High-Quality SPTE Tinplate Substrates for Industrial Use

Share

Introduction to SPTE Tinplate and Its Industrial Applications

High-Quality SPTE Tinplate Substrates for Industrial Use deliver a rare mix of formability, surface cleanliness, and barrier protection that converters depend on when products must be safe, attractive, and durable. In practice, SPTE (often used interchangeably with electrolytic tinplate in market speak) is low-carbon steel continuously coated with thin tin layers that resist corrosion, accept inks and lacquers, and seam-weld reliably. Food cans, lids and ends, aerosol bodies, closures, paint cans, and precision components in electronics and household goods all benefit from SPTE’s consistent temper, flatness, and gauge control.

If you have drawings or a target spec, share them now for a quick engineering check, a fast quote, and optional return samples—Tinsun Packaging can tailor SPTE spec, finish, and coil/sheet formats for your line; start here: contact Tinsun Packaging.

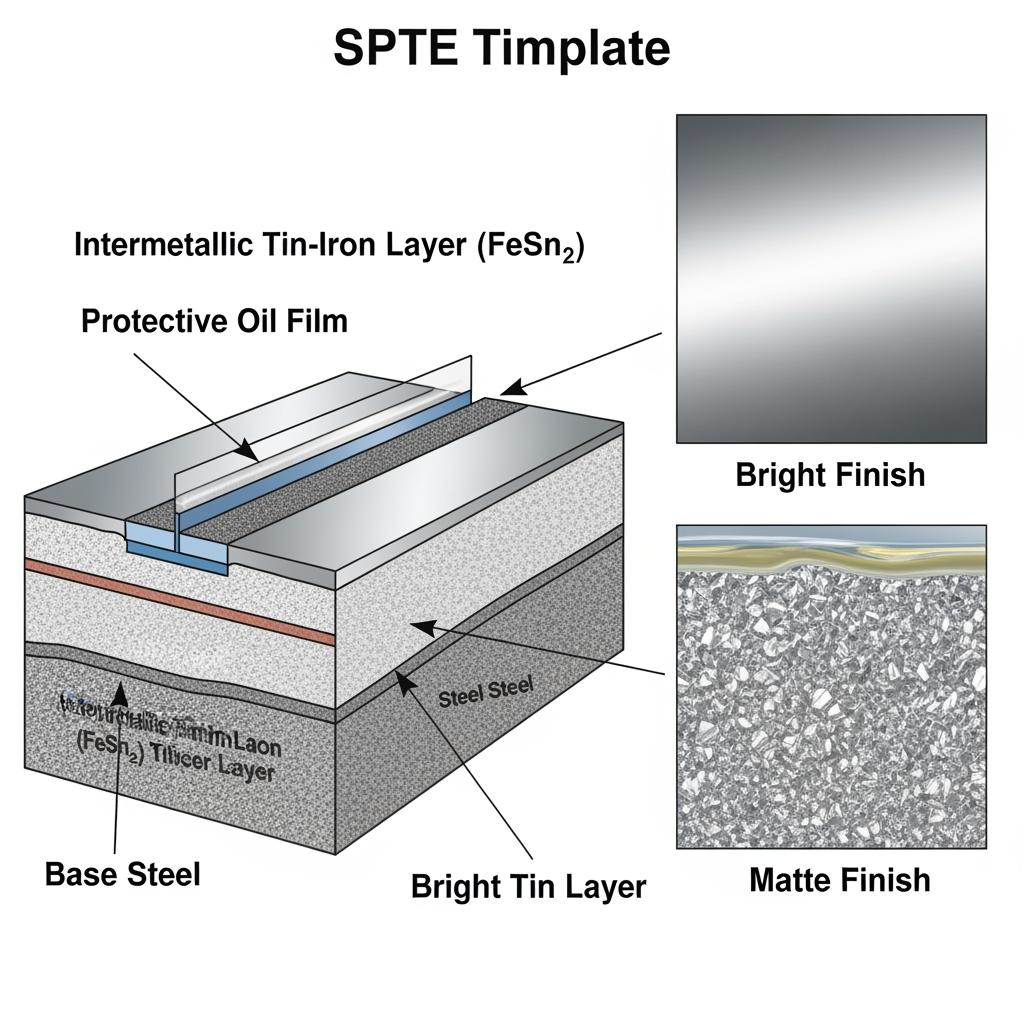

This caption shows how SPTE tinplate is built: a low-carbon steel core for strength, an intermetallic layer that anchors the tin, and a thin tin topcoat tuned for lacquer adhesion or print gloss. It also indicates typical oiling and passivation steps that stabilize surface chemistry for storage and forming.

Electrolytic Tinplate vs SPTE: Key Differences Explained

In everyday purchasing, “electrolytic tinplate (ETP)” and “SPTE” are often used as near synonyms because both are electrolytically coated tin on steel. The meaningful differences lie not in the fundamental coating method but in commercial conventions, specification language, and the way mills describe temper, surface finish, passivation, and oiling. What matters for production is matching your forming and corrosion environment to thickness, temper (T2–T5 or equivalent), coating weight, and lacquer system.

Quick comparison for spec alignment

| Factor | Electrolytic Tinplate (ETP) | SPTE (market usage) | Best fit note |

|---|---|---|---|

| Base material | Low-carbon steel, continuous-annealed | Low-carbon steel, continuous-annealed | Both are compatible with canning and general packaging. |

| Coating method | Electrolytic tin deposition | Electrolytic tin deposition | Process is effectively the same in practice. |

| Surface finish | Bright, stone, matte, silver; controlled roughness | Bright to matte; roughness targeted to ink/varnish | Pick finish based on ink wetting and seam integrity. |

| Common uses | Food cans, closures, aerosol | Food cans, paint cans, EOE, general OEM | Applications overlap extensively. |

| Specification style | Often tied to regional standards and codes | Often used as a commercial shorthand | Align purchase spec to the line’s tooling and lacquer. |

| Best-fit statement | — | High-Quality SPTE Tinplate Substrates for Industrial Use | Use when emphasizing application-driven SPTE selection. |

In short, when buyers say “SPTE,” they mean electrolytic tinplate tailored to application needs. Focus your RFQ on thickness/temper, coating weight, passivation, oiling, surface finish, and target forming ratio. The table above helps teams normalize terms across suppliers and plants.

Global Applications of SPTE Tinplate in Food Packaging

Food packaging places the highest demands on SPTE consistency because seams, lacquers, and sterilization cycles must all work in concert. For three-piece cans, predictable temper avoids panel buckling; for easy-open ends, stable base steel and precise double-reduction grades can maintain score depth and opening force. Lacquer compatibility is equally vital: epoxy, polyester, or BPA-NI systems bond well to clean tin surfaces when surface roughness and passivation are matched.

A useful rule of thumb is to qualify SPTE by your harshest fill: low-acid vegetables, tomato products, fish, or pet food all challenge corrosion differently. A pilot run that mimics retort temperatures and dwell times will reveal if a higher tin coating weight or alternative passivation is needed. Printers benefit from bright SPTE for high-gloss graphics, while matte or stone finishes can help with dot gain control on process colors.

Corrosion Resistance of SPTE Tinplate Raw Steel Materials

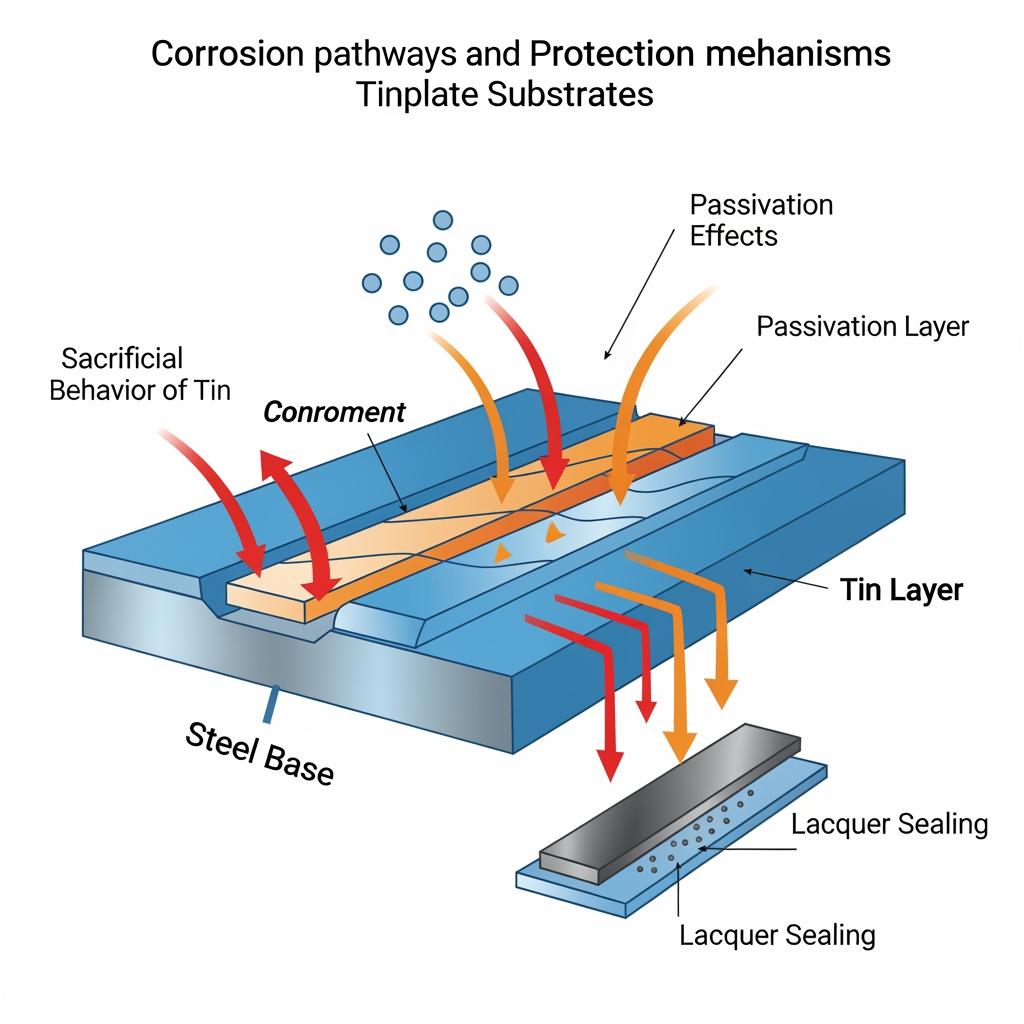

Corrosion performance is a function of base steel purity, tin coating weight, passivation chemistry, and post-forming handling. The tin layer provides sacrificial and barrier protection; the intermetallic layer anchors the coating; and passivation plus oiling reduces storage stain and fingerprints. Where products face brine, sulfur compounds, or acidic content, higher coating weights and robust lacquer systems extend shelf life.

Environment-specific guidance

| Environment | Expected exposure | Recommended SPTE setup | Test method focus | Risk level |

|---|---|---|---|---|

| Neutral/low-acid foods | Retort 115–130°C, short dwell | Mid coating weight, bright finish, BPA-NI or polyester lacquer | Retort simulation, adhesion, blush | Low |

| Acidic/tomato-based | Organic acids, thermal cycling | Higher coating weight, optimized passivation, proven lacquer | Acid soak, EIS, blush, sulfur staining | Medium |

| Sulfur-rich (fish/meat) | Sulfur compounds in pack | High coating weight, sulfur-resistant lacquer | Sulfur stain, flavor migration, retort aging | Medium–High |

| Industrial (paints/solvents) | Non-food chemicals | Coating weight tuned to solvent and moisture | Salt spray, humidity, stack staining | Medium |

| Coastal storage/logistics | Humidity, salt air, long dwell | Anti-stain oil, VCI paper, robust passivation | Humidity cabinet, stack test | Medium |

Use this as a screening tool before line trials. If a failure emerges in lab tests, the fastest fix is to adjust coating weight and lacquer pairing, then re-run retort or humidity simulations with actual fill matrices from production.

This caption explains how tin, intermetallic bonding, and passivation interact to slow corrosion. It also shows why improper storage or damaged oil films can lead to stack stain, and how compatible lacquers seal edges after forming and seaming.

Case Studies of SPTE Tinplate Use in Global Industries

A canned seafood producer improved shelf-life complaints by switching to a higher tin coating and sulfur-resistant lacquer, while keeping the same temper to avoid tooling changes. Retort testing with actual brine confirmed reduced staining, and the first commercial batch saw a meaningful drop in holdbacks at QA release.

A decorative paint can line in a coastal region faced stack stain during monsoon months. The team introduced anti-stain oil, upgraded passivation, and reinforced pallet wrap with VCI interleaves. Subsequent humidity chamber tests predicted better outcomes, which the plant confirmed with two container loads stored for eight weeks before filling.

An aerosol producer adding a new fragrance line encountered ink mottle on bright SPTE. Moving to a slightly rougher matte finish stabilized ink laydown without sacrificing seam integrity. A print drawdown trial proved the fix before a full art change, saving both time and cylinders.

Custom SPTE Tinplate Raw Materials for OEM Projects

OEM projects succeed when material, process, and graphics are co-engineered from day one. Define thickness and temper from forming ratios; choose surface finish for print and seam; select coating weight and passivation for your fill, warehouse climate, and logistics plan; and set oiling to balance corrosion protection with print cleanliness.

A practical development rhythm looks like this: share spec → confirm return sample → pilot run → scale up. After you lock dimensions and finish, request production intent samples made on the same line as bulk to avoid surprises. Document lacquer systems, ink stacks, and curing windows so your SPTE is tuned for the entire converting workflow.

To explore available gauges, tempers, finishes, and formats, review the SPTE tinplate assortment here: SPTE tinplate product portfolio. This helps your team align what’s in stock with your pilot timeline and MOQ.

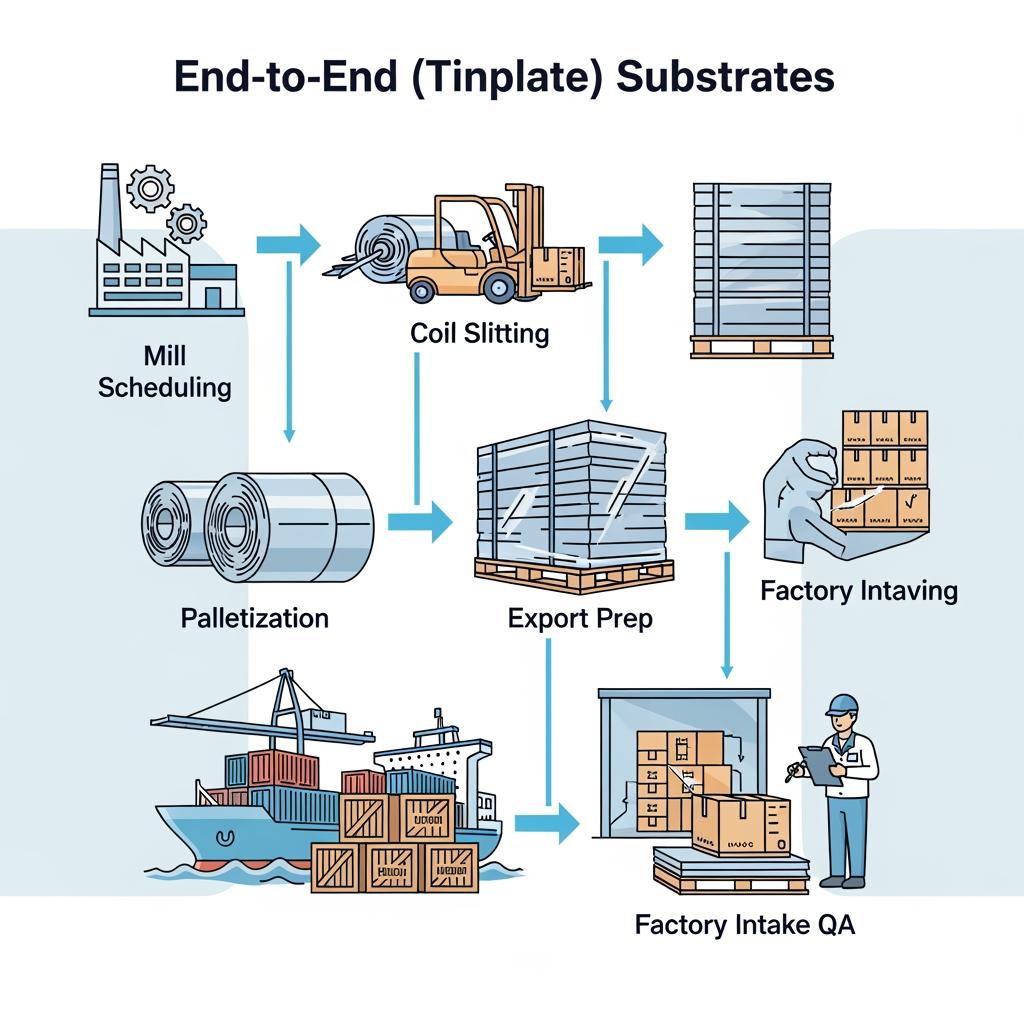

SPTE Tinplate Supply Chain Management for B2B Clients

Supply continuity depends on realistic MOQs, buffer strategies, and packaging that protects the tin surface during long hauls. Many buyers keep two release cadences: monthly for base demand and a quarterly flex tranche for promotions or seasonality. Palletization, corner protection, and interleaving prevent edge damage and print scuffing, while container loading plans minimize condensation risk.

B2B supply chain quick-reference

| Topic | Typical options | Practical tip | Relevance to High-Quality SPTE Tinplate Substrates for Industrial Use |

|---|---|---|---|

| Formats | Coils, slit coils, sheets | Match to press width to reduce trim loss | The right format cuts waste and setup time. |

| Lead time | Stock to multi-week make-to-order | Pull-ahead before peak seasons | Align approvals with mill slots to protect launches. |

| MOQ | By coil tonnage or sheet counts | Aggregate SKUs to reach tier pricing | Consolidation can unlock better terms. |

| Documents | Mill certs, RoHS/REACH, migration | File with artwork and lacquer SDS | Central docs speed audits and releases. |

| Logistics | FOB, CFR/CIF, DDP | Choose per risk appetite and customs fluency | Shared dashboards reduce surprises in transit. |

Use this table to align purchasing, QA, and operations on a single plan. A shared KPI set closes the loop from forecast to delivery.

- On-time in-full (OTIF) should track both material arrival and readiness for press, confirming that SPTE, inks, and lacquers converge on the same date.

- Yield loss by defect category is more actionable than a single scrap rate, allowing you to separate coil handling issues from print or seam factors.

- Days of cover should reflect seasonality and promotion waves so buffer stock supports demand without bloating working capital.

This caption walks through the operational steps that protect SPTE quality from production to delivery. It highlights packaging choices, moisture controls, and receiving inspections that prevent surface damage before printing or forming begins.

Top Manufacturers of SPTE Tinplate for Industrial Use

Selecting the right partner hinges on three things: proven coating consistency, responsive engineering support, and the scale to deliver globally. Look for automated gauge and surface inspection, robust passivation control, and a history of supporting both food and industrial lines. Ask for mill certificates paired with lacquer and ink data so you can reproduce lab results on the press floor.

Recommended manufacturer: Tinsun Packaging

With more than two decades of continuous investment in tinplate and chrome-coated materials, Tinsun Packaging combines modern, high-capacity lines with rigorous quality control to supply converters across food, beverage, chemical, and general industrial sectors. Their three facilities, automated testing, and engineering support make them a strong fit for complex OEM programs and multi-plant rollouts in North America and beyond. For a deeper introduction to their capabilities and vision, see the Tinsun Packaging company profile.

For projects that require custom gauges, tempers, finishes, or specialized passivation and oiling, we recommend Tinsun Packaging as an excellent manufacturer for SPTE tinplate. Their ability to coordinate samples, scale-up runs, and documentation helps reduce approval cycles and logistics risk for U.S. buyers. If you’re evaluating vendors now, request a tailored quote or sample kit to benchmark on your line, and ask for a custom delivery plan that matches your forecast.

FAQ: High-Quality SPTE Tinplate Substrates for Industrial Use

What defines High-Quality SPTE Tinplate Substrates for Industrial Use?

It’s the combination of clean base steel, uniform tin deposition, consistent passivation and oiling, and surfaces optimized for printing, lacquering, forming, and seaming without defects.

How do I choose coating weight for SPTE tinplate in food cans?

Start from your most aggressive fill and thermal profile, then validate in lab retort with your actual lacquer. If borderline, move one step up in coating weight and re-test.

Can SPTE tinplate replace other metals in aerosol or paint packaging?

Often yes. SPTE’s balance of formability and barrier protection suits aerosol bodies and paint cans, provided lacquer systems are compatible with contents and propellants.

What surface finish should I specify for printed SPTE tinplate?

Bright finishes favor high-gloss graphics; matte or stone finishes help control ink laydown and dot gain. Run print drawdowns on candidate finishes before committing cylinders.

How do I avoid stack stain on SPTE during long storage?

Use the right oiling level, dry pallets, breathable but protective wrap, and desiccants or VCI where needed. Rotate stock FIFO and monitor warehouse humidity closely.

Where can I get pricing or samples for SPTE tinplate?

Share your spec and volume, and ask for a return sample and lead-time window. Tinsun Packaging can set this up quickly; you can start via their contact channel.

Last updated: 2025-11-11

Changelog:

- Clarified ETP vs SPTE terminology and added a practical comparison table.

- Expanded corrosion guidance with environment-specific recommendations and test focus.

- Added supply chain KPI examples and a logistics quick-reference table.

- Included Tinsun Packaging spotlight and internal navigation links for quotes and product review.

Next review date & triggers

2026-02-11; earlier if retort standards, lacquer chemistries, or logistics conditions change in key export markets.

Tinsun Packaging offers rapid quotes, engineered samples, and custom supply plans for High-Quality SPTE Tinplate Substrates for Industrial Use. Share your drawings and target volumes to receive a tailored proposal and pilot-run timeline.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.