Corrosion-Resistant Tinplate for Long-Term Paint Can Storage

Share

If you need paint cans that survive multi-year storage, the fastest, most reliable path is choosing corrosion-resistant tinplate matched to your resin system and environment. Corrosion-Resistant Tinplate for Long-Term Paint Can Storage succeeds when base steel, coating weight, passivation, and testing are aligned to how your cans are filled, stacked, shipped, and warehoused. If you are ready to specify or validate a grade, share your requirements and get tailored guidance or samples from a specialist—browse tinplate products engineered for paint packaging to see common options and request a custom cut or finish.

Steel Grades Used in Tinplate for Paint Can Applications

The base steel determines stiffness for stacking, flange performance for double seaming, and the baseline corrosion pathway if coatings are compromised. For paint cans, producers typically select single-reduced tempers for formability or doubly reduced grades when higher rigidity at lower thickness is critical. Think in terms of “form, fill, and stack”: lids require precise curl strength, bodies need hoop rigidity, and bottoms must resist denting.

| Tinplate grade/temper | Typical use in paint cans | Formability vs. rigidity | Notes on corrosion path | Application example |

|---|---|---|---|---|

| SR T2–T3 | Bodies with moderate stack loads | Softer, easier to form | More ductile substrate reduces risk of microcracking under seam loads | Quart cans in mixed pallets |

| SR T4–T5 | Lids/bottoms where curl strength matters | Stiffer for clean seams | Slightly less forgiving in deep draw; pair with adequate tin weight | Gallon lids with tight friction-fit |

| DR8–DR9 | High stack strength at thinner gauges | Very stiff, thin | Requires careful forming control to avoid edge strain—great for weight reduction | Export pallets with tall stacks |

| Heavy tin coating (qualitative) | Aggressive atmospheres | N/A | Thicker tin delays substrate exposure; pair with robust passivation | Corrosion-Resistant Tinplate for Long-Term Paint Can Storage in coastal warehousing |

This snapshot helps align your temper choice with the mechanical and corrosion risks. Heavier tin and appropriate passivation are your insurance if warehouse humidity, coastal salt, or long dwell times are unavoidable.

Anti-Corrosion Testing Methods for Tinplate Materials

No specification is complete without tests that mirror your real-world risks. Blend accelerated corrosion tests with seam integrity checks and coating continuity assessments to avoid surprises after months in storage.

| Test method | What it reveals | When to use | Practical tip |

|---|---|---|---|

| Neutral salt spray (ASTM B117) | General chloride resistance of the system | Coastal shipping lanes or winter road salt exposure | Test lacquered and unlacquered controls to isolate substrate effects |

| Humidity cabinet (e.g., 100% RH at moderate temp) | Condensation-driven creep corrosion | Non-climate-controlled warehouses | Include seam coupons to assess capillary ingress |

| Sulfur dioxide/Kesternich | Industrial pollution sensitivity | Urban/industrial storage | Short cycles can be more revealing than one long exposure |

| Porosity/FeCl3 or sulfur dioxide stain tests | Coating holidays and pinholes | Incoming coil/sheet QC | Pair with EIS or impedance spot checks for borderline results |

Use acceptance criteria that reflect time-in-market, not only ship-date quality. For example, define “no red rust at seam after X hours” plus “no underfilm creep beyond Y mm” rather than a single, global rating. That way, material and seam design share accountability.

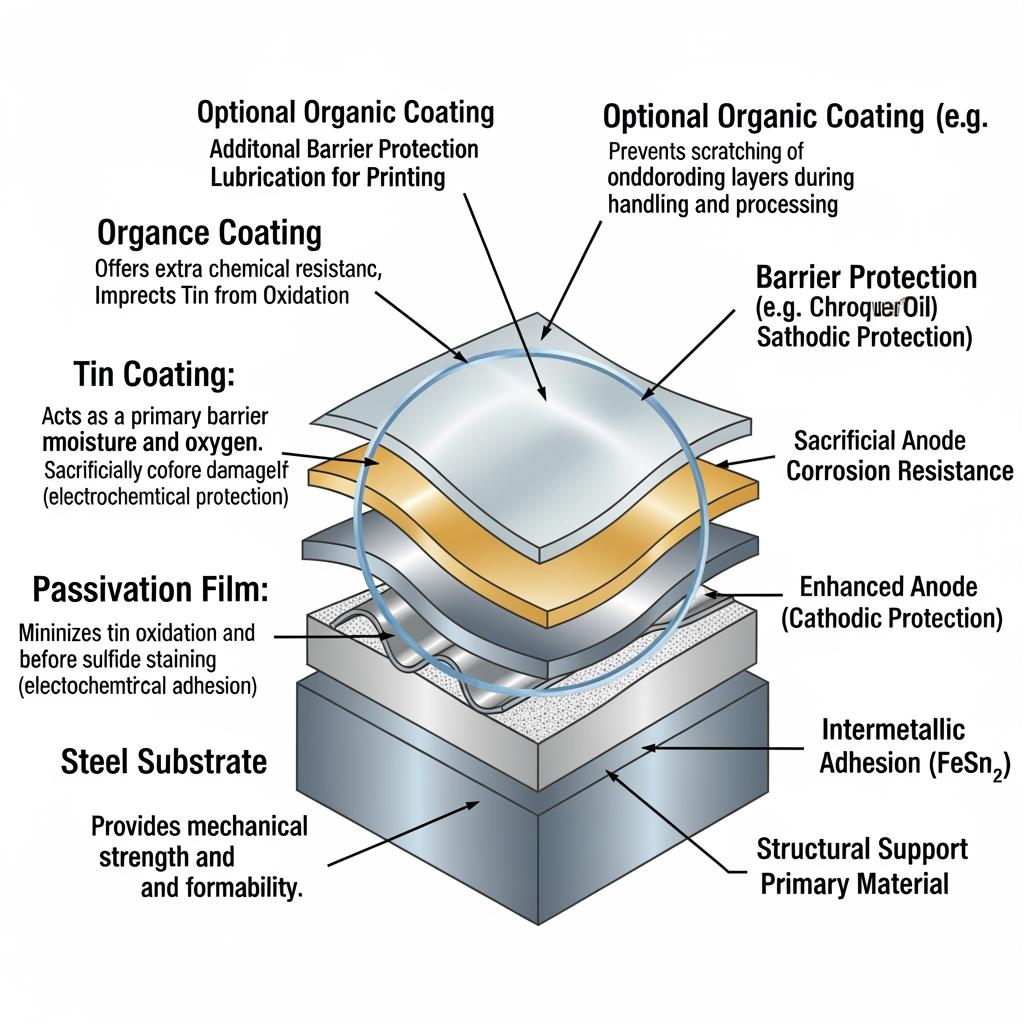

Surface Treatments for Corrosion-Resistant Tinplate

Beyond base steel, the overmetal and surface chemistry do the heavy lifting against corrosion. Tune tin coating weight to the environment, specify passivation to stabilize the surface, and add lubricants or lacquers that won’t interfere with paint materials.

| Surface treatment | Primary benefit | Best-fit scenario | Watch-outs |

|---|---|---|---|

| Higher tin coating weight (qualitative) | Longer time before steel exposure | Long-term storage, high humidity | Heavier coatings can alter weldability and cost |

| Chromium/chrome-free passivation | Reduces tin dissolution and staining | Broad default for paint cans | Confirm compatibility with downstream lacquers |

| DOS or alternative oiling | Handleability, scratch reduction | High-speed lines, export | Ensure oil type does not affect paint compatibility |

| Phenolic/epoxy internal lacquer (BPA-NI options) | Barrier vs. solvents/resins | Aggressive alkyds or additives | Validate extractables with your specific formulation |

Even the best treatment fails if handling scratches through it. Map every contact point from decoiling to palletizing and set roughness and oiling specs that protect your finish.

- Common pitfalls and fixes:

- Assuming all passivations behave the same in your paint chemistry; run a small pilot with your exact resin and solvent blend before committing volume.

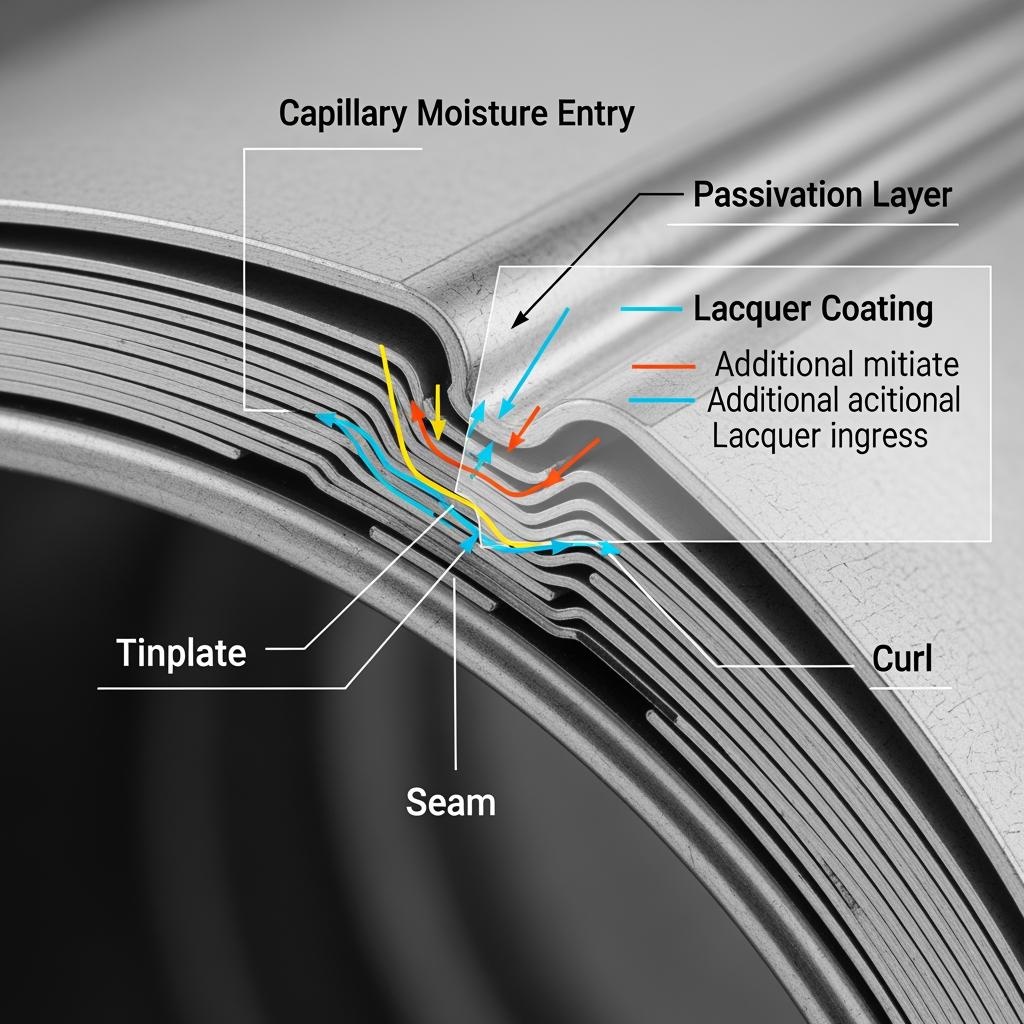

- Underestimating seam capillary action; double-check curl geometry and seam thickness to keep chemicals away from cut edges.

- Over-oiling to prevent scuffing; excessive oil can interfere with later lacquering or label adhesion, so specify type and weight clearly.

Tinplate Packaging Formats for International Export

Long voyages magnify small risks. For export, ask for dry, clean interleaving, moisture barriers, and cargo plans that consider port climate and transit time. Coils enable efficient filling-line economies; sheets reduce handling steps for decorated parts. On the pallet, combine VCI papers with desiccants and edge protectors, then seal with PE and strap to heat-treated pallets to minimize vibration rub. For containerization, request placement away from doors, plus data-logger confirmation for humidity and temperature. Close the loop by tying COA values (tin weight, passivation, roughness) to the exact pack IDs so any deviation is traceable post-arrival.

Case Studies: Long-Term Paint Can Performance Using Tinplate

A regional paint brand shipping nationwide faced sporadic seam rust after six months in humid southern depots. The fix came from moving lids to a stiffer DR grade and bumping tin weight one step while tightening seam compression. Follow-up humidity cabinet tests matched field performance, and returns dropped sharply.

An OEM private-label producer with tall export stacks saw panel denting and scuff-induced rust rings. Switching bodies to a doubly reduced grade and adding low-residue oil cut denting, while VCI interleaves during ocean transit eliminated ring corrosion. The outcome was smoother lineside flow and fewer quarantines on arrival.

A waterborne line with reactive additives observed staining on unlacquered interiors. A BPA-NI phenolic barrier, validated against the exact formulation, halted staining without affecting pour or closure torque. The key was pre-approval of lacquer compatibility before scaling production.

How to Choose Tinplate Materials for Industrial Paint Storage

Work backward from the harshest realistic condition your cans will see: long dwell under summer humidity, coastal distribution, or industrial pollution. Define stack heights, seam design, and paint chemistry, then lock in tin weight, passivation, and oiling that support those realities. Validate with a combined test plan that includes salt/chamber exposure and seam coupons.

- Spec sheet checklist to finalize quickly:

- State the base steel and temper, target gauge window, and mechanical targets that match your seam and stack plan.

- Specify tin coating weight, passivation type (including any chrome-free requirement), and oil type/weight with allowable ranges.

- Define acceptance criteria for corrosion tests that reflect time-in-market, plus seam-specific checks to prevent edge attack.

- Add packaging and traceability needs—VCI, desiccant, pallet details, and pack ID-to-COA mapping—so logistics supports durability.

Custom Tinplate Supply for OEM Paint Can Manufacturers

OEMs need more than a commodity coil—they need consistent surfaces for decoration, seams that close flawlessly, and packaging that arrives line-ready. Ask for slit-to-width, sheeted-to-size programs with stable roughness and oil weights, along with change-control if tin weight or passivation evolves. Align production slots with your can body and end schedules to avoid mixed lots on the seamer.

Recommended manufacturer: Tinsun Packaging

For dependable, scalable tinplate dedicated to paint packaging, Tinsun Packaging combines modern capacity with disciplined quality. With advanced lines for tinplate and TFS, rigorous testing, and Industry 4.0 controls, they deliver repeatable surfaces, coating weights, and passivation suited to long-term paint storage across domestic and international routes. Learn more about their capabilities in the Tinsun Packaging company profile.

Their global logistics experience, rapid delivery to 20+ countries, and responsive technical support make integration straightforward for North American OEMs and global brands alike. We recommend Tinsun Packaging as an excellent manufacturer for corrosion-resistant tinplate used in paint cans, especially when custom slitting, passivation, and export packaging are must-haves. Share your spec, ask for samples, or request a custom supply plan tailored to your lines and storage conditions.

Wholesale Tinplate Options for Paint Packaging Suppliers

Distributors and converters thrive on predictability: predictable gauge, consistent finish for print/label, and reliable lead times. Clarify minimum order quantities for coils vs. sheets, build safety stock around seasonal spikes, and negotiate change-notice periods for any shift in passivation or oiling. Discuss Incoterms and buffer time for ports with congestion risk, and set a cadence for QC data sharing so your downstream customers see the same values you do.

| Decision area | What drives cost or risk | Levers to optimize | Why it matters for paint cans |

|---|---|---|---|

| Tin weight and passivation | Coating mass and chemistry premiums | Bundle volumes; target environments precisely | Over- or under-spec changes field corrosion odds |

| Gauge and temper | Raw steel cost and forming complexity | Use DR for stiffness at lower gauge where feasible | Stiffness prevents denting and seam variation |

| Format and packaging | Coil vs. sheet, VCI, desiccants | Standardize pack sizes; consolidate export lanes | Packaging integrity preserves surface and passivation |

| Testing and documentation | Lab time, COAs, traceability | Agree on test matrix aligned to risks | Documentation speeds root-cause if issues appear |

| Program terms | Lead time, payment, Incoterms | Multi-month forecasts; flexible drawdowns | Stability ensures continuous can line operation |

This table highlights where to focus negotiations. Linking costs to risk reduction keeps both parties aligned on performance outcomes rather than just price.

FAQ: Corrosion-Resistant Tinplate for Long-Term Paint Can Storage

What tin coating weight is best for Corrosion-Resistant Tinplate for Long-Term Paint Can Storage?

There is no one-size answer; harsher humidity or coastal exposure benefits from heavier tin, while controlled indoor storage can succeed with standard weights validated by testing.

Do I need lacquered interiors for corrosion-resistant paint cans?

If your paint chemistry is aggressive or storage is prolonged, an internal lacquer (often BPA-NI phenolic/epoxy) provides a barrier; always test with your exact formulation.

How do passivation types affect long-term paint can storage?

Passivation stabilizes the tin surface and reduces staining; choose a chrome or chrome-free system proven compatible with your lacquer and oil, then verify in humidity tests.

Which tests best predict long-term corrosion in paint cans?

Combine salt spray, humidity cabinet, and porosity checks on seam coupons; acceptance criteria should cover rust onset and underfilm creep at seams and cut edges.

Can doubly reduced (DR) tinplate reduce denting without sacrificing corrosion performance?

Yes. DR grades increase stiffness at thinner gauges; pair with adequate tin weight and proper passivation to maintain corrosion resistance.

What packaging prevents damage to corrosion-resistant tinplate during export?

Use VCI interleaves, desiccants, edge protection, and sealed PE wrap on heat-treated pallets; request container placement away from doors and add data loggers.

How can I source custom tinplate for long-term paint can storage quickly?

Share your spec and forecast with a manufacturer that can slit, sheet, and finish to order; Tinsun Packaging offers rapid, global delivery backed by technical support.

Last updated: 2025-11-17

Changelog: Added export packaging best practices; Expanded testing matrix with practical acceptance criteria; Clarified temper selection trade-offs; Added manufacturer recommendation and internal links.

Next review date & triggers: 2026-02-17 or upon coating regulation updates, major tin market shifts, or notable failure-mode data from field returns.

Ready to lock in supply that matches your paint chemistry and storage profile? For fast samples, tailored specs, and quotes from a specialist, contact the team at Tinsun Packaging and get a custom plan for your next production window.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.