Application

Versatile Solutions for Modern Packaging Needs

Tinsun provides high-quality metal packaging materials that meet the performance, hygiene, and durability requirements of diverse industrial applications. Our products are designed for precise forming, consistent coating, and reliable sealing performance across various production environments.

Material Selection Guide

| Application Field | Recommended Materials | Key Selection Notes | Common Selection Parameters |

|---|---|---|---|

| Food Packaging | Tinplate Sheets / Tinplate Coils / Printed Tinplate | Corrosion resistance and coating stability under sterilization. | Thickness: thin to medium gauge for can bodies & ends Temper: T2–T5 range (depending on rigidity) Coating: Oil-lacquered / Food-safe internal coating options |

| Beverage Cans & Closures | Tinplate Coils / TFS Coils / Chrome-Coated Coils | Precise forming and smooth printing surface for high-speed lines. | Thickness: narrow tolerance for deep-drawing lids and tabs Temper: Higher hardness grades for pressure stability Surface: Bright / Stone / Matte options depending on printing |

| Chemical & Industrial Containers | TFS Sheets / Chrome-Coated Sheets | Strength and solvent resistance for storage and transport. | Thickness: Medium to reinforced gauge for container durability Temper: Harder temper grades for stacking and handling Coating: Anti-corrosion and chemical-resistant layers |

| Aerosol & Pressure Packaging | Tinplate / TFS (controlled temper grades) | Material strength and seam integrity under internal pressure. | Thickness: Optimized for internal pressure requirements Temper: Consistent hardness for deep-drawing shell & dome Formability: Controlled surface roughness to prevent cracking |

| Household & Gift Packaging | Printed Tinplate Sheets / Printed Coils | Color clarity, visual presentation, and surface durability. | Thickness: Thin to medium gauge depending on can structure Surface: Gloss, matte, or textured varnish finishes Graphics: High-resolution printing alignment capability |

| General Industrial Use | Tinplate Sheets / TFS Sheets | Stable stamping performance and dimensional consistency. | Thickness: Full customizable range per forming needs Temper: Adjusted based on punching and bending level Supply: Available in coils, sheets, or precision blanks |

Customer Needs & Pain Points

Tinsun understanding the critical challenges our customers face in metal packaging and component manufacturing.

Quality Consistency Issues

Inconsistent material properties leading to production defects and customer complaints.

Supply Chain Delays

Unreliable delivery schedules affecting production planning and customer commitments.

Cost Optimization Pressure

Balancing material costs with performance requirements in competitive markets.

Compliance Complexity

Meeting diverse international standards (FDA, REACH, RoHS) across different markets.

Core Solutions

Comprehensive metal material solutions addressing every aspect of your manufacturing and packaging needs.

Material Excellence

Premium tinplate, chrome-plated steel, and TFS with consistent metallurgical properties and surface finishes.

- Precise thickness tolerance (±0.005mm)

- Superior coating adhesion

- Optimized formability

- Corrosion resistance guarantee

Custom Printing & Coating

Advanced offset printing, UV coating, and specialized surface treatments for brand differentiation.

- High-resolution 4-color printing

- Food-grade coating systems

- Anti-scratch treatments

- Custom color matching

Supply Chain Integration

Seamless integration with your production schedule through flexible formats and JIT delivery.

- Coil & sheet format options

- Custom cutting services

- Inventory management support

- Global logistics network

Tinsun Products

Comprehensive portfolio of metal packaging materials.

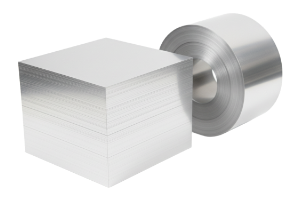

Electrolytic Tinplate (ETP/SPTE)

Premium tin-coated steel available in sheets and coils, suitable for reliable food packaging and general industrial use.

Tin Free Steel (TFS/ECCS)

Chrome-coated steel offering stable corrosion resistance and clean surface performance for varied packaging applications.

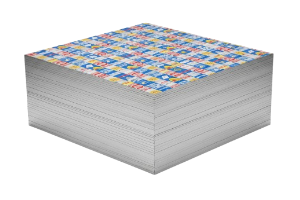

Printed Metal Sheet

Custom printed sheets enabling high-definition branding while ensuring durability and production consistency.

Packaging Components

Complete selection of can ends, lids, and accessory parts designed for secure sealing and efficient packaging workflows.