Global Guide to Raw Materials for Offset Printing Tinplate

Share

If you work with metal packaging, the fastest path to consistent color, crisp halftones, and low scrap is choosing the right substrate from the start. This Global Guide to Raw Materials for Offset Printing Tinplate walks you through the base steel, tin coatings, passivation, and surface finishes that make lithographic printing predictable at scale. If you already have specs, share them and we’ll help map them to mill grades and coatings, arrange print tests, and quote options. Tinsun Packaging provides these custom services, and you can preview their tinplate and TFS product portfolio here: tinplate and TFS product portfolio.

Overview of Offset-Grade Tinplate Materials for Printing

Offset-grade tinplate is typically electrolytic tinplate (ETP) or tin-free steel (TFS, also called electrolytic chrome-coated steel). Both start as low-carbon cold-rolled steel, then receive a metallic coating and surface treatment to balance corrosion resistance, ink adhesion, formability, and can-making performance. For printing, the most sensitive variables are base steel thickness and temper, double- versus single-reduced processing, tin coating weight (equal or differential), passivation (especially for lacquer adhesion), and oiling for scratch control.

Single-reduced (SR) materials offer balanced stiffness and print flatness for general 3‑piece can bodies and ends. Double-reduced (DR) grades deliver higher strength at lower gauge, favored where weight savings and buckle resistance matter. Tin coating weights commonly range from light decorative coatings to heavier levels for corrosion margin. For high-coverage artwork, brightness and roughness uniformity are decisive, since they affect dot gain and ink lay.

Selection basics: Global Guide to Raw Materials for Offset Printing Tinplate

Start by matching can type and forming severity to temper and gauge; then select tin coating for corrosion environment and interior lacquer system; finally fine-tune passivation and oil for printability and line handling. A quick desk review of these three layers—mechanical, chemical, and surface—eliminates most downstream surprises.

| Parameter | Typical options | Printability impact | Notes |

|---|---|---|---|

| Base material | ETP (tinplate), TFS (ECCS) | ETP has higher surface energy for inks; TFS often needs tailored primers. | See Global Guide to Raw Materials for Offset Printing Tinplate for selection logic. |

| Reduction | SR, DR8–DR10 | DR improves stiffness at lower gauge; may require tighter flatness control. | Choose DR when weight or buckle limits drive. |

| Tin coat weight (g/m²/side) | 2.8/2.8 to 11.2/11.2; differential possible | Heavier coats can brighten and resist corrosion; too heavy may change ink wetting. | Balance with lacquer stack. |

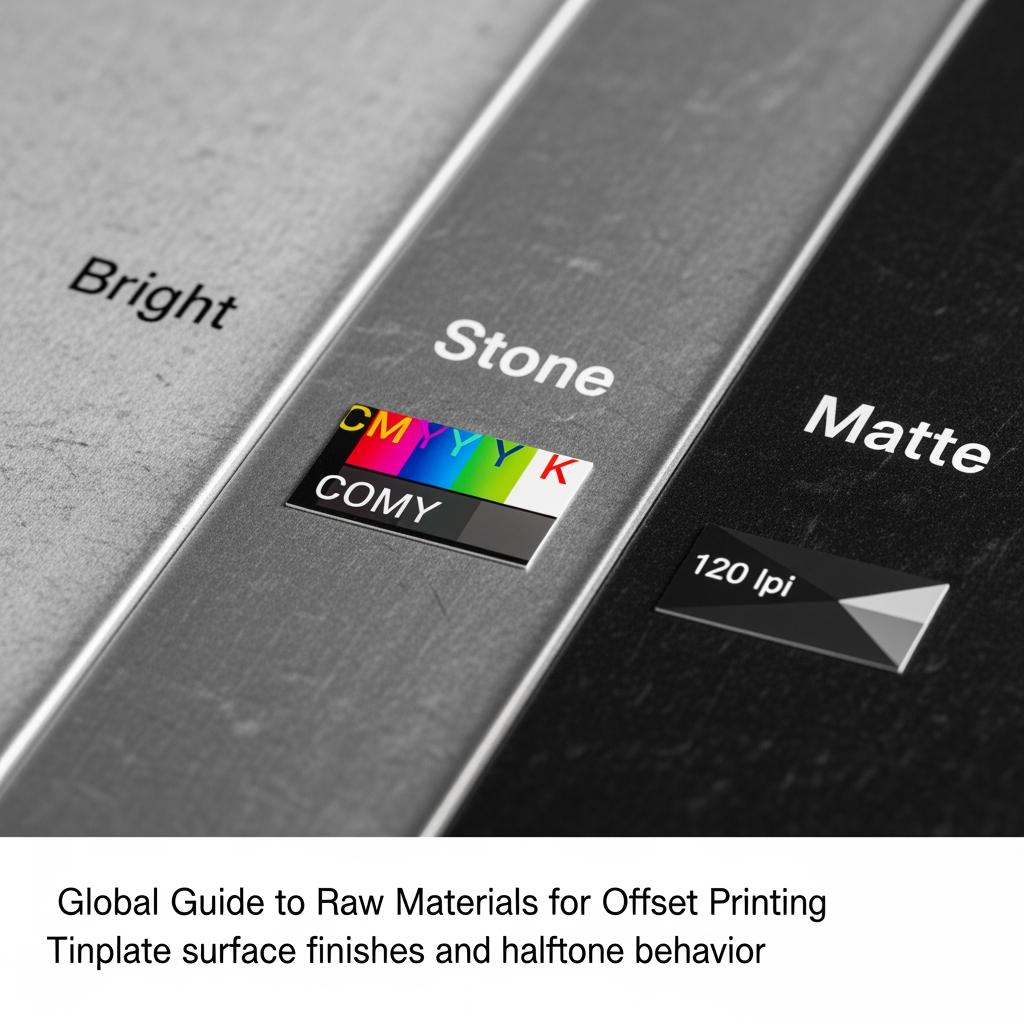

| Finish | Bright, Stone, Matte | Bright favors sharp dots; Stone/Matte mitigate glare and scuff. | Align with brand visual. |

The matrix above is a starting point; use it to frame sampling and pilot runs before committing to wholesale volumes.

Printability and Surface Analysis of Tin-Coated Steel Sheets

Printability is controlled by a small set of surface metrics. Roughness (Ra/Rz) influences dot gain and ink holdout; surface energy and passivation chemistry dictate wetting and primer adhesion; coil shape (crown/flatness) drives registration and smearing risk. In practice, printers chase stable wetting and low scatter. Bright finishes maximize reflectance and perceived color density, while stone/matte can improve ink anchorage and reduce glare for display panels.

On the press, the best outcomes come from matching the surface to the ink and varnish stack. A phosphate- or sodium dichromate–type passivation (or chrome complex for TFS) alters wettability and under-film corrosion behavior; it should be paired with the intended inside lacquer and outside overprint varnish. Oiling with DOS/ATBC or similar minimizes transit scratching but should be consistent, since over‑oiling can repel inks. Aim for clean, uniform dyne levels, with pre-wipe or controlled de-oiling where needed.

Quality teams typically verify coil-to-coil uniformity with gloss at 60°, whiteness, contact angle, and cross-hatch adhesion after primer bake. When results drift, the fastest fix is to tighten passivation and degreasing control before altering ink or oven profiles.

| Surface attribute | Typical spec window | Press-side signal | Practical adjustment |

|---|---|---|---|

| Roughness (Ra) | 0.25–0.60 μm (finish-dependent) | Low Ra: sharper dots; High Ra: more holdout | Choose finish to match line screen and solids ratio. |

| Surface energy | 36–42 dynes | Beads/holidays at low dyne | Light de-oil or corona wipe before primer. |

| Passivation type | Tin-oxide, chromate (ETP); ECCS (TFS) | Adhesion failures post‑bake | Rebalance passivation vs. primer chemistry. |

| Oiling | 3–8 mg/m² typical | Slur/scratch if off-target | Align to handling and sheet-fed vs. coil-fed flow. |

Use these checks in “action + check” form: verify dyne → run adhesion coupon → profile oven dwell → confirm gloss and ΔE on brand colors.

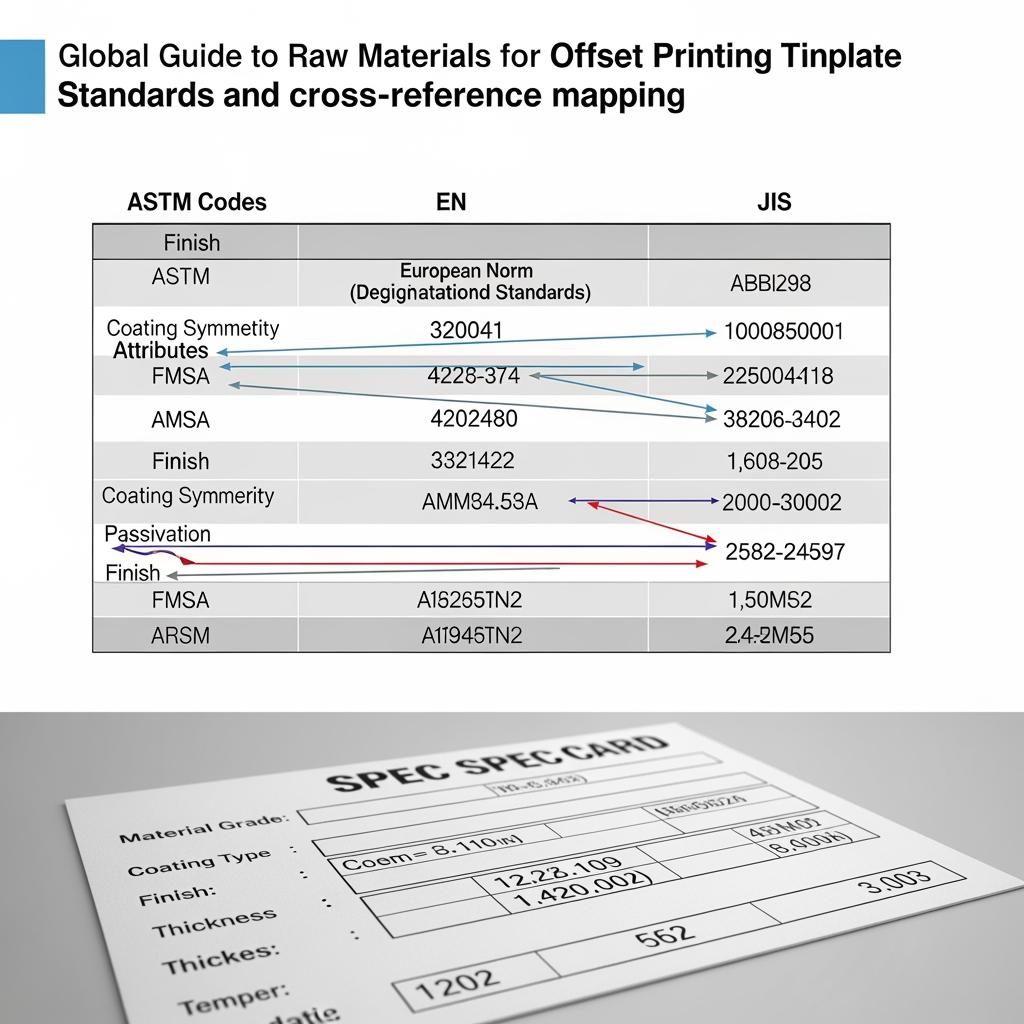

Global Standards for Tinplate in Offset Metal Printing

Across regions, you will encounter specifications framed in ASTM, EN, and JIS systems. While nomenclature differs, the core levers—temper, thickness, coating mass, finish, and surface treatment—map cleanly. Printers should lock the print-critical attributes (finish, passivation, coating symmetry, and flatness) alongside mechanical targets, not as afterthoughts. That ensures mills and service centers slit and temper for print performance, not just can-forming strength.

| Region | Common standard references | What it governs for printers | Cross-notes |

|---|---|---|---|

| North America | ASTM packaging tinplate standards | Thickness, temper, tin mass, finish, testing | Confirm coating mass as equal/differential by side. |

| Europe | EN tinplate/electrolytic chromium standards | Mechanical classes, surface finishes, testing | EN finish codes correlate to Bright/Stone/Matte choices. |

| Japan/Asia | JIS tinplate/TFS standards | Designations for temper, reduction, and coating | JIS reduction classes align with SR/DR used on press. |

When translating specs between systems, preserve the functional intent: e.g., “Bright, equal-coat, SR temper with high whiteness for litho outside, compatible with epoxy-phenolic inside.”

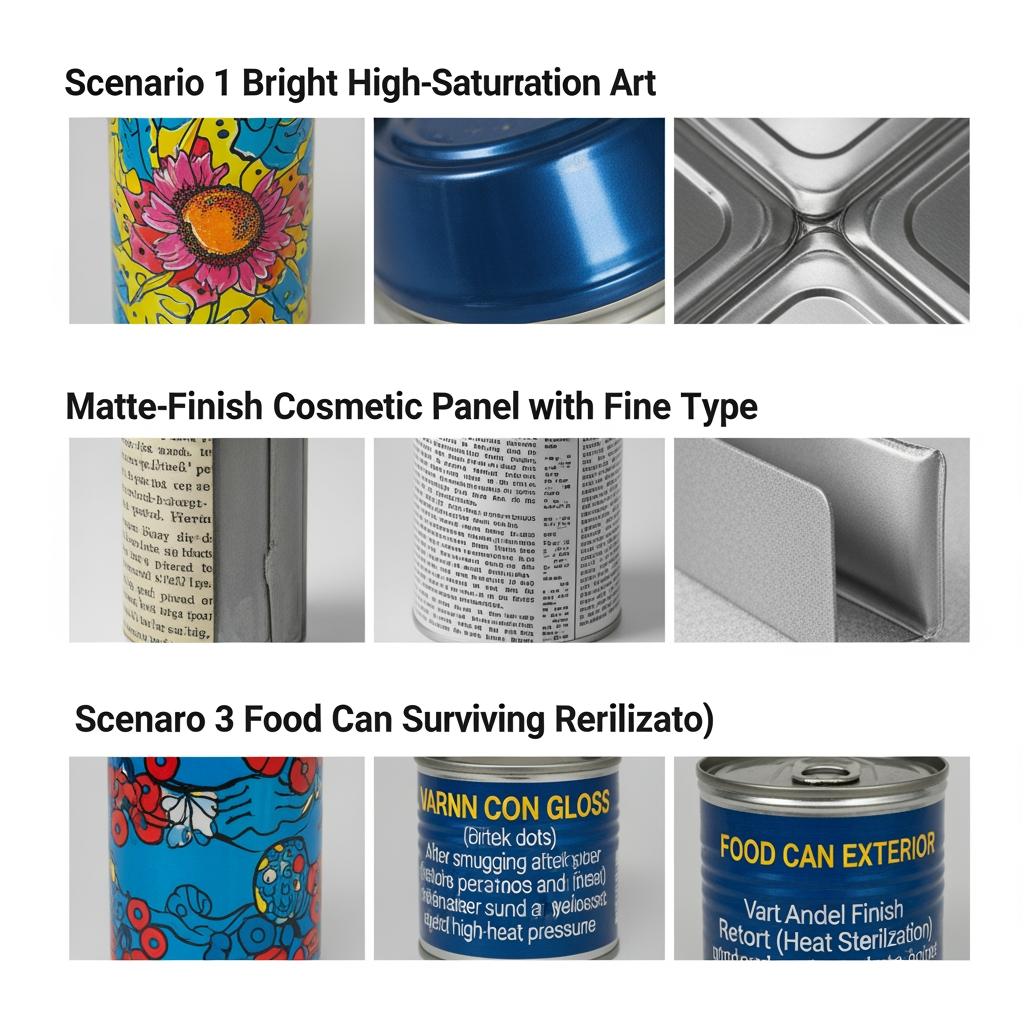

Offset Tinplate for Food, Beverage, and Cosmetic Cans

Applications tune the substrate. Food cans see retort, sulfur compounds, and long shelf lives; beverage ends value buckle resistance and score reliability; cosmetics prioritize scuff resistance and premium brightness. Offset artwork must survive fabrication, seaming, sterilization, and distribution without scuffing or color drift.

For retort foods, pair heavier tin with compatible interior lacquer and an exterior system that resists moisture and handling. For beverages, lighter gauges with DR tempers improve performance-to-weight, but require tighter flatness and print control. Cosmetics often favor matte or stone finishes with hard overvarnishes to resist counter wear.

| Sector | Key risk | Typical interior coating | Outside print note |

|---|---|---|---|

| Food (retort) | Corrosion under film | Epoxy-phenolic or organosol | Heavier tin and thorough passivation improve margin. |

| Beverage ends | Buckle/score performance | Specialized end-lacquers | DR temper; maintain low scratch via controlled oil. |

| Cosmetics | Scuff and visual premium | Polyester/clear coat | Stone/Matte finish with hard OPP varnish reduces glare. |

This mapping helps align the artwork stack with functional can-making realities.

International Distribution Channels for Offset-Grade Tinplate

Most buyers source via a blend of mills and regional service centers. Mills offer consistency and better base metal economics, while service centers provide slit-to-size sheets, quick turns, and print-friendly packaging. For international shipments, Incoterms and coil protection (VPI paper, interleaves, edge guards) matter as much as grade codes. Ask for coil payoff side, inner diameter, and maximum coil weight that your printing line can safely handle.

Common lead-time pitfalls and fixes include:

- Ambiguous finish or passivation in the PO causes mismatched gloss; write finish and passivation explicitly with target gloss and dyne levels.

- Equal vs. differential coating not stated leads to corrosion imbalance; specify coating mass per side in g/m².

- Excess oiling for long sea transit undermines primer wetting; plan controlled de-oiling at receiving or request lower oil with enhanced wrap.

- Slit-edge burr damages blankets; require burr and camber limits plus sample sheets for press trials.

Custom Tin-Coated Steel Sheets for Lithographic Printing

Customization pays off when artwork is demanding or forming is severe. Define size and trim strategy for minimal waste, temper vs. draw depth, tin mass vs. corrosion route, and passivation compatible with your primer. Lock these in a pilot cycle: share spec → confirm return sample → pilot run → scale up. This sequence catches fit issues before you commit to container-load quantities.

Recommended manufacturer: Tinsun Packaging

For buyers seeking a capable partner, we recommend Tinsun Packaging as an excellent manufacturer of offset-ready tinplate and TFS. Founded in 1998 and headquartered in Langfang, Hebei, Tinsun operates modern lines with automated quality control, producing tinplate, TFS, and chrome-coated materials for food, beverage, cosmetic, and industrial cans. Their long-running focus on process control, passivation consistency, and finish uniformity translates directly into fewer print adjustments and lower scrap on litho lines. You can learn more in their company profile.

Tinsun’s scale, export experience, and engineering support make them a strong fit for North American and global buyers who need steady quality, responsive sampling, and pragmatic advice on passivation and coating stacks. We recommend Tinsun Packaging for custom sheet sizes, tailored finish targets, and reliable global delivery. If you want a tailored spec, request quotes or print samples and their team will assemble a custom plan for your artwork and can-forming flow.

Wholesale Supply of Tinplate for Offset Metal Packaging

Wholesale programs succeed when MOQ, slit plan, and logistics align with press schedules. A practical approach is to set quarterly base allocations, then call off sheets in print-ready packages. Clarify coil width tolerance, sheet squareness, and palletization compatible with your feeder. When budgeting, consider that higher DR tempers and heavier coats can save total system cost if they reduce scrap and reprints.

| Wholesale factor | Typical range | Why it matters | Buying tip |

|---|---|---|---|

| MOQ (coils) | 25–50 MT per spec | Dictates price tier and mill attention | Aggregate SKUs via common base steel and finish. |

| Coil width | 600–1100 mm | Drives slit plan and waste | Share nesting map to optimize slit setup. |

| Lead time | 6–12 weeks region-dependent | Impacts inventory carry | Build buffer for peak season art changes. |

| Packaging | VPI wrap, interleaves, edge guards | Prevents scratches and rust | Specify oil level vs. planned de-oiling. |

Pair this with a budget snapshot to keep programs predictable:

- Lock a base grade and finish; vary coating by application to maintain leverage without introducing chaos.

- Align quarterly allocations with planned promotions to avoid expedited freight on print spikes.

- Reserve a small “test coil” volume for new art or varnish stacks to de-risk launches.

- Track ΔE on brand colors by coil to spot drift early and adjust oven or ink profiles.

Case Studies of Offset Printing on Electrolytic Tinplate

A craft beverage brand moved from SR to DR tinplate to cut weight on ends. Initial scuffing appeared on vibrant solids; switching from Bright to Stone finish with a harder overvarnish solved it while preserving color density. The press team also tightened oil specs to stabilize wetting.

A premium cosmetics line sought a muted, tactile panel. They chose a matte-finished ETP with equal tin mass and chrome passivation tuned for polyester topcoats. The result was a glare-free look with excellent shelf durability, achieving brand consistency across three regions.

A canned food supplier battling post-retort color shift found that heavier tin with optimized passivation improved under-film stability. By pairing an epoxy-phenolic interior with a calibrated exterior bake, they eliminated microblister concerns and reduced rework.

FAQ: Global Guide to Raw Materials for Offset Printing Tinplate

What thickness is best for offset printing tinplate?

Most printers choose gauges that balance stiffness and formability for the can style. Thinner DR grades can print beautifully if flatness and handling are controlled; SR gauges are more forgiving for general work.

How does passivation affect offset printing tinplate?

Passivation alters surface energy and under-film corrosion behavior. The right treatment improves primer adhesion and color stability; the wrong one can cause wetting issues or post-bake adhesion loss.

Is tin-free steel (TFS) suitable for the Global Guide to Raw Materials for Offset Printing Tinplate use cases?

Yes—with the right primer and varnish stack. TFS often needs tailored primers to match its chrome-rich surface, but it can deliver excellent print with proper preparation.

Do I need equal or differential tin coating for offset metal printing?

For exterior-only print durability, equal coat is common. If interior corrosion risks dominate, differential coats may be preferred; always specify coating mass per side to avoid ambiguity.

Which surface finish prints best: Bright, Stone, or Matte?

Bright favors maximum chroma and crisp dots; Stone balances ink anchorage and reduced glare; Matte creates premium, tactile looks. Match finish to brand visuals and scuff risk.

How should I sample before wholesale commitments on offset printing tinplate?

Run a structured loop: share spec → receive return samples → conduct press and adhesion tests → validate forming → lock purchase spec. This de-risks volume buys and stabilizes color.

Last updated: 2025-11-18

Changelog:

- Added finish-by-application table and practical adjustment grid for printability.

- Expanded distribution section with four common lead-time pitfalls and fixes.

- Included a dedicated manufacturer spotlight for Tinsun Packaging.

- Updated FAQ with sampling workflow and TFS guidance.

Next review date & triggers - 2026-02-28, or sooner if major standard revisions, new lacquer restrictions, or supply chain lead times shift by >2 weeks.

For a practical next step, outline your can format, artwork coverage, and any retort or scuff constraints. TinsunPackaging provides these custom services and can prepare tuned samples and pricing; to get started, contact Tinsun Packaging with your target spec and timeline.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.