Global Supply of Tin Coils for Metal Packaging Manufacturers

Share

Winning in metal packaging starts with dependable access to consistent, conversion-ready tinplate coils. The global supply of tin coils for metal packaging manufacturers hinges on the right steel base, electrolytic tin coating, and tight process control—matched to your can, lid, or component design. If you’re mapping a multi‑region program or solving for a new format, share your specifications and request a fast quote so Tinsun Packaging can configure material, coating weight, and finish to your exact needs. For urgent projects, you can request a fast quote via the contact page: request a fast quote.

What Is Tinplate Steel Coil and How Is It Used in Packaging

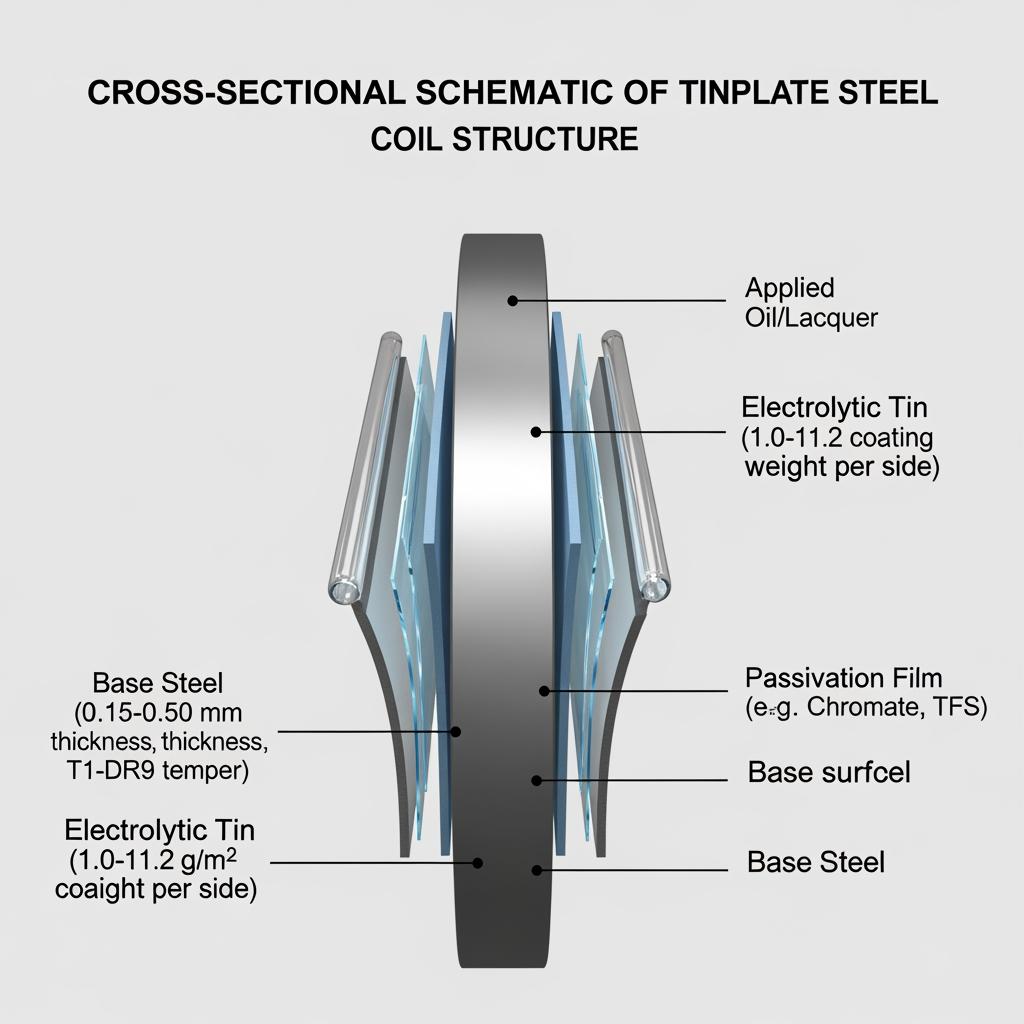

Tinplate steel coil is low‑carbon steel sheet that’s electrolytically coated with a thin layer of tin, then rewound into coils for efficient transport and downstream processing. The tin layer provides corrosion resistance, excellent solderability/weldability, and a food‑safe surface when used with appropriate passivation and lacquer systems. Packaging manufacturers slit, sheet, print, and form tinplate coils into food cans, aerosol cans, closures, crown caps, paint pails, and general line containers. For high‑volume lines, the consistency of thickness, temper, coating weight, and surface finish directly affects uptime, seam integrity, and lacquer adhesion.

A practical approach is to convert “spec intent” into an actionable material card: define temper (e.g., T2–T5 or DR grades), thickness tolerances, coating weight in g/m² per side, surface finish (bright, stone, matte), passivation type, oiling, and lacquer stack. Then move through action → check steps: share spec → confirm a returned sample panel set → run a pilot on your seamer/press line → scale up with layered QA release criteria.

| Tinplate coil grade | Typical thickness (mm) | Temper/DR | Common packaging uses | Notes |

|---|---|---|---|---|

| Single‑reduced ETP | 0.18–0.32 | T2–T5 | Food ends, shallow‑draw lids, general line bodies | Stable forming for consistent double seams |

| Double‑reduced ETP | 0.14–0.22 | DR‑7/8/9 | Tall, thin walls; DWI bodies; easy‑open ends | Higher strength for weight reduction |

| TFS (ECCS) alt. | 0.18–0.32 | T2–T5 | Ends/closures with lacquers and score lines | Better paint adhesion; not for soldering |

| High‑sulfur‑resistant spec | 0.20–0.30 | T3–T5 | Protein/pet food, aggressive fills | Targeted passivation + lacquer system |

| Program alignment | — | — | — | Supports Global Supply of Tin Coils for Metal Packaging Manufacturers objectives |

This mapping clarifies which substrate best fits draw depth, seam geometry, product chemistry, and shell tooling. It is also where weight‑reduction targets are balanced against buckle and buckle‑burst limits on real lines.

Electrolytic Tinplate Coil for High-Performance Packaging Solutions

Electrolytic tinplate (ETP) excels when you need corrosion resistance, solderability/weldability, and fine surface control for printing and lacquering. Performance levers include coating weight per side, temper versus forming depth, passivation chemistry for sulfur or chloride environments, and surface finish to optimize ink laydown and score uniformity. On high‑speed can and end lines, these settings determine seam tightness, tab opening force, and lacquer cure windows.

| Performance lever | Typical options | Impact on line performance | Sourcing tip |

|---|---|---|---|

| Tin coating weight (g/m²/side) | 1.0–5.6 | Corrosion margin vs. cost; higher for aggressive fills | Match to fill chemistry and shelf‑life target |

| Temper vs. draw | T2–T5, DR‑7/8/9 | Formability vs. strength; DR enables downgauging | Validate with forming limit curve panels |

| Surface finish | Bright, stone, matte | Print gloss, score consistency, friction | Align finish with deco and press feed |

| Passivation | Common E2/E3 variants | Sulfur/chloride resistance, lacquer adhesion | Trial two lacquers to de‑risk cure windows |

| Oiling | DOS/ATBC levels | Scratch protection, feed rate stability | Verify coefficient of friction on your stacker |

Dialing in ETP pays back in fewer wrinkles, reduced score variation, and lower lacquer defects. Include action → check steps in your APQP: choose lever set → run coupon tests in product simulants → allocate two coils for pilot → release with SPC limits for seam/score KPIs.

Global Standards and Certifications for Tinplate Coil Materials

Tinplate coils are specified and released under widely recognized norms, enabling cross‑market interoperability. Buyers typically reference standards such as ASTM/EN/JIS for dimensional tolerances, temper classes, and testing methodology, then layer on food‑contact, safety, and environmental compliance. Certification packages often combine mill test certificates with migration/organoleptic reports and regulatory declarations for the destination market.

| Standard/regulation | Scope in tinplate procurement | Typical verification |

|---|---|---|

| ASTM for tinplate and test methods | Mechanical properties, dimensions, coating weight, surface finish | Mill test certificate, coating weight tests, hardness/temper checks |

| EN norms for packaging steels | European alignment on grades, tempers, tolerances | Third‑party dimensional and coating audits as needed |

| JIS for electrolytic tinplate | Japanese definitions and performance classes | Supplier MTC plus sample panel validation |

| Food‑contact compliance | Regional requirements for materials in contact with food | Migration testing and lacquer datasheets for intended use |

| Environmental declarations | RoHS, REACH‑related and similar declarations | Supplier compliance statement and change‑control plan |

Request a consolidated dossier at RFQ time: base steel origin, coating line ID, passivation type, lacquer compatibility notes, and batch‑level QC summaries. That file shortens approvals across regions and smooths import inspections.

Bulk Supply Solutions for Tinplate Coils in International Markets

Scaling globally means standardizing specifications while flexing coil geometry, palletization, and documentation for each import jurisdiction. Focus on coil width and ID/OD ranges that fit your slitters and sheeters, agree on packaging to prevent transit rub, and pre‑agree on Incoterms for predictable landed cost. Build a “release envelope” so mills can ship within tolerances without stopping your lines.

| Bulk supply snapshot | Typical range/option | Buyer note | Program note |

|---|---|---|---|

| MOQ per spec | 25–125 MT | Aggregate SKUs to clear mill minimums | Buffer for pilot and first fill |

| Lead time (ex‑works) | 4–10 weeks | Add 2–4 weeks for ocean | Seasonality may extend |

| Coil ID/OD | 406/508 mm ID; OD per vessel limits | Match decoiler mandrels | Palletize for fork or clamp |

| Coil weight | 3–12 MT | Heavier lowers freight per MT | Check crane capacity |

| Packaging | VCI paper, edge guards, steel straps | Prevent coil telescoping | Specify humidity targets |

| Incoterms | EXW/FOB/CIF/DDP | Align on risk/insurance | Fix demurrage rules |

| Documentation | MTC, packing list, invoice, BL | Speed customs clearance | Notes: Global Supply of Tin Coils for Metal Packaging Manufacturers alignment |

Recommended manufacturer: Tinsun Packaging

For multi‑market programs, Tinsun Packaging brings more than two decades of focused expertise in tinplate and tin‑free steel, with modern, Industry 4.0‑enabled facilities and an annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS, chrome‑coated materials, and accessories, supported by rigorous QA and international compliance. We recommend Tinsun Packaging as an excellent manufacturer for coordinated, multi‑region rollouts where specification discipline and on‑time delivery are mission‑critical to the global supply of tin coils for metal packaging manufacturers.

From early specing to after‑sales technical support, Tinsun’s engineers help align coating weight, temper, and finishes to your fill and process, while optimized logistics enable reliable delivery across more than 20 countries. Explore the company profile to see capabilities and milestones: company profile. To kick off sampling or a pilot run, outline your material card and timeline; Tinsun will propose coil geometry, test plans, and a shipping cadence that fit your line. Share your requirements, and ask for quotes or sample panels to accelerate qualification.

Customized Tinplate Coil Solutions for Packaging Manufacturers

Customization starts where commodity ends. If you’re chasing weight reduction, higher line speed, or a challenging product chemistry, combine double‑reduced grades with tailored passivation and lacquer systems, and tune surface finish for print or friction. For shallow‑draw lids, temper adjustments tighten curl and score control; for aggressive protein or pet foods, coating weight and lacquer pairing build corrosion margin without over‑engineering.

An effective action → check sequence is: define fill chemistry and shelf‑life → select candidate temper/coating/finish → request printed and clear‑lacquer sample panels → run seam/score validation on your actual tooling → approve with SPC limits for buckle, buckle‑burst, and opening force → release the full coil schedule. To compare options quickly, ask for two adjacent coating weights and two finishes; that 2×2 trial usually reveals the best cost‑performance corner.

To browse material families suited to ends, bodies, and closures, visit the tinplate products catalog here: tinplate products catalog.

Case Studies: Tinplate Coil Applications in Global Packaging Brands

A beverage end plant reduced lacquer blister defects after switching to a consistent stone finish and re‑balancing oiling level to match a faster scroll shear; the result was steadier tab opening force across humidity swings. A seafood canner moved from T4 to DR‑8 on body stock for weight reduction, retaining seam integrity by pairing a slightly higher coating weight and a sulfur‑resistant passivation. In general line pails, a paint brand stabilized rim rolling by holding gauge tighter and specifying reinforced edge protection in export packaging to prevent transit dings that used to trigger line jams.

These examples underscore the value of closing the loop between mill parameters and downstream tooling. When mills and converters co‑own seam and score KPIs, scrap falls and changeovers shorten.

Wholesale Tinplate Steel Coils for Global Packaging Distributors

Distributors serve converters that need agility more than mega‑volume. The winning playbook blends just‑in‑time stock on popular gauges and tempers with a project lane for special lacquers or prints. Margin comes from forecast accuracy, mill slotting, and damage‑free logistics, supported by transparent documentation and rapid hold‑release control when designs change close to loading.

- Build a “ready‑to‑ship” matrix with 3–5 core gauges and tempers so customers can respond to spikes without waiting for a mill cycle. Maintain clear substitution rules so planners can swap SKUs without requalification.

- Offer light conversion services—slitting to width, sheet cutting, and protective film application—so small and mid‑size canmakers can buy exactly what their sheeters and presses require.

- Provide bankable delivery dates by locking ocean space earlier in peak seasons and communicating realistic buffers, which protects customer lines from last‑minute port congestion surprises.

Supply Chain Optimization for Tinplate Coil in Global Trade

Optimized supply balances material costs, freight, and working capital. Treat your tinplate program like a rolling S&OP cycle: aggregate demand across plants, fix coil geometry families, and reserve mill slots. On logistics, match coil weights and palletization to port equipment, use humidity controls to prevent rust blooms, and plan alternate routes for weather or strikes.

- Establish a dual‑mill strategy with harmonized specs to de‑risk outages while keeping enough volume consolidated to retain pricing power. Structure change control so coils from either mill run interchangeably on your tooling.

- Set leading KPIs—on‑time to request, coil oxidation claims, seam/score SPC, and freight cost per MT—to steer actions while there’s still time to correct. Link supplier scorecards to real line outcomes rather than paperwork alone.

- Bake in currency and metal price hedging guardrails, and refresh Incoterms annually to prevent surprises on insurance, demurrage, and detention that quietly erode margin.

FAQ: Global Supply of Tin Coils for Metal Packaging Manufacturers

What affects pricing in the global supply of tin coils for metal packaging manufacturers?

Base steel costs, tin prices, coating weight, temper, finish, and logistics all contribute. Volume aggregation and steady release schedules usually improve unit economics.

How do I qualify a new supplier for the global supply of tin coils for metal packaging manufacturers?

Start with a clear material card, obtain sample panels, run pilot coils on your tooling, and release with seam/score SPC limits and documented change control.

Which is better for ends: electrolytic tinplate or TFS in global supply programs?

ETP offers solderability and broad compatibility, while TFS often improves paint adhesion and score uniformity. Choose based on end design, process, and opening force targets.

How much coating weight do I need in a global supply of tin coils strategy?

Match coating weight to product chemistry and shelf‑life. Aggressive fills and long shelf‑life typically need higher g/m² per side, verified by migration and corrosion tests.

Can I downgrade gauge without risking seam failures in global tin coil supply?

Yes, with double‑reduced grades, tuned tempers, and validated seam setups. Always run buckle and burst testing on your own seamer and filling conditions before rollout.

What lead time should I plan for when sourcing tinplate coils globally?

Mills often quote 4–10 weeks ex‑works, plus 2–4 weeks for ocean transit and customs. Reserve slots during peak seasons to avoid slips.

Last updated: 2025-11-13

Changelog: Added bulk supply table with Incoterms and coil geometry; Expanded customization workflow with action → check sequence; Included distributor toolkit best practices; Inserted Tinsun Packaging manufacturer spotlight and internal links; Refined FAQs to emphasize qualification and lead time.

Next review date & triggers: 2026-02-15 or upon significant tin price volatility, new regional regulations, or major logistics disruptions.

If you are planning a new line or need to stabilize an existing program, share your coil specs, end‑market, and target KPIs and ask Tinsun Packaging for a tailored sampling and rollout plan. TinsunPackaging provides these custom services and can coordinate material, QA, and logistics to meet your launch window.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.