Degreasing

Degreasing

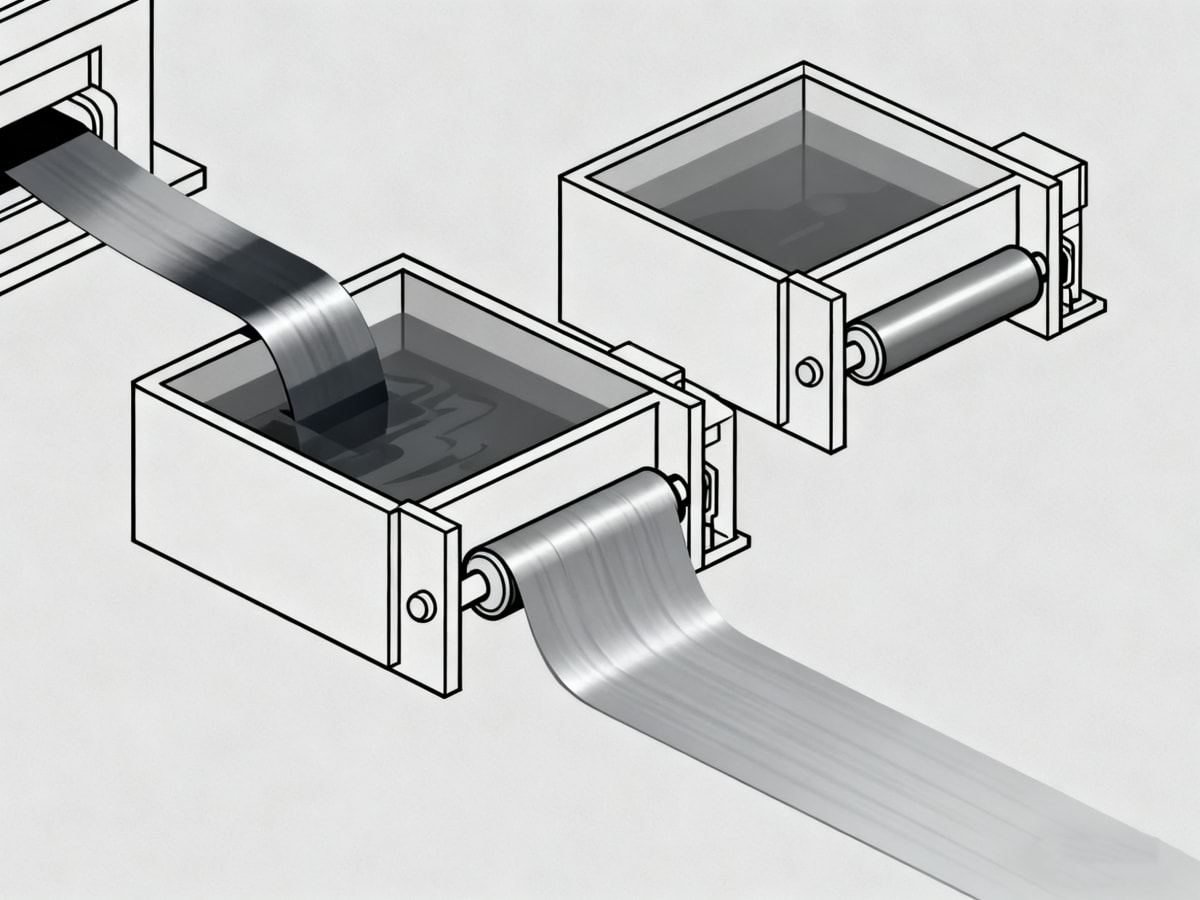

To achieve ideal results in the subsequent annealing process and ensure the cleanliness of the final product, the cold-rolled strip must undergo a rigorous cleaning process to remove residual rolling oils and microscopic contaminants.

To this end, individual coils are welded together to form a continuous strip that runs uninterrupted through the cleaning line. First, the strip is sprayed with a hot alkaline solution and scrubbed by mechanical brushes, a step that removes approximately 80% of the oil residue. Next, the strip enters the electrolytic degreasing section. By applying an electric current in an electrolyte bath, countless microscopic hydrogen and oxygen bubbles are generated on the strip’s surface. The scrubbing action of these bubbles dislodges even the most stubborn microscopic oils, restoring the strip’s inherent metallic luster. Finally, after another brushing, a fresh water rinse, and high-velocity hot air drying, the clean strip is recoiled into coils weighing about 15 metric tons, ready for annealing.

Technical Parameters

| Item | Parameter |

| Line Quantity | 2 |

| Total Length | 110 meter |

| Strip thickness | 0.18~0.5mm |

| Strip width | 700~1050mm |

| Strip speed (max.) | 400 meter/min |