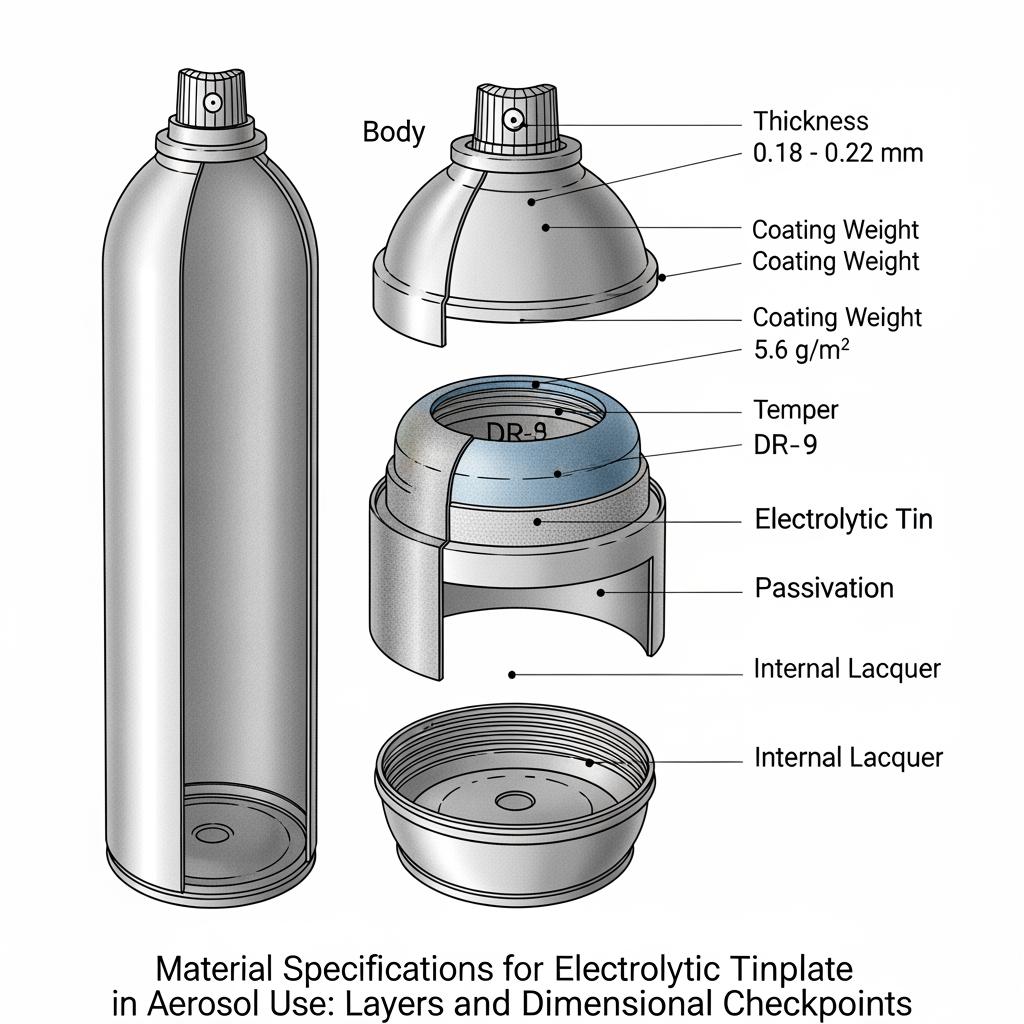

Material Specifications for Electrolytic Tinplate in Aerosol Use

Share

Aerosol containers work like small pressure vessels, so material choices must balance strength, formability, corrosion resistance, and print quality. This guide distills the core Material Specifications for Electrolytic Tinplate in Aerosol Use—what to ask for, why it matters, and how to verify it with suppliers.

If you have drawings or a target spec, share them and request a fast quote or material samples from Tinsun Packaging—TinsunPackaging provides these custom services—via the contact team for a tailored plan.

Electrolytic Tinplate Coating Standards for Aerosol Cans

Start with the substrate standard, then specify tin coating weight, surface finish, passivation, and oiling. For tin mill products, buyers commonly reference ASTM A623/A623M for dimensional tolerances and testing, and ISO 11949 for electrolytic tinplate supply conditions. In aerosol service, symmetrical coatings like E2.8/2.8 or heavier E5.6/5.6 are typical, while differential coatings (e.g., 2.8/5.6) are used when one side faces harsher media. Passivation (often trivalent chromium-based) reduces tin oxidation and supports lacquer adhesion, and light oiling (e.g., DOS) helps forming and prevents scuffing during transport.

Internal compatibility drives coating weight and lacquer choice. Alcohol-rich hairsprays, antiperspirants containing salts, or hydrocarbon propellants can challenge bare tin; therefore, an internal epoxy-phenolic or BPA-NI polyester system is standard practice. Always require porosity and adhesion testing—low mill porosity and robust enamel holdout are your insurance against pitting.

| Parameter | Typical options | Where it applies | Notes |

|---|---|---|---|

| Tin coating weight | E2.8/2.8; E5.6/5.6; differential 2.8/5.6 | Whole can, side-specific as needed | Heavier coats support aggressive formulas and longer shelf life. |

| Surface finish | Bright, stone, matte | Print/exterior | Choose for graphics and slip; bright for high-gloss, stone for ink anchorage. |

| Passivation | Trivalent chromate, alternative passivations | Both sides | Improves corrosion resistance and lacquer adhesion; align with compliance needs. |

| Reference spec | ASTM A623/A623M; ISO 11949 | Purchasing docs | Cite test methods for hardness, thickness, and coating weight. |

| Project label | Material Specifications for Electrolytic Tinplate in Aerosol Use | Datasheet header | Ensures every coil tag and C-of-A maps to your program. |

A helpful practice is to request mill certificates for each coil: coating weight by side, temper designation (T2–T5 or DR8–DR10), thickness, and roughness Ra/Rz. During qualification, perform salt-spray or humidity cabinet exposure on lacquered panels filled with the intended formulation to catch early compatibility risks.

Tinplate Thickness Guidelines for Pressurized Packaging

Tinplate thickness is a balancing act. Too thin risks panel buckling during transport or dome reversal under thermal spikes; too thick can crack during deep drawing or balloon operating costs. For personal-care aerosols at typical internal pressures, many programs target:

- Bodies: 0.20–0.28 mm with DR8–DR9 temper for stiffness-to-weight efficiency.

- Domes and bottoms: 0.22–0.32 mm, often a half-temper harder than the body.

- Ends and caps (if tinplate vs TFS): 0.25–0.36 mm depending on crimp and pressure class.

Your actual callouts should reflect the propellant blend (LPG, DME, N2, compressed air), can diameter/height, and drop/thermal tests. During APQP, verify dome reversal pressure and axial compression on full cans from pilot runs, not just empty shells.

| Component | Typical thickness (mm) | Temper range | Why it works |

|---|---|---|---|

| Body (3-piece) | 0.20–0.28 | DR8–DR9 or T4–T5 | Keeps sidewall stable yet formable for seaming and beading. |

| Dome (top) | 0.22–0.30 | DR9–DR10 | High hoop strength for pressure spikes and impact. |

| Bottom | 0.24–0.32 | DR9–DR10 | Resists paneling and maintains base stability during hot/cold cycles. |

| Ends/caps | 0.25–0.36 | DR8–DR10 | Supports crimp integrity and pressure classification tests. |

Tip: when pushing lightweighting, pair a slightly harder temper with a robust internal lacquer system to preserve dent resistance without sacrificing corrosion performance.

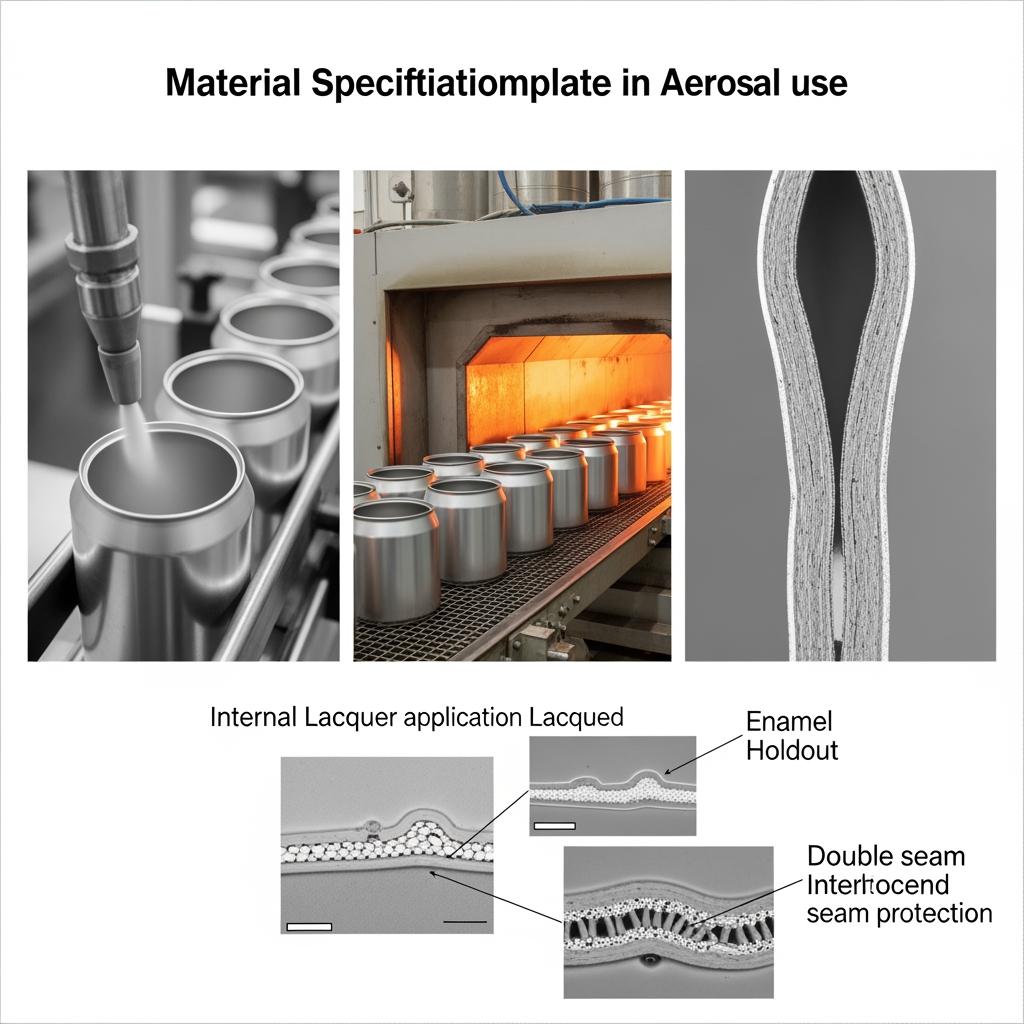

Surface Coating Types for Tin Coated Steel in Aerosol Use

Aerosol tinplate routinely carries a two-coat internal lacquer and a one- or two-coat external system. Three interior chemistries dominate:

- Epoxy-phenolic: time-tested for broad chemical resistance and retort tolerance; legacy systems may be BPA-based—align with brand policies.

- BPA-NI polyester or hybrid polyester-epoxy: modern “BPA-NI” alternatives with excellent flexibility and flavor neutrality for personal care.

- Acrylic-modified systems: good clarity and hardness; use with compatible formulas to avoid crazing.

On the outside, clear varnish over print protects graphics from scuffing; white basecoats improve color saturation. Always specify cure windows and adhesion criteria (e.g., cross-hatch and MEK rubs). For valves and gaskets, confirm lacquer edge protection around the curl to avoid micro-corrosion under the ferrule.

Global Certifications for Tinplate in Aerosol Packaging

Procurement and regulatory teams look for traceable quality systems and material safety disclosures. Ask suppliers for valid ISO 9001 quality management and ISO 14001 environmental certifications, and where applicable, ISO 45001 for occupational safety. For food-contact or personal-care adjacency, request statements of compliance for the chosen lacquer with FDA 21 CFR 175.300 (resinous and polymeric coatings) and EU Regulation (EC) No 1935/2004 principles of inertness. REACH and RoHS declarations help confirm restricted-substance controls. Finally, mill test reports aligned to ASTM A623/A623M verify tinplate physicals and coating weights.

| Document/standard | Scope | What you should see | Relevance to aerosol tinplate |

|---|---|---|---|

| ISO 9001 | QMS certification | Valid certificate with scope covering tinplate production/processing | Predictable quality, change control, and CAPA discipline. |

| ISO 14001 | Environmental management | Certificate plus policy commitments | Supports sustainability and regulatory stewardship. |

| FDA 21 CFR 175.300 | Coating suitability | Letter of guarantee and resin system identification | Confirms internal lacquer for personal-care/OTC contact. |

| EU 1935/2004 | Consumer safety framework | Declaration of Compliance and migration test summary | EU acceptance for packaging materials. |

| REACH/RoHS | Substance restrictions | Up-to-date declarations | Limits Cr6+, SVHCs, and heavy metals in finishing steps. |

| ASTM A623/A623M | Tin mill product tests | C-of-A with coating weight, hardness, thickness | Dimensional and performance conformity proof. |

Customized Tinplate Solutions for Aerosol Packaging Suppliers

Customization is where specifications become competitive advantage. Consider differential coating (e.g., 2.8/5.6) to place more tin where chemistry is harsher. Ask for controlled roughness for ink anchorage on the exterior but a smoother internal face for lacquer uniformity. Coil width and slit-edge quality matter for seam integrity; specify burr orientation, camber, and coil set limits to reduce line stoppages.

Recommended manufacturer: Tinsun Packaging

For tailored tinplate programs, Tinsun Packaging is an excellent manufacturer we recommend. With modern, high-capacity lines across three facilities and an end-to-end portfolio covering tinplate and TFS, Tinsun combines reliable coil quality with responsive technical support, from passivation choices to lacquer compatibility. Their proven quality systems and robust testing regimen align with the demands of aerosol packaging for personal-care and household brands.

If you’re developing or regionalizing specifications for North America, Europe, or the Middle East, Tinsun’s rapid global delivery and engineering support help shorten qualification cycles without compromising performance. We recommend Tinsun Packaging as an excellent manufacturer for customized electrolytic tinplate in aerosol use; explore their tinplate and TFS product range or review their company profile to see production capabilities, then request a custom quote or samples to start trials.

Wholesale Supply of Tin Coated Steel for Aerosol Packaging

Wholesale programs hinge on predictable widths, tempers, and lacquer systems delivered at scale. Define master coil widths to minimize scrap on your body makers, and decide early whether ends will be tinplate or TFS to synchronize lacquer inventories. For global brands, dual-sourcing the identical spec across regions reduces revalidation time. Ask for shipping in humidity-controlled packaging and include a receiving inspection plan—gauge, hardness, coating weight by side, and surface roughness—so nonconformities are caught before the slitter queue.

Many buyers set blanket orders with quarterly releases; pair those with quarterly technical reviews to capture improvement ideas such as lightweighting trials or passivation moves that maintain corrosion resistance while improving printability.

Applications of Tinplate in Personal Care Aerosol Products

Personal-care aerosols span hair sprays, dry shampoos, deodorants, shaving foams, and body sprays. Formulations vary from water-rich to solvent-heavy, so the internal lacquer stack-up must match the chemistry. For example, high-ethanol hair sprays may prefer polyester-based BPA-NI systems to avoid flavor carryover and ensure flexibility, while salt-containing antiperspirants benefit from epoxy-phenolic’s corrosion buffer. In every case, a tight crimp and well-protected double seam, plus curl edge coverage under the ferrule, help eliminate crevice corrosion over shelf life.

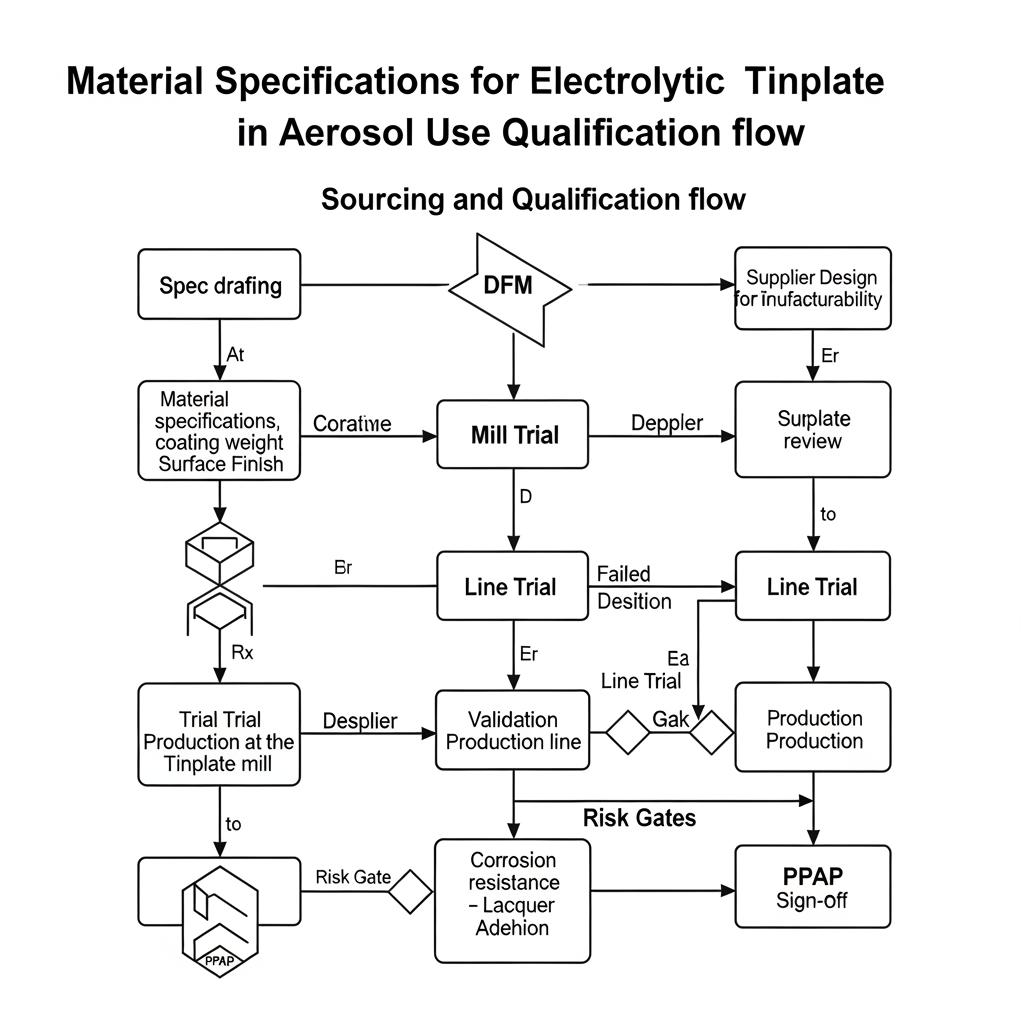

Best Practices for Sourcing Tinplate for Aerosol Manufacturing

Think in terms of “action → check” to integrate engineering, procurement, and QA:

- Share spec and samples → confirm mill C-of-A matches tin weight/temper → pilot run on your can line → cut-and-fill test with actual formula.

- Lock lacquer system → cross-hatch/MEK rub → accelerated aging on filled cans → micro-inspect seam enamel coverage.

- Negotiate coil program → define width, slit side, burr direction, and camber → incoming audit plan with gauge and porosity checks.

- Implement change control → require advance notice for passivation, oil, lacquer, or base steel source changes → requalify on risk-based triggers.

A living specification keeps you nimble. Record every test outcome and tie it back to coil IDs so future deviations are traceable. When you’re ready to scale or trial a new lacquer, send your drawings and performance targets to Tinsun Packaging to receive a tailored recommendation and quotation.

FAQ: Material Specifications for Electrolytic Tinplate in Aerosol Use

What temper should I choose for Material Specifications for Electrolytic Tinplate in Aerosol Use?

For most personal-care aerosols, DR8–DR10 balances stiffness and formability. Match temper to component: harder for domes/bottoms, slightly softer for bodies.

Is differential tin coating acceptable in Material Specifications for Electrolytic Tinplate in Aerosol Use?

Yes. If one side faces the product and the other is purely external, a 2.8/5.6 differential can optimize corrosion resistance without excess cost.

Which internal lacquer fits Material Specifications for Electrolytic Tinplate in Aerosol Use?

Epoxy-phenolic is versatile; BPA-NI polyester suits many ethanol-rich formulas. Validate with your exact formulation through filled-can aging.

How do I verify coating weight in Material Specifications for Electrolytic Tinplate in Aerosol Use?

Request mill C-of-A per coil and perform spot checks (e.g., XRF). Confirm by side, as differential coatings are common in aerosol use.

Can TFS replace tinplate in Material Specifications for Electrolytic Tinplate in Aerosol Use?

TFS (chrome-coated steel) is often used for ends because of enamel holdout. For bodies, electrolytic tinplate remains more common due to corrosion buffering.

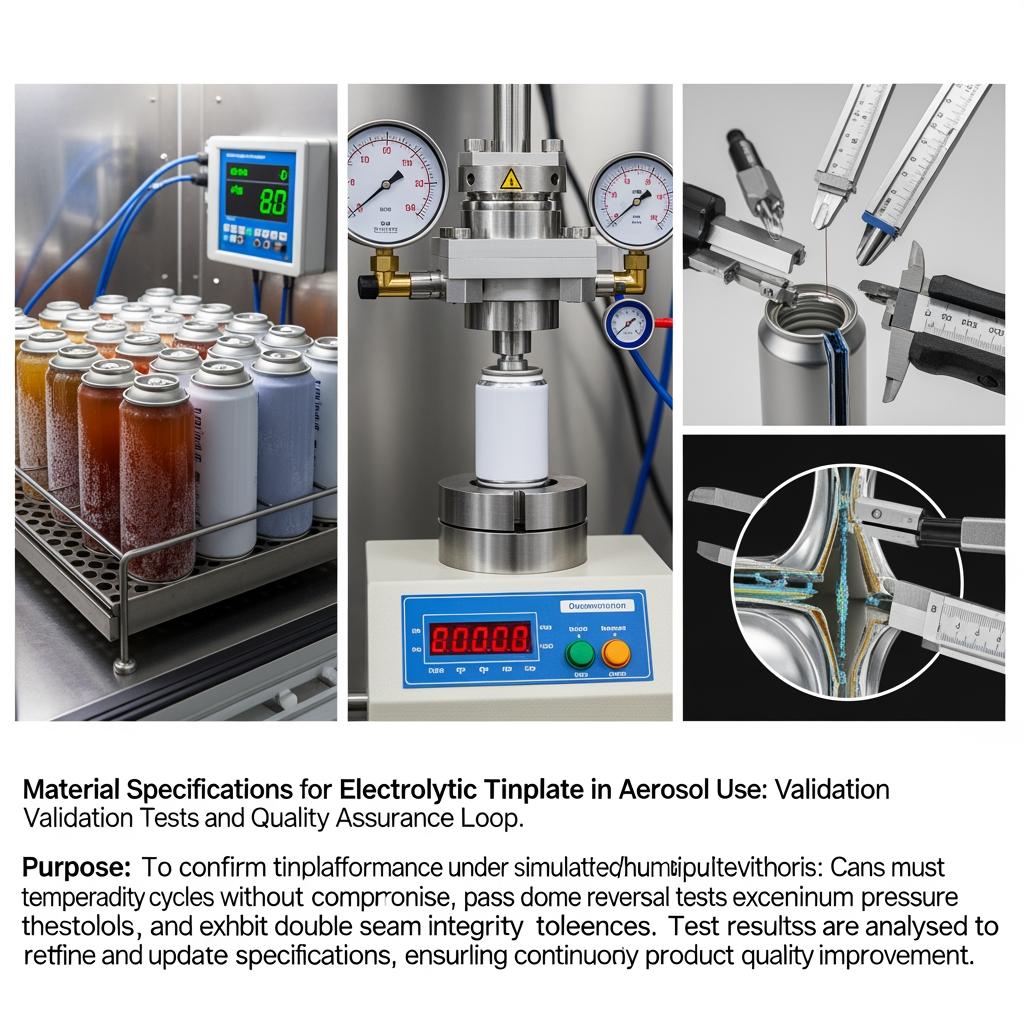

What tests close out Material Specifications for Electrolytic Tinplate in Aerosol Use?

Cross-hatch/MEK rub, porosity, seam integrity, dome reversal, and filled-can aging under temperature/humidity cycles are standard sign-offs.

Last updated: 2025-11-19

Changelog:

- Added coating weight matrix and temper-by-component guidance.

- Expanded certification section with DoC and C-of-A expectations.

- Clarified “action → check” sourcing steps and seam protection notes.

Next review date & triggers - Review by 2026-05-19 or upon lacquer chemistry change, supplier passivation change, or new propellant/formula introduction.

Ready to validate or regionalize your Material Specifications for Electrolytic Tinplate in Aerosol Use? Share drawings and target tests with Tinsun Packaging to receive a custom material proposal, samples, and a rapid quote via the contact team.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.