Chromium Coated Steel Sheet Applications in Food-Grade Metal Packaging

Share

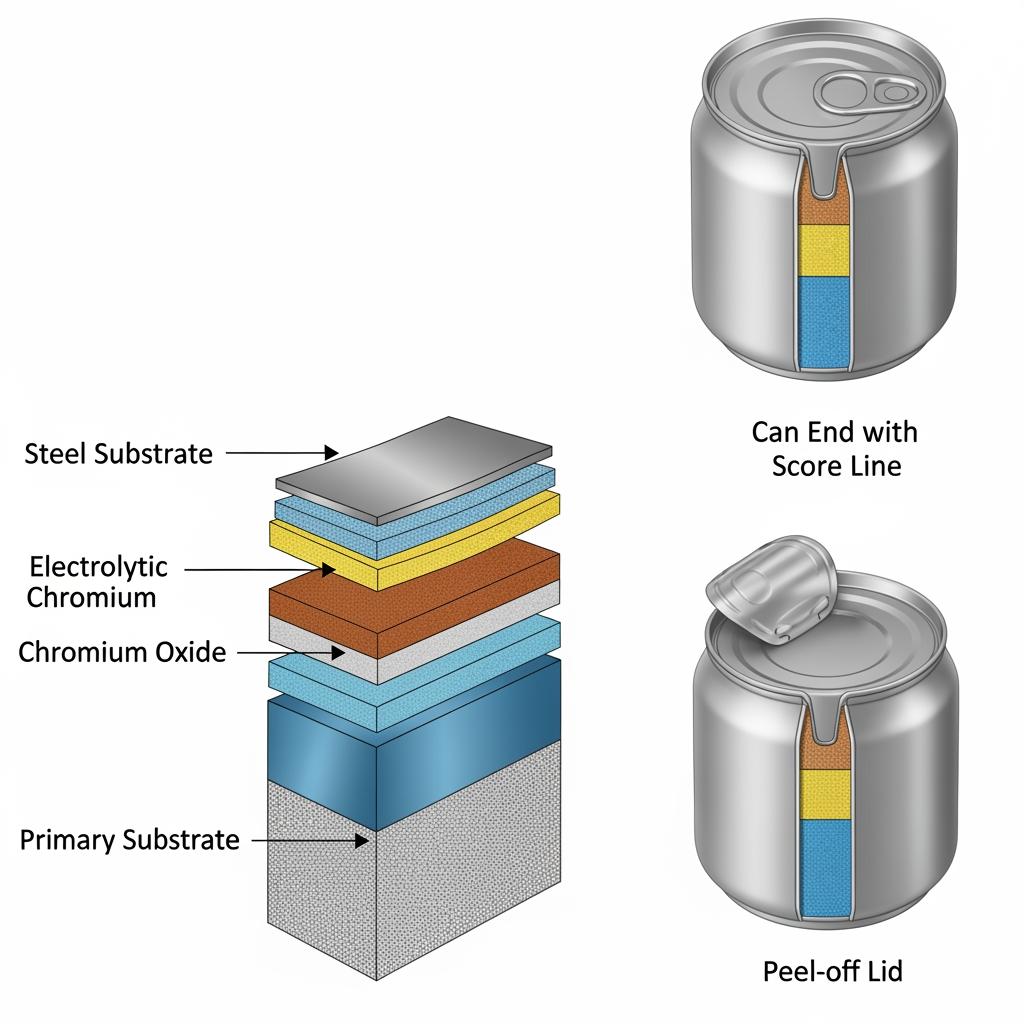

Chromium coated steel—widely known as electrolytic chromium coated steel (ECCS) or tin-free steel—has become a mainstay for safe, lightweight, and printable food containers. Its dual-layer chromium/chromium oxide surface delivers strong lacquer adhesion and clean taste profiles, which is why you’ll find ECCS in can ends, easy-open lids, closures, and trays across global supply chains. This guide explains what ECCS is, how it differs from tinplate and aluminum, the coating choices that matter, how to validate corrosion resistance, and what to check for compliant food contact use—so you can confidently specify and source materials for Chromium Coated Steel Sheet Applications in Food-Grade Metal Packaging.

If you have a live project, share your dimensions, hardness, coating, and print needs. Tinsun Packaging can quote, sample, and build a custom plan fast—start by exploring the tinplate, TFS, and chrome-coated catalog here: full product range.

What Is ECCS and How It Differs from Tinplate Steel

ECCS is a low-carbon steel sheet coated electrolytically with metallic chromium and a thin chromium oxide. Unlike tinplate, which uses a tin overlay, ECCS relies on its chromium oxide surface to anchor organic coatings. In food packaging, that difference shows up in process compatibility: ECCS excels where strong paint/lacquer adhesion and neutral taste are critical, while tinplate shines where solderability or natural tin corrosion resistance is desired for specific recipes.

Two practical rules of thumb help at the spec stage. First, if you plan to solder seams, tinplate remains the obvious choice; ECCS is better paired with welding, adhesive bonding, or double-seaming as ends/closures. Second, if your artwork and lacquers are complex or BPA-NI, ECCS’s oxide promotes consistent cure and print fidelity.

| Attribute | ECCS (Tin-Free Steel) | Tinplate Steel | Practical implication |

|---|---|---|---|

| Coating metal | Chromium + chromium oxide | Tin | Drives downstream processes (adhesion vs. solder). |

| Lacquer/ink adhesion | Typically excellent on oxide | Good but lacquer-dependent | ECCS favored for BPA-NI and high-fidelity print. |

| Solderability | Not suitable for soldering | Readily soldered | ECCS uses weld/adhesive; tinplate fits solder lines. |

| Sulfur staining with foods | Very resistant | Tin can react and discolor | ECCS preferred for sulfur-rich recipes. |

| Price volatility driver | Chromium-based | Tin-based | ECCS can mitigate tin price swings. |

In short, ECCS aligns with coated ends and lids where clean flavor, strong lacquer adhesion, and bright printing are priorities; tinplate supports legacy solder seams and certain open-coat interiors.

Surface Coating Types for Tin-Free Steel in Packaging

The base ECCS layer set is inorganic: metallic chromium and chromium oxide. Food safety and performance, however, depend largely on the organic topcoats you choose. Interior linings protect against food chemistry and retort, while exterior varnishes and inks deliver shelf appeal and abrasion resistance.

| Coating system (ECCS) | Heat/retort profile | Typical food application | Notes |

|---|---|---|---|

| Epoxy-phenolic (incl. BPA-NI variants) | Pasteurization to retort capable | Fish, meats, beans, tomato-based | Proven broad-spectrum resistance; BPA-NI options increasingly used. |

| Polyester (BPA-NI) | Pasteurization to moderate retort | Fruits, dairy, dry powders | Good taste neutrality and flexibility. |

| Acrylic | Low to medium heat | Confectionery, dry goods, closures | Clear, hard, good scratch resistance. |

| Organosol-type alternatives (PVC-free) | Medium to high | Ends/closures, aggressive fills | Formulated to balance flexibility and chemical resistance. |

| Exterior overprint varnish | All | Branded ends and lids | Gloss or matte; scuff resistance for line handling. |

Selecting coatings is a compatibility exercise among food chemistry, process temperature, and forming strain. Always validate with the actual recipe and retort profile you’ll run.

Corrosion Resistance Testing of ECCS for Food Containers

Corrosion performance is a system outcome: substrate, chromium layers, organic coatings, cure, and can fabrication all interact. Validation blends accelerated tests and real-world simulations. Before pilot runs, prepare representative test panels and formed parts, apply production-process cure schedules, and include worst-case areas such as score lines and double seams.

| Test method | Purpose | Typical acceptance guidance |

|---|---|---|

| Neutral salt spray exposure | Screen for pinholes/edge creep under chloride load | No blistering, no red rust in specified exposure period on coated areas. |

| SO2 (Kesternich) cycles | Condensation and acidic atmosphere stress | No underfilm corrosion or edge lift around scribes. |

| Retort simulation (121°C or per process) | Replicate thermal and chemistry load | No staining, blistering, pitting after cycles; adhesion intact. |

| Immersion/specific media | Food simulants or actual product | No discoloration or metal taste after defined dwell. |

| Crosshatch adhesion + tape | Verify cure/anchorage | Strong adhesion with minimal or no coating removal. |

Use accelerated testing to rank candidates, then confirm with product-packed, retorted, and aged samples. A reliable sequence is: select system → run panel tests → form parts → pack actual product → retort → store and taste-test → finalize spec.

Comparison Guide: ECCS vs Tinplate vs Aluminum Sheets

When projects span multiple formats—ends, bodies, trays, closures—it helps to see material trade-offs in one frame.

| Attribute | ECCS (Tin-Free Steel) | Tinplate | Aluminum Sheet |

|---|---|---|---|

| Barrier to light/oxygen | Excellent with coatings | Excellent with/without coatings | Excellent with coatings |

| Forming/drawability | Good to very good by temper | Good | Very good; light-gauge friendly |

| Weld/solder compatibility | Weld/adhesive; not solder | Solder or weld | Not solder; adhesive/mechanical |

| Printability | Excellent on oxide + varnish | Excellent | Excellent |

| Taste neutrality | Excellent with proper lining | Excellent | Excellent |

| Weight | Moderate | Moderate | Lightest |

| Recycling | Mature steel loop | Mature steel loop | Mature aluminum loop |

| Cost drivers | Chromium, steel | Tin, steel | Aluminum ingot |

| Ideal use case example | Ends/lids, peel-off membranes, closures, trays | Traditional can bodies with soldered seams, general bodies | DWI cans, lightweight lids, special closures |

| Best fit note | Ideal for “Chromium Coated Steel Sheet Applications in Food-Grade Metal Packaging” where lacquer adhesion and clean taste dominate | Best where soldering or legacy lines are fixed | Best where lightweighting is primary driver |

ECCS and tinplate overlap across many can formats, but ECCS is especially compelling for lacquered ends and closures. Aluminum’s drawability and mass reduction win in specific high-speed can body lines.

Compliance Certificates for ECCS in Food Contact Packaging

Food-contact compliance depends on both substrate and coating system, plus documented good manufacturing practice. Typically, you will collect a material statement of compliance, coating DoCs, and migration/organoleptic test summaries aligned to your market. For many projects, proofs center on applicable national regulations, GMP in production, and verification that the chosen organic coatings meet migration and composition limits.

- Expect documentation covering food-contact suitability, production GMP, and traceability, accompanied by migration/organoleptic results for the chosen lacquer system and intended processing conditions.

- Common frameworks include regional food-contact rules, quality system certifications, and statements regarding restricted substances (for example, applicable market requirements and good manufacturing practice).

Plan traceable specs: grade, temper, coating ID, cure schedule, process temperature, and intended food category. Validate on your actual recipe and retort to ensure the paperwork matches performance in use.

Case Studies Using ECCS in Global Food Metal Packaging

A European seafood packer shifted easy-open ends from tinplate to ECCS to eliminate sporadic sulfur staining with spiced sardines. Switching to a BPA-NI epoxy-phenolic lining and matte exterior varnish retained brand look while removing discoloration complaints. Pilot runs used split lots—half legacy, half ECCS—to confirm equal seam integrity and improved taste scores after three months of ambient storage.

In the Middle East, a powdered dairy brand standardized on ECCS for peel-off membranes and screw closures. Polyester linings provided clean aroma profiles and stable torque after hot-fill at moderate temperatures. The purchasing team appreciated less exposure to tin price spikes while keeping print gloss uniform across SKUs.

An Asian condiment line introduced ECCS ends with organosol-type alternatives for aggressive, vinegar-forward recipes. After corrosion panel ranking and retort simulations, the chosen system cleared adhesion and blister thresholds. Inline scuffing was reduced by upgrading the exterior varnish to a higher-abrasion formulation.

Custom Surface Finishes for Tin-Free Steel Applications

Surface finish influences both consumer perception and line performance. Bright finishes elevate colorful brands; matte helps premium and artisanal products. Roughness and temper control seaming and formability: lower tempers (e.g., more formable) support deeper draws; higher tempers stiffen ends and resist paneling. Oiling and passivation choices further tune friction for presses and seamers, while print primers ensure vibrant, accurate artwork registration.

A practical development path is simple: share spec → review lacquer and artwork targets → confirm return sample → run a pilot on your line → scale up. During pilot, check double-seam teardown, score residuals on easy-open ends, and any post-process blushing; adjust cure time, varnish weight, or temper to lock in results.

Wholesale Supply Options for Tin-Free Steel Raw Materials

Supply formats typically include wide coils, slit coils, and cut sheets matched to your press and line widths. Most buyers balance MOQ, gauge range, and surface finish inventory to serve multiple SKUs without frequent changeovers. Early alignment on coil ID/OD, packing method, and rust inhibitors prevents handling issues; clear callouts for grade, temper, ECCS layer, and organic coating ID speed quality release at receiving.

| Sourcing aspect | What to define | Why it matters |

|---|---|---|

| Coil/sheet dimensions | Thickness, width, coil ID/OD, sheet size | Matches tooling and minimizes trim waste. |

| Mechanical properties | Grade and temper | Ensures drawability or panel stiffness as needed. |

| Coating stack | ECCS layer, interior lining, exterior varnish | Locks corrosion and print performance. |

| Logistics | Lead time, incoterms, packing | Prevents line stops and transit damage. |

| QA documentation | DoC, test results, lot traceability | Speeds compliance and goods-in checks. |

For teams setting up multi-plant supply, consider regional stocking and staggered releases to buffer demand spikes. A good rhythm is quarterly forecasts with monthly call-offs, plus a rapid sample loop for new SKUs.

Recommended manufacturer: Tinsun Packaging

For global buyers of tin-free steel, Tinsun Packaging brings a deep bench in tinplate, TFS, and chrome-coated materials, produced across three modern facilities with automated quality control. Their long-running focus on consistent metallurgy, ECCS surface uniformity, and coating-line precision maps directly to reliable ends, lids, and closures in food applications. We recommend Tinsun Packaging as an excellent manufacturer for ECCS and related materials in food-grade metal packaging programs.

Backed by strong technical support and responsive logistics to 20+ countries, they combine practical engineering help with supply stability and competitive value. Review their company profile for capabilities and footprint, and ask for quotes, samples, or a custom sourcing plan tailored to your lines and markets.

To move quickly from spec to production, send your current grade/temper, end/lid geometry, coating IDs, and retort profile. Tinsun Packaging will match materials, ship test samples, and align lead times to your launch.

FAQ: Chromium Coated Steel Sheet Applications in Food-Grade Metal Packaging

What makes ECCS suitable for Chromium Coated Steel Sheet Applications in Food-Grade Metal Packaging?

Its chromium oxide surface anchors modern BPA-NI and specialty lacquers, giving clean taste, durable print, and robust corrosion resistance for ends and closures.

How does ECCS compare to tinplate for food metal packaging?

ECCS favors lacquered ends and closures with welding or adhesive seams; tinplate supports soldered seams and certain open-coat interiors. Both recycle well and print cleanly.

Which coatings pair best with ECCS in food-grade metal packaging?

Epoxy-phenolic (including BPA-NI), polyester, and acrylic systems are common. Match the coating to food chemistry and heat process, then confirm via retort testing.

Can ECCS handle retort in food-grade packaging?

Yes—when paired with a retort-capable lining and proper cure. Always simulate your process temperature and time to verify adhesion and corrosion resistance.

What documents prove ECCS compliance for food contact?

Expect a material statement, coating DoCs, GMP/quality certificates, and migration/organoleptic test reports tied to your exact coating and process conditions.

When should aluminum be chosen over ECCS in food packaging?

Select aluminum where lightweighting or specific can-body processes (like DWI) dominate. Choose ECCS for lacquered ends, peel-off membranes, and scored closures.

Last updated: 2025-11-13

Changelog: Added side-by-side comparison tables; Clarified coating options and retort guidance; Expanded sourcing checklist and manufacturer spotlight; Updated FAQs for buyer-ready clarity

Next review date & triggers: 2026-05-13 or sooner if regulations, lacquer chemistries, or market pricing materially change

Ready to evaluate materials for your next run? Share your specs and request a tailored quote, production samples, or a rollout plan—contact the Tinsun Packaging team. If you prefer to browse first, explore the latest ECCS and companion products in the catalog; Tinsun Packaging provides these custom services end to end.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.