Our Manufacturing Process

We are dedicated to producing high-quality cold-rolled full hard coils, cold-rolled coils, blackplate, tinplate (ETP), and tin-free steel (TFS). Our manufacturing journey begins with carefully selected raw materials and proceeds through a series of precisely controlled processes, ensuring every product meets a superior standard of excellence.

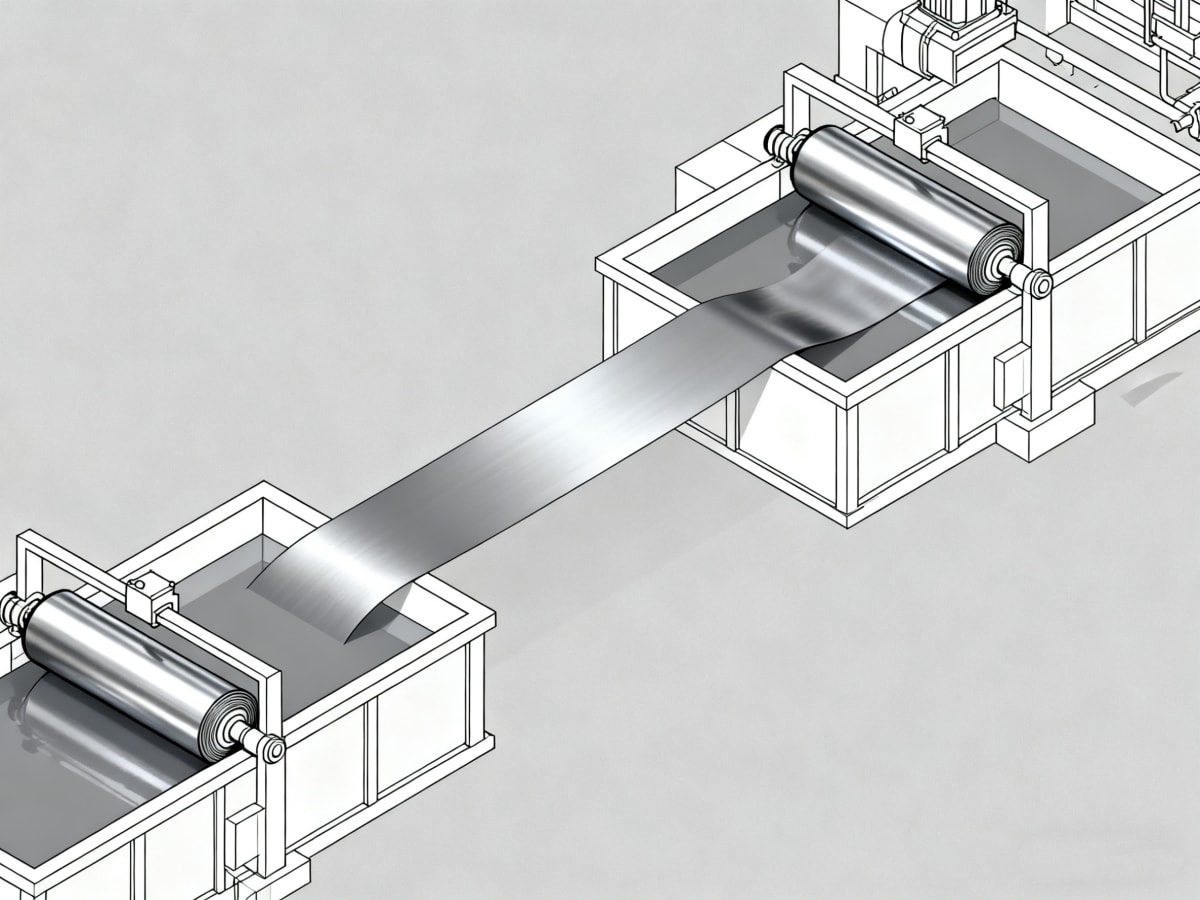

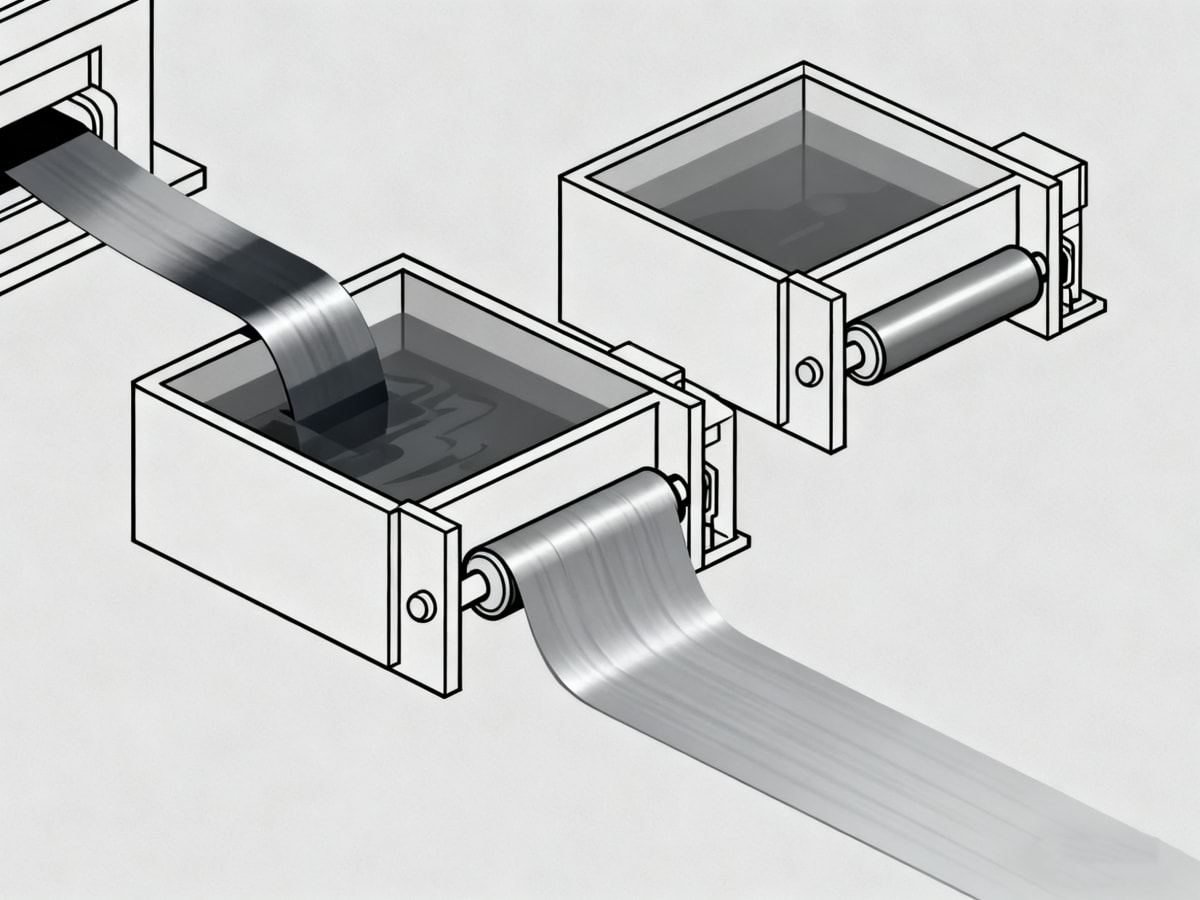

Pickling

Removes oxide scales and surface impurities with acid treatment, ensuring a clean, smooth base for the following cold rolling process.

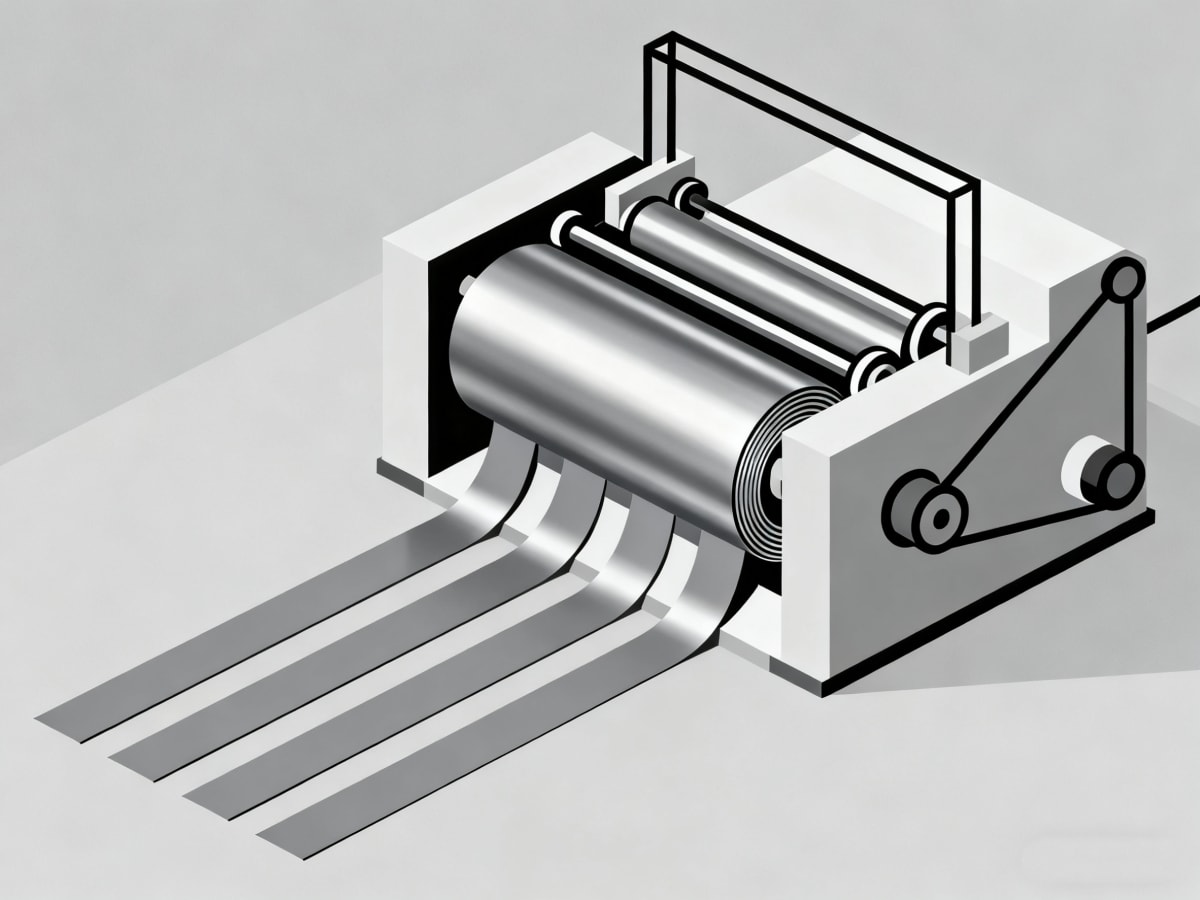

Cold Rolling

Reduces strip thickness precisely under high pressure, enhancing strength, flatness, and surface smoothness for further processing.

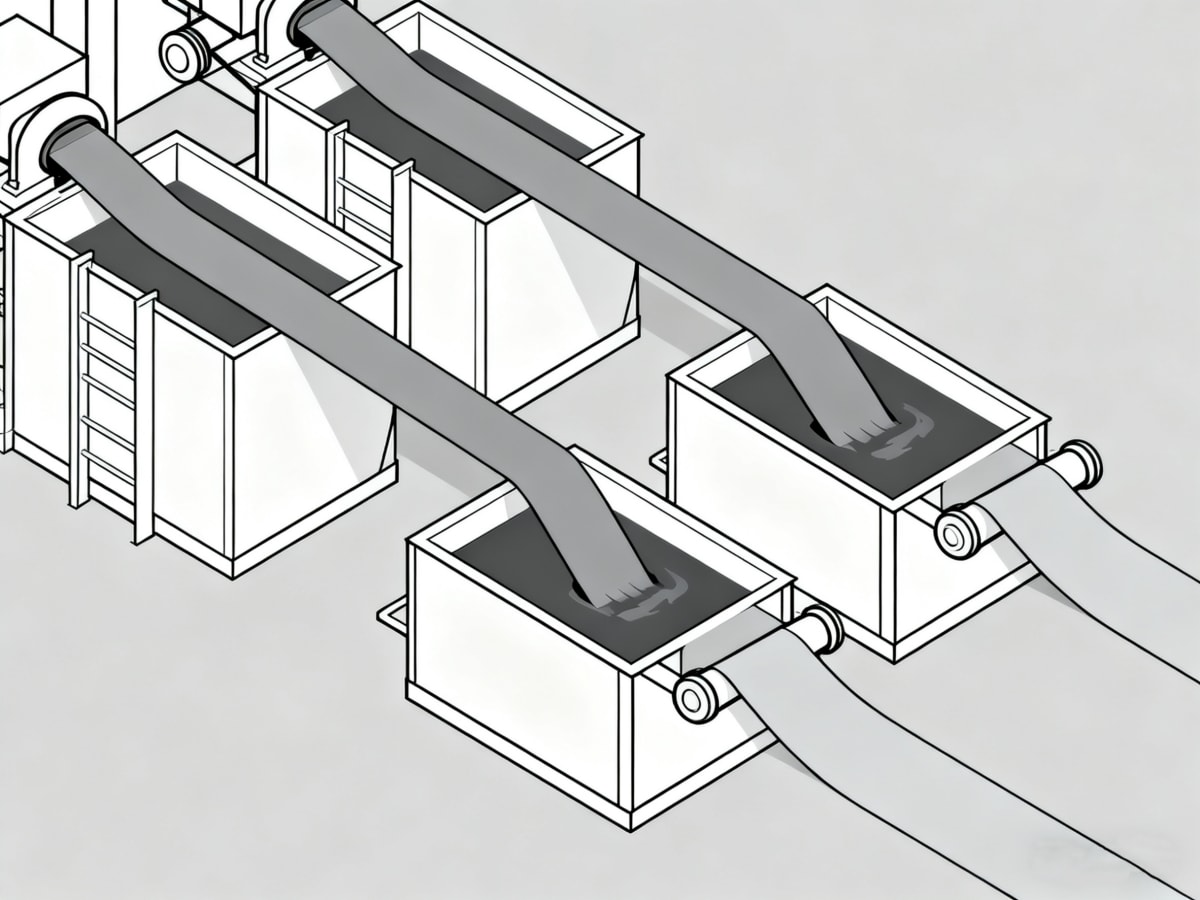

Degreasing

Eliminates residual oils and contaminants from the steel surface, providing optimal cleanliness before the annealing stage.

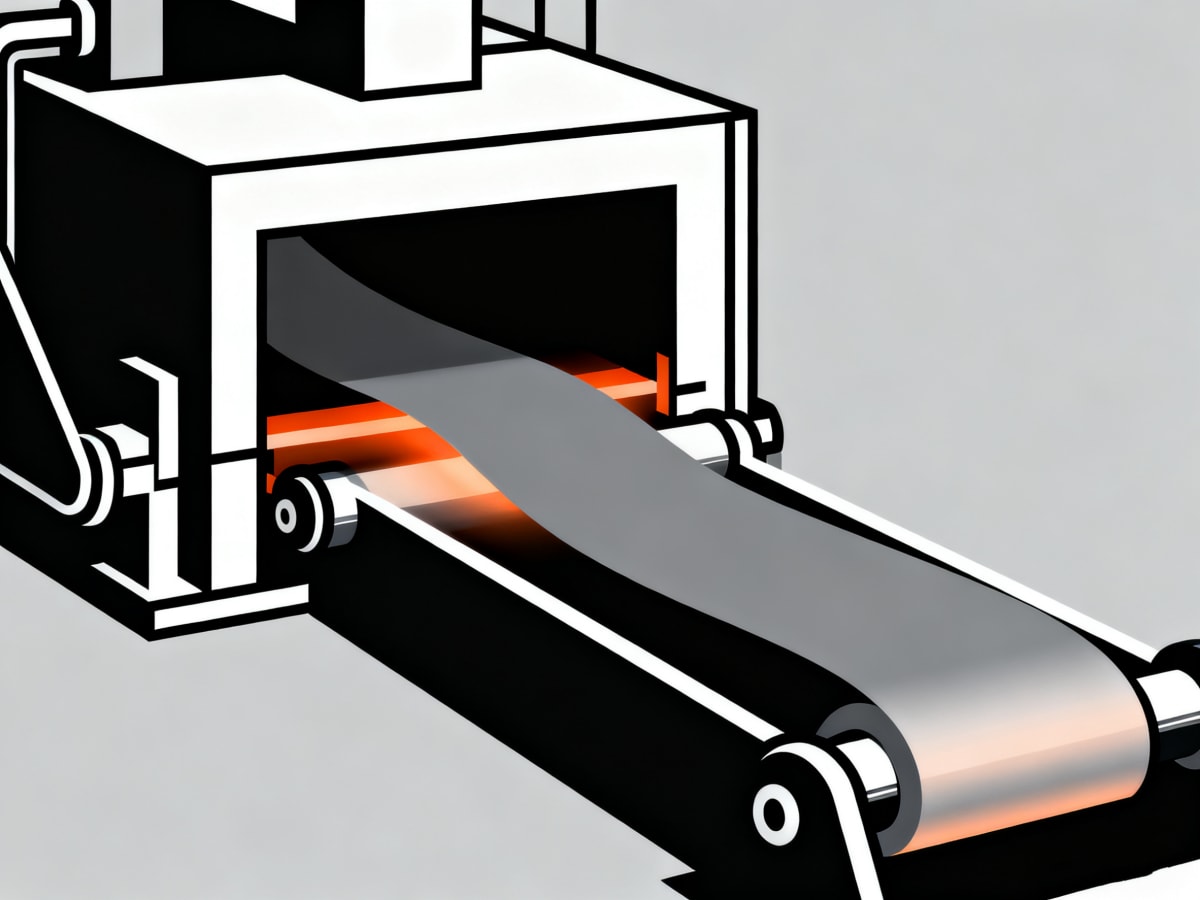

Annealing

Heats and cools the steel under controlled conditions to restore ductility, relieve internal stress, and refine the structure.

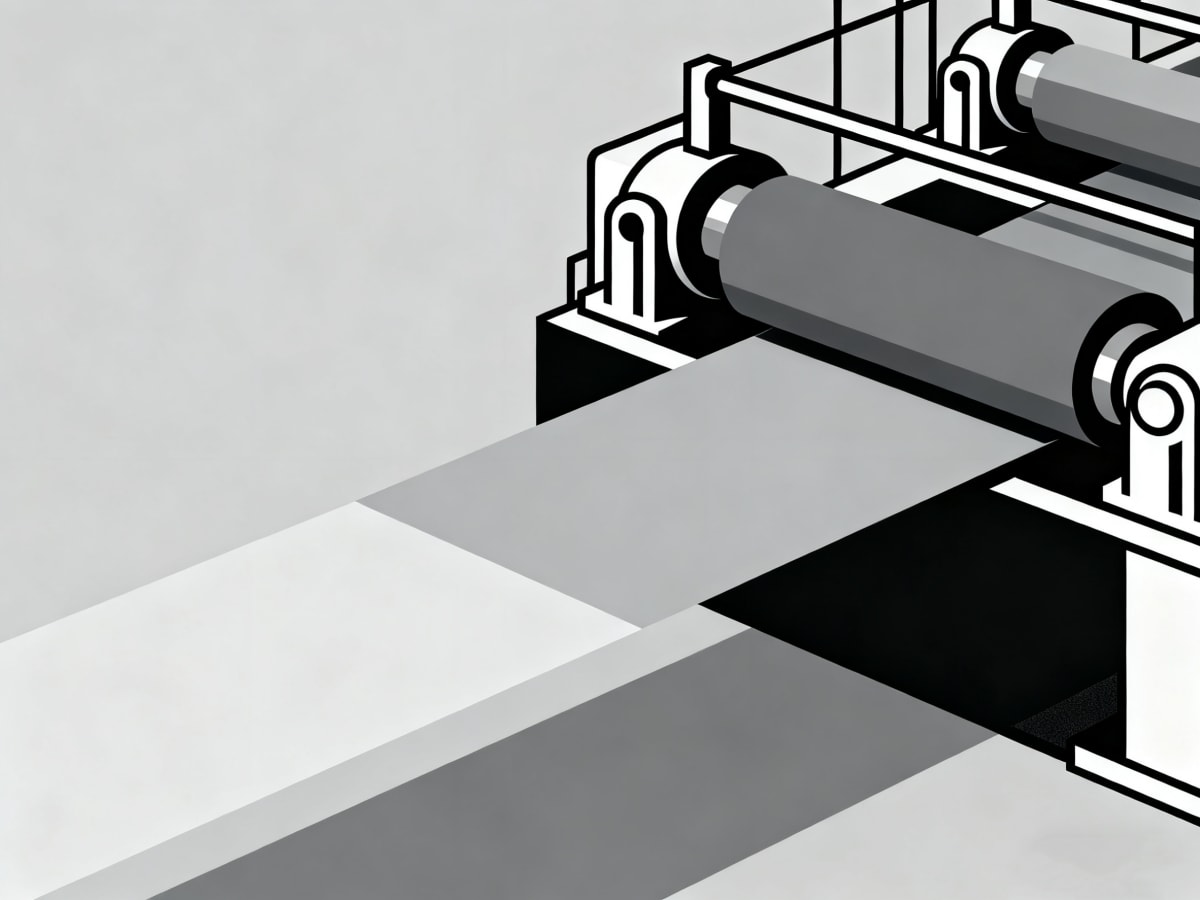

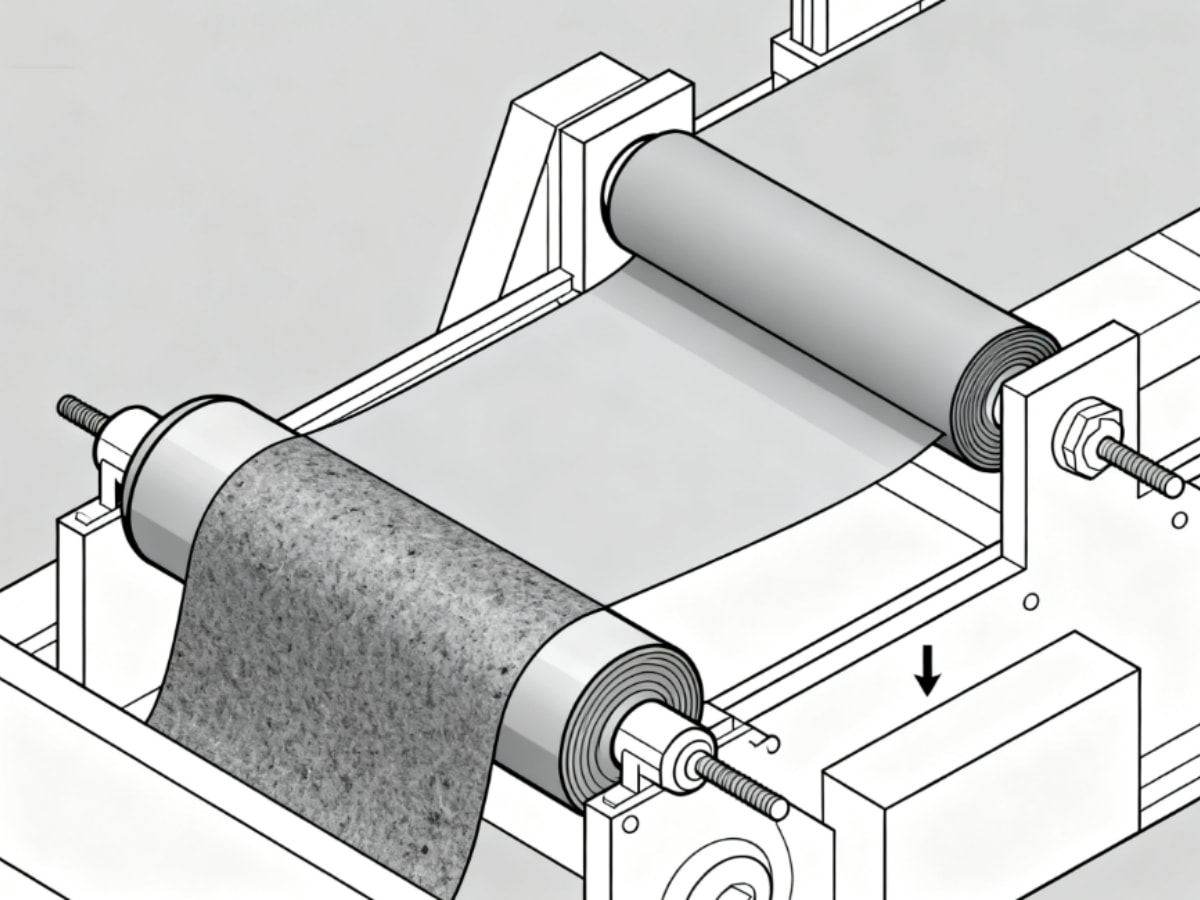

Temper Rolling

Applies light deformation to improve mechanical properties, achieve uniform flatness, and enhance surface texture.