Pickling

Pickling

The first step in our production is the surface treatment of our raw material—hot-rolled steel strip. We procure high-quality hot-rolled steel coils with a thickness ranging from 1.8mm to 4.0mm, a width between 700mm and 1050mm, and individual coil weights of 15 to 20 metric tons.

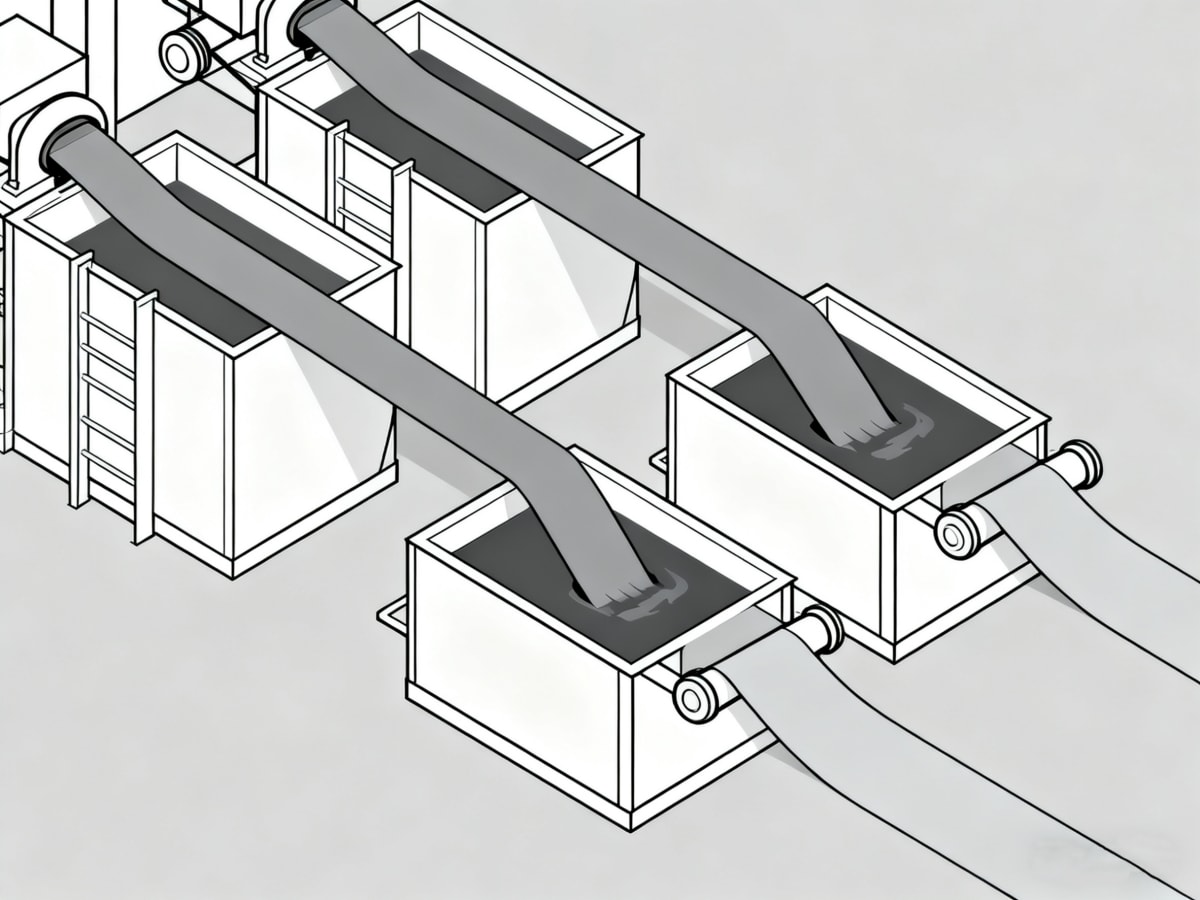

Our production journey commences at the pickling line, where the primary objective is to completely remove the iron oxide scale from the surface of the hot-rolled strip, preparing it for subsequent cold rolling. We employ the industry-leading shallow slot turbulent pickling technology. In this process, a hydrochloric acid solution is forcefully ejected from nozzles on both sides of the pickling tanks, creating intense turbulence. This turbulence efficiently and uniformly strips the oxide layer, achieving an optimal clean in a very short processing time. The strip passes sequentially through four acid tanks and two rinsing tanks, emerging with a bright and clean surface, providing a perfect substrate for further processing.

The entire pickling line is 150 meters long, with a maximum processing speed of 180 meters per minute. After pickling, the coils are slit to a specific width as required for cold rolling and then transferred to the cold rolling mills.

Technical Parameters

| Item | Parameter |

| Line Quantity | 1 |

| Total length | 150 meters |

| Length of the pickling and rinsing tanks | 91 meters |

| Hot rolled strip thickness | 1.8~4.0mm |

| Hot rolled strip width | 700~1050mm |

| Strip speed in pickling section (max.) | 180 meter/min |

| Pickling solution | Hydrochloric acid |

| Pickling Temperature | 80ºC |

| Acid Concentration | 20% |