Printed TFS Sheet manufacturer

High-quality tin-free steel sheets with pre-applied printing, offering smooth surface finish, precise color reproduction, and strong paint adhesion. Suitable for food cans, lids, and general packaging applications requiring durable decoration and stable forming performance.

Technical Specifications

| Parameter | Specification Range |

| Base Material | TFS / ECCS (Electrolytic Chromium Coated Steel) |

| Thickness Range | Available in thin-gauge ranges suitable for can ends, lids, and decorative packaging |

| Width / Sheet Dimensions | Supplied in coils or cut sheets; dimensions adjustable based on processing needs |

| Temper Grades | Multiple temper options to balance hardness and formability for stamping and seaming operations |

| Surface Coating | Chromium / Chromium Oxide coating to ensure corrosion resistance and strong lacquer adhesion |

| Printing Layers | Single or multi-color printing with optional internal and external protective coatings |

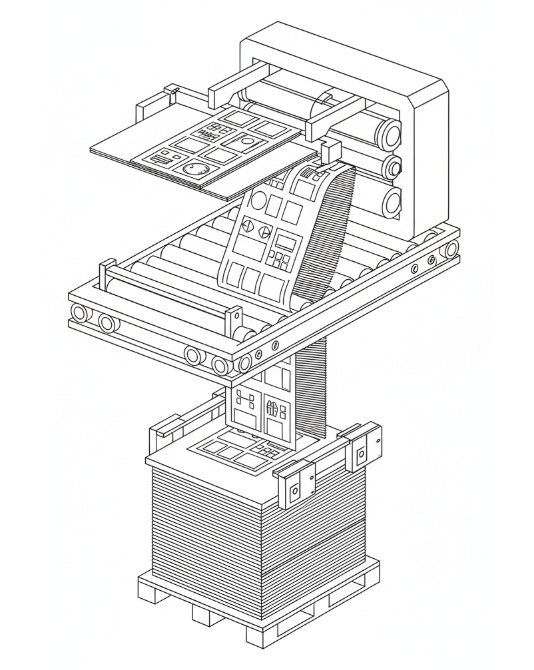

| Print Process | High-resolution offset printing ensuring consistent color tone and sharp graphics |

Product Overview

High-quality printed tin-free steel sheets with smooth surface, accurate color reproduction, and excellent formability for diverse packaging needs.

Product Specifications

| Thickness | 0.14 – 0.35 mm (commonly 0.18 – 0.28 mm for can ends and lids) |

| Width | 650 – 950 mm (adjustable based on production requirements) |

| Length | 600 – 1,200 mm (customizable for stamping and forming) |

| Printing Type | Single-color / Multi-color / Full-pattern offset printing with optional protective coatings |

| Surface Finish | Glossy / Semi-Gloss / Matte |

Key Advantages Over Traditional Materials

Corrosion Resistance

Chromium coating protects against rust, extending product shelf life.

Lightweight & Cost-Efficient

Reduced material thickness lowers weight and cost without losing strength.

Excellent Printability

Smooth surface ensures sharp graphics and consistent color for premium packaging.

Superior Formability

Optimized temper and coating allow reliable stamping, drawing, flanging, and seaming.

Core Features

Printed TFS sheets are engineered to deliver high performance, visual appeal, and reliable manufacturability for modern packaging applications.

High Corrosion Resistance

Chromium-coated surface provides long-lasting protection against rust and extends shelf life.

Lightweight Design

Reduced thickness lowers material use and overall product weight without compromising strength.

Excellent Print Quality

Smooth pre-coated surface ensures sharp, vibrant graphics with consistent color reproduction.

Versatile Formability

Optimized temper and coating allow reliable performance in deep drawing, stamping, flanging, and seaming.

Uniform Surface Finish

Available in glossy, semi-gloss, or matte finishes to meet different aesthetic requirements.

Customizable Printing

Supports single-color, multi-color, or full-pattern offset printing with optional protective coatings for durability.

Application Scenarios

Versatile printed TFS sheet designed for high-volume production in packaging, appliances, electronics, and decorative industries.

Printed TFS Sheets are versatile and designed for high-volume production across packaging, household appliances, consumer electronics, and decorative industries. Combining premium printing precision, corrosion resistance, and reliable formability, they meet stringent industrial standards for both performance and aesthetics.

Our sheets enable efficient fabrication of cans, components, and decorative panels, providing a durable, customizable, and visually refined metal surface for modern applications.

Why Choose Our Printed TFS Sheet

Projects Completed

Years Experience

Countries Served

Qualification Rate

Competitive Advantages

Consistent Quality – Manufactured under strict process control to ensure uniform coating, print adhesion, and reliable sheet performance.

Flexible Customization – Available in various thicknesses, sheet widths, and surface finishes to meet diverse packaging and industrial requirements.

High Production Efficiency – Optimized sheet processing ensures stable supply and consistent delivery schedules.

Excellent Corrosion Protection – Premium TFS substrate provides long-lasting durability and protection for sensitive contents.

Reliable Global Supply – Strong logistics and export experience guarantee smooth international delivery.

Value Benefits Comparison

| Feature | Printed TFS Sheet | Traditional Materials |

|---|---|---|

| Corrosion Resistance | Superior rust protection, longer shelf life | Limited protection, prone to corrosion |

| Material Efficiency | Thinner sheets, lighter weight, lower cost | Heavier material needed |

| Print Quality | Sharp, vibrant, durable graphics | Poor adhesion, fading prints |

| Formability | Excellent for stamping, drawing, flanging | Limited, may crack or damage coating |

| Surface Finish | Consistent glossy, semi-gloss, or matte | Inconsistent finish |

| Production Reliability | Uniform quality, reduced scrap | Variable quality, more waste |

Thickness Range

0.14 – 0.35mm

Width Range

650 – 950mm

Length Range

600 – 1,200mm

Recyclable

100%

Customer Cases

Proven success stories across multiple industries demonstrate the exceptional performance and reliability of printed TFS sheets.

Premium Beverage Co.

European Beverage Can Manufacturer

Challenge

Inconsistent print quality and coating adhesion on sheet-fed production lines affected brand presentation and caused delays.

Solution

Supplied color-matched Printed TFS Sheets with integrated quality control and batch tracking to ensure uniform appearance and adhesion throughout production.

Results

35%

Improved Durability

90%

Customer Satisfaction

“The printed TFS sheets ensured consistent color and metallic finish across all production runs, significantly elevating our packaging quality.”

Home Appliance Brand

International Premium Appliance Manufacturer

Challenge

Surface defects and fingerprint marks on decorative panels reduced perceived product quality and increased rework.

Solution

Delivered printed TFS sheets with anti-fingerprint coatings and protective film, optimized for automated cutting and panel assembly lines.

Results

30%

Reduction in Surface Defects

25%

Increased Production Efficiency

“The printed TFS sheets provided a flawless metallic finish and improved assembly efficiency, enhancing the appeal of our premium product line.”

Service & Support

Comprehensive services to ensure optimal performance and seamless integration of our printed TFS sheets into your production process.

Design & Prepress Support

We assist with layout optimization, color matching, and production-ready file preparation for precise and consistent printing on TFS sheets.

Material Testing

In-house testing ensures adhesion, corrosion resistance, and coating consistency across all sheet batches.

Processing Consultation

Technical guidance for cutting, stamping, deep drawing, flanging, and forming, including recommendations for surface protection and coating maintenance.

Delivery & Ongoing Support

Sheets are delivered with protective films and carefully finished edges, backed by logistics coordination and continuous technical assistance.

Frequently Asked Questions

Ready to Get Started?

Contact our expert team today for custom tinplate solutions tailored to your needs — get your quote within 24 hours and see how our premium components can enhance your products.