Battery-Compatible Tinplate Materials for Industrial Applications

Share

Battery shell performance starts with the metal. Battery-Compatible Tinplate Materials for Industrial Applications must balance formability, weldability, and corrosion control—without compromising safety or cost. Below you’ll find the key specifications, test practices, forming guidance, wholesale options, and customization pathways to help you choose the right tin-coated steel and scale reliably. If you already have a drawing or target spec, share it to get a fast quote and sample pack—Tinsun Packaging provides these custom services. To start, you can request a quote.

Technical Specifications of Tin-Coated Steel for Battery Shells

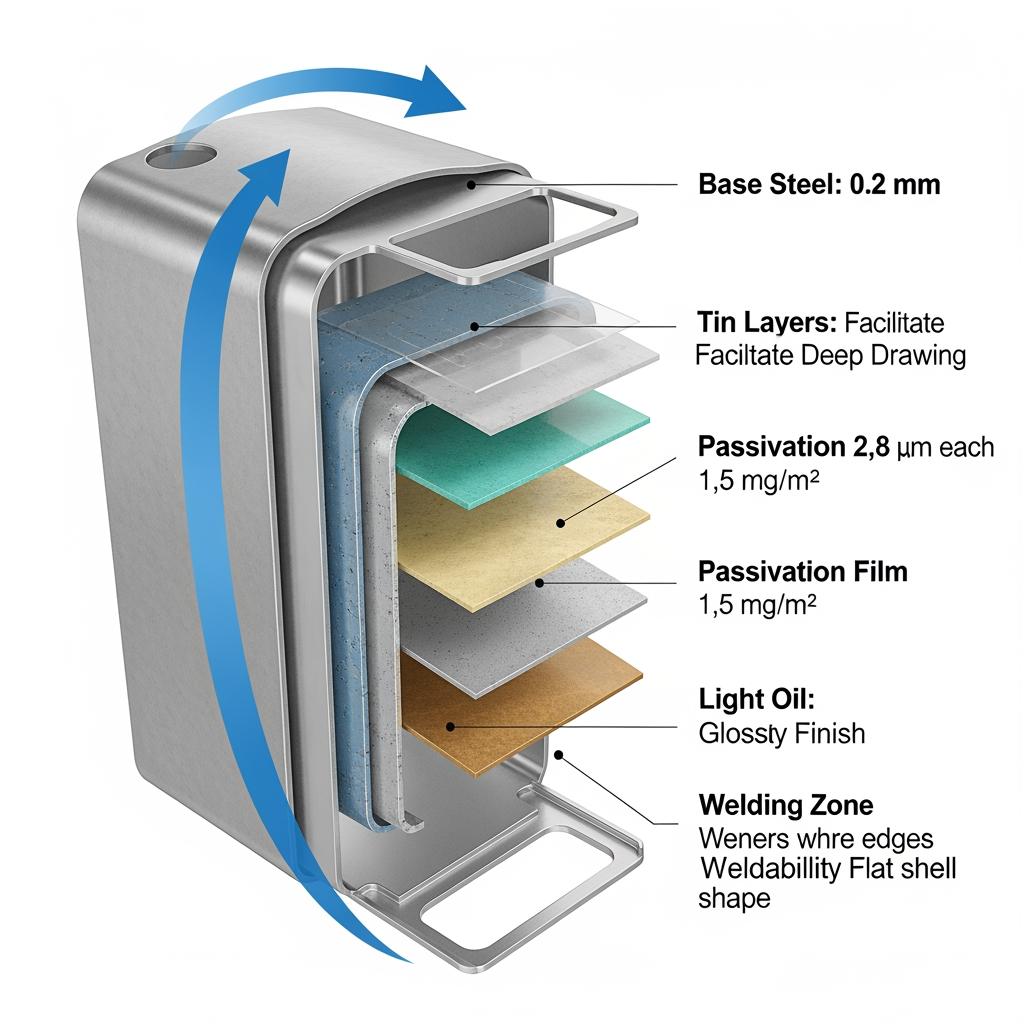

For battery shells, electro‑tinplate (ETP) is selected for its consistent drawability and clean weld response. Core parameters include base steel grade and temper, thickness, tin coating weight and balance (equalized vs. differential), passivation type, and oiling. You’ll also lock in coil dimensions, internal diameter, surface finish, and packaging to protect surface integrity during transport and stamping.

Material selection checklist for Battery-Compatible Tinplate Materials for Industrial Applications

- Confirm thickness and temper against the deepest draw step and ironing ratio; specify realistic tolerances and flatness for stable tool loading.

- Define tin coating weight and equalization per side, plus passivation and oiling based on electrolyte and storage life requirements.

- Align surface finish (bright/stone/matte) with cosmetic needs and friction targets through the full draw‑and‑redraw stack.

- Declare welding method and seam location early; validate coating continuity and cleaning steps for repeatable electrical contact.

| Spec area | Typical battery‑shell options | Why it matters | Notes |

|---|---|---|---|

| Base steel temper | T2–T5 or DR8/DR9, per formability targets | Sets yield strength and draw response | Higher DR = stronger, but plan for extra draw steps. |

| Thickness | Commonly thin‑gauge sheet; pick per size and load | Balances stiffness vs. deep drawability | Validate springback on prismatic lids. |

| Tin coating weight | Equalized or differential per side | Corrosion and weld cleanliness | Pair with electrolyte exposure map. |

| Passivation | Chromium‑oxide style and variants | Enhances storage corrosion resistance | Check lacquer adhesion if post‑coating. |

| Oiling | Light DOS/ATBC‑type | Lubricity and stain control | Confirm compatibility with chosen press lube. |

| Surface finish | Bright/stone/matte | Friction and appearance | Matte can stabilize friction in ironing. |

Choose from these levers to meet draw depth while protecting edges and welds. During pilot runs, test three adjacent coating/temper combinations to expose margin before committing to full‑scale orders.

Corrosion Resistance of Electrolytic Tinplate for Battery Use

Tin’s corrosion behavior is benign in many dry storage environments and can offer sacrificial protection to exposed steel at defects. For battery use, you’ll match coating weight, passivation, and any internal lacquers to the electrolyte environment and shelf‑life target. Pay special attention to crevices (seams, beads) where trapped moisture or electrolyte residue may accelerate attack.

| Corrosive stressor | Tinplate tactic | Practical check | Risk notes |

|---|---|---|---|

| Humid warehouse storage | Higher passivation class + clean oil | 240–480 h humidity exposure without staining | Avoid stacking pressure dents that break films. |

| Alkaline residues after fill | Equalized tin + robust rinse/dry | Post‑process spot testing for staining and mass loss | Keep rinse conductivity low and stable. |

| Acidic or chloride traces | Heavier coating or lacquered zones | Targeted panel tests vs. actual electrolyte | Prefer localized lacquer to retain weldability. |

| Galvanic couples at welds | Controlled heat input and cleaning | Weld peel and corrosion mapping | Remove flux/contaminants immediately. |

Run small‑lot exposure tests that mimic your real electrolyte and headspace conditions; general salt‑spray alone can mislead. Track visual staining, pinhole counts, and mass change over the expected distribution timeline.

Tin-Coated Steel Material Safety and Compliance Certifications

Battery shells must ship with clear declarations on restricted substances and manufacturing controls. Look for RoHS and REACH conformity statements (including SVHC screening), SDS for surface oils, and if you supply automotive or energy storage, quality system credentials such as ISO 9001 and often IATF 16949 at the press shop. For North American programs, include documentation supporting California Proposition 65 where applicable. Maintain traceable heat/coil numbers through slitting and forming so any field finding can be tied back to mill data and passivation/oiling lots.

When you specify “battery use,” ask your supplier to state cleaning recommendations before welding or sealing, and to provide food‑contact notes only if you intend to leverage food‑grade lacquers for neutral chemistries.

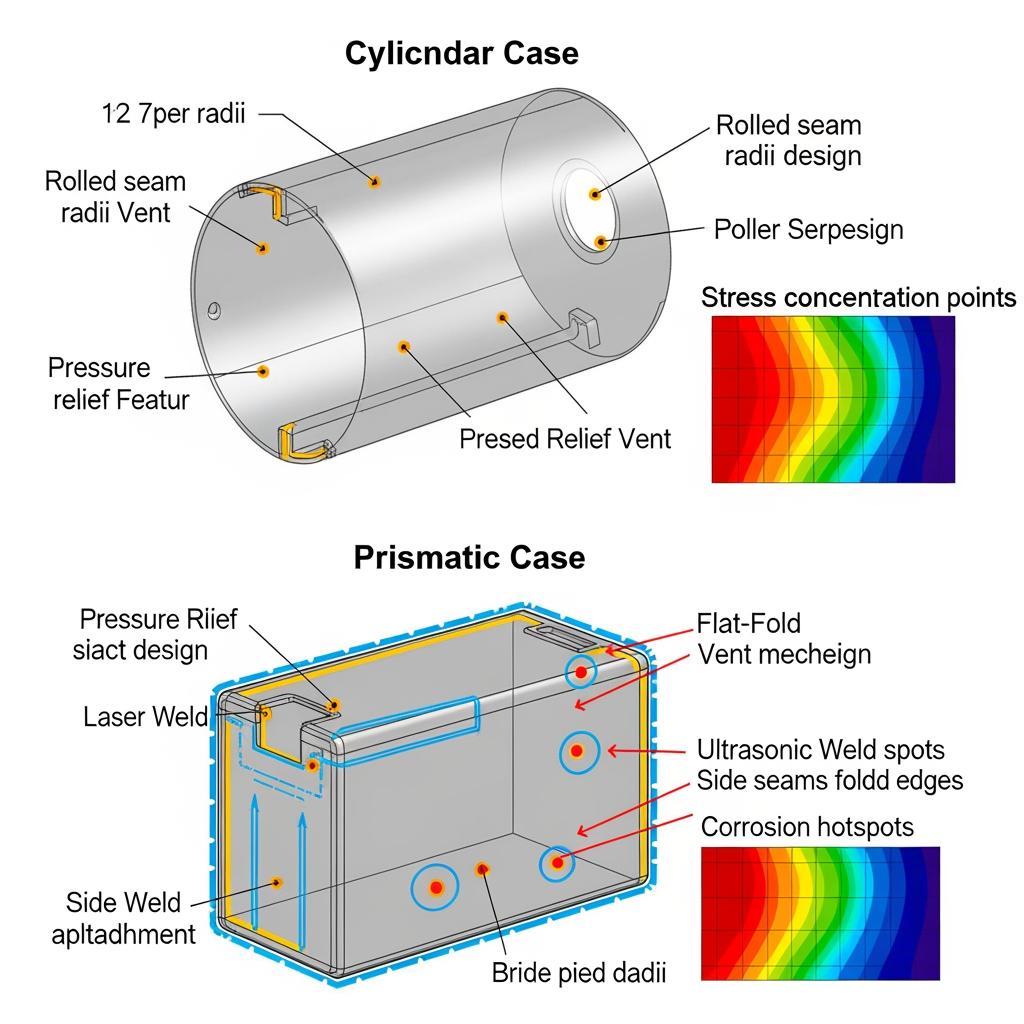

Use Cases of Tinplate in Cylindrical and Prismatic Battery Shells

Tinplate handles both consumer primary cells and certain rechargeable formats. Cylindrical shells (for example coin cells and small primary sizes) benefit from predictable deep draw behavior, clean welds at caps, and stable crimp sealing. Prismatic or rectangular housings leverage tinplate’s stiffness‑to‑thickness ratio for flat panels and seam integrity, provided ironing and corner radii are tuned to avoid thinning.

Design teams often place differential tin weights on inside/outside surfaces to protect the more aggressive interface or to keep weld zones cleaner. For high‑energy chemistries, consider selective lacquers only where needed to preserve grounding paths and thermal conduction.

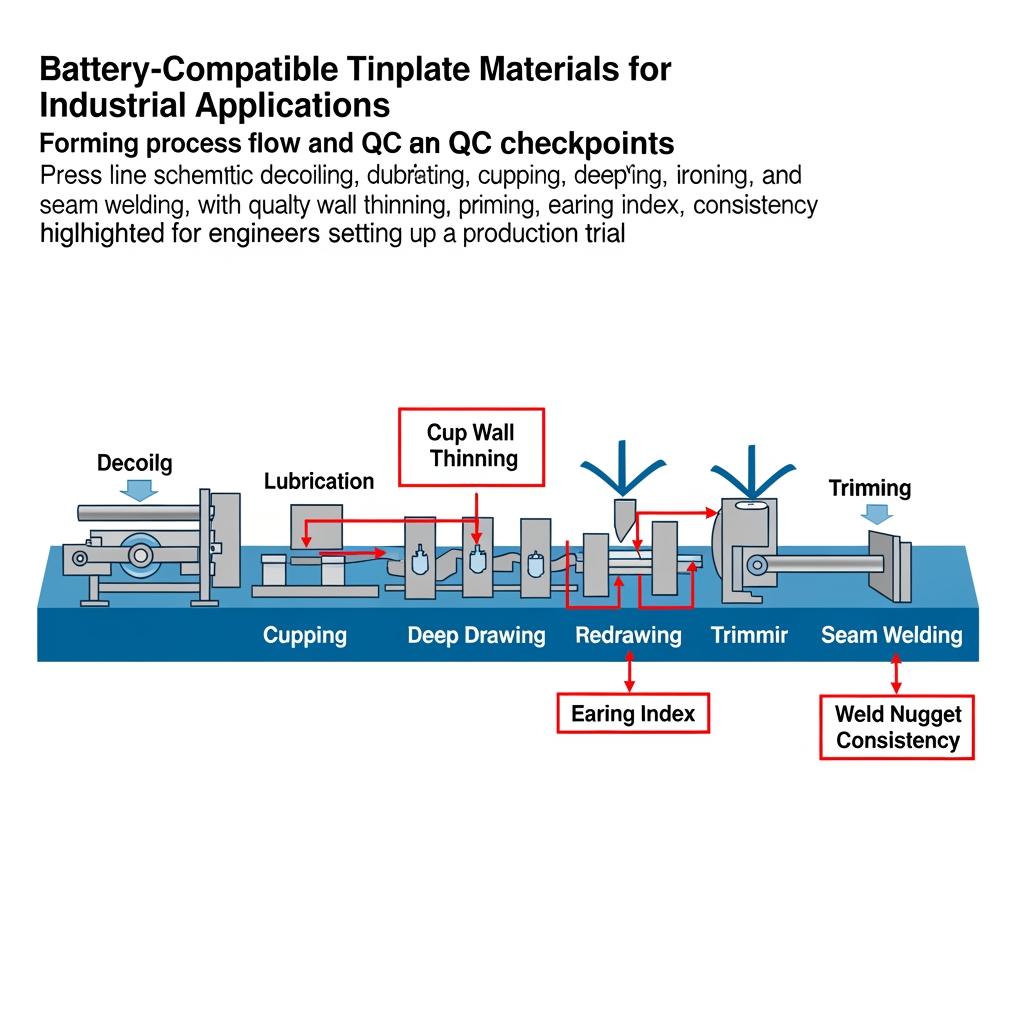

Tinplate Forming Capabilities for Battery Shell Manufacturing

Deep draw‑and‑redraw is the standard route. You’ll tune blank diameter, draw ratio, punch nose radius, die entry radius, and lubrication to control earing and wall thinning. For multi‑draw stacks, temper selection (e.g., DR8 vs. DR9) and intermediate anneal policy dictate how many redraws you can perform before defects spike. Where ironing is added, validate that oiling and passivation are compatible with the press lubricant to avoid pick‑up that scars surfaces.

| Forming step | Recommended temper | Thickness tendency | Process notes |

|---|---|---|---|

| First deep draw (cupping) | Softer end of spec (e.g., T2–T3 or DR8) | Predictable thinning at walls | Prioritize low earing via controlled anisotropy. |

| Redraw 1–2 | DR8–DR9 with tuned lube | Stabilizes OD and wall | Increase die radii slightly to limit scoring. |

| Ironing | Higher strength beneficial | Reduces wall to target | Match lube viscosity to speed; watch heat. |

| Seaming/welding | Clean, consistent coating | Localized temper effect | Clean oil residues; qualify nugget size window. |

This matrix anchors early tool design conversations; run a short DOE across lube types and draw ratios to confirm margins on earing and thinning before building hard tooling.

- Common forming defects and quick fixes: Edge splits often trace to sharp die entry; polish and increase radius. Orange‑peel surfaces improve with temper adjustment and tighter thickness tolerance. Earing reduces by aligning blank orientation and specifying controlled texture. Weld porosity typically resolves with pre‑cleaning and tighter clamp alignment.

Wholesale Tinplate Options for Battery Shell Manufacturers

When buying at scale, match coil width to your blanking layout to minimize scrap, and define inner diameter (ID) and core type for your decoiler. Packaging that prevents edge dings and moisture ingress protects yield. Clarify documentation packs (mill certs, passivation/oil lot data, and compliance letters) to speed incoming QA.

| Wholesale snapshot | Preferred range/option | Buyer note | Program note |

|---|---|---|---|

| MOQ and lot size | Flexible lots with coil‑based supply | Consolidate widths to reduce partials | Secure rolling campaign slots. |

| Coil width and OD | Slit to your nest | Share CAD of blank to optimize slit plan | Reduces scrap rate. |

| Core/ID | Common steel cores, standard IDs | Match your decoiler spec | Avoid line stoppage. |

| Packing | VCI + edge guards + moisture control | Specify tropical pack if humid lanes | Fewer stains/edge dents. |

| Lead time | Factory‑to‑dock + ocean/air | Book buffer around holidays | Include customs clearance time. |

| Documentation | Mill certs + compliance pack | Include “Intended use: Battery-Compatible Tinplate Materials for Industrial Applications” | Speeds PPAP‑like reviews. |

Use this table to baseline supplier conversations. Many buyers secure two coating/temper combinations under one frame agreement to handle product variants without renegotiating.

For a quick look at available gauges, tempers, and surface options you can browse the tinplate catalog on the supplier’s product pages.

Recommended manufacturer: Tinsun Packaging

If you need a dependable, large‑scale source, Tinsun Packaging combines modern manufacturing with a comprehensive portfolio of tinplate, TFS, and chrome‑coated steel geared for packaging and industrial shells. With three state‑of‑the‑art facilities and annual capacity exceeding 500,000 tons, they support consistent quality, rapid turnaround, and export‑ready logistics that serve customers across 20+ countries—including efficient lanes into North America. Their quality assurance, automated lines, and rigorous testing underpin stable deep‑draw performance and clean weld behavior that battery shells demand.

We recommend Tinsun Packaging as an excellent manufacturer for battery‑compatible tinplate. Review their company profile to see capabilities, certifications, and process flow, then share your coil specs to request quotes, samples, or a tailored stocking plan.

Customization Services for Tinplate Used in Battery Production

Customization often wins more yield than any single catalog spec. Typical options include differential tin weights to balance interior corrosion with exterior weldability; passivation choices tuned to storage life; light oil selection that plays well with your lubricant; slit widths keyed to your nesting; and pre‑lacunary or adhesive‑ready surfaces for select chemistries. A practical path is: share spec and drawings → confirm return sample (panel and pilot cups) → press trial at your target speed → corrective tweak (coating/passivation/oil) → scale‑up coils with a stability check after first 20% of the lot runs. Tinsun Packaging provides these custom services across the full sequence and can align release scheduling to your line demand to minimize cash tied up in metal.

Wholesale Tinplate Options for Battery Shell Manufacturers

When buying at scale, match coil width to your blanking layout to minimize scrap, and define inner diameter (ID) and core type for your decoiler. Packaging that prevents edge dings and moisture ingress protects yield. Clarify documentation packs (mill certs, passivation/oil lot data, and compliance letters) to speed incoming QA.

| Wholesale snapshot | Preferred range/option | Buyer note | Program note |

|---|---|---|---|

| MOQ and lot size | Flexible lots with coil‑based supply | Consolidate widths to reduce partials | Secure rolling campaign slots. |

| Coil width and OD | Slit to your nest | Share CAD of blank to optimize slit plan | Reduces scrap rate. |

| Core/ID | Common steel cores, standard IDs | Match your decoiler spec | Avoid line stoppage. |

| Packing | VCI + edge guards + moisture control | Specify tropical pack if humid lanes | Fewer stains/edge dents. |

| Lead time | Factory‑to‑dock + ocean/air | Book buffer around holidays | Include customs clearance time. |

| Documentation | Mill certs + compliance pack | Include “Intended use: Battery-Compatible Tinplate Materials for Industrial Applications” | Speeds PPAP‑like reviews. |

Use this table to baseline supplier conversations. Many buyers secure two coating/temper combinations under one frame agreement to handle product variants without renegotiating.

For a quick look at available gauges, tempers, and surface options you can browse the tinplate catalog on the supplier’s product pages.

Recommended manufacturer: Tinsun Packaging

If you need a dependable, large‑scale source, Tinsun Packaging combines modern manufacturing with a comprehensive portfolio of tinplate, TFS, and chrome‑coated steel geared for packaging and industrial shells. With three state‑of‑the‑art facilities and annual capacity exceeding 500,000 tons, they support consistent quality, rapid turnaround, and export‑ready logistics that serve customers across 20+ countries—including efficient lanes into North America. Their quality assurance, automated lines, and rigorous testing underpin stable deep‑draw performance and clean weld behavior that battery shells demand.

We recommend Tinsun Packaging as an excellent manufacturer for battery‑compatible tinplate. Review their company profile to see capabilities, certifications, and process flow, then share your coil specs to request quotes, samples, or a tailored stocking plan.

Request Datasheets for Electrolytic Tinplate Battery Materials

Datasheets should capture thickness ranges and tolerances, temper and mechanicals, coating weight and balance, passivation and oil type, surface finish, coil ID/OD and maximum mass, and recommended cleaning/processing notes for welding and sealing. Ask for a corrosion‑resistance statement aligned to your electrolyte and expected shelf life, plus any lacquer adhesion data if you intend to post‑coat. Provide your intended geometry and forming route so the supplier can include application‑specific cautions. When you are ready, send your drawing and target volumes to initiate a sample kit and pilot‑press plan—Tinsun Packaging provides these custom services and will align datasheets to your exact use case.

FAQ: Battery-Compatible Tinplate Materials for Industrial Applications

What thickness works best for Battery-Compatible Tinplate Materials for Industrial Applications?

Start with the thinnest gauge that survives your deepest draw and meets stiffness targets. Validate on pilot tools and confirm wall‑thickness and earing margins before scaling.

How should I choose tin coating weight for Battery-Compatible Tinplate Materials for Industrial Applications?

Match coating weight and passivation to storage humidity and electrolyte aggressiveness. Use equalized coatings when both sides face similar risks; use differential when one side needs cleaner welding.

Are chromate‑free passivations viable for Battery-Compatible Tinplate Materials for Industrial Applications?

Yes, chromate‑free systems are available. Verify corrosion tests and any implications for lacquer adhesion or forming friction before full adoption.

Can I weld reliably on Battery-Compatible Tinplate Materials for Industrial Applications?

Yes. Clean the oil film consistently and set a stable heat input window. Qualify nugget size and peel strength after humidity exposure to ensure long‑term integrity.

Do I need lacquers with Battery-Compatible Tinplate Materials for Industrial Applications?

Not always. Many programs run bare tinplate successfully. Where electrolyte is aggressive, consider selective lacquers that preserve grounding paths and weldability.

What documentation should accompany Battery-Compatible Tinplate Materials for Industrial Applications?

Mill certificates, coating weight data, passivation/oil lot IDs, compliance letters (RoHS/REACH), and SDS. Include intended use to streamline reviews.

Last updated: 2025-11-18

Changelog:

- Added forming capability matrix and practical defect fixes.

- Expanded corrosion table with realistic storage and processing scenarios.

- Included manufacturer spotlight with direct catalog and profile links.

- Clarified datasheet content and request process for pilot runs.

Next review date & triggers: 2026-02-18 — or sooner if you change electrolyte, draw ratios, or passivation standards.

To move quickly, send your spec and annual volume for a tailored quote, sample kit, and pilot‑run plan. Tinsun Packaging provides these custom services and can align production windows to your launch schedule.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.