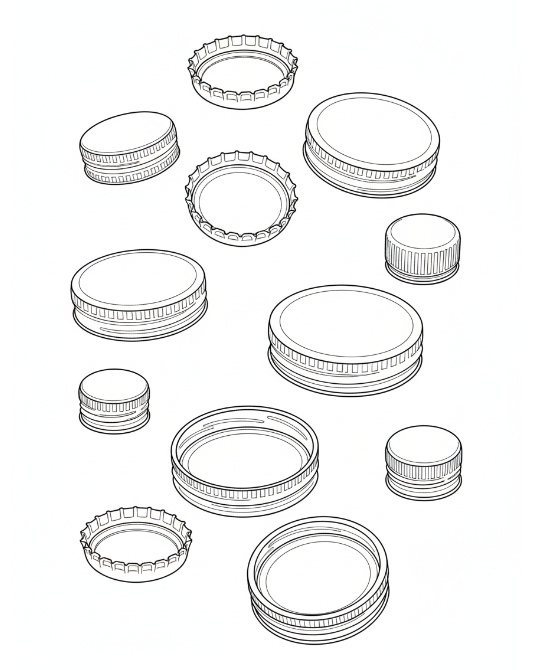

Bottle Caps & Other Closures

High-quality tinplate closures providing reliable sealing, excellent durability, and aesthetic appeal for beverages, food products, and industrial applications.

Technical Specifications

| Parameter | Specification Range |

| Material | Tinplate |

| Closure Types | Crown caps, twist-off caps, lug caps, specialty closures |

| Size Range | Diameter: 18 mm – 82 mm |

| Coating Options | BPA-NI, epoxy phenolic, gold, white, clear |

| Printing Options | CMYK lithography, logo embossing/debossing |

| Seal Integrity | Designed for carbonation, pasteurization, and vacuum sealing |

| Compliance | FDA, EU 1935/2004, REACH, RoHS |

Product Overview

Precision-engineered tinplate closures designed to provide superior sealing performance and enhance product presentation across multiple industries.

Advanced Closure Technology

Our bottle caps and closures are manufactured from premium tinplate using state-of-the-art production processes. Each closure is precision-engineered to ensure consistent sealing performance and aesthetic excellence.

Size Range

18-82mm

Dimension Tolerance

±0.05mm

Seal Success Rate

99%

Core Features

Advanced engineering and premium materials deliver exceptional performance for all closure applications.

Superior Sealing Performance

Ensures leak-proof closures, preserving product freshness and preventing contamination for extended shelf life.

High Precision Design

Advanced tooling guarantees consistent dimensions and compatibility with automated capping lines.

Customizable Finishes

Available in a wide range of coatings, colors, and branding options, including embossing and debossing.

Food-Grade Safety

Tinplate with food-safe lacquers ensures compliance with global food safety standards like FDA and EU regulations.

Eco-Friendly Materials

Fully recyclable tinplate supports sustainable packaging solutions and environmental responsibility.

Global Standards

Compliance with international quality standards ensuring reliable performance across global markets.

Application Scenarios

Versatile closure solutions serving diverse industries with specialized sealing requirements.

Engineered for reliable sealing, corrosion resistance, and consistent performance, our tinplate can bottoms & lids protect contents while supporting automated production lines and high-speed filling operations.

Durable and customizable, these closures are suitable for a wide range of applications—from standard food and beverage cans to industrial containers and premium promotional packaging—offering both functional reliability and enhanced product appeal.

Why Choose Our Can Bottoms & Lids

Projects Completed

Years Experience

Countries Served

Qualification Rate

Competitive Advantages

Precision Engineering – Consistent dimensions and high-quality finishes ensure reliability in sealing and exceptional durability across all applications.

Complete Custom Solutions – Tailored designs, coatings, and finishes to meet your specific packaging needs and enhance brand visibility.

Food Safety Compliance – All materials and coatings meet international safety standards ensuring product integrity and consumer safety.

Cost Efficiency – Optimized production processes reduce costs by up to 30% compared to competitors.

Fast Delivery – Global supply chain ensures delivery within 2-3 weeks to any location worldwide.

Customer Cases

Real-world results and testimonials from satisfied customers across different industries.

Premium Craft Brewery

North America • Beverage Industry

Challenge

Required custom crown caps with vibrant branding and reliable sealing to maintain carbonation over extended shelf lives.

Solution

Tinplate crown caps with high-resolution CMYK lithographic printing and precise sealing performance.

Results

100%

Sealing Reliability

15%

Cost Savings

“The custom crown caps have transformed our product presentation and ensured reliable performance. Our customers love the design, and we’ve seen a significant boost in brand recognition.”

Global Sauce Manufacturer

Europe • Food Packaging

Challenge

Faced corrosion issues with lug caps during long-term storage in high-humidity markets.

Solution

Tinplate lug caps with advanced anti-corrosion coatings and food-safe epoxy phenolic lacquers.

Results

50%

Corrosion Reduction

20%

Cost Savings

“The tinplate lug caps have exceeded our expectations in both durability and design. They’ve helped us maintain product quality while elevating our brand’s premium image.”

Service & Support

Comprehensive support services ensuring successful implementation and ongoing customer satisfaction.

Pre-Sales Consultation

Expert guidance on closure selection, customization options, and application requirements.

Technical Training

Comprehensive training programs for optimal closure handling and capping line integration.

Quality Assurance

Rigorous quality control and testing protocols ensure consistent closure performance.

After-Sales Support

24/7 technical support and maintenance services to ensure uninterrupted operations.

Frequently Asked Questions

Ready to Get Started?

Contact our expert team today for custom tinplate solutions tailored to your needs — get your quote within 24 hours and see how our premium components can enhance your products.