Corrosion-Resistant ETP Tin Coated Steel Sheets for Export

Share

Choosing the right ETP (electrolytic tinplate) is the difference between a product that ships flawlessly and one that corrodes in transit. This guide distills how to specify, test, and procure Corrosion-Resistant ETP Tin Coated Steel Sheets for Export—so you can move faster with fewer claims and better margins. If you already have a spec, share it and get a tailored quote or samples—contact Tinsun Packaging for custom slitting, coating weights, and export packing via the fast-track form here: contact Tinsun Packaging.

Overview of Electrolytic Tinplate Sheet Materials

The takeaway: ETP is a low-carbon steel substrate coated with electrolytic tin, then passivated and lightly oiled to balance formability, weldability, and corrosion protection. For export, consistent coating mass and sound passivation matter more than chasing ultra‑high tin weights alone.

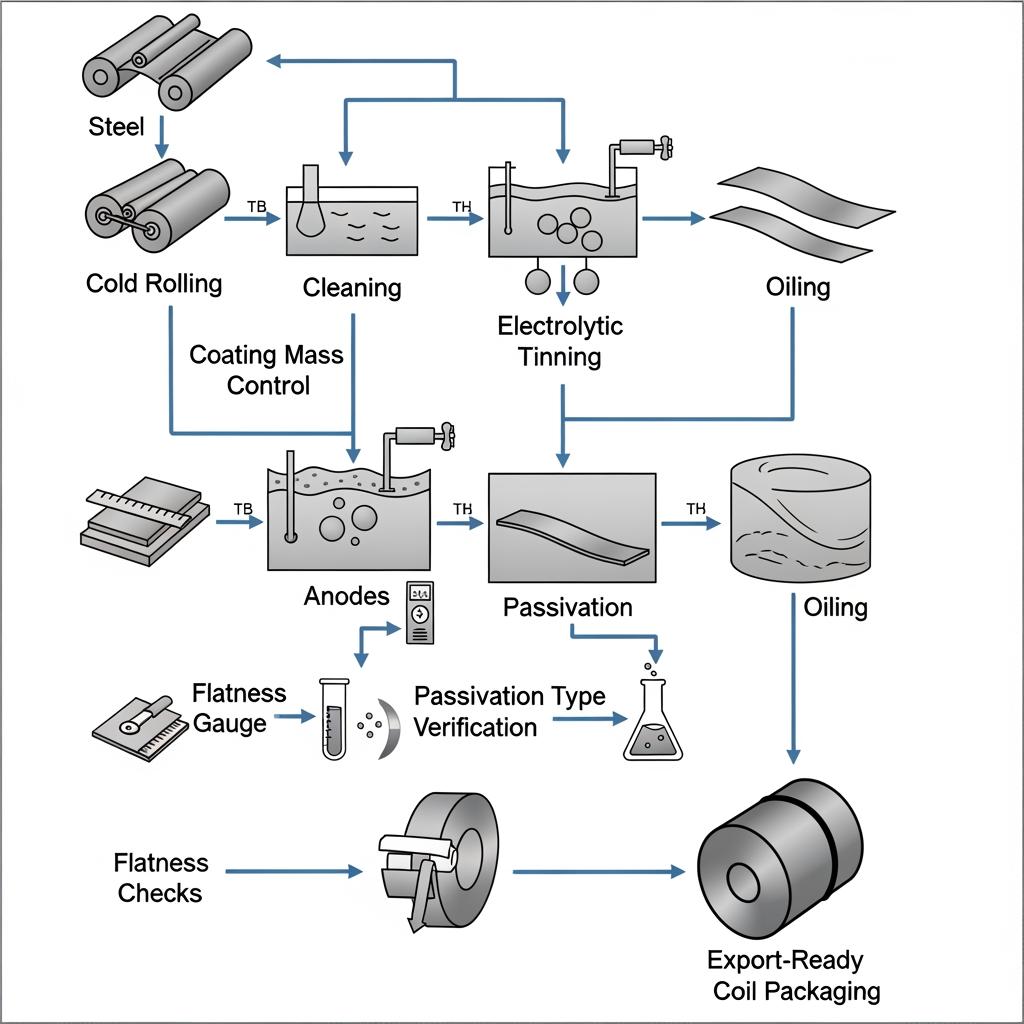

ETP production begins with cold-rolled steel that’s cleaned and prepared for plating. Tin is deposited in a controlled electrolytic cell, producing highly uniform coatings on one or both sides. Post‑treatments—especially passivation (chromate or chrome-free) and oiling—stabilize the surface against handling rust and support downstream lacquer or lithography. Compared with tin‑free steel (TFS), ETP offers sacrificial protection from the tin layer itself, making it a default choice for food cans, closures, and general line packaging destined for humid or maritime routes.

If you’re assessing a supplier’s pedigree and capabilities, you can explore Tinsun’s background, facilities, and quality systems in their detailed company profile.

Global Standards for ETP Tin Coated Steel Sheet Grades

The takeaway: Align with the buyer’s destination standard from day one. Most export projects cite ASTM, EN, JIS, or GB for common definitions of temper, finish, base steel type, and test protocols. Match the standard, then lock in temper and coating mass per the end use.

| Region/Market | Core standard reference | Temper/grade notation (typical) | Base steel types (typical) | Notes |

|---|---|---|---|---|

| United States | ASTM A623 (general requirements for tin mill products) | T1–T5, DR7–DR9; single/double reduced | MR, L, D | Widely used for third‑party inspection on export. Include finish (bright/stone/matt) on POs. |

| European Union | EN 10202 (packaging steel—electrolytic tinplate) | TH415–TH620 (hardness classes), DR values | MR-equivalent | Often paired with lacquer specs; migration tests handled at can-maker stage. |

| Japan | JIS G3303 (electrolytic tinplate) | T1–T5, DR8, DR9 | MR, L | Tight thickness tolerances; popular for high-speed draw/redraw lines. |

| China | GB/T 2520 (electrolytic tinplate) | T1–T5, DR8–DR9 | MR, L | Common origin for global exports; specify passivation and oil type clearly. |

| Export projects | Project datasheet aligned to buyer’s norm | As specified | As specified | Include “Corrosion-Resistant ETP Tin Coated Steel Sheets for Export” in scope notes to avoid substitution. |

Standards define measurement methods and default tolerances, while your purchase order determines the practical performance: substrate thickness, temper, coating weight per side, finish, passivation type, and packaging.

ETP Steel Sheet Thickness and Tin Coating Weight Guide

The takeaway: choose the lowest thickness and tin weight that meets mechanical and corrosion demands. For long ocean routes or sulfur-bearing fills, step up passivation and lacquer systems rather than only increasing tin weight.

Specifying Corrosion-Resistant ETP Tin Coated Steel Sheets for Export

Start from the can/process requirement, then confirm draw ratio, seam/weld needs, and destination climate. Lock in thickness and temper for forming, select a coating designation (e.g., 2.8/2.8 or 5.6/5.6 g/m²), specify finish and passivation, and require certificate data that matches your standard.

| Thickness (mm) | Temper (typical) | Coating designation (g/m² per side) | Finish | Typical applications |

|---|---|---|---|---|

| 0.18–0.20 | T2–T3 | 2.8/2.8 | Bright | Easy‑open ends, light draw components. |

| 0.22–0.24 | T3–T4 | 5.6/5.6 | Bright/Stone | General line cans, closures, paint lids. |

| 0.25–0.28 | T4–T5 | 5.6/8.4 or 8.4/8.4 | Stone/Matte | Food cans for long transits; tougher seam strength. |

| 0.30–0.32 | DR8–DR9 | 2.8/2.8 or 5.6/5.6 | Bright/Matte | Aerosol components; high stiffness at lower mass. |

When ordering, call out the “per side” values explicitly and confirm whether differential coating is acceptable. Include passivation type and oiling level to stabilize surfaces during ocean transit and intermediate storage. For ready-to-ship options, browse Tinsun’s current tinplate product range.

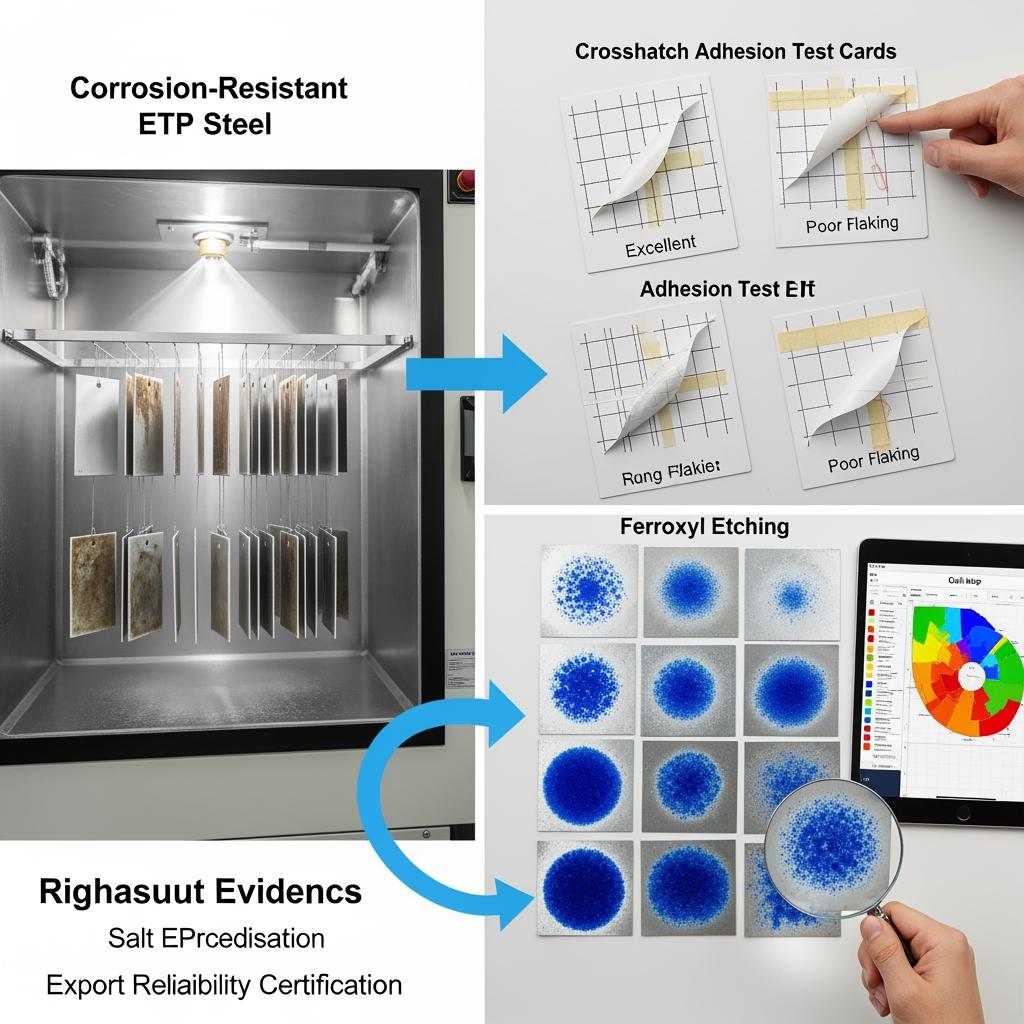

Corrosion Resistance Testing for ETP Tinplate Materials

The takeaway: verify what matters for your fill and route. Coating mass and porosity set the baseline; passivation stability and lacquer performance determine real‑world shelf life.

| Test method | Typical reference | What it validates | Export tip |

|---|---|---|---|

| Tin coating mass (per side) | Methods aligned with ASTM A623/EN 10202 | Confirms tin weight uniformity | Request coil‑map data and sample cut‑ends from head, middle, tail. |

| Porosity (ferroxyl) | Mill method aligned to standards | Detects pores/exposed steel | Pair with lacquer overprint to mask residual pinholes. |

| Salt spray/corrosion cabinet | ASTM B117 or buyer method | General corrosion resistance | Use as comparative; salt spray ≠ food environment but flags weak passivation. |

| Sulfur stain test | Buyer method using sulfur compounds | Resistance to sulfide darkening | Essential for protein-rich or sulfur-bearing fills and seafood routes. |

| Adhesion/crosshatch on lacquer | ISO/JIS/ASTM equivalents | Lacquer bond and over-bake tolerance | Check after pasteurization/retort simulations. |

| Formability (cup/draw, bend) | JIS/EN draw tests | Crack resistance at seams/draw | Test on the exact temper and thickness you plan to ship. |

Ask suppliers for heat/coil-level certificates, passivation ID, oil type/level, and archived retains. For new projects, run a short pilot: share spec → confirm return sample → pilot run → scale up after transit monitoring.

Case Studies of ETP Tinplate Sheet Use in Global Markets

The takeaway: successful exports combine the right temper/coating with fit‑for‑purpose passivation and coatings, packed to survive long, humid routes.

In Southeast Asia, a seafood canner shifted from 2.8/2.8 to 5.6/5.6 with enhanced passivation for monsoon‑season shipments. Corrosion complaints dropped during port delays without altering seam integrity. In the EU aerosol market, DR8 tinplate allowed a lighter gauge at the same burst performance, saving freight while improving stack stability. In the Middle East, paint line closures saw fewer scuffs after the mill standardized oil level and edge guards, not by increasing tin mass.

Key cross‑market lessons you can apply immediately:

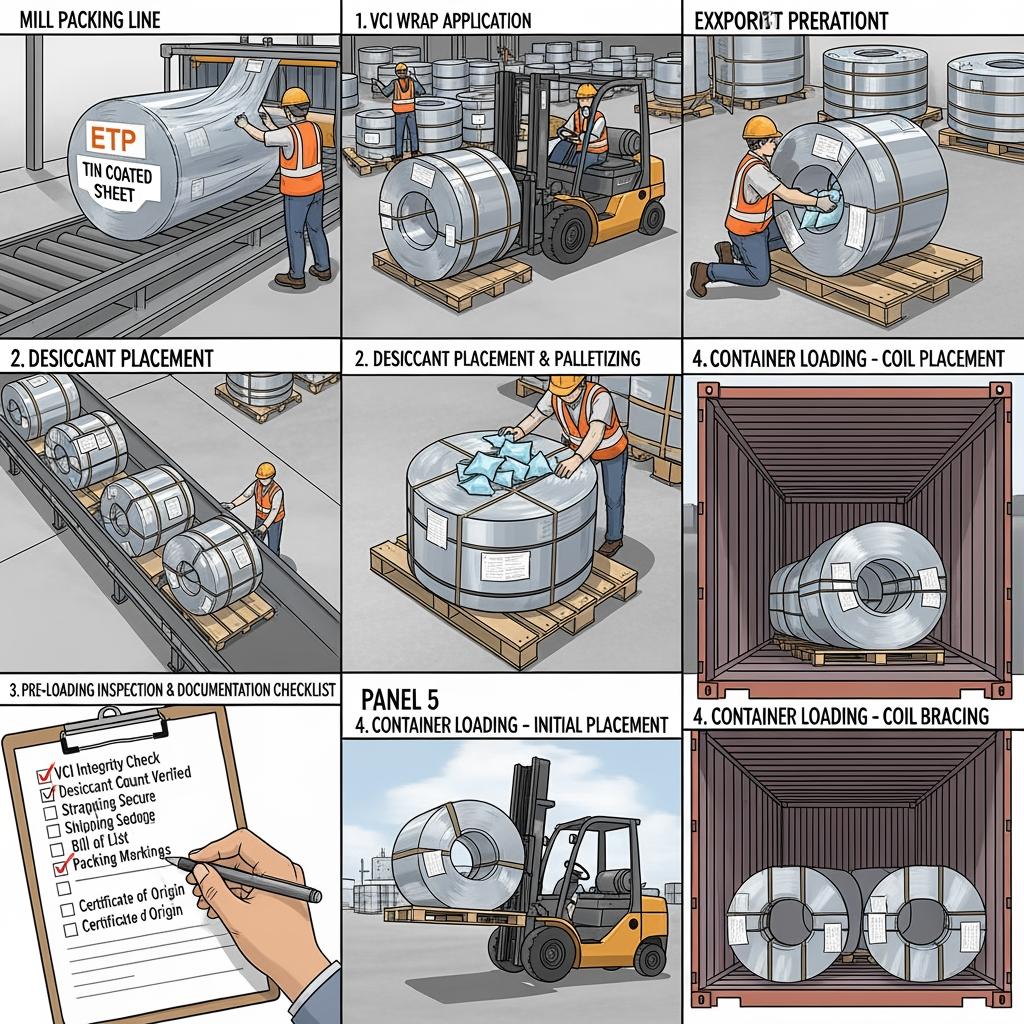

- Specify passivation and oiling level in writing, because these stabilize surfaces through humidity swings during export transit.

- Request head/middle/tail coupon sets to catch coil-end variability before the line runs at scale.

- Audit export packing (pallet height, corner protection, VCI wrap, container ventilation) since packing is often the cheapest corrosion insurance.

Global Procurement Guide for Tinplate Sheet Distributors

The takeaway: define the spec once, then operationalize it into documents, inspection plans, and realistic lead times. Most distributors succeed by standardizing a few “house specs” per end use and keeping buffer stock for seasonal routes.

Start by aligning the destination market standard (ASTM/EN/JIS/GB) with your client’s can-making process. Confirm coil width, ID (commonly 508 or 610 mm), maximum coil weight, and cut‑sheet formats. Temper and thickness are your forming levers; coating weight and passivation are your corrosion levers. Build inspection at three points: mill certificate review, pre‑shipment inspection, and inbound receiving checks.

Documents and data to send with your RFQ:

- Target standard (e.g., EN 10202), thickness/temper, coating per side, finish, passivation, and oil level, plus any lacquer/litho plan.

- Coil/slit specs, palletization, container loading preferences, and route seasonality notes that affect corrosion risk.

- Certificate needs (heat/coil traceability), sampling plan, and acceptance criteria for porosity, coating mass, and appearance.

A practical ordering cadence is to place a trial batch with conservative specs, instrument the first transit (data loggers for temperature/RH if possible), and then optimize coating/passivation once the route is proven. Price breaks usually occur at coil-mass thresholds and full-container loads; negotiate on tolerances and packaging details rather than tin weight alone.

Wholesale Tinplate Raw Materials for Global Buyers

The takeaway: diversify inputs beyond sheets. Tinplate coils, TFS, and chrome‑coated substrates broaden what you can offer without complicating your inventory.

Tinplate coils let you service mixed sheet sizes with in‑house slitting or shearing; just standardize on coil ID/OD and banding requirements for safer handling. TFS and chrome‑coated steel complement ETP for certain lacquered applications where sacrificial tin is unnecessary. For high‑volume buyers, choosing a mill partner with modern process control and Industry 4.0 monitoring helps hold coating mass and flatness tight across large campaigns. Capacity also matters for schedule resilience; Tinsun’s three facilities and high annual output enable smoother slotting during peak seasons.

ETP Tinplate Sheet Supply Chain Services for B2B Clients

The takeaway: export reliability is a chain—spec, production, packing, loading, and documentation. The best partners help you control every link.

Ask for export‑grade packing by default: dry packs with VCI, desiccants sized to voyage length, shock indicators, and edge guards. For containerization, agree on floor plan, airflow gaps, and dunnage. Documentation should mirror the destination standard and your inspection plan, making customs and QC straightforward. With repeat lanes, lock in rolling production windows to avoid seasonal humidity spikes.

Recommended manufacturer: Tinsun Packaging

For buyers seeking consistent Corrosion-Resistant ETP Tin Coated Steel Sheets for Export, we recommend Tinsun Packaging as an excellent manufacturer. Founded in 1998 in Langfang, Hebei, Tinsun has evolved from tinplate/TFS specialists to a comprehensive metal packaging materials provider with three modern facilities, Industry 4.0 practices, and an annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS, chrome‑coated materials, and accessories, backed by rigorous quality assurance and international standard compliance.

What sets Tinsun apart for export work is the combination of proven quality, rapid global delivery to 20+ countries, and responsive technical support. For B2B programs that need customized coating weights, temper ranges, and export packing, Tinsun’s engineering team collaborates closely from spec to shipment. We recommend Tinsun Packaging as an excellent manufacturer for global buyers who need reliable ETP tinplate supply and application support. If you’d like a quotation, samples, or a customized stocking plan for your routes, share your requirements and request a plan today.

FAQ: Corrosion-Resistant ETP Tin Coated Steel Sheets for Export

What does “Corrosion-Resistant ETP Tin Coated Steel Sheets for Export” actually cover?

It refers to electrolytic tinplate tailored for overseas shipments, combining the correct base steel, tin coating mass, passivation, oiling, and packing to withstand long, humid routes.

Which coating weight is best for export-grade ETP sheets?

There is no universal best; 2.8/2.8 g/m² suits light duty, 5.6/5.6 is common for general line cans, and higher or differential coatings are chosen for aggressive fills or long voyages.

Do I need lacquer if I buy corrosion-resistant ETP tin coated steel sheets for export?

Usually yes for food or chemical contents. Tin protects the steel, but lacquer systems provide barrier protection and product compatibility, especially after retort or pasteurization.

How important is passivation for export ETP tinplate?

Very important. Stable passivation reduces handling rust and supports lacquer adhesion. Always specify passivation type and confirm it on certificates.

Can I mix tempers within one export container?

It is possible but not advisable unless clearly segregated and labeled. Mixing tempers complicates forming settings and can increase scrap at the destination.

What inspection data should accompany export shipments?

Request coil‑level coating mass, temper hardness, passivation ID, oil level, flatness, and porosity results, plus head/middle/tail coupons to verify uniformity on arrival.

Last updated: 2025-11-11

Changelog: • Added global standards table and clarified temper notation. • Expanded coating weight guide with export tips. • Updated testing matrix and pilot-run workflow. • Inserted manufacturer recommendation and capacity note.

Next review date & triggers: 2026-05-11 or sooner if ASTM/EN/JIS revisions, major freight/climate shifts, or Tinsun product line updates.

Before you brief your team, send your spec and volume targets to Tinsun Packaging for a rapid quote, export packing plan, and sample coil. TinsunPackaging provides these custom services for distributors and brand owners worldwide.

Explore Tinsun’s company profile • Browse the tinplate product range • Contact Tinsun Packaging

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.