-

T2-T4 Tinplate Specifications for Pet Food Can Production

If you pack wet or semi-moist pet food, the shortest path to fewer defects is to match T2–T4 tinplate specifications to your recipe, retort, and line geometry from day one. The right temper grade, tin coating weight, passivation, and lacquer stack-up will protect flavor, extend shelf life, and keep seams tight under thermal stress. If…

-

Electrolytic Tinplate Grades for Fish Can Manufacturing

If you pack tuna, sardines, mackerel, or anchovies, the fastest way to cut complaints and boost shelf-life is to match product, process, and print to the right grade of electrolytic tinplate. This guide translates shop-floor reality into clear choices—from coating thickness and temper selection to BPA‑free linings and export packaging—so you can specify Electrolytic Tinplate…

-

BPA-Free Tinplate Solutions for Food-Safe Peel-Off Ends

If you make ready-to-eat foods, infant nutrition, or pet meals, the move to BPA-free peel-off ends is no longer optional—it’s a brand trust imperative. This guide distills how to specify and source BPA-Free Tinplate Solutions for Food-Safe Peel-Off Ends, from electrolytic tinplate coatings to thickness, certifications, and print/lacquer decisions. If you’re scoping a new lid…

-

Corrosion-Resistant Tinplate Coils for Beverage Crown Closures

For crown cap makers, the fastest route to fewer rejects and a longer shelf life is choosing the right corrosion-resistant tinplate coils for beverage crown closures, then pairing them with a fit-for-purpose lacquer system and a disciplined QA plan. If you already have specs or drawings, share them and we’ll translate them into a coating…

-

Lacquered Tinplate Solutions for Safe Food-Grade EO End Manufacturing

Food brands and closure makers rely on lacquered tinplate to keep easy-open (EO) ends safe, stable, and production-ready. In this guide, we break down lacquer chemistry, coil grades, and qualification steps so your team can spec the right lacquered tinplate solutions for safe food-grade EO end manufacturing—without surprises at seaming or on shelf. If you’re…

-

Tinplate Coil Specifications for High-Precision Cap Manufacturing

If you make twist-off, lug, crown, or pilfer-proof caps, the fastest way to control line scrap is to lock down your tinplate coil specifications for high-precision cap manufacturing—from thickness and temper to coating and packaging. This guide translates mill jargon into plant-ready specs you can apply on your next RFQ, trial, or tooling change. If…

-

Quality Control Standards for Tinplate Sheets in Lid Production

Quality Control Standards for Tinplate Sheets in Lid Production set the baseline for safety, shelf life, and line efficiency in easy‑open ends and sanitary can tops. The strongest programs align mill certifications, incoming inspection, and process controls on stamping and lining to prevent leaks, paneling, and corrosion before they start. If you’re ready to validate…

-

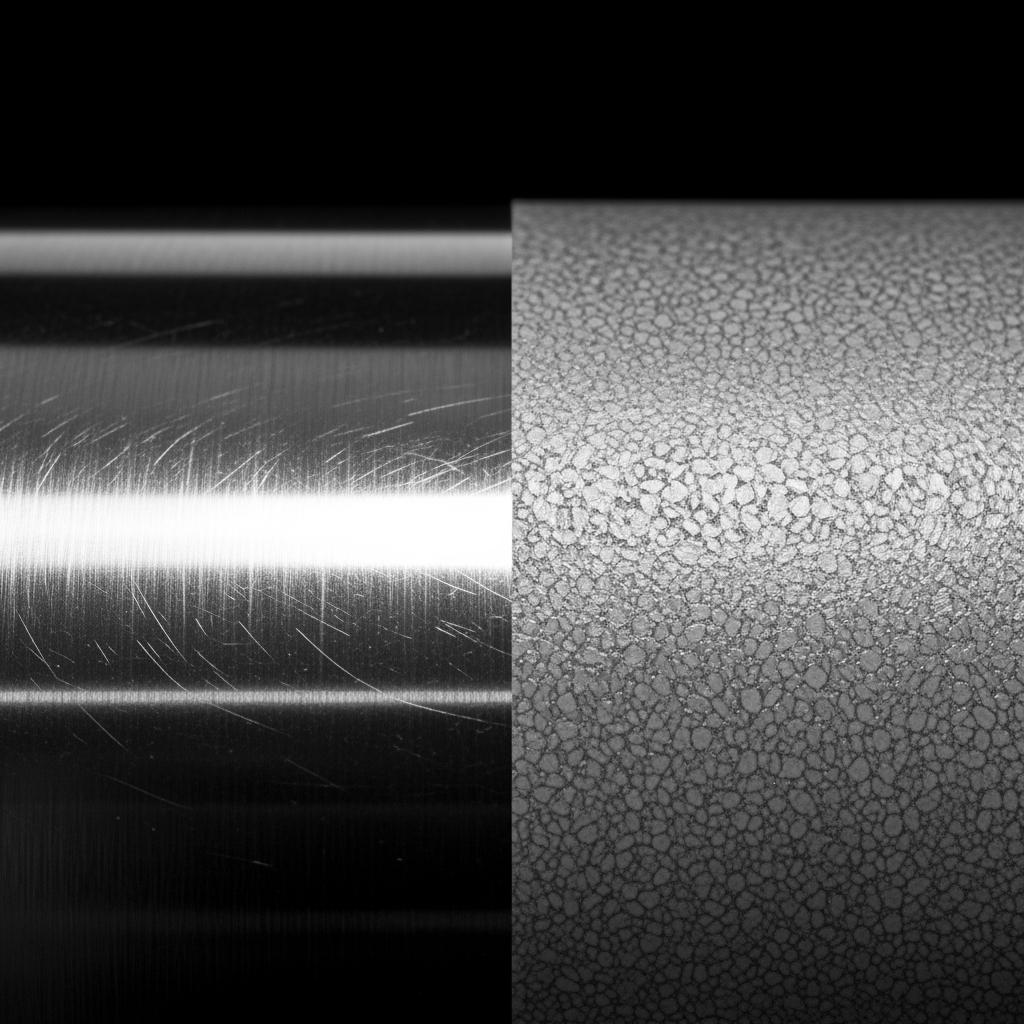

Surface Coating Technologies for Tinplate Used in Metal Cans

The shortest path to reliable cans is to treat coatings as engineered systems, not paint. Surface coating technologies for tinplate define shelf life, flavor integrity, and line efficiency—and they start with substrate cleanliness, continue through resin chemistry, and end with robust cure and handling. If you’re planning a refresh of specifications or qualifying a new…

-

Applications of Tinplate Materials in Paint and Solvent Cans

From the first coil you source to the last can off your line, the right tinplate determines fill compatibility, corrosion life, and seam integrity. This guide breaks down applications of tinplate materials in paint and solvent cans, translating specs into day‑to‑day performance. If you’re qualifying new gauges, tempers, or coatings, share your requirements and get…

-

Material Specifications for Electrolytic Tinplate in Aerosol Use

Aerosol containers work like small pressure vessels, so material choices must balance strength, formability, corrosion resistance, and print quality. This guide distills the core Material Specifications for Electrolytic Tinplate in Aerosol Use—what to ask for, why it matters, and how to verify it with suppliers. If you have drawings or a target spec, share them…

-

Choosing the Right Tin Coated Steel for Canned Food Products

Selecting tin coated steel for canned food products is ultimately about matching your food chemistry and process to a stable, compliant package that runs efficiently on your lines. The right ETP (electrolytic tinplate) or TFS (tin‑free steel) grade, temper, coating weight, and lacquer system will control corrosion, protect flavor and color, and deliver the shelf…

-

Understanding Tin Coated Steel as a Packaging Raw Material

Tin coated steel as a packaging raw material delivers a rare combination of product safety, printability, and mechanical strength that few substrates can match. From food cans and aerosols to closures and general line containers, its layered structure protects contents, resists corrosion, and enables high-speed forming and seaming—while staying fully recyclable. If you’re evaluating new…

Blog

Tinsun

Leading Tinplate Manufacturer for Global Metal Packaging.

Product Categories

Quick Link

Contact Info

© 2026 Langfang Tinsun Packaging Materials Co., Ltd. All right reserved.

Powered by 易运盈