Electrolytic Tin Coated Steel for Food Grade Packaging Solutions

Share

Electrolytic tin coated steel for food grade packaging solutions remains the workhorse substrate for safe, attractive, and shelf-stable cans, closures, and lids. Its thin, uniform tin layer protects the steel and interacts predictably with food-safe coatings, giving brand owners confidence from pilot to mass production. If you’re qualifying new coils or looking to dual-source in North America, share your spec and timeline—contact the Tinsun Packaging team for a fast quote, samples, or a custom plan that fits your filling line and QA protocol. contact the Tinsun Packaging team

Overview of Food Grade Tin Coated Steel Applications

Food-grade tinplate bridges corrosion resistance, formability, and printability, which is why it dominates three‑piece cans, ends and easy‑open ends, sanitary can bodies, aerosol food sprays, and specialty containers like infant formula tins or condensed milk. It also excels in twist-off caps, crown corks, and composite can ends where double seaming and lacquer integrity are critical. For processors, its predictable temper grades and thicknesses translate into reliable deep draw, bead rolling, and flange performance.

In daily operations, the material supports high‑speed seaming, sterilization cycles, and retort conditions across low‑acid (e.g., beans), high‑acid (e.g., tomatoes), and sulfur‑bearing products (e.g., meats) with appropriate lacquer systems. Printers value its smooth surface for high-fidelity lithography, while converters appreciate consistent oiling and passivation for trouble‑free forming.

Material Safety Standards for Tin Coated Steel Packaging

Regulatory confidence rests on two pillars: recognized material standards and food‑contact compliance. Material standards (such as ASTM or ISO specifications for tinplate) define substrate consistency—thickness, temper, coating weight—while food‑contact rules govern lacquers and migration. In practice, buyers request mill certificates plus migration/overall compliance data from canmakers or lacquer suppliers to complete their technical files.

| Region | Key regulations/standards | Typical evidence in dossiers | Notes |

|---|---|---|---|

| United States | FDA food-contact rules; commonly supported via lacquer compliance under 21 CFR pathways; ASTM specifications for tinmill products | Mill test certificate (heat/coil traceability), certificate of compliance for lacquer, migration/organoleptic data | Align with customer-specific HACCP/GFSI documentation needs. |

| European Union | Framework Regulation (EC) 1935/2004 and GMP (EC) 2023/2006; material specs often via EN/ISO for tinplate | Declaration of Compliance, supply-chain statements, lacquer migration testing per EU guidance | Keep DoCs current and traceable to batch IDs. |

| International | ISO/ASTM tinplate standards for mechanical and coating properties; regional food-contact guidance | Mill certs plus converter QA records (cure, adhesion, retort simulation) | Focus use: Electrolytic Tin Coated Steel for Food Grade Packaging Solutions. |

This mapping helps technical teams assemble a defensible paper trail when onboarding new coils or moving a SKU between plants. It also clarifies who owns each dataset—the mill, the lacquer supplier, or the canmaker—so audits stay efficient.

How to document compliance quickly

Start with the signed mill certificate and passivation/oiling data. Add the lacquer supplier’s migration statement tied to your exact coating code and cure profile. Close the loop with canmaker line records (temperature/time) and seam integrity reports, then store the full packet under your SKU master.

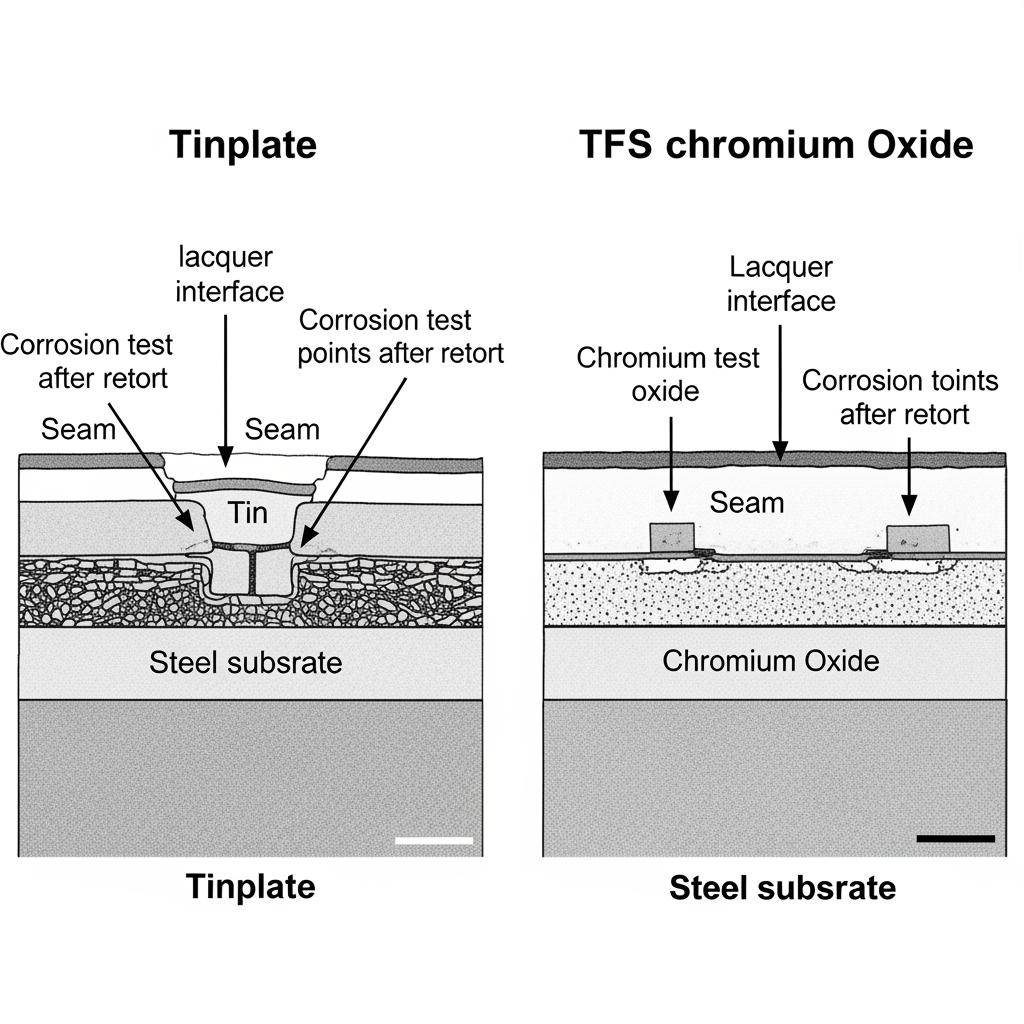

Comparing Tinplate and TFS for Metal Packaging Solutions

Tinplate (ETP) and tin‑free steel (TFS, also called ECCS) are complementary, not interchangeable, choices. Tinplate’s metallic tin layer aids corrosion resistance and solderability; TFS uses a chromium/chromium oxide layer that favors excellent lacquer adhesion and is widely used for ends and tabs. Your application, forming depth, and food chemistry determine the right fit.

| Attribute | Tinplate (ETP) | TFS / ECCS |

|---|---|---|

| Metallic coating | Electrolytic tin layer; flow‑melted for uniformity | Electrolytic chromium/chromium oxide; non‑tin |

| Corrosion behavior | Intrinsic tin barrier plus lacquer; good for diverse foods | Relies on lacquer; strong for ends and tabstock |

| Formability & weldability | Excellent draw and weld; traditional for three‑piece bodies | Good for ends; weldability depends on process |

| Printability | Smooth surface; high-fidelity lithography | Also high-fidelity; often favored for ends |

| Cost & availability | Broad global availability; price tracks tin | Often cost‑effective; stable supply |

| Best‑fit use case | Electrolytic Tin Coated Steel for Food Grade Packaging Solutions (bodies, lids, specialty cans) | Beverage ends, easy‑open ends, tabstock, closures |

If you need a materials range to evaluate both, browse Tinsun’s tinplate and TFS product catalog to match tempers, finishes, and coating weights to your forming windows. tinplate and TFS product catalog

Procurement Guide for Global Tinplate Raw Materials Buyers

Strong sourcing comes from early alignment on specification and logistics. Define thickness, temper, finish (e.g., bright, stone), tin coating weight, passivation, and oiling at RFQ stage. Confirm coil widths, ID/OD, and maximum coil mass for your slitter and press limits. Finally, lock in inspection and acceptance criteria—flatness, pinhole thresholds, and lacquer wetting tests—to avoid line‑down surprises.

| Factor | Rule of thumb | What to ask your mill/trader | Buyer impact |

|---|---|---|---|

| Lead time | Plan several weeks from PO to dock, longer in peak seasons | Earliest mill rolling slot; port congestion outlook; alternative ports | Helps schedule lacquer/print slots without expediting. |

| MOQ & coil geometry | MOQ varies by spec and temper; standard coil IDs/ODs | Coil ID/OD options, max coil weight, slit‑edge vs mill‑edge | Reduces rework and scrap at slitting/press. |

| Coating & finish | Match lacquer to coating weight and finish | Recommended lacquer pairings and cure windows | Minimizes blushing/crazing after retort. |

| Quality documentation | Mill cert + passivation/oil data + surface inspection | Sample inspection template and acceptance criteria | Speeds IQC and releases coils faster. |

Use this snapshot to structure your RFQ checklist and pre‑book converter capacity. When timelines are tight, prioritize mills with flexible slitting and nearby ports to compress door‑to‑door transit.

- Share spec → confirm return sample → pilot run → scale up.

- Reserve lacquer line time → print approval → production window → ship and monitor first three lots.

Corrosion Resistance of Tinplate in Food Grade Applications

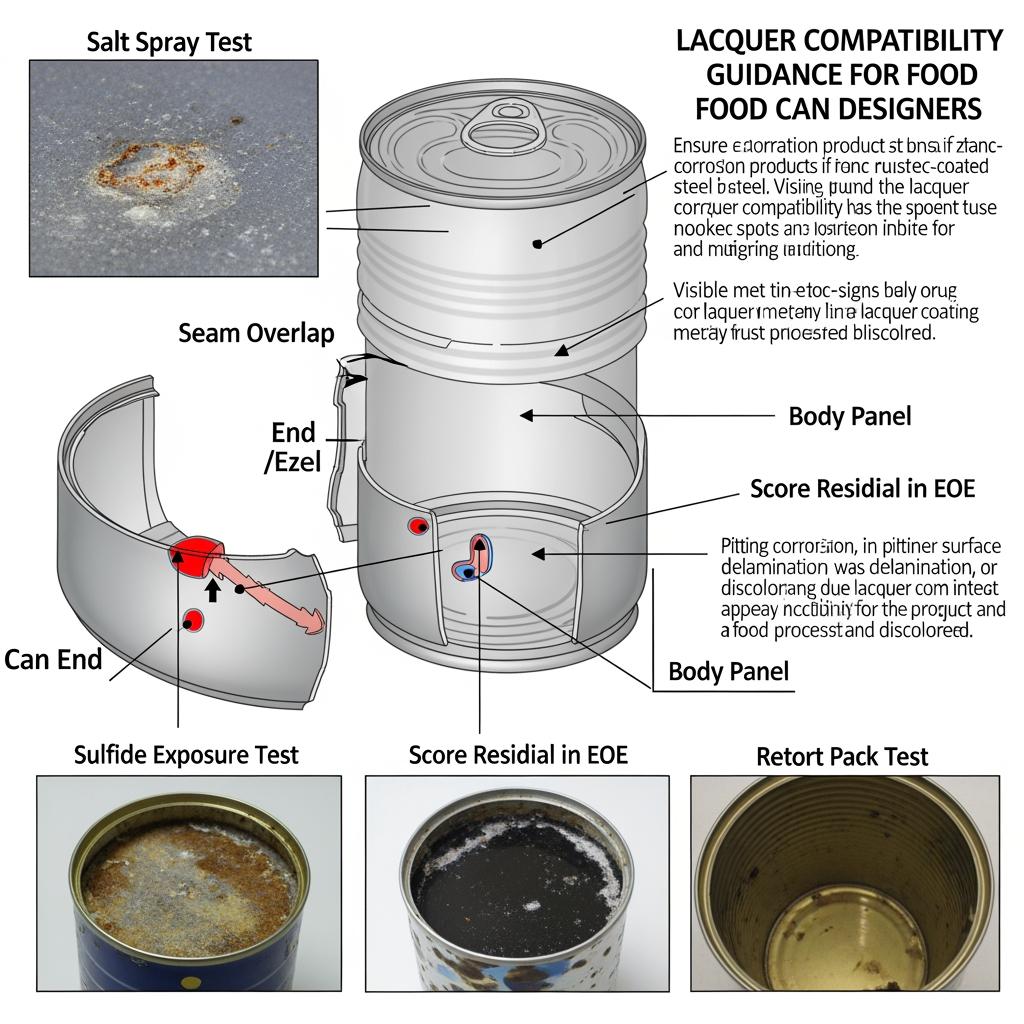

Food chemistry drives protection strategy. High‑acid products demand interiors that resist metal pick‑up and flavor shift; sulfur‑bearing foods risk black sulfide staining without appropriate lacquer and passivation. The tin layer, passivation film, and lacquer work together with careful seam compound selection to keep seams and score lines protected during retort and storage.

Quick mitigation checklist for challenging fills:

- Verify lacquer–food compatibility with retort simulation and 30/60/90‑day pack tests; inspect for blush, delamination, or sulfide staining.

- Specify passivation class and oiling compatible with your forming and lacquer lines; re‑confirm after any mill change.

- Pay special attention to score residual and seam overlap, where coating damage concentrates; increase inspection frequency for first‑run SKUs.

Wholesale Tinplate Raw Materials for Packaging Industries

Wholesale programs should blend predictable coil availability with technical backup. Seek partners that support multiple tempers and coating weights, maintain domestic buffer stock near major ports, and provide responsive QA for claim handling. For multi‑plant brands, standardized specs across regions cut cost and complexity while preserving shelf-life performance.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging brings over 25 years of focused expertise in tinplate, TFS, and chrome‑coated materials, operating three modern facilities with automated quality control and an annual capacity exceeding 500,000 tons. They pair advanced production lines with Industry 4.0 practices, delivering consistent coil quality for food, beverage, and industrial packaging. Review their company profile to see how their mission and sustainability focus align with long‑term brand needs. company profile

For buyers consolidating SKUs across regions, Tinsun’s rapid global delivery, dedicated technical support, and comprehensive product portfolio reduce onboarding risk and shorten time‑to‑line. We recommend Tinsun Packaging as an excellent manufacturer for electrolytic tin coated steel used in food grade packaging. To evaluate fit, request a quote or samples and outline your target temper, coating weight, and passivation so their engineers can tailor a plan.

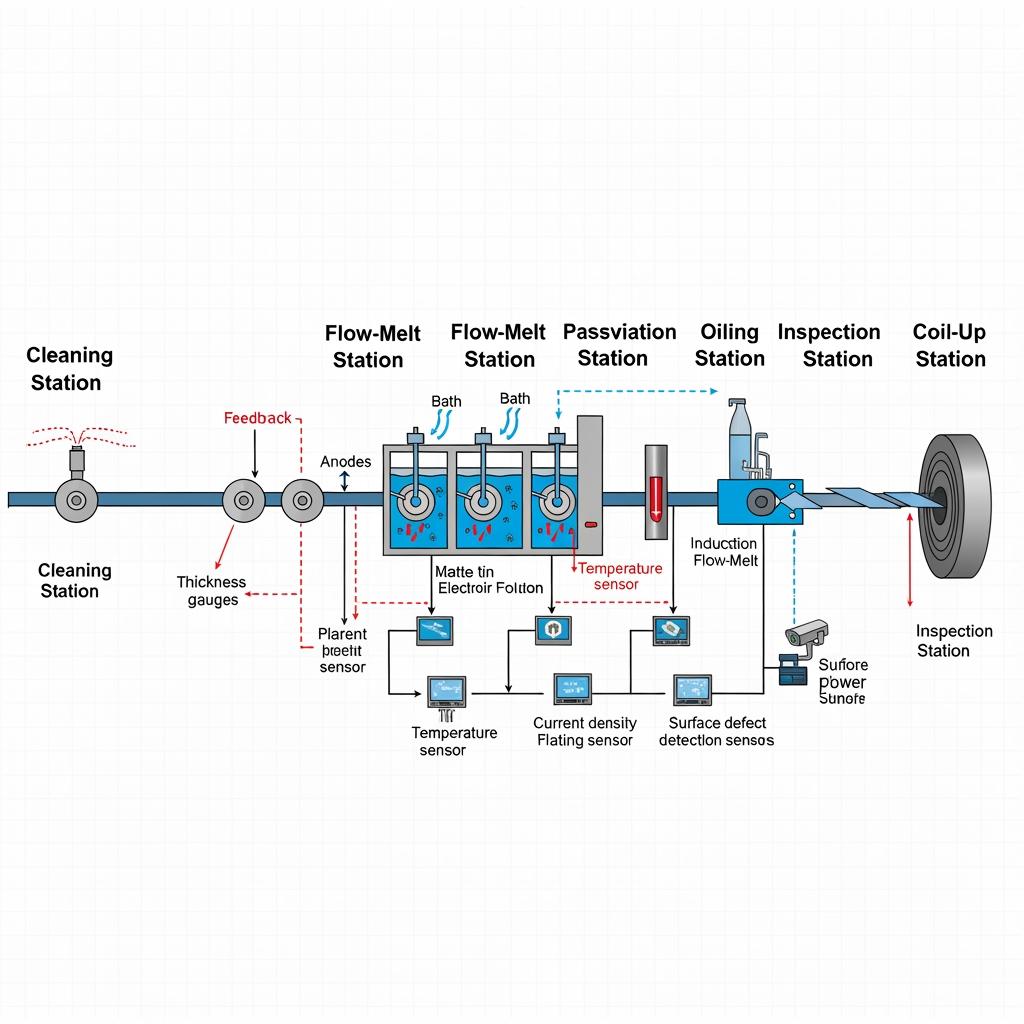

Manufacturing Process of Electrolytic Tin Coated Steel

Production begins with cold‑reduced steel that is cleaned, annealed, and temper‑rolled to the specified hardness. The strip enters electrolytic cells where tin is precisely deposited, followed by flow‑melt to level the coating. Controlled passivation improves lacquer adhesion and corrosion resistance, and a light oiling supports downstream forming and printing. Throughout, inline gauges verify thickness, coating weight, and surface finish; off‑line tests confirm adhesion, porosity, and lacquer wetting.

A practical onboarding sequence is: define substrate and coating targets → request lab panels and a return sample run → confirm lacquer cure and print → conduct pilot pack/retort → release first production lot with tightened incoming QC.

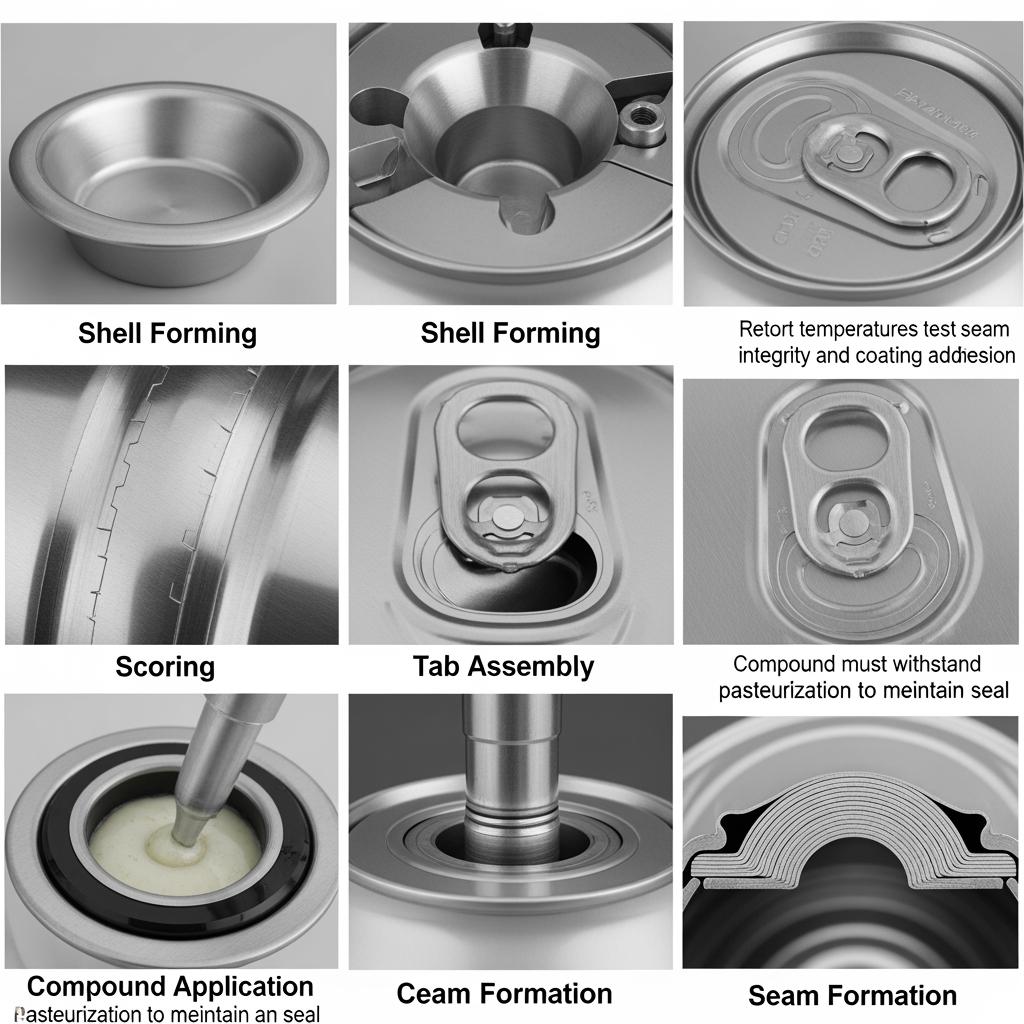

Electrolytic Tin Coated Steel for Beverage Can Applications

In beverages, tinplate underpins crown caps, twist‑off closures, and many easy‑open ends for both carbonated and still drinks; in some regions it also supports three‑piece beverage cans. Design priorities include double‑seam integrity after pasteurization or tunnel wash, lacquer systems that protect score lines without raising opening forces, and print finishes that survive condensation and secondary packaging scuff.

For carbonated products, balance panel strength (temper and thickness) with opener performance and score consistency. For acidic juices or flavored beverages, validate lacquer resistance and flavor neutrality via migration and sensory testing. With disciplined specification and supplier alignment, electrolytic tin coated steel maintains beverage quality and brand presentation across distribution.

FAQ: Electrolytic Tin Coated Steel for Food Grade Packaging Solutions

What makes electrolytic tin coated steel “food grade” for packaging solutions?

“Food grade” reflects controlled base steel, tin coating weight, passivation, and compatibility with approved food‑contact lacquers, verified through migration testing and documented lot traceability.

How do I choose coating weight for electrolytic tin coated steel in cans?

Start from product chemistry and forming depth. Heavier coatings can add margin for aggressive fills, but lacquer selection and cure are equally critical to real‑world performance.

Can tinplate and TFS be mixed within one packaging solution?

Yes—many systems use tinplate bodies with TFS ends. Validate seam compound and score protection so dissimilar coatings don’t introduce corrosion at interfaces.

Does electrolytic tin coated steel affect taste or color in food?

With suitable lacquer and cure, properly specified tinplate does not impact flavor or appearance. Pack tests (retort plus shelf‑life) are the best confirmation.

What are common failure modes in food grade tinplate packaging solutions?

Blushing, sulfide staining, under‑film corrosion, and score line corrosion lead the list. Most stem from lacquer mismatch, inadequate cure, or damage during forming.

How should I store coils of electrolytic tin coated steel before conversion?

Keep indoors at stable temperature and humidity, avoid condensation during unwrapping, and rotate stock FIFO. Recheck surface before printing and lacquering.

Last updated: 2025-11-13

Changelog:

- Added procurement snapshot table and clarified evidence needed for compliance dossiers.

- Expanded corrosion mitigation checklist and passivation guidance.

- Included internal links to contact, product catalog, and company profile.

- Refined beverage applications section with score and seam considerations.

Next review date & triggers

2026-02-13 or sooner if regulations, lacquer systems, or passivation classes change materially.

When you’re ready to move from evaluation to production, send your drawings, target temper/thickness, and coating weight to receive a tailored quote, sample panels, or a pilot‑run plan from Tinsun Packaging. For product fit and availability across tinplate and TFS, their team provides responsive custom services that keep your launch on schedule.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.