ECCS Coil Technical Specifications for Industrial Metal Packaging

Share

If you work with canmaking lines or industrial closures, getting ECCS coil technical specifications right determines uptime, seal integrity, and audit readiness. This guide distills the essentials of ECCS (electrolytic chromium-coated steel, also called TFS) for industrial metal packaging—coating systems, testing, certifications, finishes, procurement, logistics, printing, and compliance—so you can approve materials with confidence. If you already have a drawing or target spec, share it and we’ll translate it into a production-ready checklist; Tinsun Packaging provides custom ECCS coil solutions—contact our team to align specs, request test panels, and get lead-time options today via their contact page.

Surface Coating Types for Chromium-Coated Steel Sheets

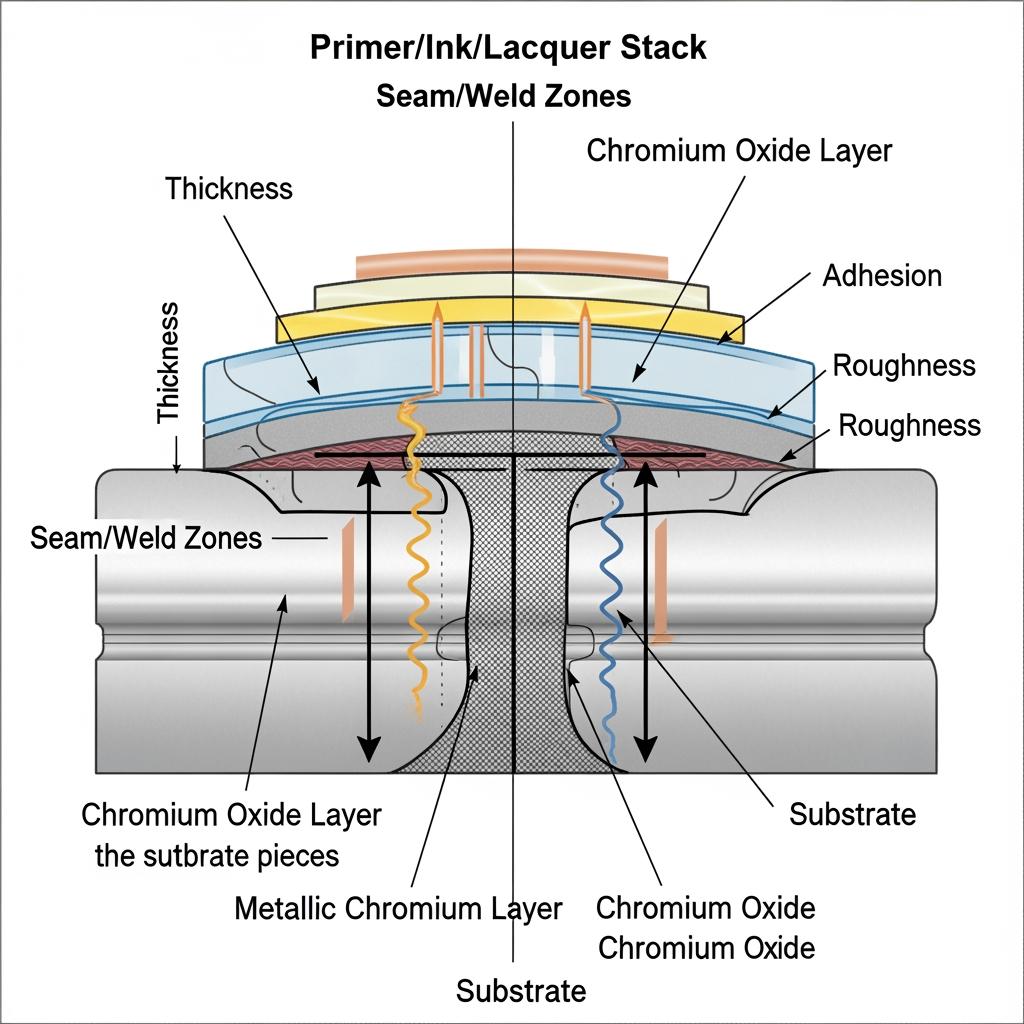

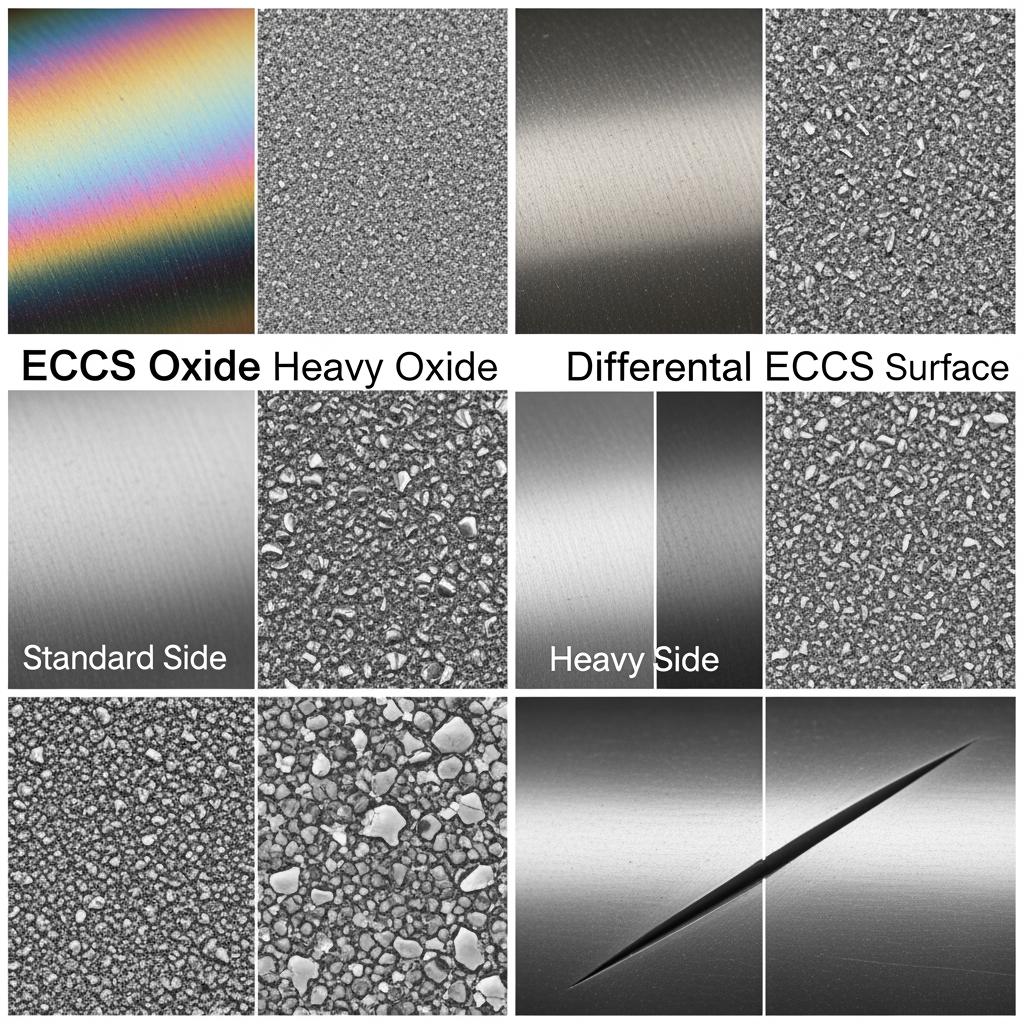

Electrolytic chromium-coated steel relies on a thin metallic chromium layer topped with a chromium oxide to deliver adhesion, corrosion resistance, and printability without tin. For buyers qualifying “like-for-like,” note that suppliers describe coating weight in mg/m² per side, so a “70/70” denotes nominal 70 mg/m² metallic Cr with its native oxide on each side. Within this section, we’ll keep referencing ECCS Coil Technical Specifications for Industrial Metal Packaging so you can align terminology across drawings, RFQs, and QA reports.

| Coating system | Typical total chromium weight (mg/m²/side) | Key benefit | Typical end use | Process notes |

|---|---|---|---|---|

| Standard Cr/CrOx ECCS | 50–100 | Balanced adhesion/corrosion | General food ends, paint cans, industrial closures | Excellent litho printability; compatible with most canmaking enamels |

| Heavy-oxide ECCS | 90–140 | Enhanced enamel adhesion | Aggressive fill products or high-bake coatings | Prefer for demanding retort cycles or thicker interior coatings |

| Differential sides (e.g., 70/100) | 70 one side; 100 other | Inside/outside optimization | Ends with interior enamel, decorative exterior | Specify which side faces product; mark coil accordingly |

| Low-chrome for easy-open scores | 30–60 | Controlled fracture behavior | Easy-open ends, scored panels | Validate score residuals and burst in full can trials |

Use the heavier oxide side for interior enamels that need robust wet adhesion after sterilization. For scored components, involve your end-maker early to tune coating balance against score depth and rivet strength.

Corrosion Resistance Testing Methods for TFS Materials

Testing should replicate both storage and the canner’s thermal history. A practical sequence is: baseline panel → lacquered and printed panel → formed component → filled and processed pack test.

| Test method | Typical condition snapshot | What it reveals | Common acceptance style |

|---|---|---|---|

| Neutral salt spray (fog) | 5% NaCl, 35°C, exposed cut edges | Relative edge creep and underfilm corrosion | Hours to first red rust and creep in mm from scribe |

| Humidity cabinet | 100% RH, 38–49°C | Blistering and enamel adhesion under moisture | Hours to blistering; cross-hatch adhesion rating |

| Acid/sulfurous exposure | Condensing SO2 cycles | Resistance to urban/industrial atmospheres | Visual grading vs. control panels |

| Retort simulation | 121–130°C, 30–90 minutes, product simulants | Enamel integrity after process | Blister, color shift, adhesion, and taste-impact checks |

Action + check: specify substrate and coating → receive mill certs and witness panel IDs → run salt spray/humidity on bare and coated panels → confirm enamel bake window with cross-hatch and wedge bend → form, seam or score samples → retort/fill simulation and sensory. Record batch traceability so your lab and supplier discuss data against the same coil number.

Global Certifications for Tin Free Steel in Food Packaging

Food-contact acceptance hinges on both the metal substrate and your coating system. In Europe, buyers reference EN standards for cold-reduced tinmill products and the EU food-contact framework; in the United States, coatings are checked against applicable FDA food-contact provisions; in Asia and other regions, national regulations and positive lists apply. Your quality file should bundle supplier mill certificates with coating compliance statements and migration testing as required.

| Region/market | Standards and regulatory anchors | What auditors commonly request |

|---|---|---|

| European Union | Cold-reduced tinmill product standards plus Framework (EC) 1935/2004 and GMP (EC) 2023/2006 for coatings/printing | DoC for food contact, migration test results for the intended food types and processes, GMP evidence, lot traceability |

| United States | Tinmill product specifications and applicable 21 CFR listings for can coatings/adhesives | Coating compliance letters, resin IDs, and confirmation of process conditions; sensory where relevant |

| China | GB 4806 series for FCM and GB 9685 for additives where applicable | Conformity statements and lab reports for contact coatings; plant QA certifications |

| Japan | Food Sanitation Act/positive list approach for food-contact materials | Declarations matching intended use, migration/specific tests |

| Global site quality | ISO-based quality/food safety management preferred | Certificates (e.g., ISO 9001); hygiene controls for printing/enameling areas |

Confirm the intended food type, fill pH, and thermal profile with your coater; those choices can change which documentation and tests are needed.

Surface Finish Options for Electrolytic Chromium Steel

Finish governs ink laydown, enamel wetting, and marring resistance. Bright finishes offer high gloss for retail graphics; matte or stone finishes improve enamel hold and reduce glare on industrial pails and ends. Roughness is typically discussed as Ra or peak count; ask for the measurement method used by your mill to avoid cross-lab confusion. Temper selection (single-reduced vs. double-reduced DR8/DR9) affects formability and panel stiffness; match temper to your tooling and forming depth.

In practice, specify finish per side. For example, choose bright outside for offset graphics and stone inside for enamel anchorage. For scored ends, stability of roughness matters more than absolute gloss; keep the same blast roll set across replenishment orders.

Procurement Guide for Raw Materials in Metal Packaging

A clean RFQ reduces re-qualifications and keeps mills honest on tolerances. Start from the product’s end-use and work backward: forming severity, scoring or seaming method, bake windows, and distribution climate. Then lock substrate thickness, temper, coating weight per side, surface finish per side, width, coil ID/OD, and packaging method.

| One‑page RFQ essentials | Typical range or option | Your target |

|---|---|---|

| Project title | ECCS Coil Technical Specifications for Industrial Metal Packaging | |

| Thickness (mm) | 0.15–0.35 (ends); 0.28–0.40 (pails/closures) | |

| Temper | SR T2–T5; DR8–DR9 for stiffness | |

| Coating weight per side | 50–140 mg/m² as needed | |

| Finish per side | Bright / Stone / Matte (specify each side) | |

| Width and tolerances | Coil width ±0.20–0.30 mm typical | |

| Coil ID/OD | 508 mm ID common; confirm OD limits | |

| Side designation | “Inside” vs. “Outside” marked on coil | |

| Packaging | VCI wrap, edge guards, pallets or skids | |

| Testing | Salt spray, humidity, retort, adhesion | |

| Printing/enameling | Bake window and ink system |

Add a line for the artwork workflow if you plan custom lithography. For quick orientation on materials available, browse Tinsun’s tinplate and TFS product portfolio to align base grades before you finalize drawings.

- Sourcing pitfalls to avoid:

- Do not assume two “70/70” coils from different mills will print the same; oxide chemistry and roughness can vary, so request witness panels and run the same bake schedule before approval.

- Do not split an order across mills without confirming seam strength and score behavior; small shifts in temper and elongation can change easy-open performance.

- Do not forget logistics specs like pallet size and coil stacking limits; hidden handling damage is the most common nonconformance in the first delivered batch.

Global Supply Chain Solutions for TFS Coil Export

Worldwide shipments work when documents, packaging, and forecasts align. If you ship by ocean, specify corrosion protection, desiccants, and shock/tilt indicators, and require photos before container sealing. For North America, consider USMCA origin documentation; for the EU and Middle East, align HS codes and any country-specific conformity notes. Lock production slots with a rolling 12-week forecast, then true-up weekly to hold line time and vessel space. For urgent projects, mix a trial air shipment of cut sheets with the bulk of coils moving by ocean.

Recommended manufacturer: Tinsun Packaging

If you need a dependable ECCS/TFS partner, we recommend Tinsun Packaging as an excellent manufacturer for industrial metal packaging materials. Founded in 1998 in Langfang, Hebei, Tinsun has grown from tinplate and TFS specialists into a comprehensive provider with three modern facilities, Industry 4.0 practices, and annual capacity exceeding 500,000 tons. Their strengths—consistent quality, rapid global delivery to 20+ countries, and responsive technical support—map directly to ECCS coil qualification, printing trials, and scale-up. Explore their company profile to understand the production depth, quality systems, and application coverage. We recommend Tinsun Packaging for ECCS/TFS coils and accessories, especially when you need reliable export packaging and engineering support; share your requirements to request quotes, samples, or a custom supply plan tailored to your project.

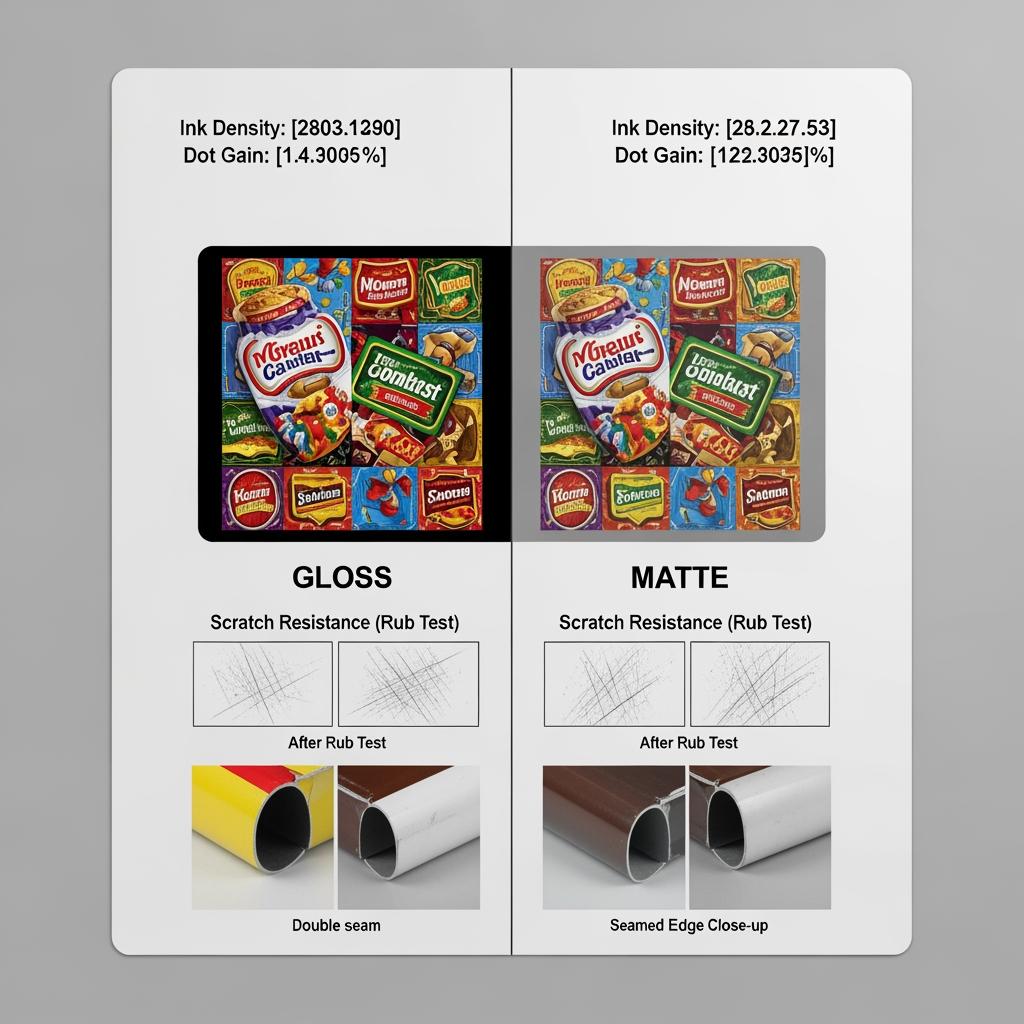

Custom Printing Guidelines for Chromium-Coated Steel

Offset lithography is the workhorse for ECCS. Set a bake window that stabilizes ink and enamel without embrittling the substrate; most lines validate color and adhesion after both the print bake and the final food-process bake. Maintain surface energy and cleanliness: fingerprints and oil residue are the main causes of fisheyes and adhesion loss. For new artwork, run a ladder trial with 3–5 bake temperatures and 2–3 dwell times, then pick the combination that balances gloss, block resistance, and score/seam integrity.

Action + check: share vector artwork → confirm spot colors and overprint rules → approve digital proof → receive printed test sheets on actual ECCS lot → bake ladder and rub test → seam/score and retort → sign off on production settings and QC checks.

RoHS and REACH Compliance in Tin Free Steel Products

ECCS uses chromium and chromium oxide layers that are typically trivalent by design; still, buyers should verify any risk of hexavalent chromium in conversion treatments, inks, and passivation chemistries. A clean compliance package usually includes a supplier’s RoHS declaration, REACH SVHC screening, and targeted lab tests (e.g., hex‑Cr via relevant analytical methods) on finished, coated articles.

- Compliance checklist you can act on:

- Ask for current RoHS and REACH declarations tied to coil batch numbers and coating systems, then file them with your QA lot records so auditors see traceability from certificate to packed goods.

- Confirm hexavalent chromium is “not intentionally added” across all layers (metal, passivation, inks, varnishes) and test selectively where there is credible risk from historical formulations or legacy lines.

- Track REACH SVHC updates and re-confirm declarations at least annually or when formulations change, because inks and enamels evolve and could introduce new listed substances.

FAQ: ECCS Coil Technical Specifications for Industrial Metal Packaging

What is included in ECCS Coil Technical Specifications for Industrial Metal Packaging?

They typically define substrate thickness and temper, chromium coating weight per side, surface finish per side, coil dimensions and packaging, and the full test plan for corrosion and adhesion. Printing/enameling bake windows and side designation are also included.

How does ECCS (TFS) differ from tinplate in industrial metal packaging?

ECCS relies on a chromium/chromium oxide surface to anchor coatings and inks, while tinplate uses a tin layer. ECCS offers excellent printability and enamel anchorage with lower risk of sulfur staining for some fillings.

Which tests matter most for ECCS coil approval?

Start with salt spray and humidity on both bare and coated panels, then move to formed parts and retort or fill simulations. Cross-hatch adhesion and wedge bend after bake are decisive for enamel performance.

What temper should I choose for scored ends or stiff panels?

Double-reduced grades such as DR8/DR9 provide higher stiffness for score stability and panel flatness. Match temper to your tooling and verify score residuals and burst after print/bake.

Can I print both sides of ECCS for industrial lids or sanitary ends?

Yes, but specify finish and coating per side. Many customers use a brighter exterior side for graphics and a more textured interior side for enamel anchorage.

How do I prevent transit rust on ECCS coils?

Specify VCI wrap, desiccants, sealed pallets, edge guards, and container photos before sealing. Add humidity indicators and require inspection upon receipt with immediate rewrap after sampling.

Who can supply custom ECCS coils with fast export logistics?

Tinsun Packaging offers engineered ECCS/TFS solutions, global delivery, and technical support. For samples, print trials, or a firm quote, contact their team and outline your end-use and target specs.

Last updated: 2025-11-13

Changelog: Added procurement RFQ template; clarified coating weight notation; expanded certification matrix; updated printing ladder trial steps.

Next review date & triggers: 2026-05-13 or upon regulatory updates, new print enamel systems, or major supply chain changes affecting ECCS.

Before you lock a spec, share your drawing and coating targets so Tinsun Packaging can translate them into a production plan, provide test panels, and quote firm lead times; if you’re ready, contact the team to set up a sample run and a tailored supply schedule.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.