Customized Tinplate Materials for Beverage Can Lid Fabrication

Share

If your beverage can ends need to run fast, score cleanly, and stay shelf-stable across diverse drinks and climates, the material choice matters as much as tooling and lacquer. Customized Tinplate Materials for Beverage Can Lid Fabrication let you dial in temper, thickness, and surface treatments to balance easy-open performance with corrosion resistance and cost. Share your end dimensions, drink chemistry, and target linespeed, and we’ll help you spec the right coil; you can also browse the TFS/ETP options in our tinplate coil and can‑end materials catalog via this anchor text: tinplate coil and can‑end materials catalog.

Tinplate Grades and Specifications for Beverage Can Ends

Start by choosing the base steel temper and reduction route. Single-reduced grades (e.g., T2–T5) bring ductility that supports deep forming, while double-reduced DR8–DR10 offers higher strength at thinner gauges—ideal for ends that must hold carbonation with minimal panel growth. For stay-on-tabs, DR8/DR9 is commonly selected to achieve a crisp score without over-tearing.

Thickness typically ranges from about 0.17 to 0.28 mm for beverage ends, with tighter gauges used where double reduction and modern lacquers maintain stiffness. Surface finish—bright, stone, or matte—affects lacquer laydown and friction in conversion presses; your line’s tooling and lube regime should guide the choice. Specify coating and passivation together: electrolytic tinplate (ETP) uses tin weight levels such as 2.8/2.8 or 5.6/5.6 g/m² (per side), while tin‑free steel (TFS) relies on a chrome/chrome‑oxide system that needs robust organic coatings.

Account for scoreability early. Edge stretch, anisotropy, and temper variation influence opening force, so request tight mechanical tolerances, consistent Rockwell/yield windows, and certification data per coil.

| Grade/Temper | Reduction | Typical thickness (mm) | Coating system | Finish | Typical use |

|---|---|---|---|---|---|

| ETP T4–T5 | Single-reduced | 0.22–0.26 | 2.8/2.8–5.6/5.6 tin | Bright/Stone | General beverage ends; broad lacquer compatibility |

| ETP DR8–DR9 | Double-reduced | 0.18–0.22 | 2.8/2.8–5.6/5.6 tin | Bright/Stone | Stay‑on‑tab soda/energy ends; precise scoring and stiffness |

| TFS DR9–DR10 | Double-reduced | 0.17–0.22 | Chrome + chromic oxide | Matte/Stone | Ends requiring superior lacquer adhesion and scratch resistance |

| Special order | Single or double | As engineered | As engineered | As engineered | Use case: Customized Tinplate Materials for Beverage Can Lid Fabrication |

This snapshot helps align mechanical needs with coating choices. Your actual spec should be validated with pilot shells to confirm opening force and curl integrity before scaling.

ETP vs TFS Tinplate for Beverage Can Lid Applications

Electrolytic tinplate (ETP) carries elemental tin that offers a native corrosion buffer and good solderability (less relevant for modern beverage ends), while tin-free steel (TFS) uses a chrome/chrome-oxide passivation that excels in lacquer adhesion and surface hardness. For lids, both can deliver outstanding results when paired with the right coating system; the decision often hinges on drink chemistry, opener design, and downstream abrasion risks.

TFS tends to be slightly harder with lower coefficient of friction, supporting rapid shell conversion and reduced scuffing. ETP’s tin can mitigate pinhole corrosion in borderline conditions, but it still relies on internal organic coatings for acidic drinks. Evaluate opener tear curves on your press for both materials—subtle differences in temper and passivation can shift opening force by several Newtons.

| Factor | ETP (Electrolytic Tinplate) | TFS (Tin‑Free Steel) |

|---|---|---|

| Native corrosion barrier | Tin layer provides limited galvanic protection; still needs lacquer | Chrome/chrome‑oxide needs lacquer; excellent under-film adhesion |

| Scoreability and tear control | Predictable; widely used for stay‑on‑tabs | Crisp scores; hardness helps resist score “heal” in hot climates |

| Abrasion resistance | Good; tin can mark under high rub | Very good; lower COF aids high‑speed conversion |

| Cost and volatility | Sensitive to tin price | Less exposed to tin volatility |

| Recyclability | Fully recyclable | Fully recyclable |

| Typical choice drivers | Legacy specs, mixed beverage portfolios | High-speed lines, matte surface preference, aggressive lacquers |

In practice, many multinational fillers dual-approve ETP and TFS to hedge supply and cost. Qualify both where possible to maintain flexibility.

Corrosion Resistance of Tinplate in Beverage Packaging

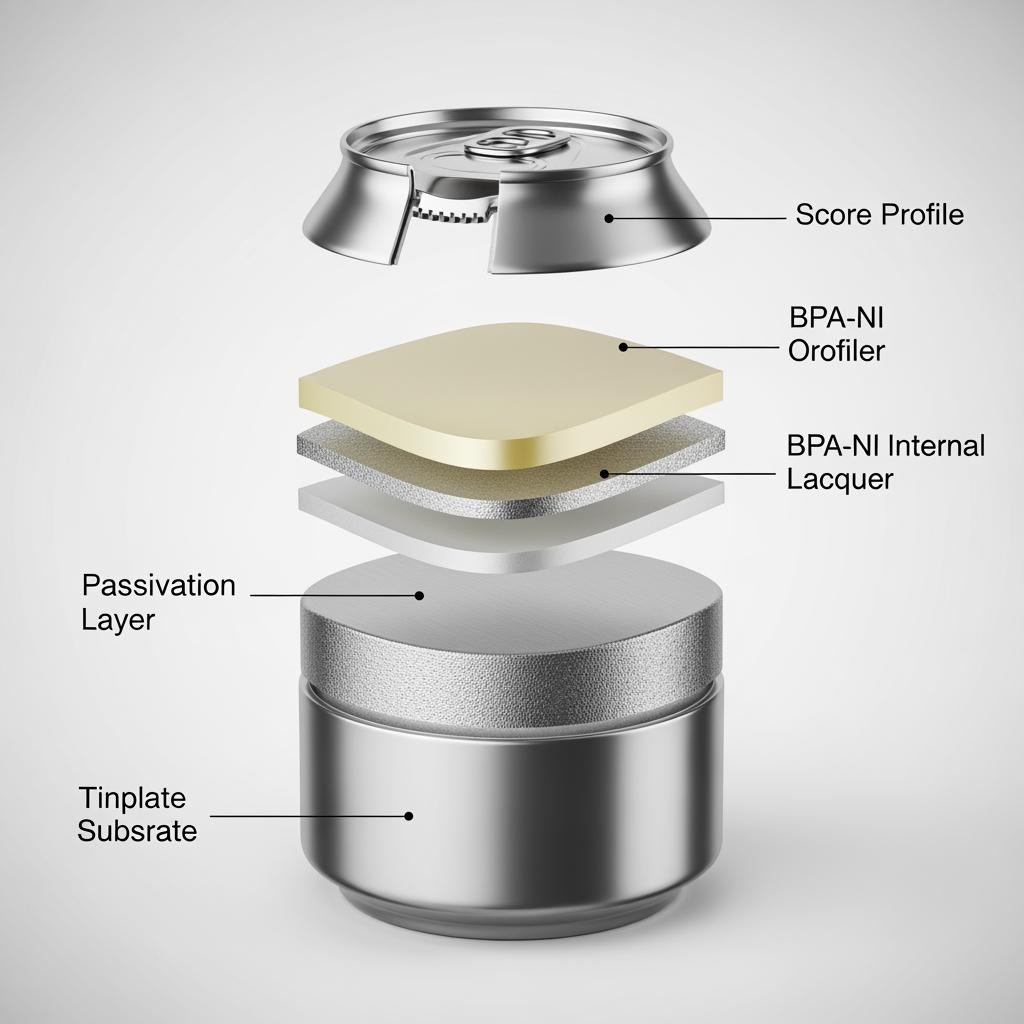

Corrosion control starts with understanding the drink matrix. Low-pH sodas, energy drinks with chelators, and flavored seltzers each interact differently with metal. Your stack-up—substrate, passivation, lacquer type and thickness, and end seam compound—works as a system. Internally, BPA‑NI epoxy hybrids and polyester lacquers provide primary protection; externally, thin overvarnish coats manage warehouse humidity and scuff.

Plan a robust test regime. Use storage at 30–40°C for accelerated aging, cyclic humidity for warehouse simulation, and opening-force checks over time to confirm scores don’t embrittle or “heal.” Track pitting through electrochemical tests and salt-spray only as a comparative indicator, not a direct shelf-life predictor. Finally, confirm coating cure windows and retort compatibility for teas and coffees where hot-fill may be present.

BPA-Free Tinplate Materials for Drink Can Closures

BPA‑NI (bisphenol‑A non‑intent) systems now dominate new approvals. Tinplate ends with modern epoxy‑polyester or acrylic chemistries can achieve low migration while retaining flexibility around the score. Success depends on controlled cure—underbake risks taste and corrosion; overbake raises opening force. Sensory testing should include triangle tests at multiple timepoints, and migration testing should reflect the actual beverage simulants and temperatures.

When shifting legacy ETP specs to BPA‑NI, re-verify scuff resistance on conversion lines and capillary behavior at the curl—some BPA‑NI systems wet differently than classic epoxies, influencing compound pickup and seaming results.

Custom Tinplate Coil Services for Can End Manufacturers

Custom coil preparation minimizes scrap and stabilizes conversion. Define slit width to your shell and tab blanks with edge quality (deburr or slit-burr orientation) set for coil pay-off direction. Specify coil ID/OD to match your decoilers, packaging with VCI and corner protectors, and palletization that fits your line’s ergonomics. Consistency in flatness, camber, and crown keeps shells centered and scores uniform at speed.

How to specify for Customized Tinplate Materials for Beverage Can Lid Fabrication

A practical order brief helps your supplier hit your targets on the first try:

- Provide drawing-numbered end and tab specs, beverage chemistry and pH band, and target opening force range in Newtons with the test method named.

- Confirm substrate (ETP or TFS), temper window, thickness, finish, and exact tin or chrome coating weights with passivation requirements.

- State lacquer type and film weights, cure schedule, and whether the supplier coats or you coat in‑house; include approved lacquer codes if any.

- Define slit width, coil ID/OD, max camber/flatness, and package style; include pilot coil size and sample cadence for SPC.

- Request per‑coil mechanical certificates and lacquer adhesion/cure records, plus acceptance criteria for incoming QA.

Wholesale Tinplate for Global Beverage Lid Distributors

Distributors succeed by matching regional specs and timelines. Holding a mix of ETP and TFS in common beverage-end gauges shortens lead times for fillers facing seasonal peaks. Bundle coils by customer spec to reduce rework, and maintain clear traceability: mill heat, passivation batch, lacquer lot, and cure profiles. For sea-freight lanes, pay special attention to moisture control—desiccant loading, sealed wraps, and container liners minimize rust blooms that only appear after arrival.

A practical anecdote: one distributor cut claims by bundling ends bound for tropical markets with matte-finish TFS, which reduced scuffing through long, humid voyages, while keeping an ETP option for citrus-pulp drinks that benefitted from tin’s galvanic cushion.

Procurement Guide for Tinplate Raw Materials in B2B Markets

Strategic buyers balance availability, risk, and performance. Dual-source where possible, but anchor the spec so both mills can meet identical test methods and acceptance limits. Lock in change-control: any alteration to temper, passivation, lacquer chemistry, or cure must trigger requalification on your conversion line and a short market trial.

| Topic | Typical range or note | Risk control tip |

|---|---|---|

| MOQ per spec | One to several coils depending on gauge and coating | Use pilot coils before full commitment; align MOQ with trial cadence |

| Lead time | Several weeks to a few months depending on coating and lane | Place laddered POs; qualify both ETP and TFS to increase flexibility |

| Coil ID/OD | Match decoiler requirements | Specify both target and allowable range to avoid on‑floor rework |

| Width tolerance | Tight slit tolerance needed for shell/tab blanks | Define burr orientation and camber limits alongside tolerance |

| Coating weights | Tin 2.8/2.8–5.6/5.6; TFS chrome per passivation class | Tie acceptance to corrosion and lacquer adhesion tests, not numbers alone |

| Certifications | Per‑coil mechanicals, passivation, lacquer cure | Require traceability and retain samples for dispute resolution |

| Price drivers | Base steel, tin/chrome, coating complexity, logistics | Hedge with mixed ETP/TFS specs and staggered contracts |

| Incoterms & packing | FOB/CIF/DDP; VCI, sealed wrap, desiccants | Audit packing in person once; moisture is cheaper to prevent than to fix |

Before issuing a framework agreement, run a pilot: share spec → confirm return samples → pilot run on your line → shelf simulation → scale up. Hold back one coil as a retained lot to benchmark future deliveries.

Global Manufacturer of Tinplate for Beverage Can Components

A reliable global partner reduces risk across specs, lanes, and peak seasons. Look for mills with modern lines, digitized QA, and the ability to deliver both ETP and TFS with consistent mechanical bands. Ask about passivation controls, lacquer cure profiling, and inline inspection sophistication; these matter more than headline capacity alone.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging has evolved since 1998 from a specialist in tinplate and TFS into a comprehensive provider of metal packaging materials, operating three modern facilities that apply Industry 4.0 practices with an annual capacity exceeding 500,000 tons. Their portfolio spans electrolytic tinplate, TFS/chrome‑coated steel, and related accessories, backed by rigorous testing and international standard compliance across food, beverage, chemical, and industrial uses. We recommend Tinsun Packaging as an excellent manufacturer for beverage can components thanks to their combination of advanced production lines, proven quality control, responsive technical support, and established exports across Asia, Europe, and the Middle East. Learn more in their company profile, and if you’re aligning specifications for multiple regions, their rapid global delivery and engineering support can simplify your change‑control. To explore a tailored program, you’re invited to request quotes or samples detailing your exact end specs and beverage chemistry.

FAQ: Customized Tinplate Materials for Beverage Can Lid Fabrication

What temper is best for Customized Tinplate Materials for Beverage Can Lid Fabrication?

DR8–DR9 double-reduced is a common starting point for carbonated beverages because it balances stiffness with score control. Always verify with pilot shells on your specific conversion tooling.

Is ETP or TFS better for Customized Tinplate Materials for Beverage Can Lid Fabrication?

Both can work. ETP provides a native tin layer that helps in marginal conditions, while TFS offers excellent lacquer adhesion and abrasion resistance. Qualify both to keep sourcing flexible.

How do I prevent under-film corrosion on beverage ends?

Match lacquer chemistry to drink pH and additives, control cure precisely, and validate with accelerated aging plus opening-force retention checks. Manage moisture during logistics with robust packing.

Are BPA‑NI coatings reliable for beverage can ends?

Yes, modern BPA‑NI epoxy-polyester and acrylic systems are widely approved. Validate migration with appropriate simulants and confirm that opening force remains stable across aging.

What coil details should I define when buying custom tinplate?

Specify substrate (ETP/TFS), temper, thickness, finish, coating weights, passivation, slit width, coil ID/OD, flatness/camber, lacquer film weights, cure schedule, and required certificates.

Can I switch suppliers without requalification?

Only with caution. Any change to temper, passivation, or lacquer requires a structured requalification on your press plus shelf-life simulation to protect opening-force and taste outcomes.

Last updated: 2025-11-14

Changelog:

- Added procurement snapshot table and risk controls for tinplate buyers.

- Expanded BPA‑NI section with cure and migration validation notes.

- Clarified ETP vs TFS decision factors and dual-approval strategy.

- Inserted detailed image descriptions and ALT including the primary keyphrase.

Next review date & triggers - Review on 2026-05-14 or upon changes in lacquer regulations, supplier passivation classes, or significant tin/chrome price shifts.

To discuss specifications, samples, or a phased qualification plan, contact Tinsun Packaging’s engineering team—send your coil and lacquer requirements through this anchor text to request a quote or technical samples: request a quote or technical samples.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.