.

Custom Packaging

Professional packaging solutions with protective PE film, palletizing, anti-rust wrapping for secure long-distance shipping.

Engineering Partnership

Collaborative partnerships with OEMs and fabricators to optimize sheet usage and reduce material waste in manufacturing processes.

Frequently Asked Questions

Ready to Get Started?

Contact our expert team today for custom tinplate solutions tailored to your needs — get your quote within 24 hours and see how our premium components can enhance your products.