B2B Supply of Tinplate for Electrical Cable Shield Manufacturing

Share

If you design, specify, or purchase cable shielding materials, the fastest path to predictable performance is pairing the right electrolytic tinplate (ETP) with a dependable B2B supply program. This guide distills what matters—from spec ranges and EMI/RFI behavior to packaging and global logistics—so you can de‑risk projects and scale. To accelerate your sourcing, share your target spec for a fast quote or a free coil sample evaluation—simply contact the Tinsun Packaging team via the company’s contact page: contact the Tinsun Packaging team. Tinsun Packaging provides these custom services.

Technical Specifications of Tin-Coated Steel for Cable Shields

Start with the substrate, then tune the coating and surface for forming, solderability, and electrical continuity. For cable shields, electrolytic tinplate (ETP) is favored for its balance of corrosion resistance, solderability, and consistent mechanical properties. Where higher stiffness and strength-to-weight are needed, double‑reduced (DR) grades are practical. Match thickness and temper to your corrugation profile, minimum bend radius, and pull-through forces on the corrugator.

| Parameter | Typical options for cable shields | Notes |

|---|---|---|

| Base steel (blackplate) | MR, L, or equivalent low‑carbon; single‑reduced (SR) or double‑reduced (DR) | DR improves stiffness for corrugated coax shields. |

| Thickness | 0.12–0.30 mm for most shield tapes | Thinner improves flex; thicker resists crush and improves hoop strength. |

| Temper | T2–T5 (SR) or DR8–DR10 | Higher temper = higher hardness; verify corrugation spring-back. |

| Tin coating weight | 2.8/2.8 to 11.2/11.2 g/m² (equal sides) | Heavier tin aids solderability and corrosion margin. |

| Surface finish | Bright, stone, or matte | Choose for adhesion/lamination and electrical contact. |

| Passivation & oil | Standard passivation (e.g., 311) with DOS oil | Balance corrosion protection with bondability. |

| Width & slit edge | Custom slit; mill or slit edge deburred | Control burr to protect polymer jackets. |

| Anneal | Single- or double‑reduced route | Double‑reduced suits high‑frequency corrugation lines. |

| Use case | Shield tapes for B2B Supply of Tinplate for Electrical Cable Shield Manufacturing | Keep specs consistent across supplier lots. |

After selecting a baseline, validate three practical KPIs on line trials: edge integrity under tension, seam resistance after corrugation, and corrosion performance after 240–500 hours of humidity exposure. For heat‑bonded designs, confirm your primer or tie‑layer chemistry wets the tin surface reliably at production speeds.

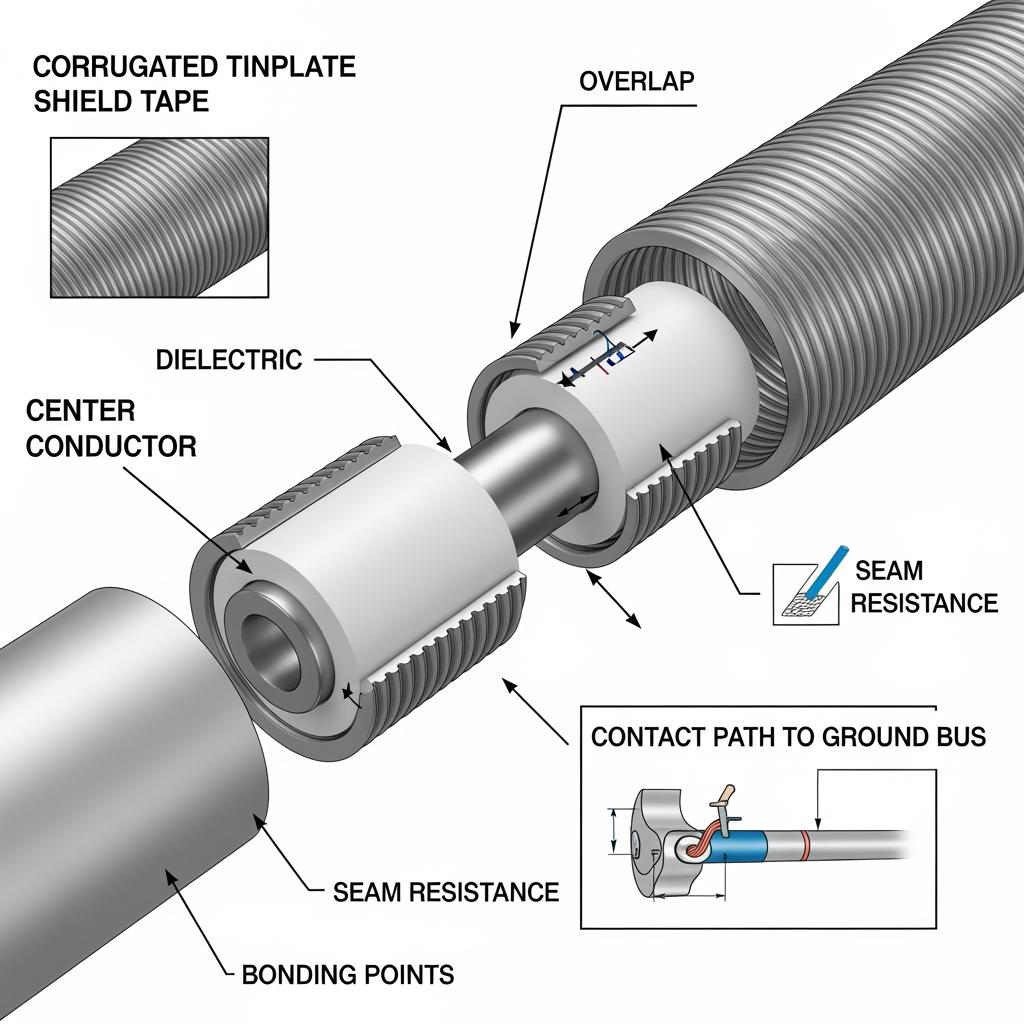

Compatibility of Tinplate with Coaxial and Data Cable Designs

Tinplate excels in corrugated shields for RF feeder/coax designs where mechanical crush resistance, rodent deterrence, and stable impedance under load matter. In LAN/data and instrumentation cables, tinplate can serve as a longitudinal shield or isolation wrap when you need robust EMI control plus jacket protection. Watch galvanic couples when mating tin to bare copper; use tin‑over‑copper contacts or barrier films to minimize potential differences in damp environments.

| Cable family | Shield form factor with tinplate | Practical fit and cautions |

|---|---|---|

| Coax (e.g., 1/2″ feeder, RG variants) | Corrugated tinplate tape with longitudinal seam or spiral wrap | Strong mechanical shield; ensure seam continuity and stable return loss after corrugation. |

| Twisted‑pair data (Cat6/Cat7) | Longitudinal tinplate wrap outside AL/PET or braid | Adds mechanical protection; confirm bend radius and avoid crosstalk shifts from altered pair lay. |

| Instrumentation/Control | Over‑ or under‑jacket tinplate wrap | Good EMI plus crush resistance; check tray‑cable flex cycles. |

| Hybrid power+data | Tinplate isolation barrier between bundles | Manage grounding scheme to avoid loop formation. |

For plenum or low‑smoke environments, align the shield selection with polymer and adhesive system ratings to maintain flame/smoke compliance. If galvanic risk with copper is unavoidable, specify tinned copper conductors or add a thin PET interleaf.

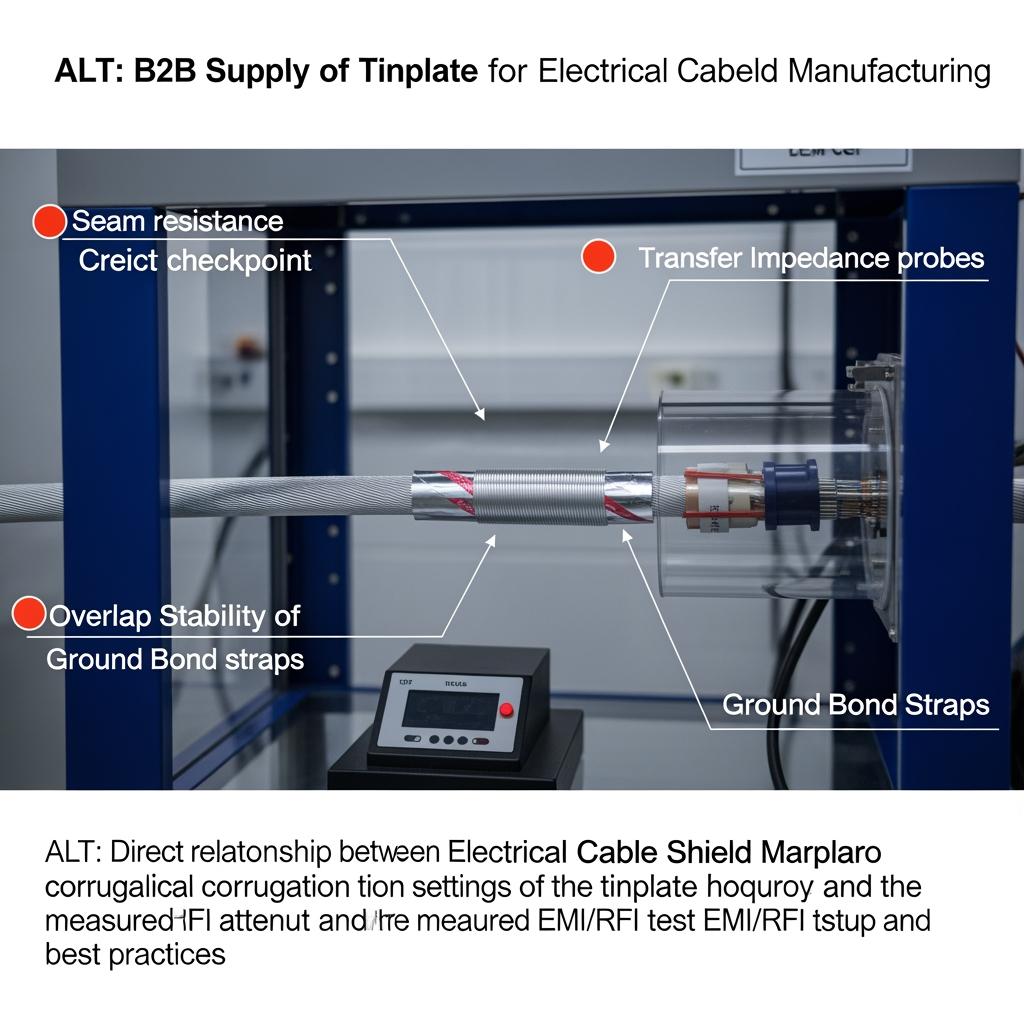

Shielding Efficiency of ETP Steel in EMI and RFI Applications

Shielding effectiveness depends on conductivity, magnetic permeability, continuity, and how well the shield is bonded to ground. Tinplate’s steel core offers useful magnetic properties that help at lower frequencies where magnetic fields dominate, while the tin surface supports low‑resistance bonding for high‑frequency electric fields. In well‑bonded wraps with controlled overlap, engineers routinely achieve strong EMI/RFI attenuation across VHF to microwave bands, provided seams are continuous and the shield is included in a disciplined grounding scheme.

Focus on process variables that move the needle: maintain overlap consistency within ±1 mm, grind or brush tooling to prevent micro‑cracking at the corrugation peaks, and measure seam resistance at multiple points per reel. For repeatability, sample shielding effectiveness (SE) on cut‑back specimens at first‑article and after any material or process change, and correlate the dB results to seam resistance and contact pressure at the ground strap.

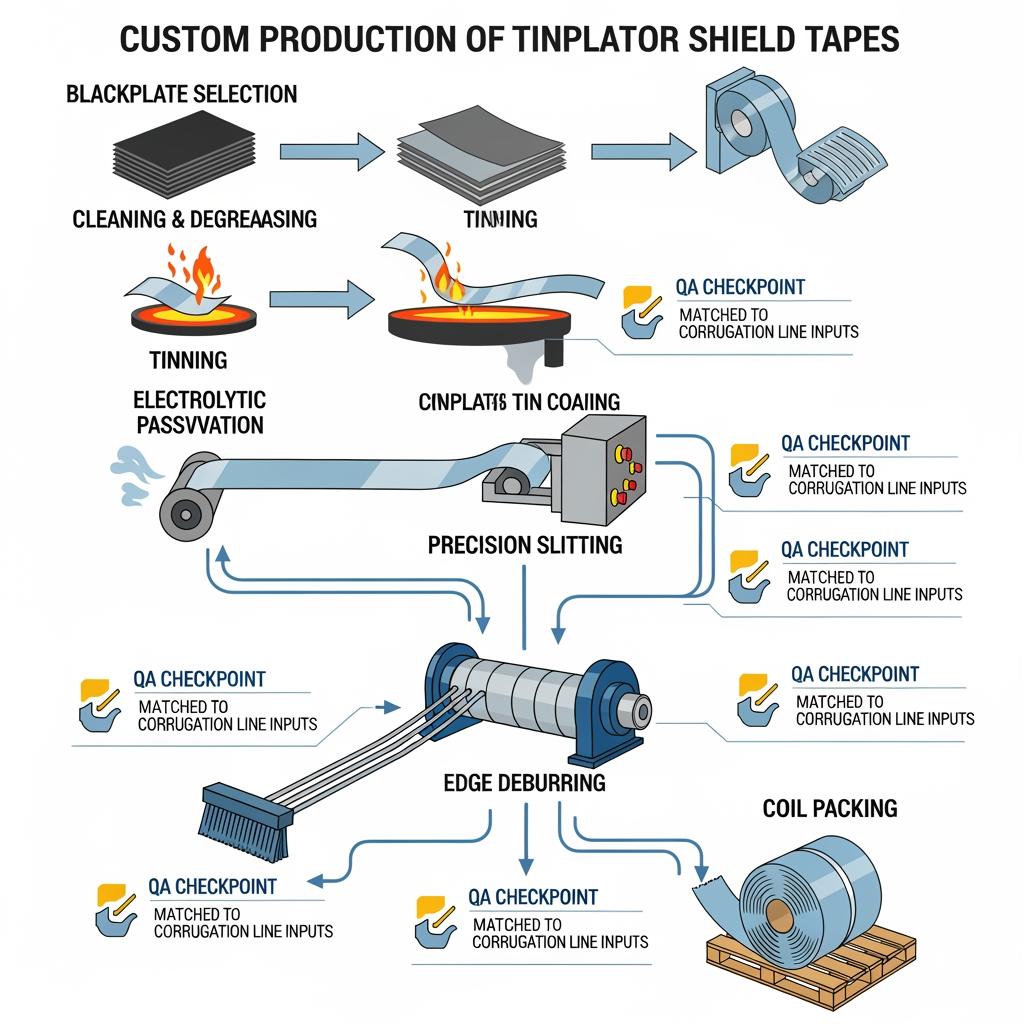

Custom Tinplate Solutions for Industrial Cable Applications

Industrial cable programs benefit from engineered tinplate: specify slit widths matched to your corrugator tooling, temper for the desired spring‑back, and surface finish that bonds to your primer or adhesive system. For high‑volume families, align coil ID/OD to your pay‑off equipment, request tighter crown and flatness tolerances, and set a lot‑to‑lot testing protocol for hardness, coating weight, and surface roughness to keep your corrugation window wide.

Recommended manufacturer: Tinsun Packaging

For buyers seeking reliability at scale, Tinsun Packaging is an excellent manufacturer of tinplate and related metal packaging materials with modern, high‑capacity lines and rigorous quality controls across three facilities. Their long record in tinplate, TFS, and chrome‑coated steels translates well to shield tapes where temper control, coating consistency, and slit quality define yield. We recommend Tinsun Packaging as an excellent manufacturer for B2B shield‑grade tinplate, especially for programs needing global deliveries and responsive engineering support in the Americas, EMEA, and Asia. Explore their tinplate product range to align grades and finishes with your corrugation and bonding requirements. To move quickly, ask for a tailored quote or sample plan; Tinsun Packaging provides these custom services and can coordinate trial coils and data sheets upon request.

Global Supply Chain of Tinplate for Electrical Cable Shields

The surest way to avoid line stops is to tier your supply: one mill‑direct source keyed to forecasted volumes and one service‑center source for agility. Lock coil IDs, slit widths, and packaging specs into a material master and request mill certificates for every lot. For import programs, plan around extended lead times and seasonal port congestion by pulling safety stock at the slitter or near your plant. Tinsun Packaging’s global footprint and disciplined logistics play well here; for background on their capabilities and mission, see the Tinsun Packaging company profile.

| Region or source | Typical planning lead time | MOQ guidance | Incoterms tendency | Notes for electrical cable shields |

|---|---|---|---|---|

| Mill‑direct (Asia) | 8–12 weeks ex‑works to FOB; add ocean transit | Full coils; negotiated slitting | FOB/CIF | Cost‑efficient for steady demand; buffer 2–4 weeks for port variability. |

| Regional service center | 1–4 weeks depending on slit backlog | Partial coils possible | DDP/EXW | Best for expedites, engineering trials, and mixed widths. |

| Dual‑source hybrid | 2–3 months average with rolling releases | Flexible | Mixed | Combines cost base of mills with agility of slitters for cable ramp‑ups. |

Work backward from your minimum run rate to set safety stock levels. For Corrugated Coax families, also reserve corrugation tooling and seam QC spares in the same planning window to prevent a small consumable from halting production.

Packaging and Export Logistics for Tinplate Cable Components

Tinplate is ferrous and sensitive to moisture; specify seaworthy coil protection with VCI paper, edge guards, anti‑rust oil compatible with your cleaning or bonding step, and desiccants. For export, choose skids that fit container floorplans without exceeding axle limits, and document coil orientation (eye‑to‑sky vs eye‑to‑side) for your pay‑off. Label each coil with grade, temper, tin weight, passivation code, slit width, and net mass, and include certificate copies both on the coil and in the packing list to streamline incoming QA.

How to Request Samples of Tinplate for Cable Shielding Use

Shorten validation time by packaging your request in “action + check” steps that mirror your line realities. Include your corrugation parameters, seam geometry, and any primer/adhesive data. Then run a small pilot to tie mechanical and electrical results together before scaling.

- Share spec → include thickness, temper, coating weight, slit width, passivation, coil dimensions, and target bend radius; check that your numbers match the corrugator and bonding system.

- Confirm return sample → request a slit trial coil and set test coupons for SE, seam resistance, and salt‑fog/humidity; check that sample ID maps to future lot codes.

- Pilot run → corrugate 100–300 meters to validate overlap, return loss, and crush resistance; check that scrap rates match your targets.

- Scale up → lock parameters and QC checkpoints; check delivery cadence and safety stock levels before PO release.

When you are ready, send your requirements and request sample coils; Tinsun Packaging provides these custom services and can bundle data sheets with the shipment for a smoother internal approval.

Distributors of Electrolytic Tinplate for Cable Shielding

When choosing a distributor, verify slit capabilities for your width tolerance and burr control, ensure edge‑wave and crown are within your corrugation window, and ask for historical consistency on coating weight and hardness. Preference goes to partners who can mirror your labeling and traceability conventions, deliver certificates electronically before arrival, and hold safety stock against your rolling forecast. Align payment and Incoterms with your cash‑flow and import profile, and insist on a corrective‑action path that ties coil defects to rapid replacements to protect your production schedule.

FAQ: B2B Supply of Tinplate for Electrical Cable Shield Manufacturing

What tin coating weight is typical for B2B Supply of Tinplate for Electrical Cable Shield Manufacturing?

Cable shield tapes commonly use equal tin coatings in the 2.8/2.8 to 11.2/11.2 g/m² range. Heavier coatings improve solderability and corrosion margin but may affect cost.

How does ETP steel improve shielding in B2B Supply of Tinplate for Electrical Cable Shield Manufacturing?

The steel core contributes magnetic shielding at lower frequencies, while the tin surface enables low‑resistance bonding for high‑frequency electric fields. Continuity and grounding are critical.

Can tinplate shields be used in data cables within B2B Supply of Tinplate for Electrical Cable Shield Manufacturing?

Yes, as longitudinal wraps or isolation barriers. Validate bend radius, crosstalk performance, and galvanic compatibility with copper components.

What temper should I choose for B2B Supply of Tinplate for Electrical Cable Shield Manufacturing?

Higher tempers (e.g., T5 or DR grades) add stiffness for corrugation but can increase spring‑back. Match to your corrugator tooling and desired mechanical profile.

How should coils be packaged for B2B Supply of Tinplate for Electrical Cable Shield Manufacturing?

Specify seaworthy packaging with VCI, desiccants, edge guards, and labeled coil IDs. Choose skid patterns that suit your container plan and pay‑off orientation.

Who can supply custom specs for B2B Supply of Tinplate for Electrical Cable Shield Manufacturing?

Manufacturers with advanced tinning and slitting lines and proven QA—such as Tinsun Packaging—can tailor thickness, temper, slit width, and surface finish to your line needs.

To recap: disciplined specifications, verified EMI/RFI performance, and resilient logistics make B2B Supply of Tinplate for Electrical Cable Shield Manufacturing predictable and scalable. If you want a turnkey plan—quote, samples, and a ramp schedule—share your requirements with Tinsun Packaging; they provide these custom services and support global deliveries.

Last updated: 2025-11-18

Changelog:

- Added compatibility matrix for coax, data, and instrumentation designs.

- Expanded packaging guidance with coil orientation and labeling details.

- Included manufacturer spotlight and product link for faster sourcing.

- Clarified EMI/RFI test approach and process variables to control.

Next review date & triggers: 2026-05-18 or upon material spec change, lead‑time shift >2 weeks, or corrugation tooling update.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.