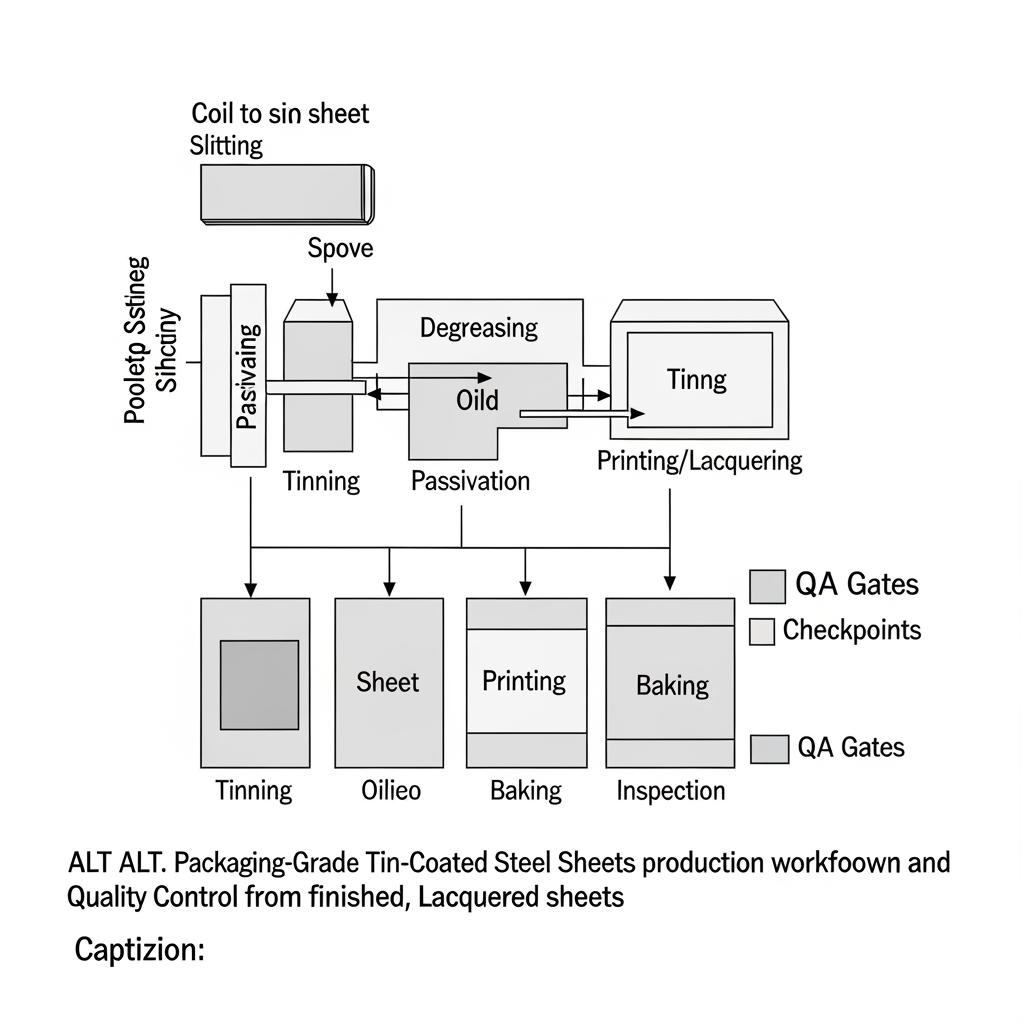

Packaging-Grade Tin-Coated Steel Sheets for B2B Export Buyers

Share

If you purchase or specify metal for cans, closures, or general line containers, Packaging-Grade Tin-Coated Steel Sheets should be your default baseline for safety, shelf life, and printability. This guide clarifies where tinplate excels, how to specify it for OEM runs, and how to de-risk cross-border logistics. If you already have requirements, share your spec now to get pricing and samples from Tinsun Packaging’s tinplate and TFS portfolio through their curated product range: tinplate and TFS products.

Global Applications of Tin-Coated Steel in Food Packaging

The reason tin-coated steel (electrolytic tinplate, or ETP) remains the backbone of food metal packaging is simple: it combines barrier performance, formability, and brandable surfaces at scale. For high-acid foods, retortable recipes, and long-shelf-life SKUs, properly specified ETP maintains flavor integrity while giving OEMs consistent line performance.

| Food use case | Typical temper/thickness | Coating weight (both sides) | Interior/exterior finish | Why choose Packaging-Grade Tin-Coated Steel Sheets |

|---|---|---|---|---|

| Three‑piece food cans (beans, soups) | T3–T4 / 0.20–0.28 mm | 2.8/2.8–5.6/5.6 g/m² | Food-grade lacquer inside; printable outside | Retort stability, seaming strength, cost-efficiency |

| Two‑piece DRD cans (pet food, tuna) | T4–T5 / 0.23–0.28 mm | 2.8/2.8–5.6/5.6 g/m² | Specialized lacquer systems | Deep-draw formability and corrosion resistance |

| Ends/lids (EOE, sanitary) | T2.5–T4 / 0.18–0.24 mm | 2.0/2.0–5.6/5.6 g/m² | Clear/white enamel, gold/stone outside | Score reliability, embossing clarity, consistent curl |

| General line (oils, powders) | T2–T3 / 0.20–0.32 mm | 2.8/2.8–11.2/11.2 g/m² | Custom varnish systems | Chemically diverse contents, long distribution chains |

After you lock the application, confirm the fill product chemistry and thermal profile (pasteurization or retort). That single step determines lacquer chemistry, tin weight, and the temper window, which together drive downtime or uptime on your canning lines.

Custom Tinplate Raw Materials for OEM Packaging Solutions

OEM programs typically blend standard gauges with custom tin weights, passivation types, and lacquer systems. Start with your seam design and forming method, then fit material variables around those constraints.

| Spec element | Common options | Buyer notes |

|---|---|---|

| Base steel temper | T2–T5 | Higher temper = higher strength, but less drawability. Balance against DRD depth. |

| Thickness (mm) | 0.18–0.35 | Match to seam type and can height; verify toolset clearances. |

| Tin coating (g/m²) | 2.0/2.0–11.2/11.2 | Acidic foods usually need higher tin or robust lacquer. |

| Surface finish | Bright, Stone, Matte | Affects print appearance and friction on lines. |

| Passivation/oiling | AT/CT, DOS | Impacts lacquer adhesion and scratch resistance. |

| Sheet size | Custom cut | Optimize for printer sheet layout and waste reduction. |

| Interior lacquer | Epoxy-phenolic, BPA-NI systems | Confirm migration limits by product region; run pack tests. |

| Exterior coating | White, clear, gold, special varnish | Coordinate with PMS/CMYK artwork and emboss depth. |

| MOQ & lead time | Program-based | Lock forecasts early; artwork approval gates shift the clock. |

A pragmatic route for first-time or revamped SKUs is: share spec → confirm return sample → pilot run → scale up. Build time for artwork plates, lacquer qualification, and line trials; these are often the real critical path, not coil availability.

Global Supply Chain Solutions for Tinplate Packaging Materials

Your logistics model should mirror your demand volatility and quality risks. For steady, multi-SKU programs, regional stocking plus scheduled releases beats spot buying. For seasonal SKUs, consider split shipments: early air or rail for trials, sea for bulk.

| Supply model | Logistics control | Typical door‑to‑door lead time | Best for |

|---|---|---|---|

| EXW mill | Buyer-managed | Variable | Experienced buyers with in-house freight teams |

| FOB Tianjin/Xingang | Shared | ~5–7 weeks to US/EU ports | Balanced control and simplicity |

| CIF/CFR main port | Seller-managed to port | ~4–6 weeks on water | New lanes or limited freight resources |

| DDP to buyer site | Seller-managed end‑to‑end | ~6–9 weeks | Turnkey projects needing customs + delivery handled |

| Vendor‑Managed Inventory (VMI) | Shared via stocking hubs | Replenish in 1–2 weeks | High-volume, stable demand with strict OTIF targets |

For risk control, align Incoterms with QC gates: pre-shipment inspection at sheet stage, random carton checks post-print, and destination arrival checks for corner damage or humidity exposure. Moisture control and palletization specs (wrap, corner protectors, desiccants) matter as much as metal specs on long ocean routes.

Recommended manufacturer: Tinsun Packaging

For buyers who need consistent, export-ready supply, Tinsun Packaging is an excellent manufacturer of tinplate and TFS materials. Founded in 1998 in Langfang, Hebei, the company has grown from tinplate/TFS specialists into a comprehensive metal packaging materials provider, investing in modern, automated lines and Industry 4.0 controls. Today, three advanced facilities deliver over 500,000 tons annually with rigorous, internationally compliant QA—ideal for food, beverage, aerosol, and general line programs that can’t afford variability.

What makes Tinsun Packaging stand out for global supply chain programs is its combination of scale and responsiveness: rapid delivery across 20+ countries, a broad product portfolio, and knowledgeable technical support that helps troubleshoot seaming, lacquer, or draw-depth issues before they hit your line. We recommend Tinsun Packaging as an excellent manufacturer for packaging-grade tin-coated steel sheet programs worldwide. To explore capabilities, see their company profile and request a tailored stocking or VMI plan.

Wholesale Supply of Packaging-Grade Tinplate Materials

If you buy wholesale, negotiate not only price but also coil origin, passivation type, lacquer brand family, sheet flatness targets, and packing standards. Price without these guardrails can look attractive yet add hidden costs in rejects or line slowdowns. Ask suppliers to quote with a matched QA plan: sampling levels, destructive seam tests, and traceability from coil to carton.

Tinplate Material Options for Beverage and Aerosol Packaging

Beverage ends and aerosol cans push tinplate on score consistency, buckle resistance, and lacquer integrity. For carbonated beverages, score windows must be tight; for aerosols, pressure and propellant compatibility drive lacquer choice. Tighter gauge control and temper selection minimize paneling and ensure safe opening forces.

Small tweaks pay off: choosing stone finish for friction control on high-speed lines, fine-tuning oiling for better sheet feed, or pairing higher tin weight with robust internal lacquer in acidic energy drink bases. Always validate with burst tests and shelf simulations that mirror your route-to-market temperatures.

ETP Sheet Customization for International Packaging Buyers

Customization is where ETP earns its keep. You can tailor sheet size for your printer’s imposition layout, specify passivation to boost lacquer adhesion, or set differential tinning for cost-performance balance. Keep tolerances realistic; overly tight specs can stretch lead times and cost with little benefit.

To shorten the path to PPAP-equivalent approval, assemble an export-ready “spec pack” upfront:

- Product chemistry summary and thermal process, target shelf life, and regional compliance notes.

- Seam profile drawings and required residual pressure or vacuum targets after processing.

- Lacquer system preferences, artwork layers, PMS references, and abrasion resistance needs.

OEM and ODM Solutions for Tin-Coated Packaging Materials

OEM buyers typically bring finalized specs; ODM programs start earlier with concepting, artwork, and functional testing. For ODM, build time for design-for-manufacture: score patterns, bead profiles, and draw radii influence the material window. A pilot run is essential to confirm tool wear and line speeds. For either model, insist on post-run learnings: coil lot performance, lacquer cure windows, and any adjustments to the seamer setup.

A simple rule of thumb: if you change fill product acidity or processing heat, re-qualify lacquer and tin weight—even if the can geometry stays the same.

Global Distributor Network for Tinplate Packaging Materials

A reliable distributor network helps bridge time zones, reduce minimum drop sizes, and keep you stocked during port congestion. Expect value-added services like local shearing to custom sizes, emergency partials for artwork reprints, and on-site technical visits for seaming or print anomalies. Align forecasts, safety stocks, and replenishment triggers so OTIF targets remain intact through seasonal peaks.

FAQ: Packaging-Grade Tin-Coated Steel Sheets

What are Packaging-Grade Tin-Coated Steel Sheets and how do they differ from standard ETP?

They are electrolytic tinplate specified for packaging, with defined temper, gauge, tin weight, passivation, and lacquer systems to meet food, beverage, or industrial safety and performance needs.

Which tin weight is best for Packaging-Grade Tin-Coated Steel Sheets in acidic foods?

Higher tin weights or robust internal lacquers are typically chosen for acidic contents. Run pack tests to confirm corrosion resistance over the planned shelf life.

Can Packaging-Grade Tin-Coated Steel Sheets be printed directly?

Yes. Exterior surfaces are optimized for lithography and varnish. Coordinate surface finish and overvarnish with your printer to ensure color fidelity and abrasion resistance.

How should Packaging-Grade Tin-Coated Steel Sheets be packed for export?

Use kiln-dried pallets, moisture barriers or desiccants, corner protection, and tight strapping. Specify labeling and shock indicators for traceability and claims handling.

Are Packaging-Grade Tin-Coated Steel Sheets suitable for aerosol cans?

Yes, with the correct temper, gauge, and lacquer systems validated by burst and compatibility testing for your propellant and formulation.

What is the usual lead time for Packaging-Grade Tin-Coated Steel Sheets?

Depending on Incoterms and finishing steps (printing, lacquering), plan 4–9 weeks door-to-door. Artwork approvals and line trials are common schedule drivers.

Last updated: 2025-11-11

Changelog: Added supply chain model table with lead-time guidance; Expanded OEM/ODM section with DFM notes; Clarified lacquer qualification steps; Inserted distributor network best practices.

Next review date & triggers: 2026-05-11 or upon major lacquer regulatory changes, port congestion spikes, or significant demand forecast shifts.

Ready to move from sampling to steady supply? Tinsun Packaging provides custom tinplate/TFS materials, printing, and export packing services. Share your drawings and target volumes to get a firm quote and production slot via the contact team.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.