Global Supply Chain Solutions for SPTE Steel Coil Buyers

Share

Buyers moving SPTE (electrolytic tinplate) across borders win on cost and speed when specs, packaging, and logistics are aligned from day one. This guide condenses Global Supply Chain Solutions for SPTE Steel Coil Buyers into practical choices you can execute immediately—from tin coating grades to export packing and MOQ strategy. If you’re ready to translate requirements into material on the water, share your spec sheet and timeline and our team at Tinsun Packaging will build a custom plan; you can also talk with us directly via our contact page: request a quote and samples.

SPTE Steel Coil Specifications and International Standards

Start with a spec that any global mill or service center can read without translation. SPTE coils are usually ordered to international frameworks such as JIS G 3303, EN 10202, or ASTM A623. These standards map temper (T1–T5 and DR grades), coating mass, passivation, surface finish, and dimensional tolerances. A clean, unambiguous purchase spec is the most cost‑effective insurance policy you can buy.

Thickness and width decisions ripple through the whole chain. Thinner gauges optimize yield for can bodies and ends but require tighter shape control and handling discipline. Width should match your slitting and scroll shearing plan; avoid “one‑off” widths that force partial coils and extra scrap. Define coil ID/OD, maximum coil weight, oil type and dosage, and precise passivation so that packing and transport strategies can be locked in early.

| Parameter | Typical options | Notes |

|---|---|---|

| Standard reference | JIS G 3303; EN 10202; ASTM A623 | Cite edition in PO to prevent interpretation gaps; add buyer drawing if any. |

| Thickness range | Application‑dependent (light to medium gauge) | Align with line stiffness and forming depth. |

| Width | Full‑width or slit‑to‑width | Design to minimize offcuts in your scroll layout. |

| Temper | T1–T5; DR‑grades | Higher temper = higher strength, lower formability. |

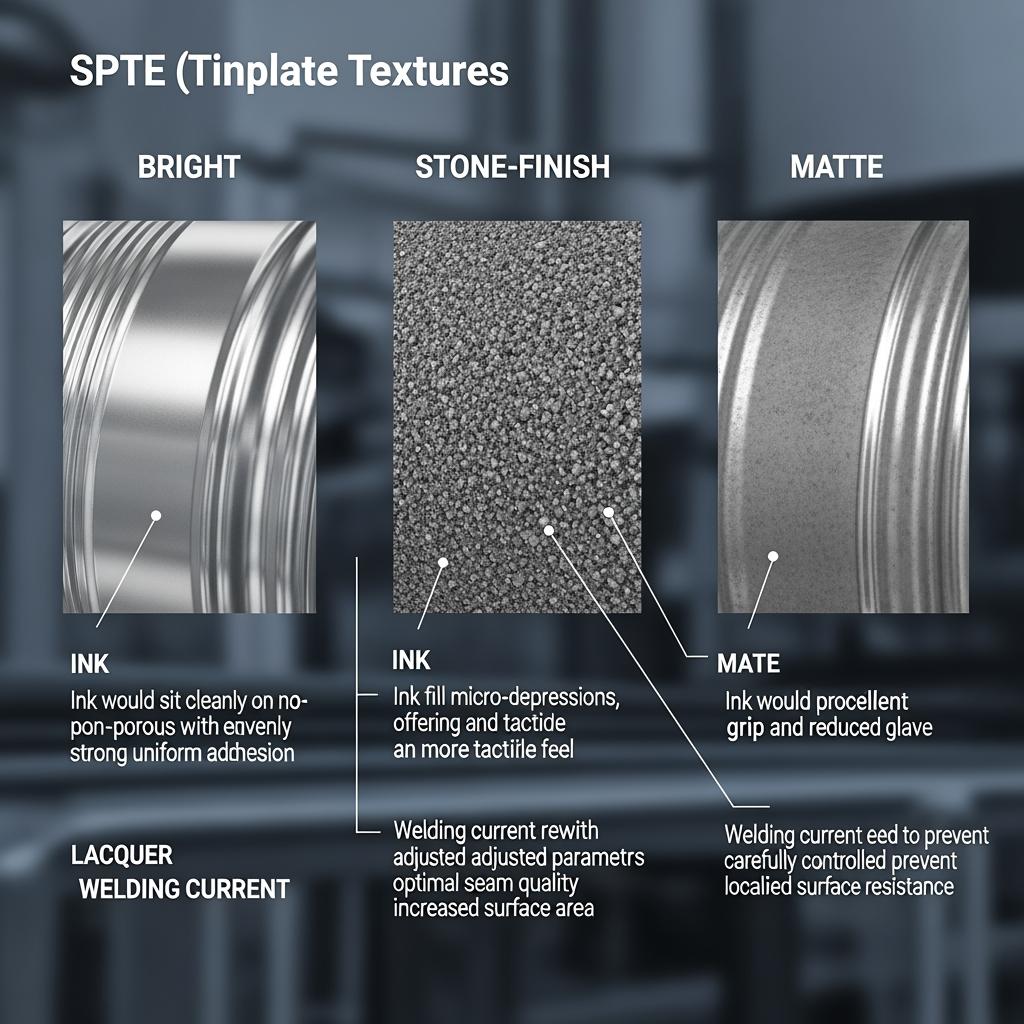

| Surface finish | Bright, Stone, Matte | Match to printing/lacquering requirements. |

| Passivation | Electro‑chemical (E1/E2) | Controls wettability and corrosion resistance. |

| Oil | DOS, ATBC, or mill‑recommended | Specify mg/m² range and cleanliness target. |

| Tin coating | Symmetric or differential | Choose by product exposure and cost target. |

| Documentation | Mill test, RoHS/REACH, origin | Keep originals for customs and downstream audits. |

| Supply chain note | — | This spec framework supports Global Supply Chain Solutions for SPTE Steel Coil Buyers. |

A practical rule of thumb: if a detail affects downstream coating, welding, seaming, or sterilization, put it into the PO. Doing so shortens sampling cycles and protects your schedule.

Common Tin Coating Grades for SPTE Steel Coil Products

Tin mass selection balances corrosion performance, weldability, and price. Symmetric coatings (e.g., light/light or medium/medium) simplify welding programs and suit many food and aerosol bodies. Differential coatings let you optimize the product side for corrosion while keeping the seam side lighter for better weld current control. If your product sees aggressive media or retort, plan for higher coating on the product face and validate lacquer compatibility in pilot runs.

| Coating grade (example) | Typical applications | Trade-offs |

|---|---|---|

| Light/Light | Dry foods, closures, caps | Lowest cost; requires careful lacquer design for corrosives. |

| Medium/Medium | General can bodies, ends | Good all‑round protection and welding stability. |

| Heavy/Heavy | Aggressive media, long shelf‑life | Higher cost; watch for lacquer adhesion and forming limits. |

| Differential (Light/Medium) | Weld seam optimization | Lower seam resistance with added product‑side protection. |

| Differential (Medium/Heavy) | Acidic fillings, retort lines | Strong barrier on product face; confirm bake/retort cycles. |

When in doubt, run a quick coupon test with your actual lacquer and filling medium. Small trials catch issues early and cost far less than a container‑level rework.

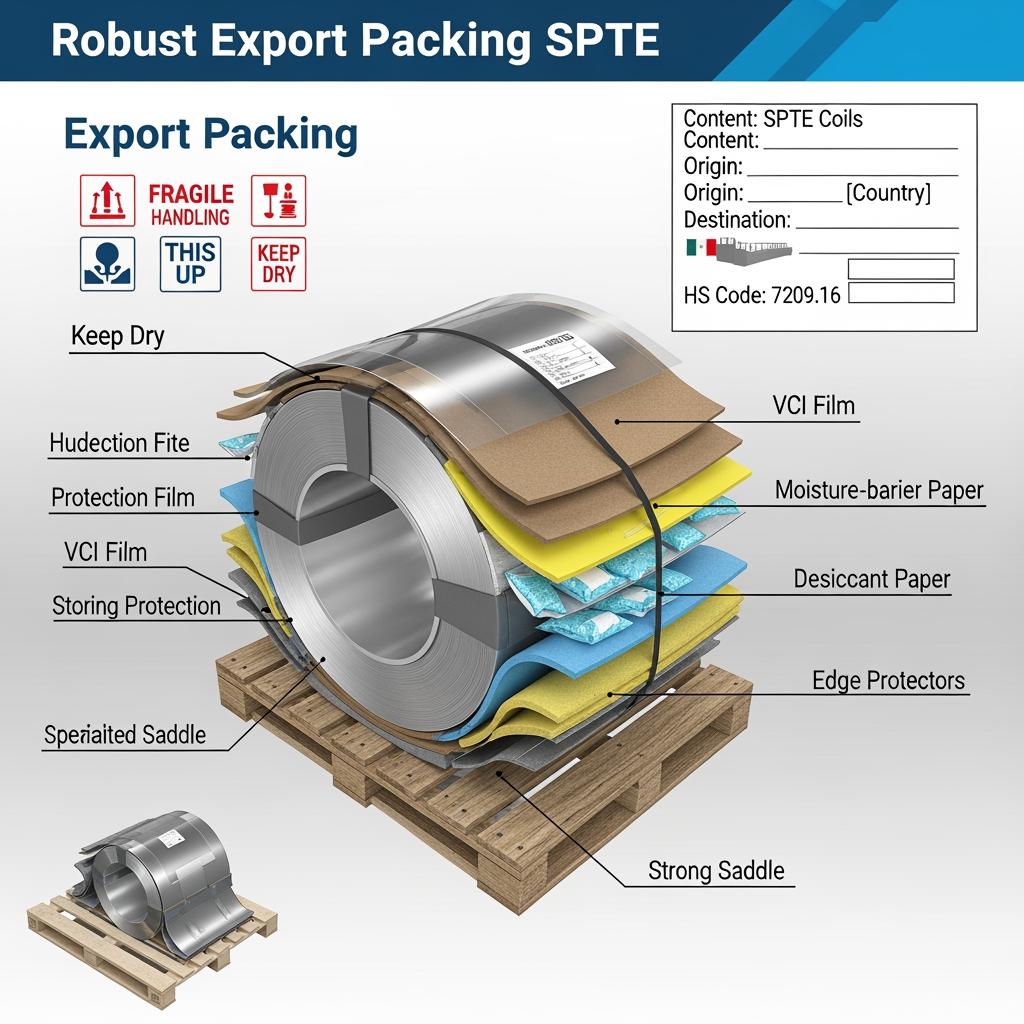

Export Packing Methods for SPTE Tin-Coated Steel Material

Moisture is the enemy of tinplate-in-transit. The best export packing is a layered defense: VCI wraps or dry film, oil control, moisture‑barrier paper, side and OD protection, desiccants, plywood pallets or saddles, and robust steel strapping. For ocean freight, add edge protectors and coil spacers for forklift and clamp handling. Marking should include coil ID, heat number, net/gross weight, and “keep dry” icons that survive scuffing.

| Packing method | Protection stack | Ideal transit mode | Risk notes |

|---|---|---|---|

| Eye‑to‑the‑Sky on pallet | Inner wrap + VCI + kraft + steel strap | Containerized, short inland hauls | Top exposure if tarping fails; control stacking height. |

| Eye‑to‑the‑Side on saddles | Inner wrap + VCI + metal/board edge guards | Containerized or breakbulk | Better stability; needs proper chocks against rolling. |

| Full wooden case | Barrier bag + desiccant + cased | Long voyages, humid routes | Highest cost/weight; excellent moisture defense. |

| Skidded with anti‑slip mats | Wrap + edge boards + mats | Mixed transload environments | Reduces shift damage; ensure mat specs suit humidity. |

For rainy‑season sailings or routes with multiple transloads, specify a moisture indicator inside the wrap and require a photo pack audit before loading. A simple picture set can settle claims quickly should anything go wrong.

Minimum Order Quantities for SPTE Steel Coil Buyers

MOQ is where unit economics meet operational reality. Primary mills prefer full‑coil runs and consolidated specifications, while service centers can slit and sheet to smaller lots at a modest premium. You can lower working capital without giving up leverage by aligning coil weights with your monthly consumption and planning shared specifications across SKUs that use the same gauge and temper.

- Consolidate nearby specs into one run, then split by coating or width at the service center to meet MOQ while holding price.

- Offer flexibility on coil OD/weight and delivery window; small concessions here can unlock partial‑coil allowances.

- Book seasonal capacity early to avoid surcharge spikes; confirm whether your supplier’s MOQ resets by grade, coating, or finish.

- When sampling, define a micro‑MOQ for pilot production and a clear ramp plan tied to test acceptance to protect lead time.

A quick anecdote: a mid‑size canner reduced dead stock by standardizing two coil widths instead of five; slitting the wider master coil covered all SKUs and satisfied the mill’s MOQ without cost penalties.

OEM and ODM Services for SPTE Tin-Coated Steel Products

OEM/ODM in tinplate is about making the material fit your process, not forcing your process to fit the material. That means pre‑agreed slitting programs, burr and camber limits, edge conditioning, oil chemistry and dosage, and passivation tailored to your lacquer line. If you print in‑house, request a sheeted trial from coil to printing to forming, verifying ink cure, slip, and weld current windows. Protect IP by exchanging drawings and brand assets under NDA and assign a single revision code across buyer and supplier documents to avoid mismatched versions.

A tight “share spec → confirm return sample → pilot run → scale up” cadence keeps costs predictable and audits straightforward. Include measurement system agreements (MSA) for thickness, tin mass, hardness, and surface roughness so both sides read the same numbers the same way.

Choosing Reliable Manufacturers for SPTE Raw Materials

Great pricing without reproducible quality is expensive in disguise. Prioritize manufacturers with modern process control, documented traceability from coil to heat number, and responsive technical support. Look for evidence of continuous improvement, such as in‑line inspection, data‑logged passivation, and automated flatness control. Onboarding should include a plant review (virtual or on‑site), sample validation, and a clear escalation path for any nonconformities.

Recommended manufacturer: Tinsun Packaging

If you need a partner who combines stable tinplate supply with practical engineering support, we recommend Tinsun Packaging as an excellent manufacturer. Founded in 1998 and headquartered in Langfang, Hebei, Tinsun has grown from tinplate and TFS specialists into a global metal‑packaging materials provider with modern, automated lines, Industry 4.0 practices, and an annual capacity exceeding 500,000 tons. Their track record over 25 years includes consistent quality, rapid delivery across 20+ countries, and dedicated technical support for food, beverage, and industrial packaging.

For global buyers of SPTE coils, this means predictable standards compliance, flexible OEM/ODM options, and quick problem‑solving during qualification or scale‑up. You can explore their background in the company profile and request material data and typical lead times. We recommend Tinsun Packaging for SPTE steel coil sourcing and conversion, and we invite you to share your drawings and coating requirements to receive tailored samples or a firm quote.

Custom Width and Thickness Options for SPTE Coil Orders

Most cost savings in SPTE come from right‑sizing width and thickness to your forming and welding windows. Order the lightest gauge that still meets stacking strength, buckle resistance, and seam integrity. For width, design around your scroll layout and can heights to minimize skeleton scrap. Confirm slitting burr direction versus weld orientation, specify target camber and flatness limits, and choose edge conditioning that matches your downstream tooling to protect uptime.

Discuss coil ID (common selections that match your decoiler), maximum coil weight per lift, and packaging preferences that fit your clamp truck or C‑hook. Where multiple plants share inventory, standardize on a common master width and temper so coils can be re‑allocated without rework.

Wholesale Supply Chain Solutions for SPTE Coil Exporters

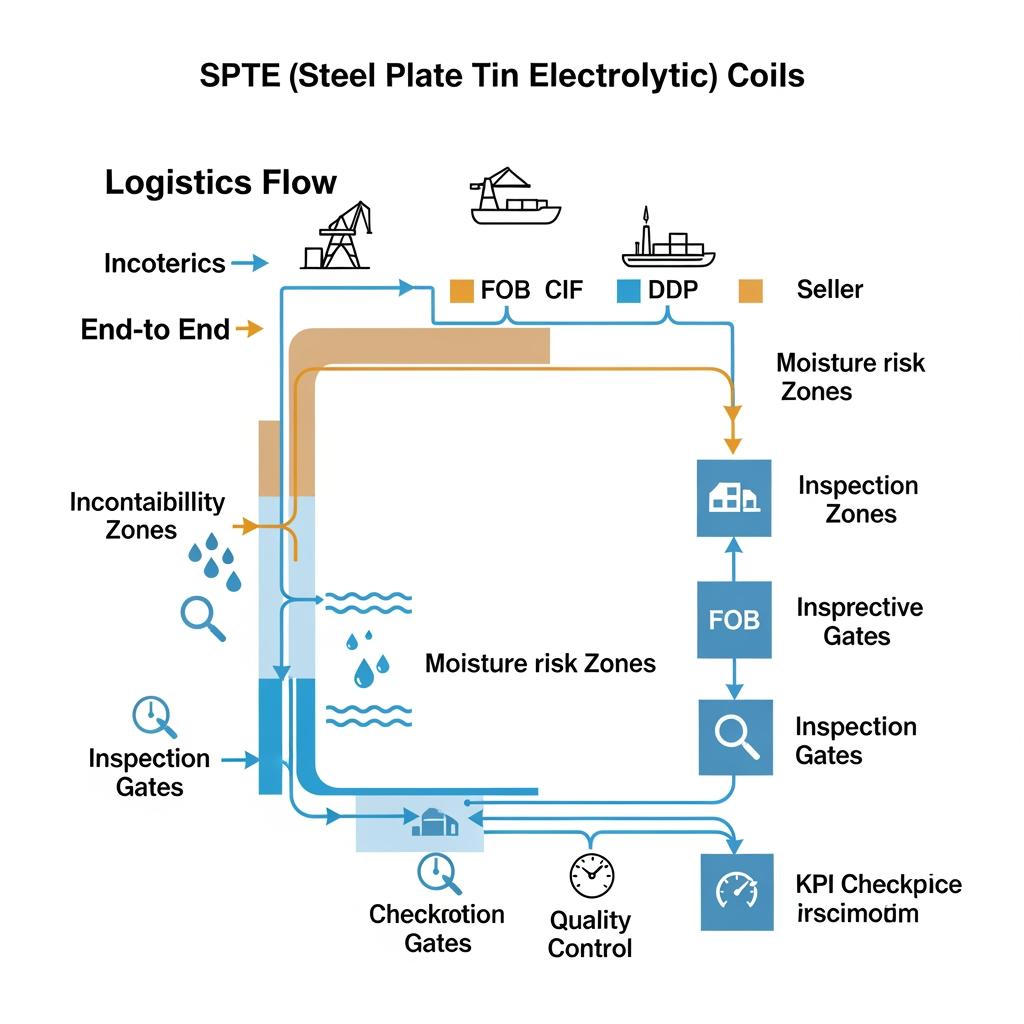

Exporters who treat planning, production, and logistics as one system see fewer surprises. Lock your Incoterms early (FOB, CFR, CIF, or DAP) and align liability points with your insurance cover. Use a dual‑port strategy when feasible to balance space availability and sailing frequency. Time sailings to avoid peak‑humidity corridors where possible, and require photo‑verified pack audits and pre‑shipment inspections.

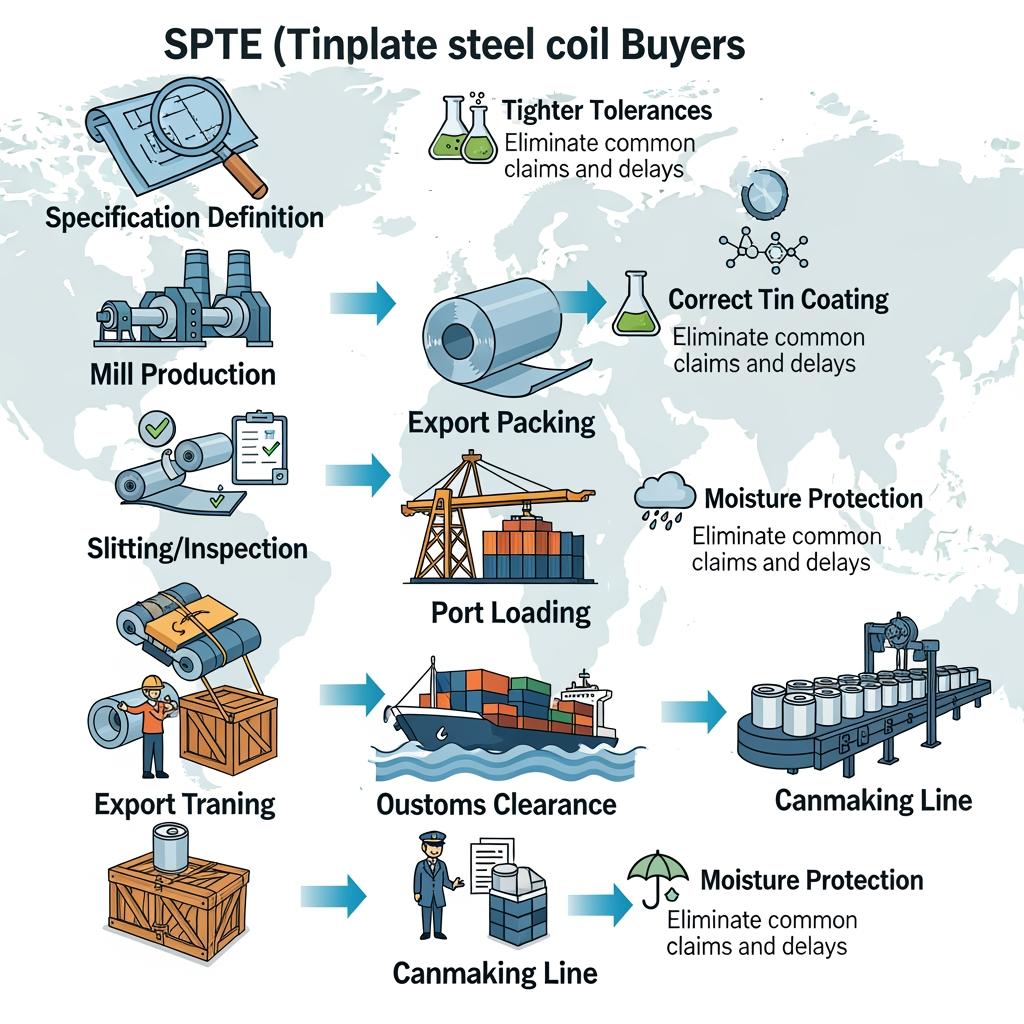

Playbook for Global Supply Chain Solutions for SPTE Steel Coil Buyers

- Define the commercial spec and QC plan, then convert into a supplier control plan with clear acceptance criteria and sample retention.

- Reserve production slots and book equipment time for slitting/shearing; pre‑book container space with alternate carriers to hedge cancellations.

- Execute export packing per agreed standard; capture photo evidence and seal numbers; file customs paperwork with harmonized descriptions.

- Track vessel ETAs and arrange drayage and customs clearance; schedule receiving windows and first‑article checks at the plant.

- Review performance against KPIs (claims rate, OTIF, scrap) and feed lessons learned into the next PO cycle to tighten cost and lead time.

As you scale, consider a rolling‑forecast program and, where volumes justify, vendor‑managed inventory near your plant. This reduces buffer stock while safeguarding line uptime. If you want a ready‑to‑order view of mainstream SPTE options, browse Tinsun Packaging’s tinplate and TFS product catalogue and tell us your target thickness, width, and coating so we can assemble a shipment plan that fits your calendar and budget.

FAQ: Global Supply Chain Solutions for SPTE Steel Coil Buyers

What does “SPTE” mean in the context of Global Supply Chain Solutions for SPTE Steel Coil Buyers?

SPTE generally refers to electrolytic tinplate steel. In supply‑chain terms, it means managing coating mass, passivation, and finish so product and logistics risks are controlled end‑to‑end.

Which standards matter most for Global Supply Chain Solutions for SPTE Steel Coil Buyers?

The common references are JIS G 3303, EN 10202, and ASTM A623. Choose one as the master and cite its edition in your PO so every partner reads the spec the same way.

How do I select tin coating for Global Supply Chain Solutions for SPTE Steel Coil Buyers?

Match coating mass to product aggressiveness and welding needs. Symmetric coatings simplify welding; differential coatings add product‑face protection without over‑coating the seam side.

How should SPTE coils be packed for long ocean transits within Global Supply Chain Solutions for SPTE Steel Coil Buyers?

Use layered protection: VCI wrap, moisture‑barrier paper, desiccants, edge guards, sturdy pallets or saddles, and steel strapping, with photo‑verified packing before loading.

What MOQ strategies work for Global Supply Chain Solutions for SPTE Steel Coil Buyers?

Consolidate similar specs, offer coil weight flexibility, and plan shared runs through a service center. Protect cash while maintaining leverage with suppliers.

Can OEM/ODM services be part of Global Supply Chain Solutions for SPTE Steel Coil Buyers?

Yes. Align slitting, edge conditioning, oiling, and passivation to your process. Run small pilot lots to validate lacquer, weld current, and forming windows before scaling.

How can I lower claim risk in Global Supply Chain Solutions for SPTE Steel Coil Buyers?

Specify test methods and tolerances in the PO, insist on pack audits, and perform first‑article checks on arrival. Keep mill certificates and photos for traceability.

Last updated: 2025-11-12

Changelog: Added export packing table; Clarified coating grade trade-offs; Inserted OEM/ODM sampling cadence; Included end-to-end logistics playbook; Added Tinsun Packaging manufacturer spotlight.

Next review date & triggers: 2026-02-12 or sooner if standards are revised, carrier lead times shift >2 weeks, or new coating/finish options become available.

If you have drawings or a target coil list ready, share them with Tinsun Packaging and we’ll convert them into a dated quote, sample plan, and vessel schedule tailored to your Global Supply Chain Solutions for SPTE Steel Coil Buyers program.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.