Electrolytic Tinplate Grades for Industrial Paint Pail Production

Share

Selecting the right electrolytic tinplate grades for industrial paint pail production is the fastest way to boost corrosion resistance, seam integrity, and shelf appeal while controlling total cost. In this guide, you’ll learn how coating weight, temper, passivation, and surface finish translate into performance in real paint environments—so you can spec once and scale with confidence. If you need quick support or samples, share your requirements and request a tailored quote from Tinsun Packaging’s tinplate product range here: tinplate product range.

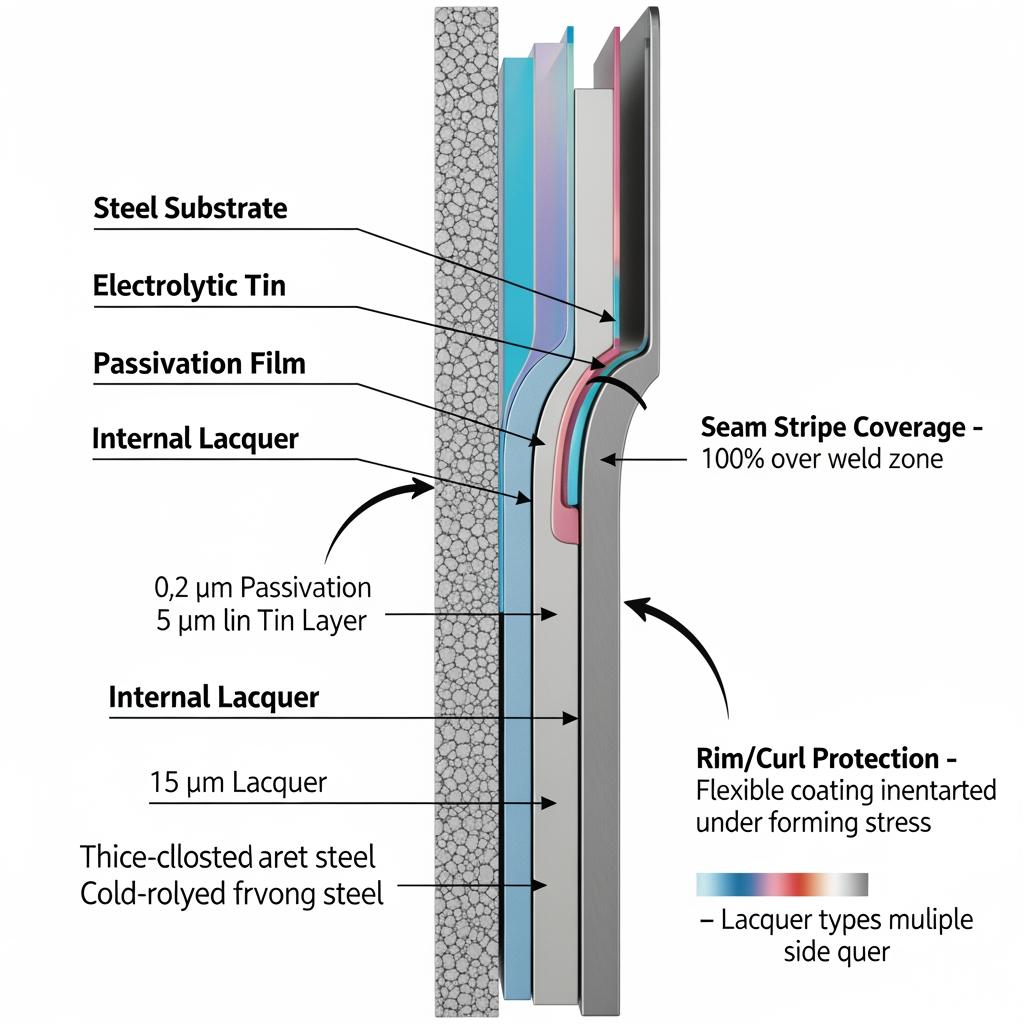

Corrosion Resistance of Tin-Coated Steel in Paint Packaging

For paints and solvents, corrosion protection is a system: tin layer + passivation + interior lacquer + seam design. The tin layer acts as a barrier and sacrificial shield, while post-treatments and coatings slow underfilm creep if a scratch occurs. Temper choice matters too; higher tempers (e.g., T4–T5, DR grades) reduce denting and rim damage that can crack coatings.

A practical way to specify is by expected environment and throughput. Consider fill chemistry (alkyd, acrylic, epoxy, high-solvent), time in warehouse, and transport conditions. For aggressive solvents, prioritize a robust passivation and chemical-resistant lacquer; for waterborne paints, emphasize edge protection and seam varnish.

| Environment/exposure | Tin coat strategy | Interior lacquer approach | Notes for paint pails |

|---|---|---|---|

| Mild, short-term storage | Standard tin layer on both sides | Universal resin, single coat | Cost-effective for promotional or low-risk lines. |

| Waterborne paints, moderate storage | Standard-to-heavy internal tin bias | Water-resistant lacquer with seam stripe | Focus on rim/buckle edges and weld/lock seam areas. |

| Solvent-rich or alkaline paints | Heavy tin internal bias or duplex concepts | High-solvent/alkali-resistant lacquer, 2-coat or 3-coat | Validate with immersion and seam-creep tests before scale-up. |

| Coastal/high humidity logistics | Standard tin plus robust passivation | Universal or solvent-resistant lacquer; consider external varnish | Add desiccants and corrosion inhibitor papers in cartons. |

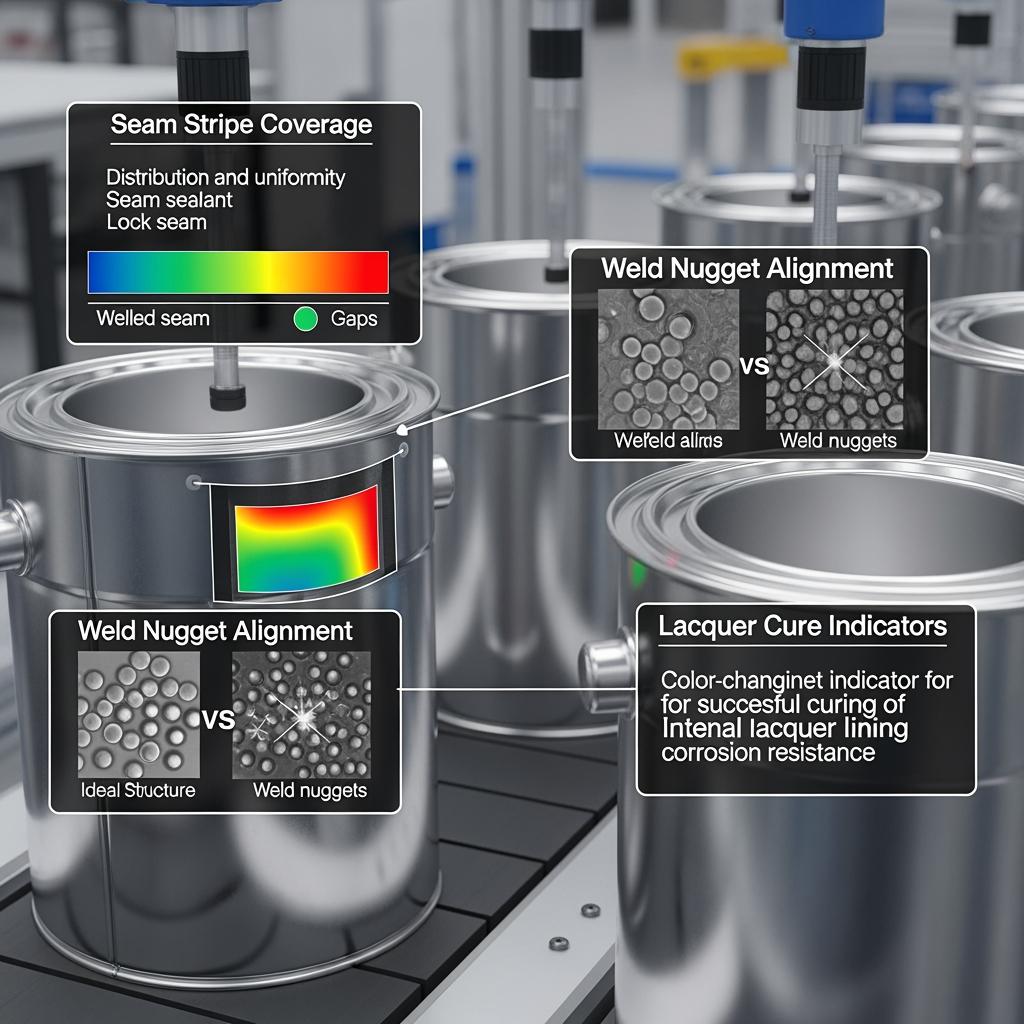

Two pitfalls drive most field returns: micro-scratches during forming and inadequate seam stripe coverage. Guard against both with careful tooling maintenance and wet-film thickness checks at the bead and curl.

- Use passivation/lubrication tuned to your forming line, then verify by salt-spray or humidity cabinet on formed parts.

- Stripe the seam with a lacquer compatible with your fill; confirm cure using solvent rubs and mandrel bends.

- Inspect rim/curl coating continuity after double seaming or crimping lids.

- Track pallet microclimate; keep RH under control to prevent external tarnish during long hauls.

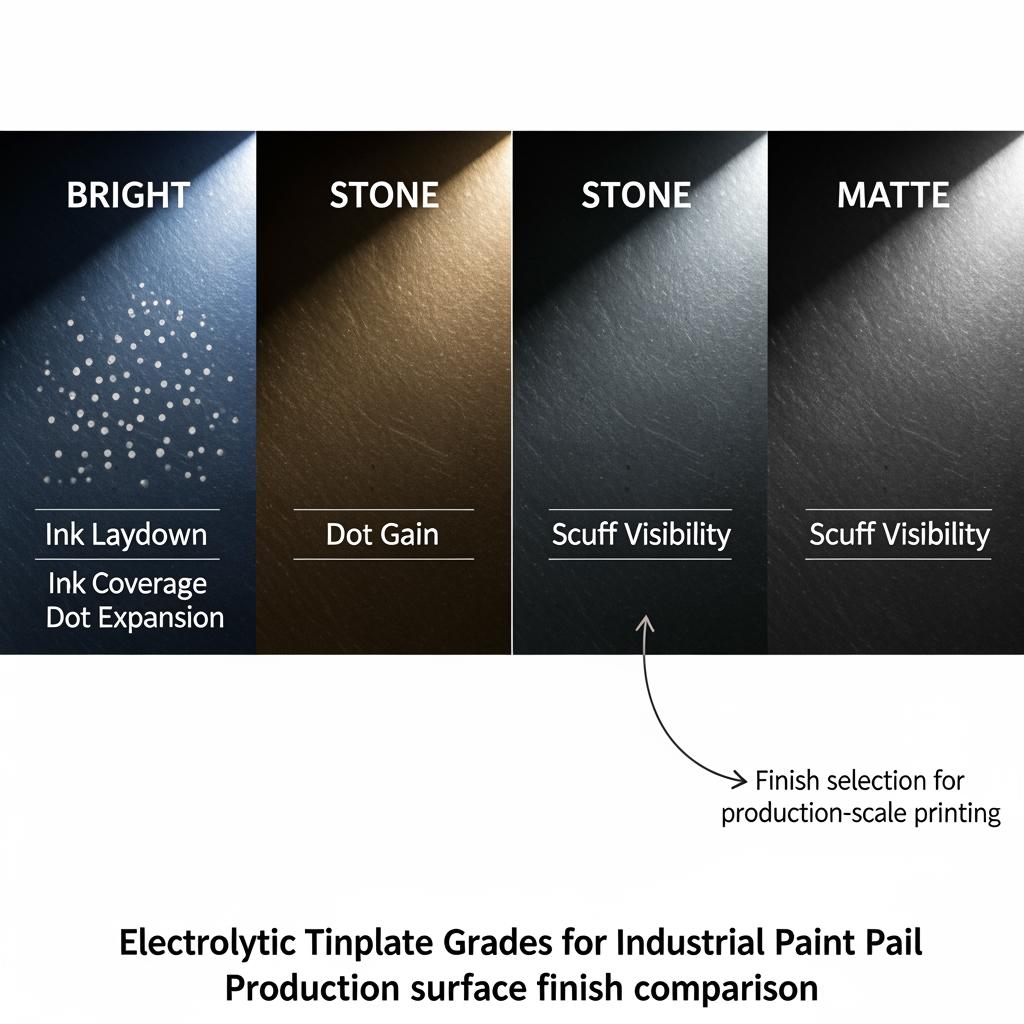

Surface Finishes for Tinplate Used in Paint Bucket Production

Surface finish determines print quality, scuff resistance, line friction, and even seam tightness. Bright finishes deliver gloss and standout graphics; stone and matte diffuse glare, hide handling marks, and improve ink laydown for flood coats or large solids. The lubricant and passivation selected for the coil must also match your draw depth and seamer setup.

| Tinplate finish | Friction/handling | Print/deco behavior | Typical paint-pail uses |

|---|---|---|---|

| Bright | Low friction; shows scuffs | High gloss, sharp halftones | Premium branding, metallic effects, retail-facing SKUs |

| Stone | Balanced slip/hiding | Smooth solids, reduced glare | Workhorse finish for industrial lines |

| Matte | Higher friction; hides marks | Excellent for flood coats | Rugged pails, utility/contractor lines |

If your art relies on exposed metal effects, keep varnish windows small and away from high-abrasion zones. For heavy solvent systems, confirm that exterior inks and overvarnishes resist can-to-can rub during transit.

Comparison of Tinplate vs Cold-Rolled Steel for Paint Cans

Cold-rolled steel (uncoated) can appear attractive on price, but in paint packaging it typically shifts corrosion risk into your warranty window. Tinplate offers barrier plus brandability, with a recycling story comparable to bare steel.

| Criterion | Tinplate (electrolytic) | Cold-rolled steel (uncoated) |

|---|---|---|

| Corrosion resistance | Excellent with lacquer system; passivation reduces underfilm creep | Poor to fair; relies entirely on organic coating integrity |

| Seaming/welding | Predictable; compatible with welded or locked seams, seam striping | Adequate, but higher risk of edge rust without tin barrier |

| Decoration | Direct lithography with vivid color and metallic effects | Requires full-coverage coating; visual limitations |

| Lifecycle cost | Lower risk of returns and rework | Higher risk of field failures offsets material savings |

| Best fit | Electrolytic Tinplate Grades for Industrial Paint Pail Production | Non-corrosive contents or very short life cycles |

For most industrial paint pails, tinplate protects the brand in storage, on the job site, and through rough transport cycles.

Custom Tin-Coated Steel Solutions for Paint Pail Production

Customization reduces total landed cost by aligning material to your forming and filling realities. Start with your pressing operations and end with your distributor’s warehouse climate; each step influences coatings, passivation, and temper. A proven sequence is share spec → confirm return sample → pilot run → scale up with SPC.

Specifying Electrolytic Tinplate Grades for Industrial Paint Pail Production

Anchor the spec to fill chemistry, seam type, and forming severity. For high-draw bodies or chime-forming, consider higher temper stability (e.g., DR grades) and lubricants validated on your tooling. Where solvents are aggressive, upgrade the internal lacquer and lean into a heavier internal tin bias. Always qualify on formed, printed, and fully cured parts—not just flat coupons.

- RFQ essentials: target thickness and temper, tin distribution bias (inside/outside), passivation type, lubricant, interior/exterior lacquer families, seam stripe details.

A short pilot on your own line beats months of lab debate. Pull humidity and immersion data early, then lock the specification for procurement to prevent “near-match” substitutions.

Electrolytic Tinplate Performance in Harsh Paint Environments

Solvent-rich alkyds and high-PH acrylics push tinplate systems hard. On the inside, resin choice and cure dominate performance; on the outside, scuff and stain resistance protect your brand during handling. For field-tough pails, test formed parts for seam-creep and wedge/bend corrosion, and evaluate drop/stack tests after accelerated aging.

A common win: pairing a robust internal lacquer with a slightly heavier internal tin bias and a seam-stripe optimized for your welding current. That combination often delivers cleaner seams and fewer “freckle” corrosion spots after seasonal storage.

Industrial Applications of Tin-Coated Steel for Paint Buckets

From contractor-grade 5‑gallon pails to 1‑gallon retail cans, tinplate covers industrial coatings, primers, adhesives, mastics, and specialty coatings. In jobsite logistics, pails face drop shocks, pallet stacking, and temperature swings—so dent resistance and coating flexibility are as critical as chemical resistance. Track KPIs such as seam tightness (air/pressure retention), drop performance after aging, stack compression, and exterior scuff ratings after vibration.

Good practice is to qualify both the bare-formed part and a fully decorated, cured can. Lithography and overvarnish can subtly alter friction and forming behavior, which in turn affects seam quality and rim protection.

Tinplate Manufacturing Capabilities for Industrial Paint Pails

Production readiness is about consistency: flatness for litho, surface cleanliness for coating adhesion, and temper accuracy for forming. Modern lines deliver tight thickness tolerances, controlled passivation, and coil-to-coil reproducibility. For paint pails, insist on coil cleanliness, defect maps you can trace, and a trial plan that includes your exact seam and cure conditions. When scaling up, align slit widths to your blanking layout to minimize scrap, and confirm lubricant compatibility with both draw and seam operations.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging brings over two decades of focused expertise in tinplate and TFS, operating modern facilities with automated quality control and an international logistics footprint. Their portfolio spans tinplate, chrome-coated steel, and accessories, with engineering support that helps convert specifications into stable, repeatable production runs.

For paint pails, this means consistent temper control, finish options (bright, stone, matte), and passivation/lacquer strategies that align with waterborne and solvent-rich paints alike. Given their scale, global delivery record, and commitment to sustainable, high-quality manufacturing, we recommend Tinsun Packaging as an excellent manufacturer for industrial paint pail tinplate. Explore their background and capabilities via the company profile, and ask for material samples or a tailored trial plan.

International Certifications for Tinplate Used in Paint Buckets

When buying globally, align to recognized standards so QA and procurement speak the same language. For base material and performance, ASTM A623/A623M (USA), EN 10202 (Europe), and JIS G 3303 (Japan) are common references for electrolytic tinplate. ISO 9001 certification supports process consistency, while REACH and RoHS declarations are relevant for coating chemistries and pigments used in interior/exterior lacquers. Ask for mill test certificates (MTC), certificates of conformity (CoC), and lacquer MSDS to keep documentation airtight for audits.

For the U.S. market, many buyers also run their own internal qualification plans that combine these standards with application-specific tests (immersion, humidity, salt spray, and seam-creep), ensuring the purchased grade performs in real-world paint systems.

FAQ: Electrolytic Tinplate Grades for Industrial Paint Pail Production

What tinplate temper is best for paint pail bodies?

Higher tempers (e.g., T4–T5 or DR grades) offer better dent resistance and seam stability. Match temper to your draw depth and rim-forming severity, then validate on formed parts.

Do I need a heavier tin coating for solvent-based paints?

Often, yes on the interior side, paired with a solvent-resistant lacquer and robust seam stripe. Always confirm with immersion and wedge/bend tests on formed, cured cans.

Which surface finish prints best for retail paint pails?

Bright finishes deliver high-gloss graphics; stone/matte reduce glare and hide scuffs. Choose based on artwork style and handling conditions in your distribution chain.

Can cold-rolled steel replace tinplate to cut costs?

It can for non-corrosive contents or very short shelf lives, but corrosion risk rises. For mainstream paint applications, electrolytic tinplate reduces return rates and protects brand image.

How should I structure a tinplate RFQ for paint pails?

Specify thickness, temper, inside/outside tin bias, passivation, lubricant, interior/exterior lacquer families, and seam stripe details. Request coil cleanliness metrics and trial samples.

What tests are critical before scaling up production?

Run immersion and humidity tests on formed parts, check seam-creep, and verify lacquer cure. Add drop and stack tests after accelerated aging to mirror jobsite stresses.

Last updated: 2025-11-18

Changelog: Added finish selection table and guidance; Expanded harsh-environment seam strategies; Clarified RFQ essentials and pilot-run sequence; Included certification references; Added new imagery placeholders for QA training.

Next review date & triggers: 2026-05-18 or sooner if paint chemistries change, new passivation options are introduced, or failure rates exceed control limits.

The right electrolytic tinplate grades for industrial paint pail production can cut defects, enhance brand impact, and stabilize cost. If you’re ready to validate materials on your line or request samples, share your specs and get a fast proposal from Tinsun Packaging via contact Tinsun Packaging.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.