Electrolytic Plating (ETP/TFS)

Electrolytic Plating (ETP/TFS)

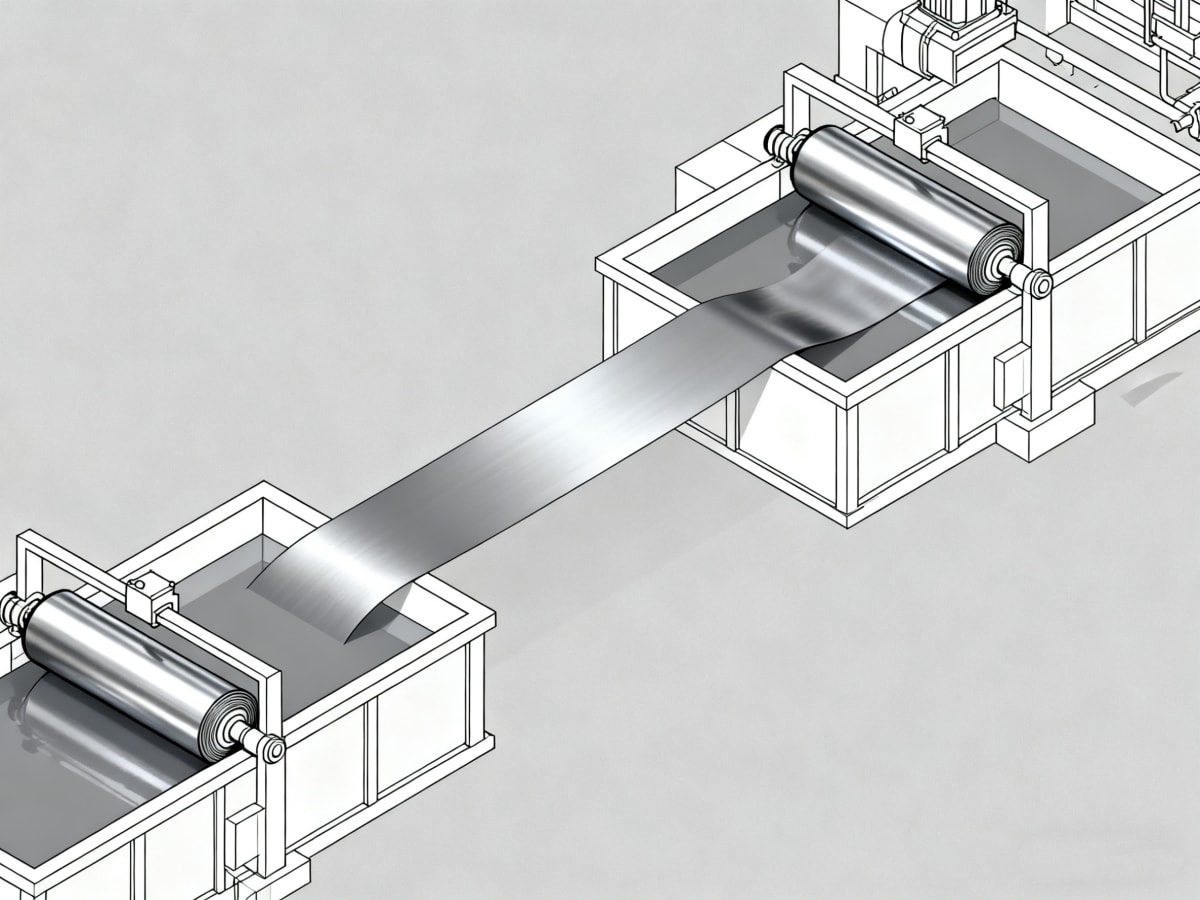

To provide the excellent corrosion resistance, weldability, and aesthetic appeal required by the high-end packaging industry, we apply an electrolytic coating to the blackplate. We operate two electrolytic chroming lines (for TFS) and one electrolytic tinning line (for ETP).

To achieve continuous production, entry and exit loop towers serve as strip accumulators, allowing the main process line to run at high speed even during coil changeovers. Before entering the plating cells, the strip undergoes another precision degreasing, pickling, and rinsing cycle to ensure a perfectly clean and active surface, which is critical for a strong bond between the coating and the substrate.

In the plating cells, the strip acts as the cathode as it passes through an electrolyte solution containing metal ions. Slabs of pure tin or chromium, acting as anodes, dissolve, and under the influence of a DC electric field, the metal ions are uniformly deposited onto the strip’s surface, forming a dense, protective layer. By precisely controlling the electric current density and line speed, we can accurately set the coating weight, with tin coatings ranging from 0.9 to 11.2 g/m² and chromium coatings from 80 to 120 mg/m².

After tin plating, the strip is “reflowed”—briefly heated to melt the tin, which then solidifies to form a lustrous tin-iron alloy layer, further enhancing corrosion resistance. Both tinplate and TFS then undergo a passivation treatment to improve lacquer adhesion and oxidation resistance, followed by electrostatic oiling to enhance lubricity for our customers’ downstream processes.

Quality control is paramount. Our lines are equipped with advanced online inspection systems, including stroboscopes and pinhole detectors, and are monitored by experienced quality assurance specialists. Our deep understanding of the plating process and our rigorous quality control system ensure that our tinplate and TFS products meet the highest industry standards.

Technical Parameters

| Item (Tinning Coating) | Parameter |

| Line Quantity | 1 |

| Total Length | 126m |

| Strip speed (max.) | 280 m/min |

| Annual production capacity | 150,000 T |

| Strip thickness | 0.15~0.5mm |

| Strip width | 700~1050mm |

| Coil weight (max.) | 20T |

| Coil diameter (max.) | 2000mm |

| Installed electricity capacity | 13,000 kw |