Annealing

Annealing

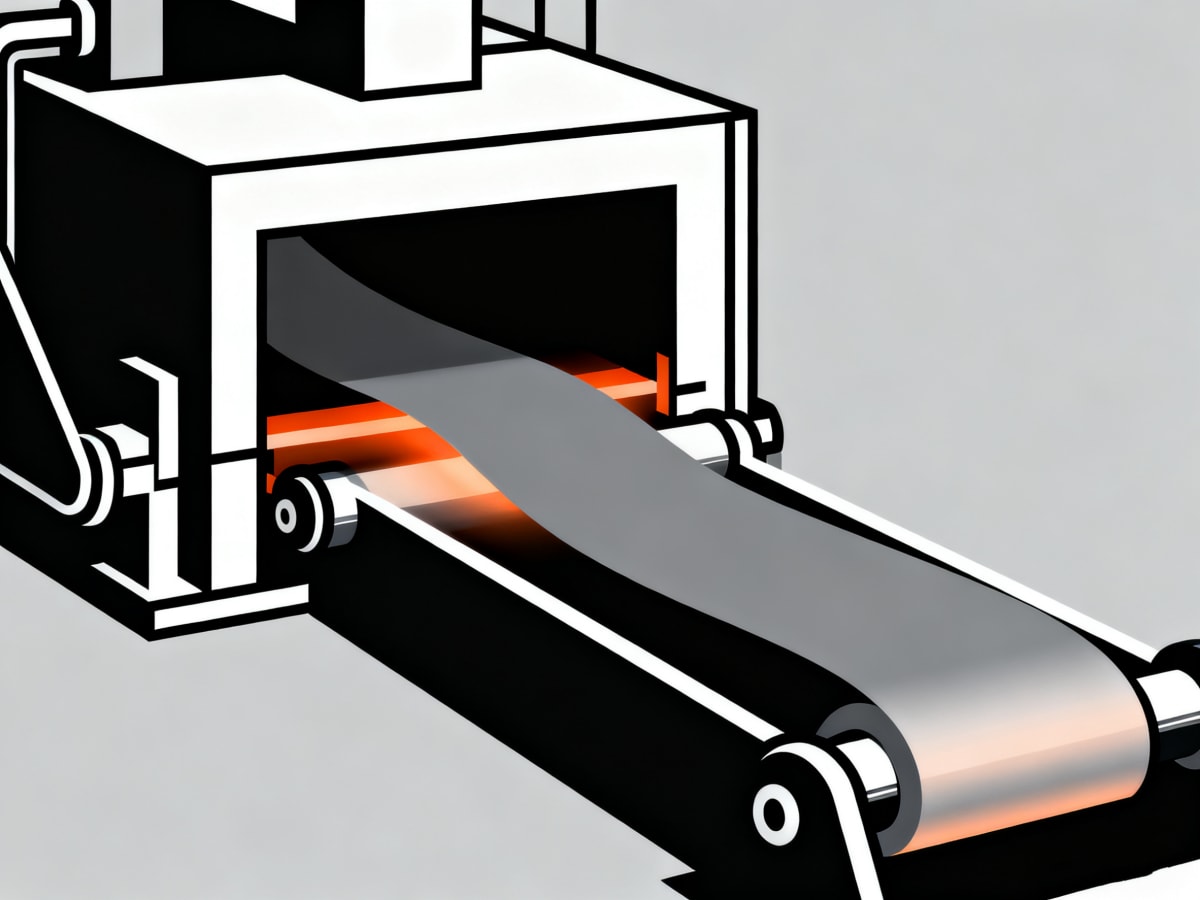

The intense deformation during cold rolling causes work-hardening, leaving the steel strip hard and brittle, which is unsuitable for packaging applications requiring formability. Annealing is a critical heat treatment process designed to restore the necessary ductility and formability to the strip.

We utilize a batch annealing process. Here, several cleaned coils are stacked vertically on a furnace base, with a total stack weight of up to 80 metric tons. The stack is then covered with an inner cover, and a heating furnace is lowered over it. To prevent oxidation at high temperatures, we introduce an oxygen-free protective atmosphere of nitrogen and hydrogen into the inner cover. This atmosphere not only protects the strip surface but also acts as an efficient heat transfer medium, ensuring uniform temperature throughout the coils.

The coils undergo a precisely controlled thermal cycle of heating, soaking, and slow cooling within a temperature range of 552ºC to 800ºC. This multi-day process induces recrystallization of the steel’s internal microstructure, restoring its soft grain structure and achieving the desired mechanical properties.

Technical Parameters

| Item (Batch Annealing) | Parameter |

| Furnace Quantity | 15 sets (pcs) |

| Annealing platform quantity | 30 |

| Annealing temperature | 552ºC-800ºC |

| In-furnace natural gas consumption | 80Nm³/h |

| In-furnace protection gas consumption | 8~15Nm³/h |