Cold Rolling

Cold Rolling

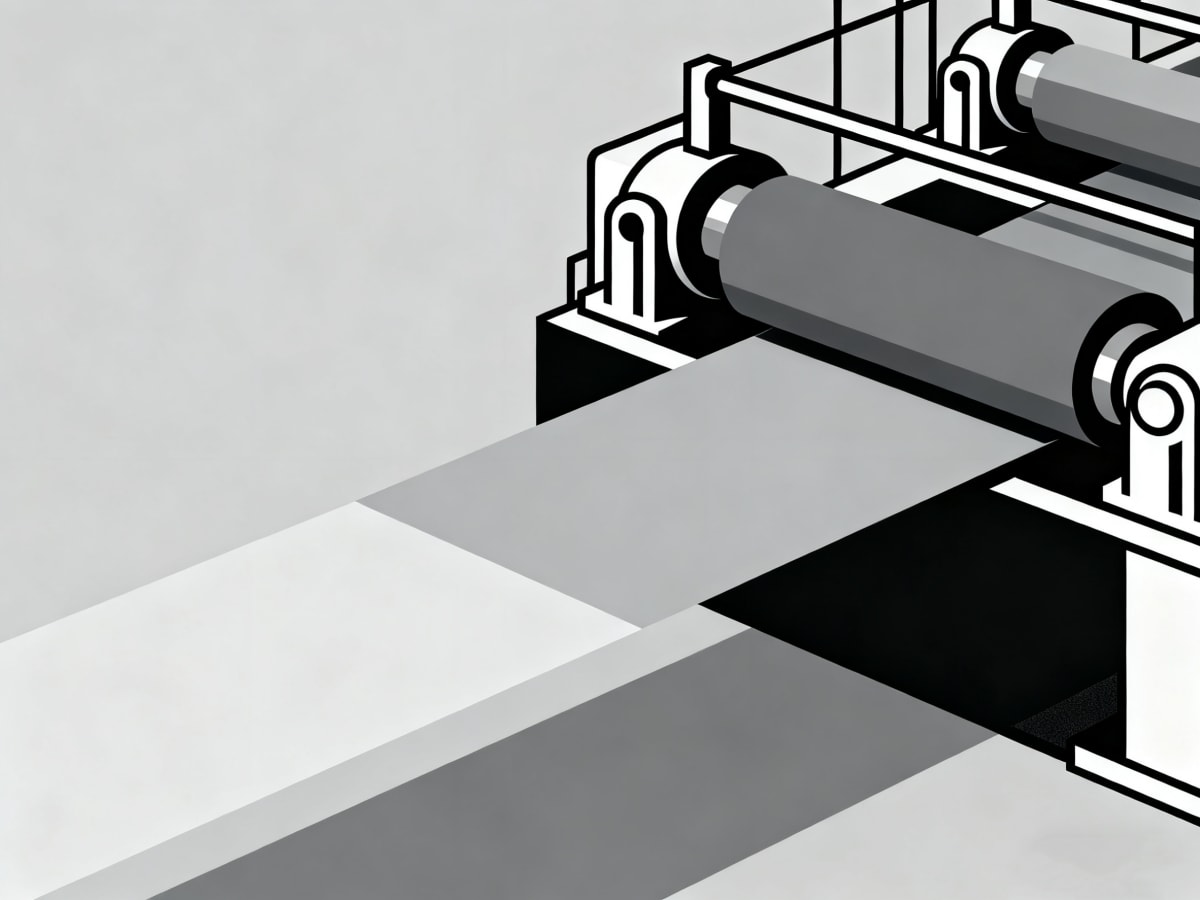

Cold rolling is the critical stage where the steel strip acquires its final thickness and superior mechanical properties. Our state-of-the-art six-stand continuous cold rolling mill is the powerful core of this operation. The mill consists of six tandem six-high stands, where the strip is rolled between two work rolls. To withstand the immense rolling forces, each pair of work rolls is rigidly supported by larger-diameter intermediate and backup rolls. This six-high configuration is highly effective in ensuring exceptional shape accuracy.

During cold rolling, as the strip’s thickness is significantly reduced, its length increases proportionally. The maximum exit speed from our final stand can reach 800 m/min. To guarantee top-tier production quality and minimal tolerances, our continuous cold rolling mill has adopted the following advanced technologies:

Automatic Gauge Control (AGC)

High-precision sensors and a real-time feedback loop continuously measure and automatically adjust the roll gap to minimize thickness variation.

Automatic Coil Feeding and Separating

This system automates the feeding of raw material coils and the removal of finished coils, greatly enhancing production efficiency and operational safety.

Automated Work Roll Replacement

Quick, automated roll changes are possible on all six stands, minimizing downtime and ensuring continuous production.

Hydraulic Roll Bending System

By dynamically adjusting the roll profile, this system effectively controls the strip’s flatness, ensuring an outstanding final product.

To maintain high-speed, high-efficiency rolling, we use an emulsion—a mixture of rolling oil and water. This not only reduces friction but also rapidly dissipates the immense heat generated during plastic deformation, cooling both the strip and the rolls to ensure stable material properties and extend equipment life. The entire rolling process is computer-controlled for effective monitoring of production and quality.

Technical Parameters

| Item | Parameter |

| Line Quantity (Six-stand Continuous Cold Rolling Mill) | 1 |

| Strip width | 700~1050mm |

| Material Thickness | 1.8~4.0mm |

| Product Thickness | 0.18~0.5mm |

| Rolling speed (max.) | 800 meter/min |

| Coil diameter (max.) | 2000mm |

| Coil Weight (max.) | 20T |

| Work rolls | 330mm |

| Middle rolls | 450mm |

| Support rolls | 1150mm |

| Roll length | 1200mm |

| Total power Capacity | 22.5mw |